Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

302results about How to "Free from scratches" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Silicon wafer chemical and mechanical polishing composition with high stability

InactiveCN102093820AWide applicabilityPracticalOther chemical processesPolishing compositions with abrasivesOrganic acidCompound (substance)

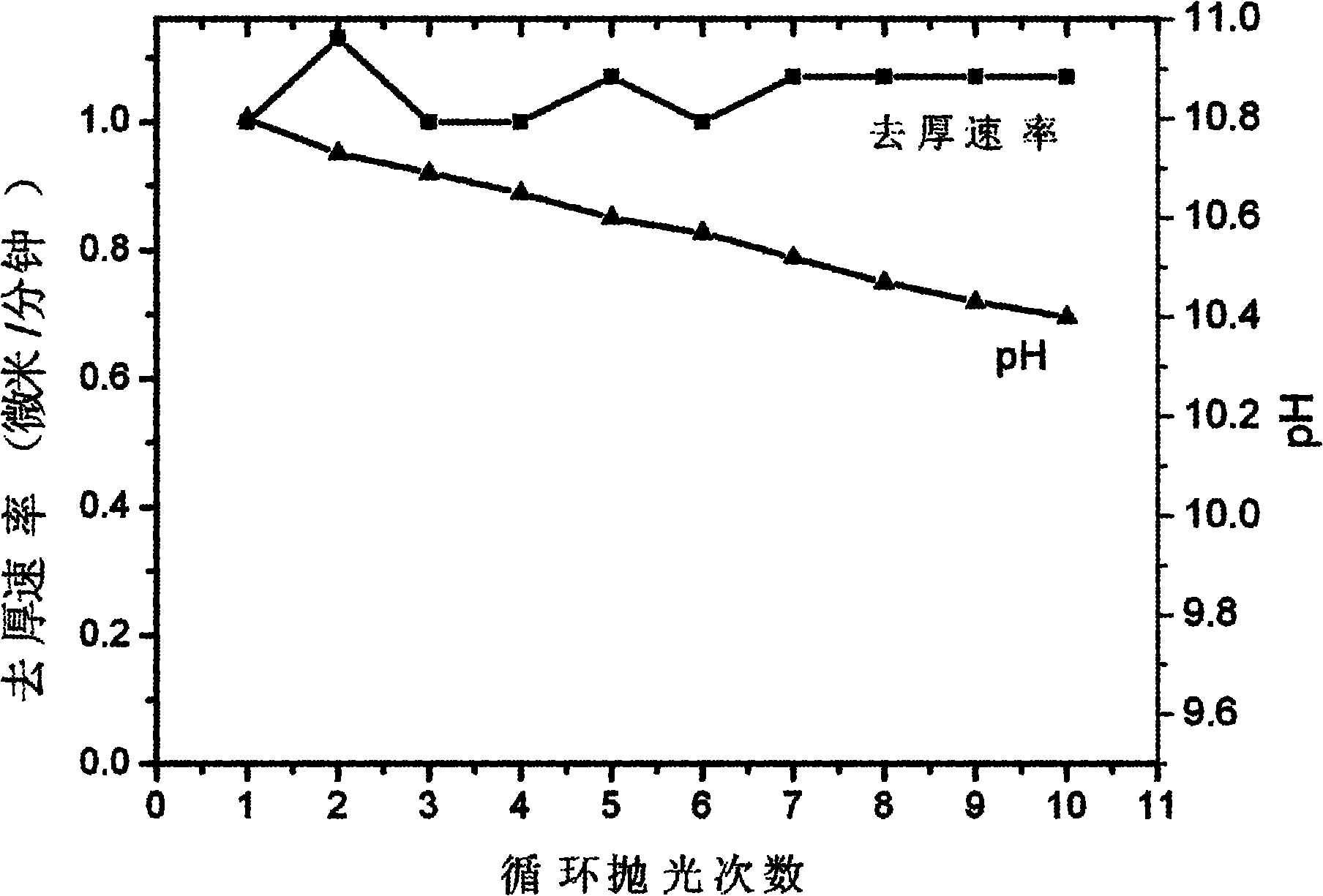

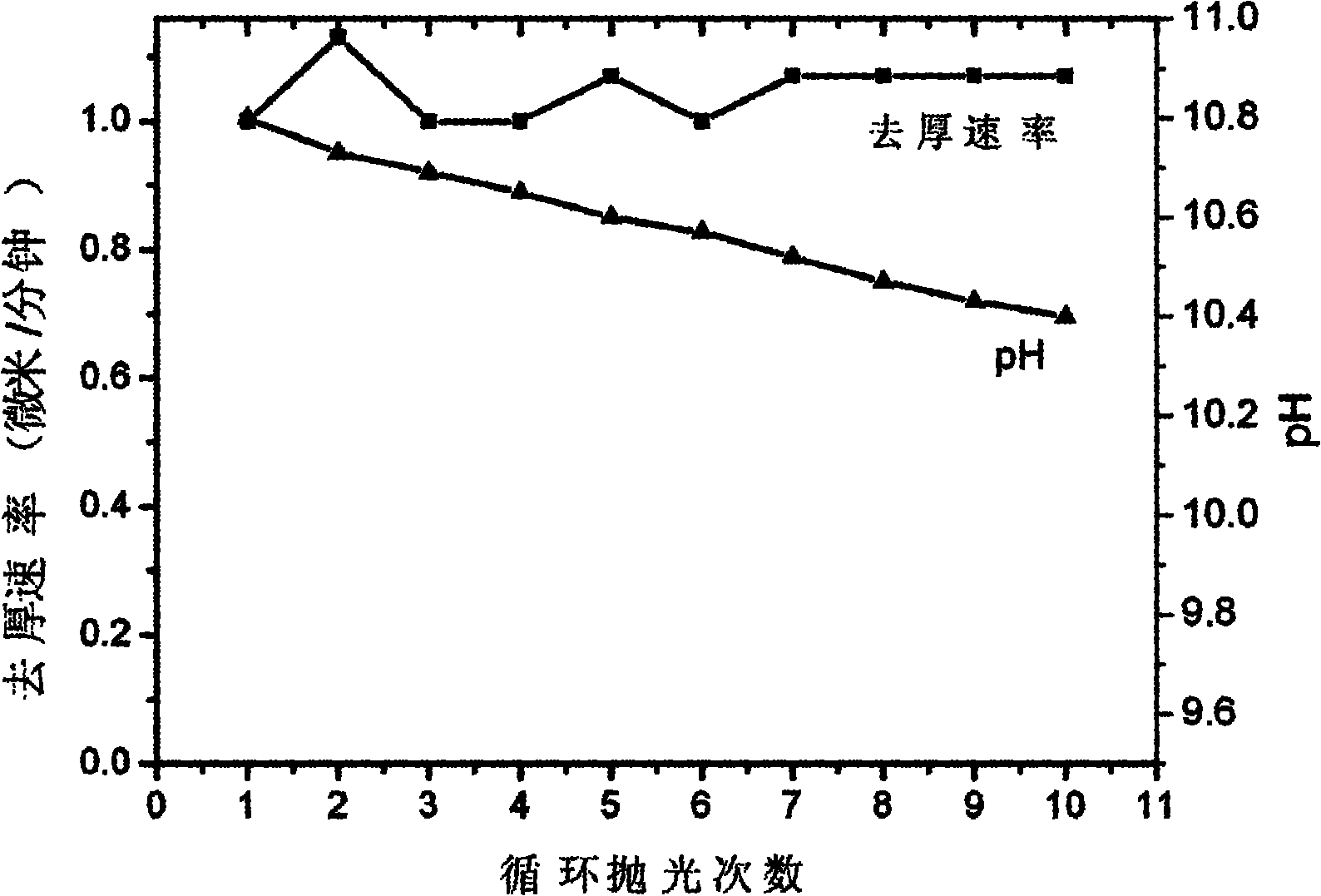

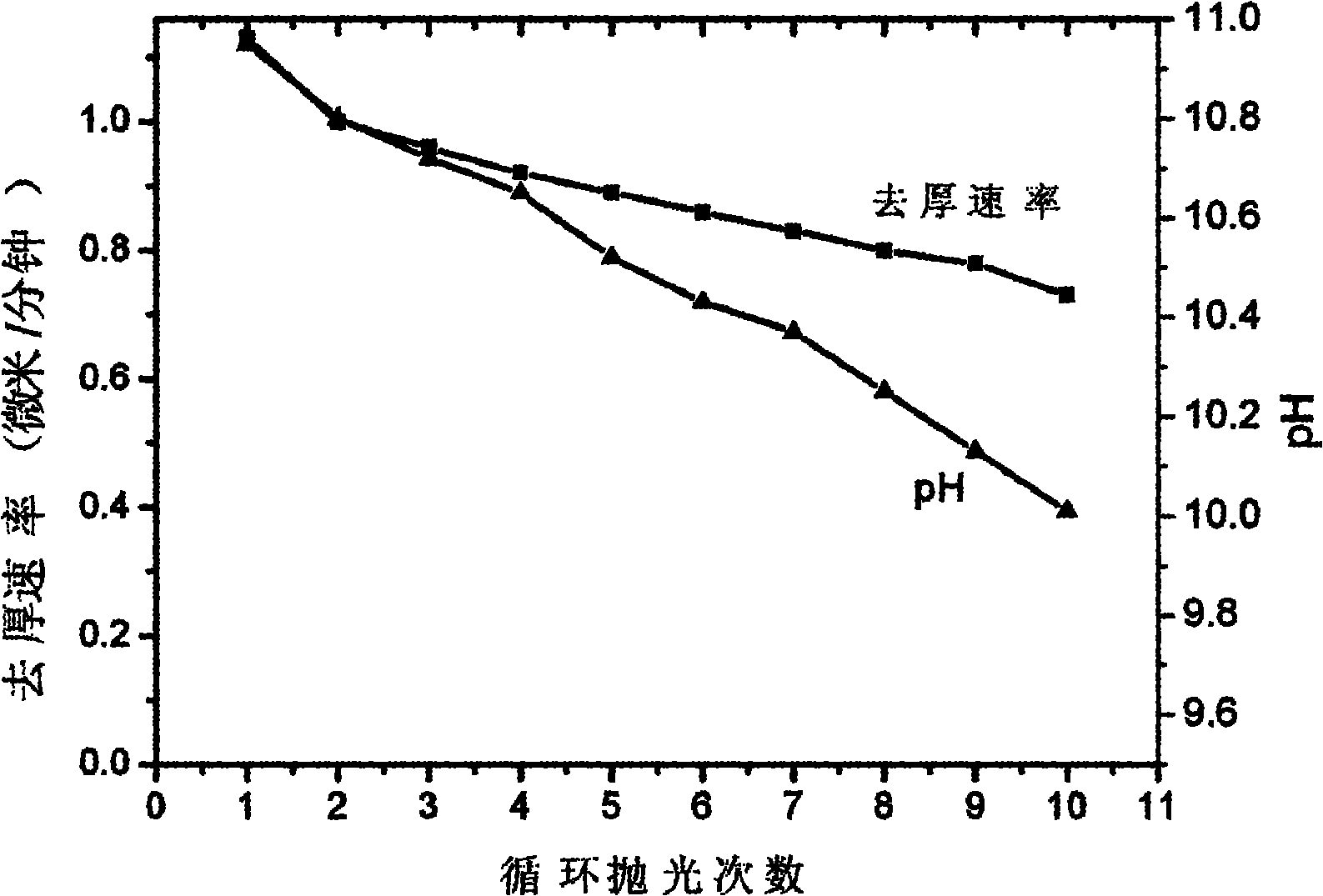

The invention discloses a silicon wafer chemical and mechanical polishing composition with high stability, belonging to the technical field of polishing compositions for roughlly polishing a semiconductor silicon substrate material. The polishing composition comprises the following components in percentage by weight: 0.5-50 percent of silicon dioxide abrasive particles, 0.01-10 percent of silicon-containing stabilizer, 0.01-20 