Magnesium alloy melt continuous liquid supply purifying device and technology

A purification device and magnesium alloy technology, which is applied in the field of magnesium metal smelting and rolling processing, can solve the problems that the melt purification device cannot be completely and effectively purified, the corrosion resistance of production materials is reduced, and the production cost is increased, so as to improve the purity, Guarantee the effect of continuous liquid supply and short process control

Active Publication Date: 2017-03-29

湖南金镁科新材料有限公司

View PDF3 Cites 4 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

For continuous casting and rolling, casting and other processes, if the thickness of the thin plate and strip produced is between 0.5-2.0mm, tiny impurities may cause product defects, resulting in reduced yield and increased production costs

[0003] In order to remove oxide inclusions, the traditional process uses a large number of solvent + refining agent treatment, and auxiliary tools for slag removal, so solvent inclusions are prone to occur, which reduces the corrosion resistance of production materials, and the existing melt purification devices cannot be completely, Effectively purifies and provides continuous fluid supply

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 2

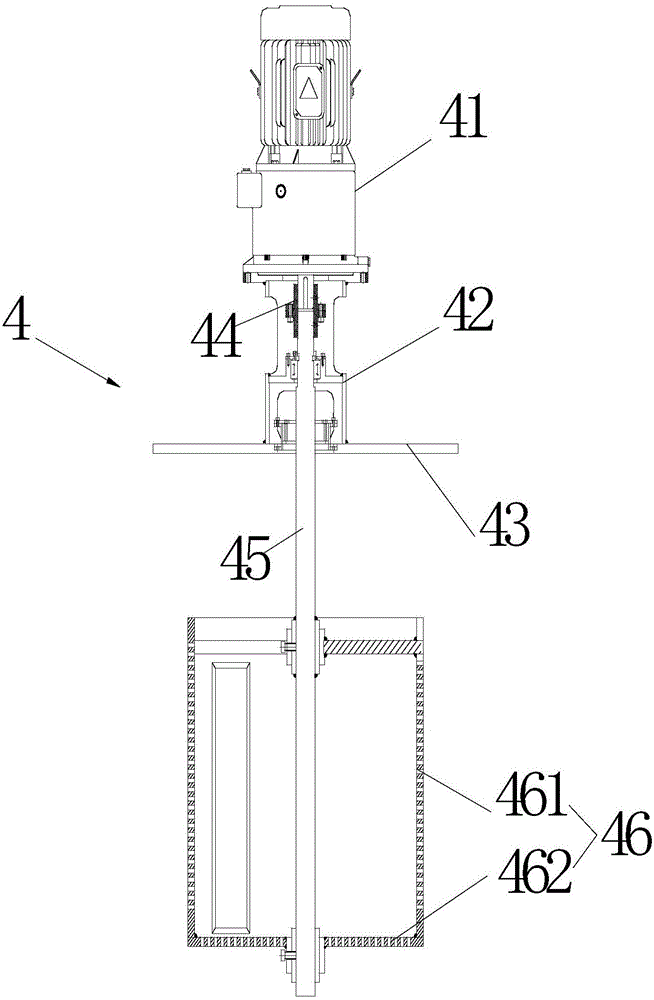

[0057] The feature of this embodiment is: the melt transfer device is a centrifugal pump, and the melt in the melting furnace flows into the heat preservation and standing furnace through the way of transferring liquid through the centrifugal pump. Others are the same as in Example 1.

Embodiment 3

[0059] The feature of this embodiment is: the number of the centrifugal filter is two, one for standby and one for use. Others are the same as in Example 1.

