Method for rapidly and integrally pickling salted egg yolk

A salted egg yolk and rapid technology is applied in the field of rapid overall pickling of salted egg yolk, which can solve the problems of high cost, less processing, long pickling time, etc., and achieve the effects of simple production operation, high production efficiency and labor saving.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

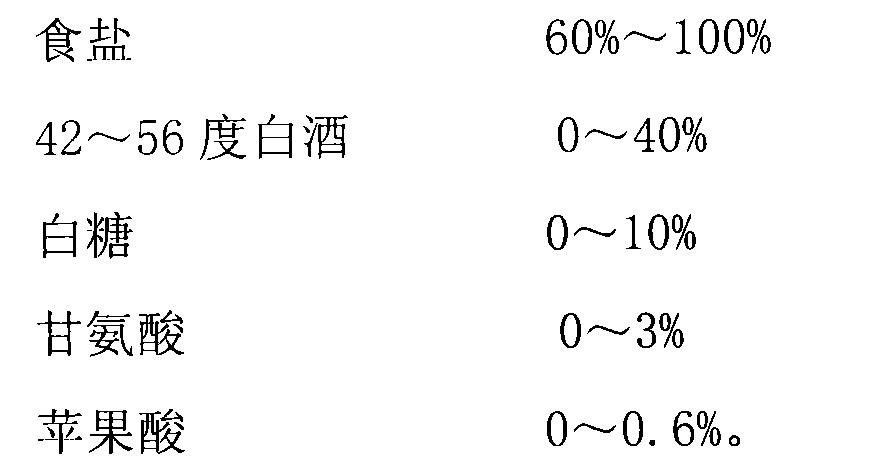

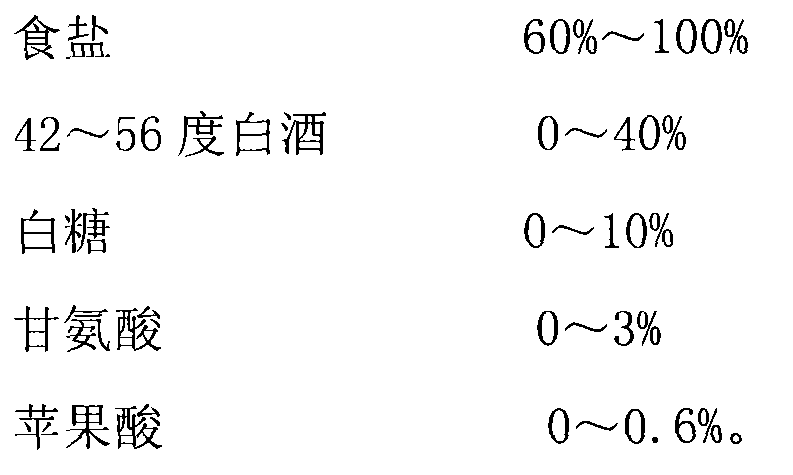

Method used

Image

Examples

Embodiment 1

[0032] The preparation of embodiment 1 salted egg yolk

[0033] Put 5 kg of egg yolk into a small stainless steel chemical reactor, then add 0.5 kg of salt, 0.1 kg of white sugar, and 0.25 kg of white wine (53 degrees). Start the stirring device to fully mix the egg yolk and all the ingredients evenly, control and marinate at room temperature for 50 hours, dissolve 2.5 grams of malic acid and 7.5 grams of glycine with water and add them to the egg yolk liquid, marinate for another 20 hours, stir and pump Vacuum dehydration, heat up to 120°C to ripen the egg yolk, then put it into a tissue grinder to grind at high speed, then add 0.1 kg of microcrystalline cellulose, and press it into the shape of an egg yolk in a molding machine to obtain salted egg yolk products.

Embodiment 2

[0034] The preparation of embodiment 2 salted egg yolk

[0035] Put 5 kg of egg yolks into a sealed container with heating and stirring functions, then add 0.3 kg of salt, start the stirring device to fully mix the egg yolks and salt, control the temperature at about 45°C and marinate for 48 hours, stir and smoke Vacuum dehydration, heat up to 100°C to let the egg yolk mature, put the cured salted egg yolk into the roller grinder to grind the oil sand, then add 0.05 kg of microcrystalline cellulose, 0.05 kg of sodium carboxymethyl cellulose and salty egg yolk Egg yolks are mixed and pressed into the shape of egg yolks in a molding machine to obtain salted egg yolk products.

Embodiment 3

[0036] The preparation of embodiment 3 salted egg yolk

[0037] Put 5 kg of duck egg yolk into a small fermenter, add 0.4 kg of salt, add a stirring device to fully mix the egg yolk and salt, then add 0.15 kg of white sugar and 0.3 kg of white wine (52 degrees), stir evenly, 15 ° C ~ 25 ° C Marinate for 90 hours, vacuumize and dehydrate under stirring, let the egg yolk ripen at 85°C, add 0.05 kg of corn starch, 0.1 kg of corn oil, and 0.05 kg of sodium carboxymethyl cellulose to pulverize to obtain salted egg yolk products.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com