percent of organic alkali corrosive, 0.01 -10 percent of organic acid chelating agent, 0.01-5.0 percent of other functional auxiliaries and the balance of deionized water. The polishing solution has a stabilization period of over 2 years, can perform repeated polishing or cyclic polishing, and has stable pH value and removal speed, wherein the number of cyclic polishing times can be up to 10. Meanwhile, the polishing composition has high silicon wafer removal rate up to over 1.0 mum / min, and the cyclic polishing removal rate in multiple times can be stable. The polishing solution is convenient to prepare and easy to use, has low cost, and is suitable for the rough polishing of silicon wafers of various types and sizes in the semiconductor industry.

Owner:TSINGHUA UNIV +2

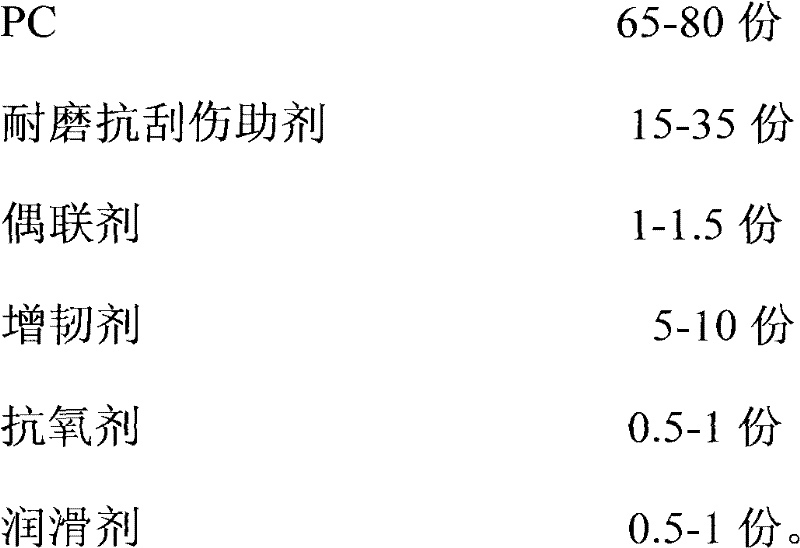

Highly-abrasion-resistant anti-scratching modified PC (polycarbonate) material and preparation method thereof