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

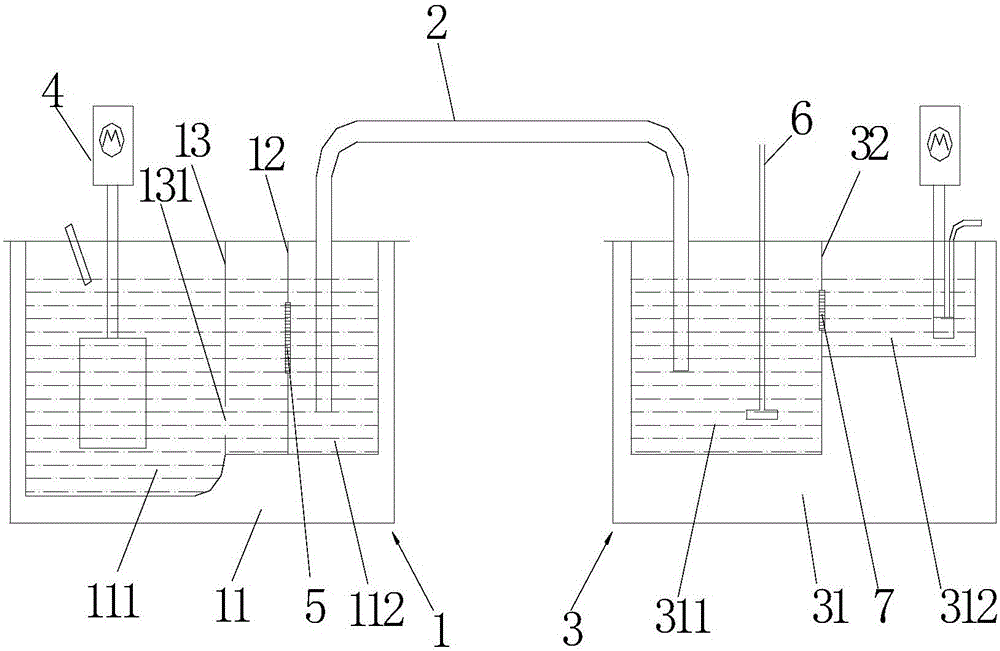

The invention discloses a magnesium alloy melt continuous liquid supply purifying device and technology. The magnesium alloy melt continuous liquid supply purifying device comprises a melting furnace, a heat insulation standing furnace and a melt transferring device. An inner cavity of a melting furnace body is divided into a melt melting cavity and a melt transferring cavity. A centrifugal filter is arranged in the melt melting cavity. An inner cavity of a heat insulation standing furnace body is divided into a separation cavity and a heat insulation standing cavity. An Ar gas input device is arranged in the separation cavity. A first filter is arranged in a first connecting port. A second filter is arranged in a second connecting port. According to the magnesium alloy melt continuous liquid supply purifying device and technology, melting treatment and purifying treatment are conducted in the wholly-sealed furnace, a solvent-free method is adopted, a corrosion source is prevented from entering melt, inclusions or films or particles and harmful gas in the magnesium alloy melt can be effectively removed, and purity of the magnesium alloy melt is improved. The magnesium alloy melt continuous liquid supply purifying device and technology have the beneficial effects of being short in process control and simple in operation; continuous liquid supply of the heat insulation standing furnace during casting and cast rolling is ensured; the melt purifying quality of casting and cast rolling is improved; the production efficiency is improved; and the production cost is reduced.

Description

technical field [0001] The invention relates to a magnesium alloy melt continuous liquid supply purification device and a purification process, belonging to the technical field of magnesium metal smelting and rolling processing. Background technique [0002] Magnesium alloy has good comprehensive properties such as high specific strength, specific stiffness, shock absorption, thermal conductivity, electromagnetic shielding, easy cutting and easy recycling, so it has become a popular choice in industries such as automobiles, motorcycles, aerospace and electronic communications. one of the important raw materials. Because magnesium is very active, it is very easy to react with oxygen, nitrogen, etc. during the processing of magnesium alloys, which will pollute the magnesium alloy melt and affect the quality of magnesium alloy products. For example, in the melting process, since the magnesium alloy melt is not completely isolated from the air, magnesium is very easy to react w...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): C22C1/03C22C1/06C22C23/00

CPCC22C1/03C22C1/06C22C23/00

Inventor 陈晓阳段江峰

Owner 湖南金镁科新材料有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com