InactiveCN102391634AIncrease wear resistance and scratch resistanceAvoid oxidative degradationPolymer scienceAntioxidant

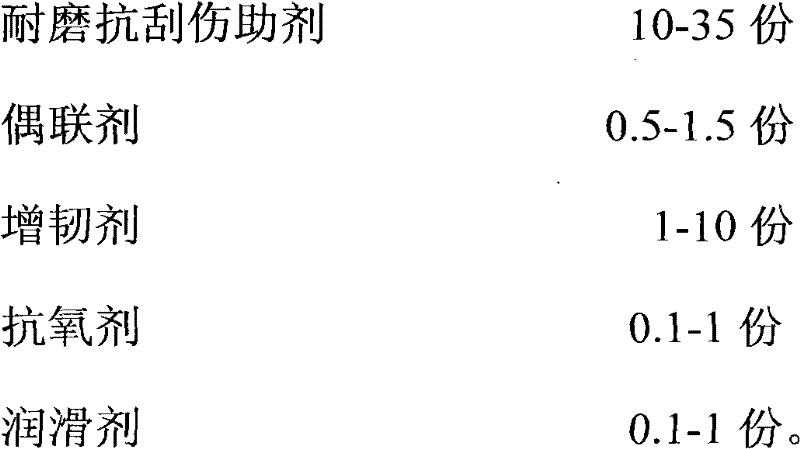

The invention relates to the field of high polymer materials and particularly relates to a highly-abrasion-resistant anti-scratching modified PC (polycarbonate) material and a preparation method thereof. The high-abrasion-resistant anti-scratching modified PC material comprises the following raw materials in parts by weight: 65-90 parts of PC, 10-35 parts of abrasion-resistant anti-scratching auxiliary agent, 0.5-1.5 parts of coupling agent, 1-10 parts of toughening agent, 0.1-1 part of antioxidant and 0.1-1 part of lubricating agent. According to the invention, PC is used as a substrate material, and composite systems such as the abrasion-resistant anti-scratching auxiliary agent, the lubricating agent, other auxiliary agents and the like are added, so that the abrasion-resistant anti-scratching property of the material is improved; the abrasion-resistant anti-scratching modified PC material is prepared by adopting high-temperature smelting, mixing and extruding modes in a twin-screw extruder, thus the hardness and abrasion-resistant anti-scratching effect of PC are improved; and modified PC has the advantages of high rigidity, high toughness, high flowability, high heat resistance, bright surface and the like.

Owner:GUANGDONG JANUS SMART GRP CO LTD

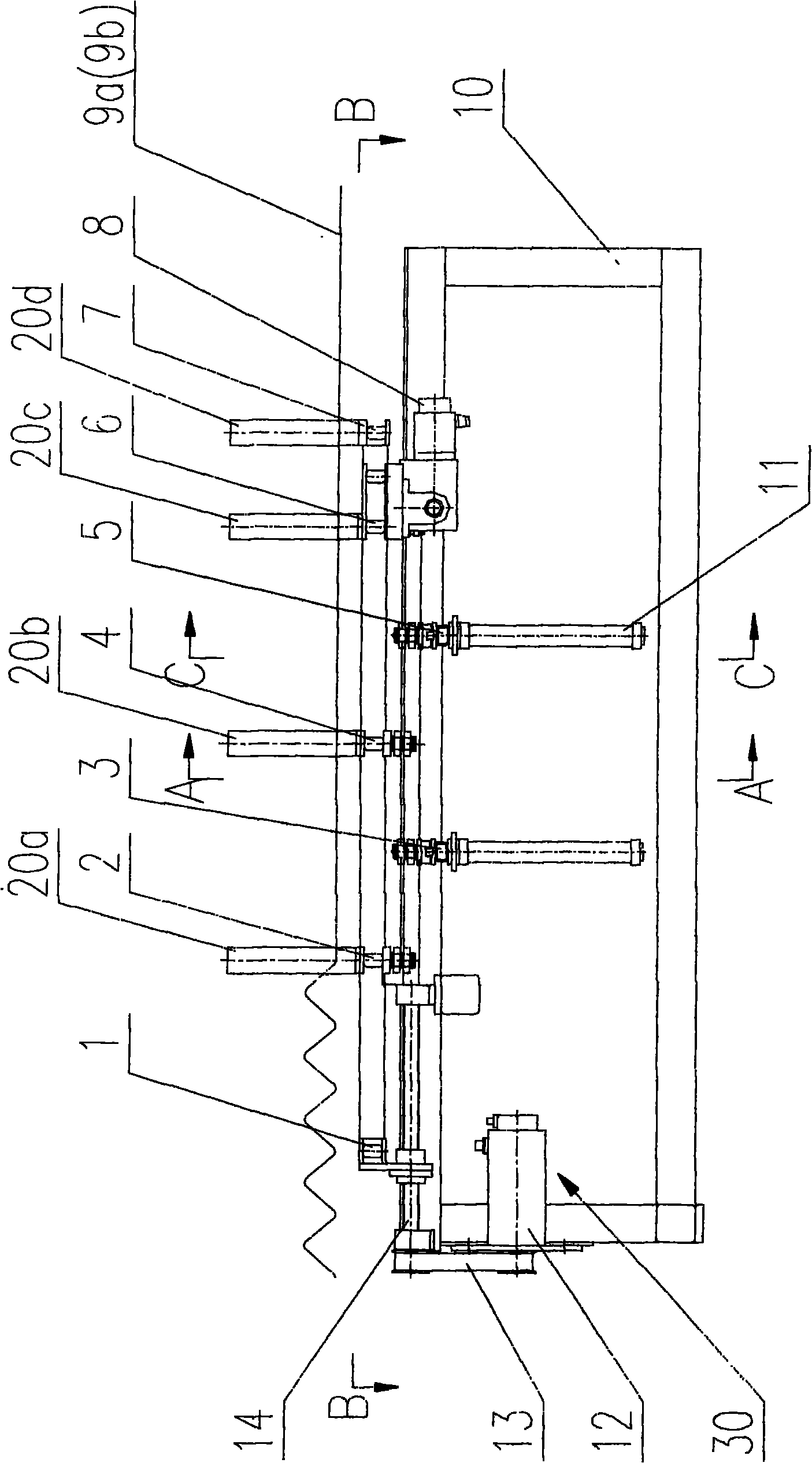

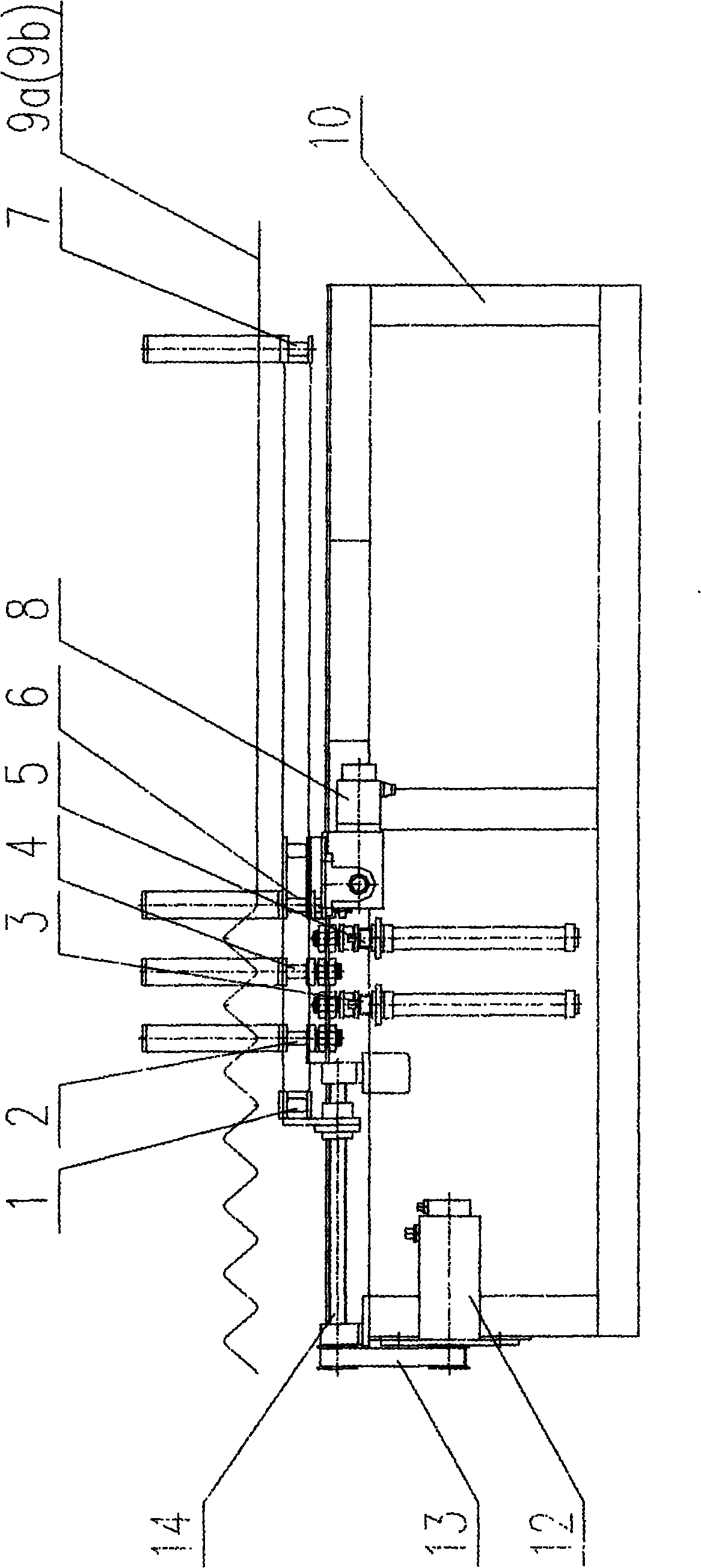

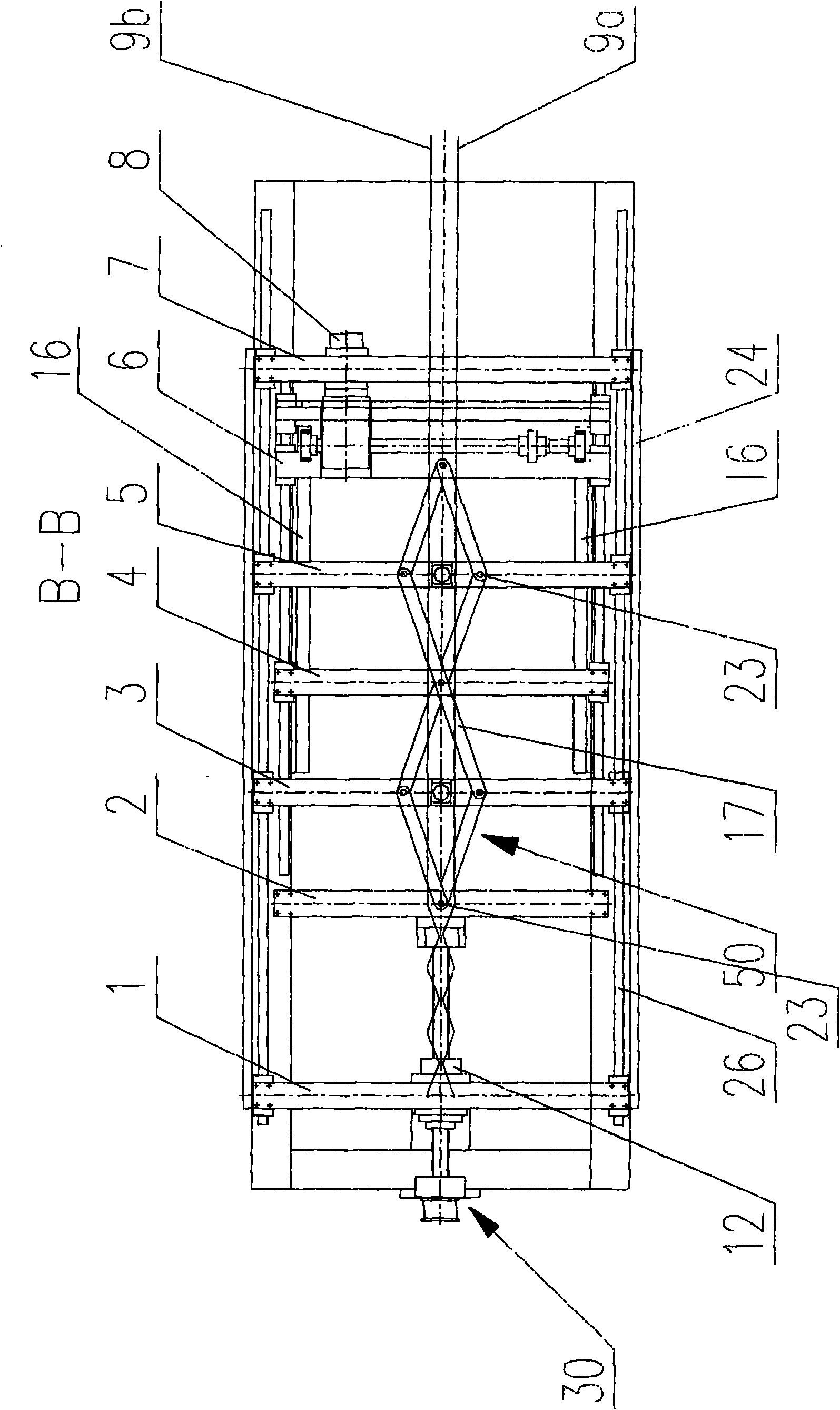

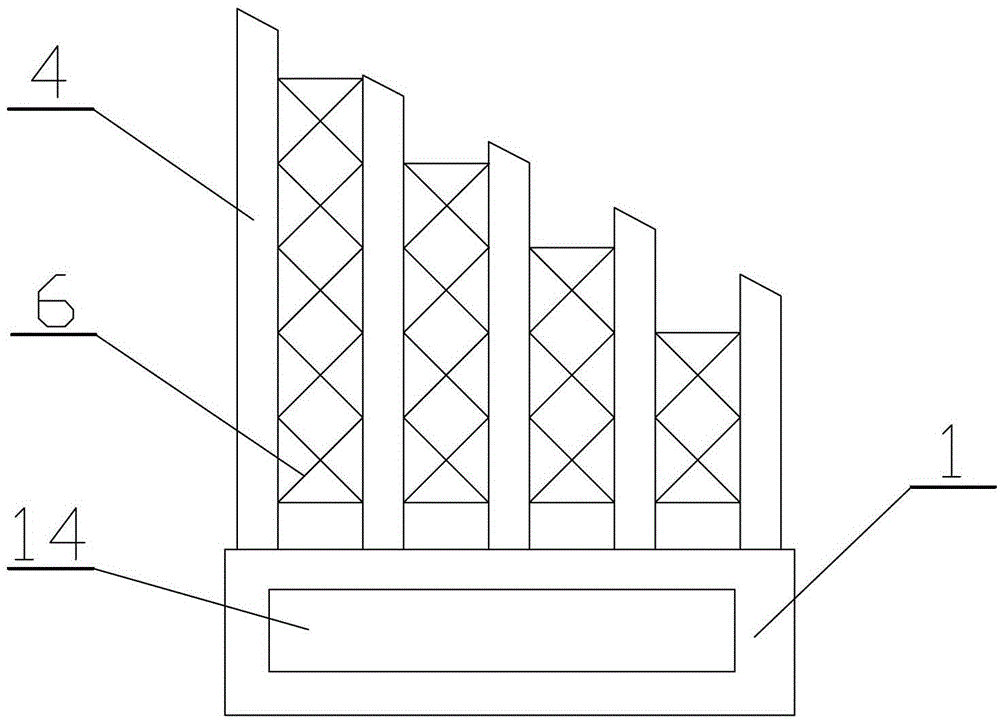

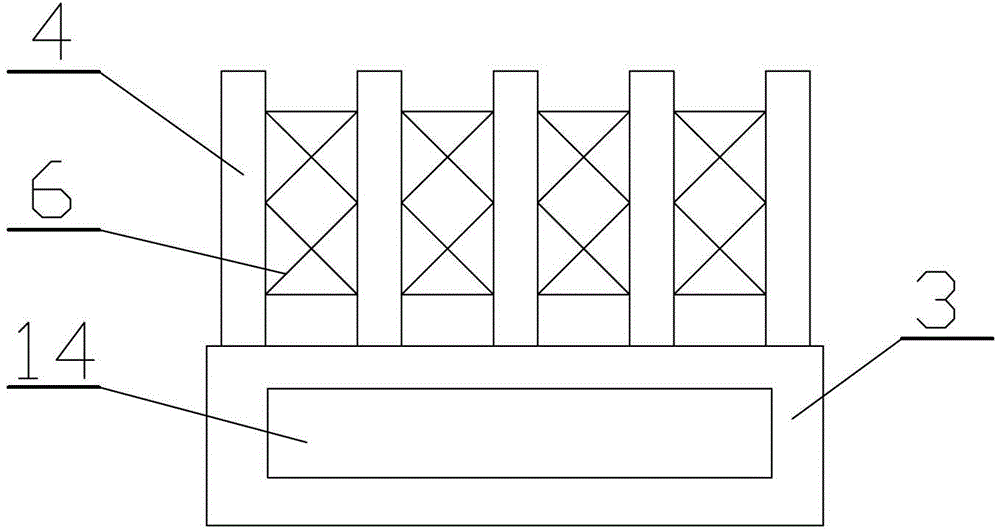

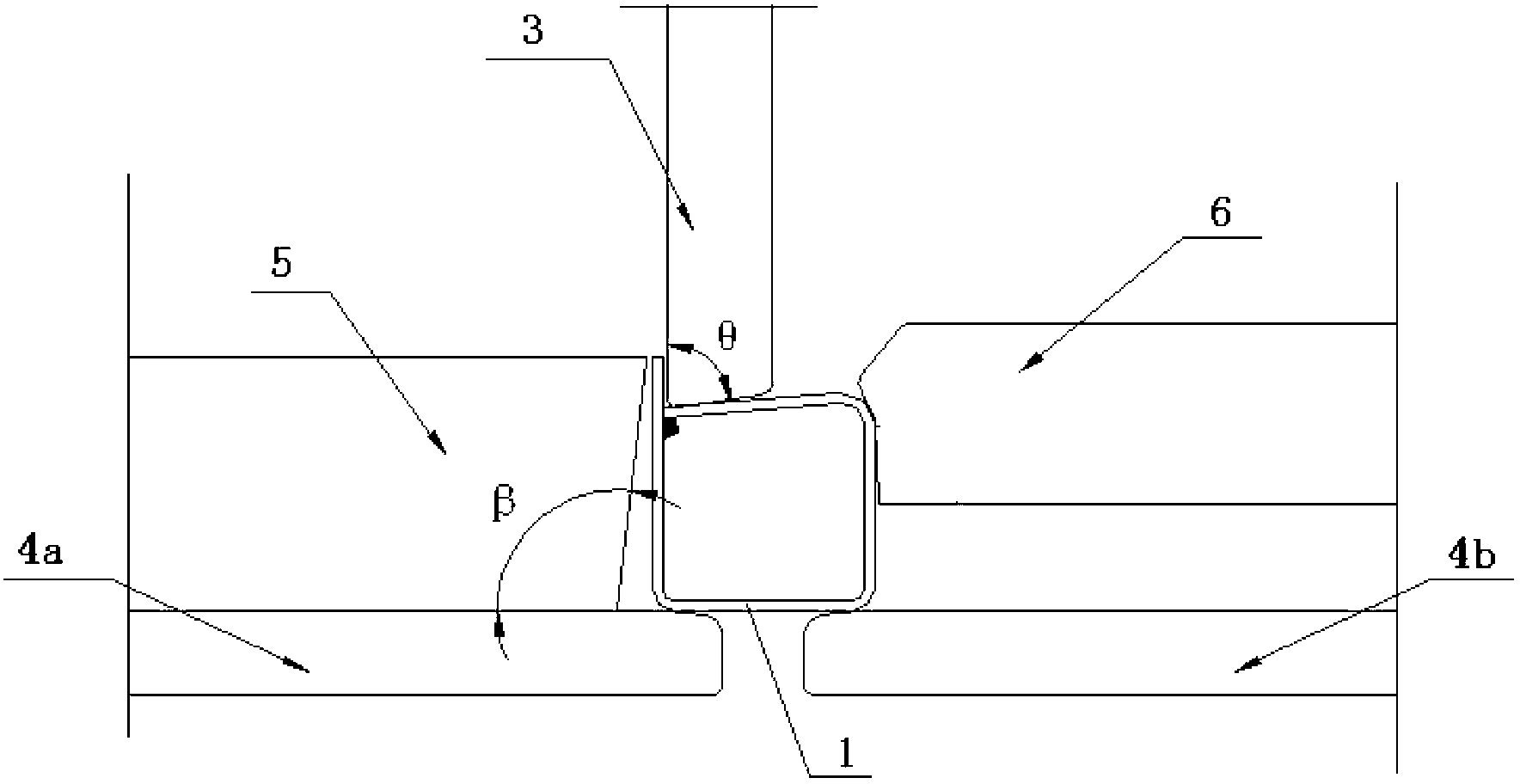

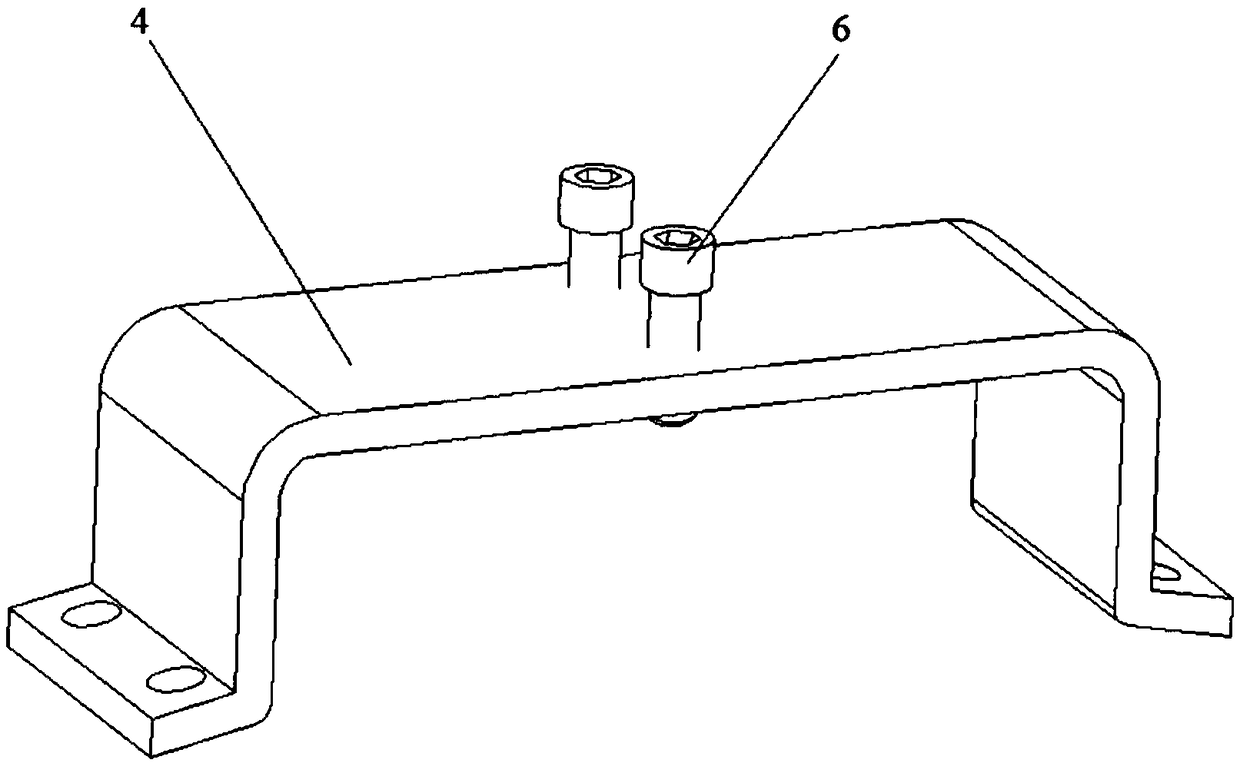

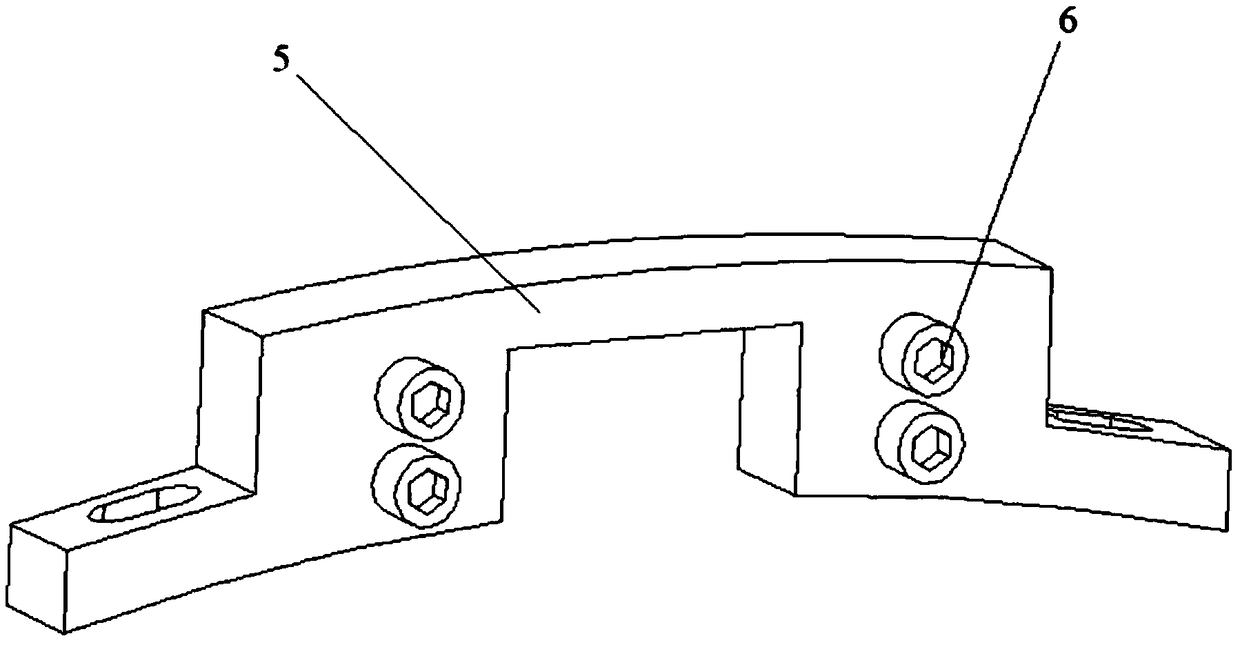

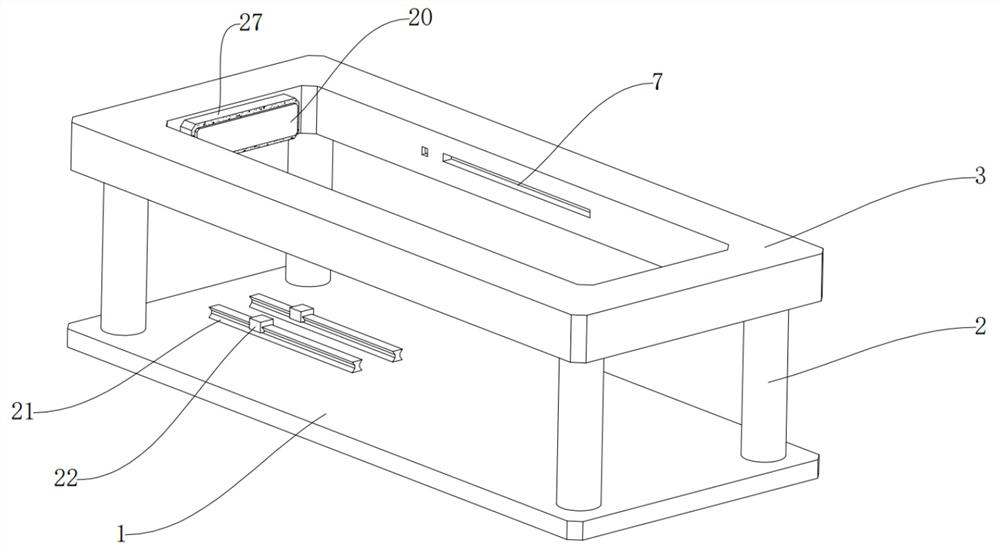

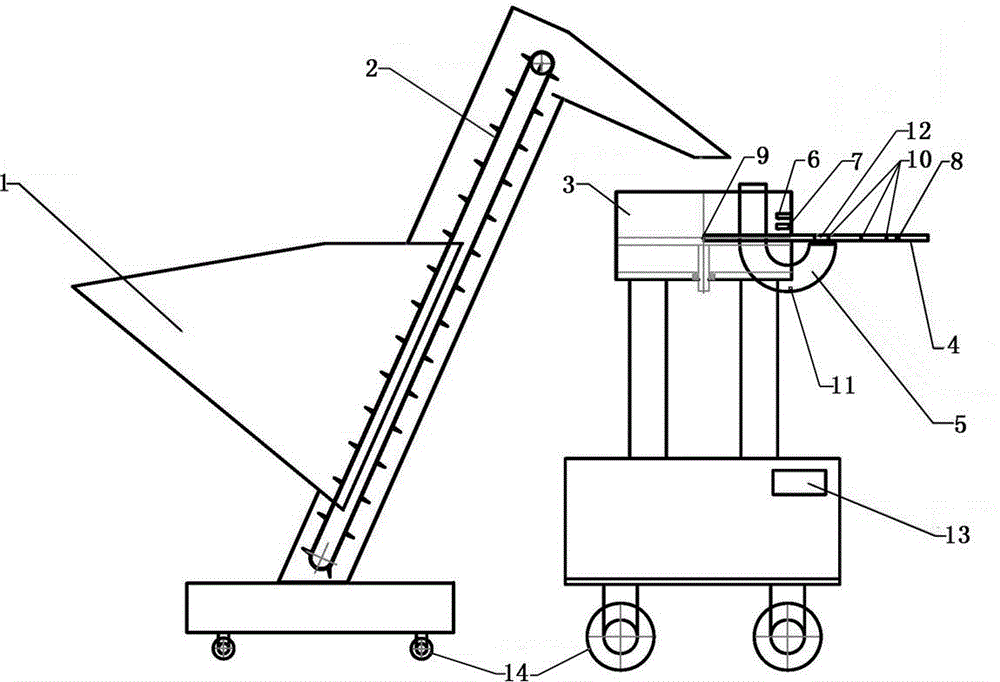

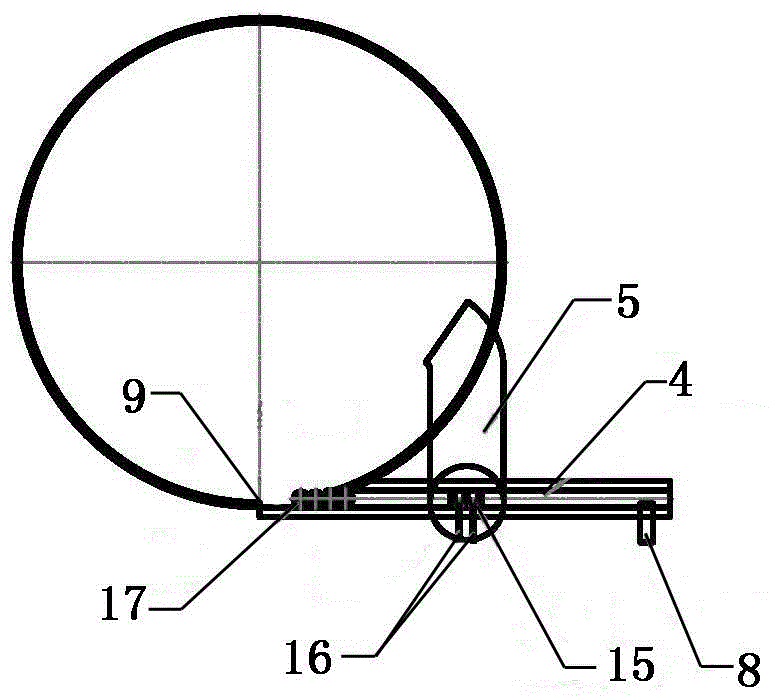

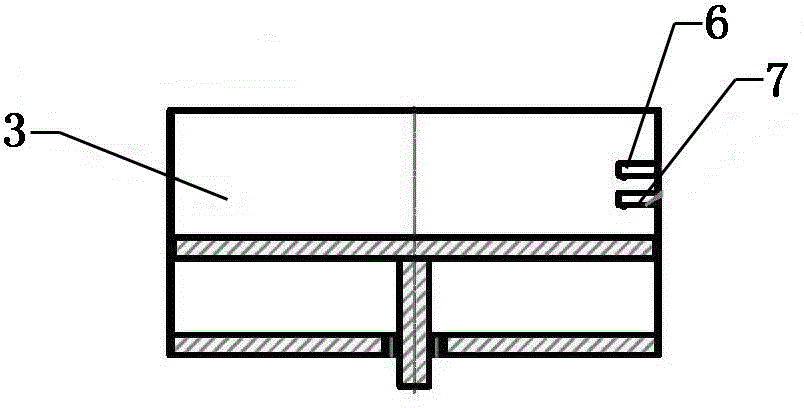

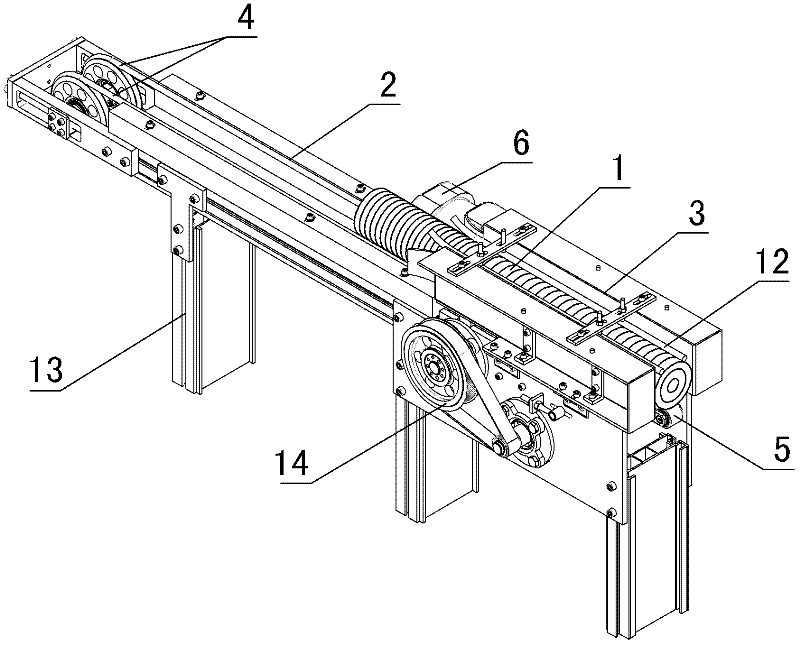

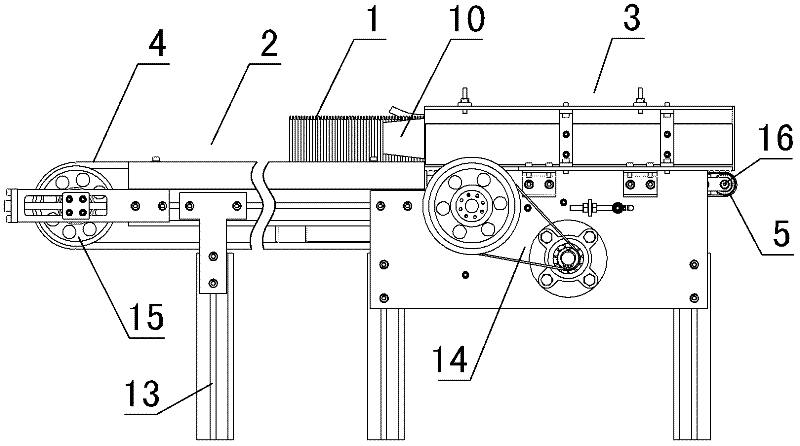

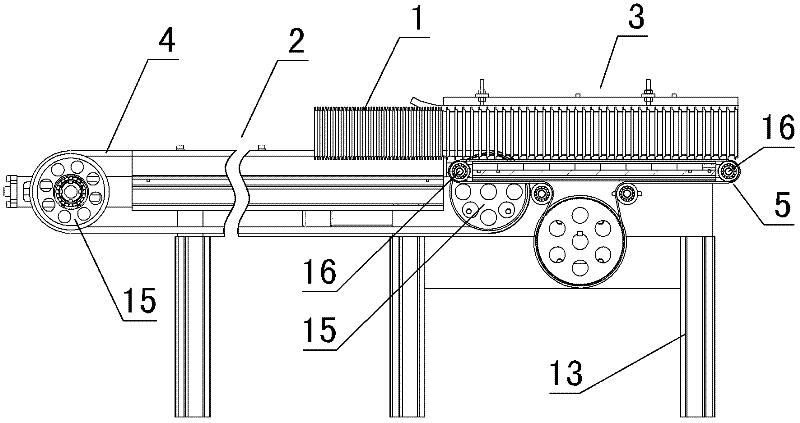

Pneumatic truss side rib bending forming mechanism

The invention discloses a pneumatic truss side rib bending forming mechanism which comprises a stand provided with a straight rail, a side rib traction mechanism, two sets of dome ejection rod mechanisms, a crank mechanism and a crank moving mechanism. The side rib traction mechanism is arranged at the left side of the stand and comprises a servo motor, a synchronous belt, a ball screw, a side rib traction cross beam, a side rib traction pressing cross beam, and a travel-adjustable cylinder and a side rib clamping device which are arranged on the side rib traction pressing cross beam. The dome ejection rod mechanisms are arranged at the lower side of a workbench surface in the side rib moving direction and comprise horizontally-arranged travel-adjustable cylinders and side rib clamping devices as well as vertically-arranged air cylinders and ejection rods. The invention has the advantages that the defects of the prior art are overcome, the production efficiency is higher, forming is regular, the truss side rib has no scratch, the bending pitch and the height of the truss side rib can be conveniently adjusted, thereby being applicable to the production of truss side rib bending wires with different pitches and heights.

Owner:TJK MACHINERY TIANJIN

Method for producing cerium-based abrasive and cerium-based abrasive produced thereby

InactiveUS6901684B2High-accuracy polished surfaceImprove wear resistancePigmenting treatmentDrying using combination processesCeriumCe element

This invention is a method for producing a cerium-based abrasive which includes: a step of grinding raw material for the cerium-based abrasive; a step of roasting the ground raw material; and a step of subjecting the roasted raw material to wet processing, the method being characterized in that it further includes a lower-temperature re-roasting step of heating the wet-processed raw material at 200 to 700° C. In the invention disclosed in this application, an abrasive with particularly preferable properties can be produced by fully drying the wet-processed raw material in a drying step, and subsequently subjecting the dried raw material to the lower-temperature re-roasting step.

Owner:MITSUI MINING & SMELTING CO LTD

Polishing solution for precision polishing of LED sapphire substrate

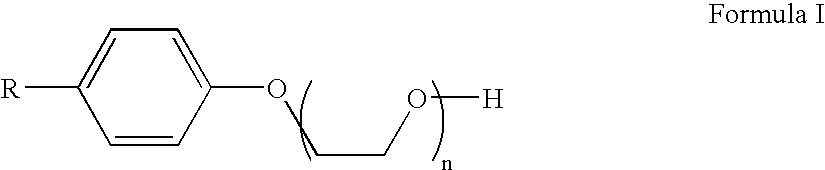

InactiveCN103184010AImprove liquidityConsistent removal ratePolishing compositions with abrasivesOrganic baseActive agent

The invention relates to a preparation formula of a polishing solution for precision polishing of an LED sapphire substrate. The polishing solution comprises the following components in percentage by weight: 0.7-1.0% of organic base diethanol amine, 25-35% of silica solution with grain diameter of 50-70nm, 0.4-0.7% of dispersing agent ethanediamine, and 0.1-0.3% of activating agent nonylphenol polyoxyethylene ether. The removal rate of the polishing solution can be up to 28 nm / min; the surface roughness Ra is smaller than 0.5 nm, which can meet the main performance index requirements for sapphire substrate CMP (chemical mechanical polishing). The polishing solution has the advantages of high removal rate, low surface roughness and cost, non-pollution to the environment and non-corrosion to equipment.

Owner:铜陵市琨鹏光电科技有限公司

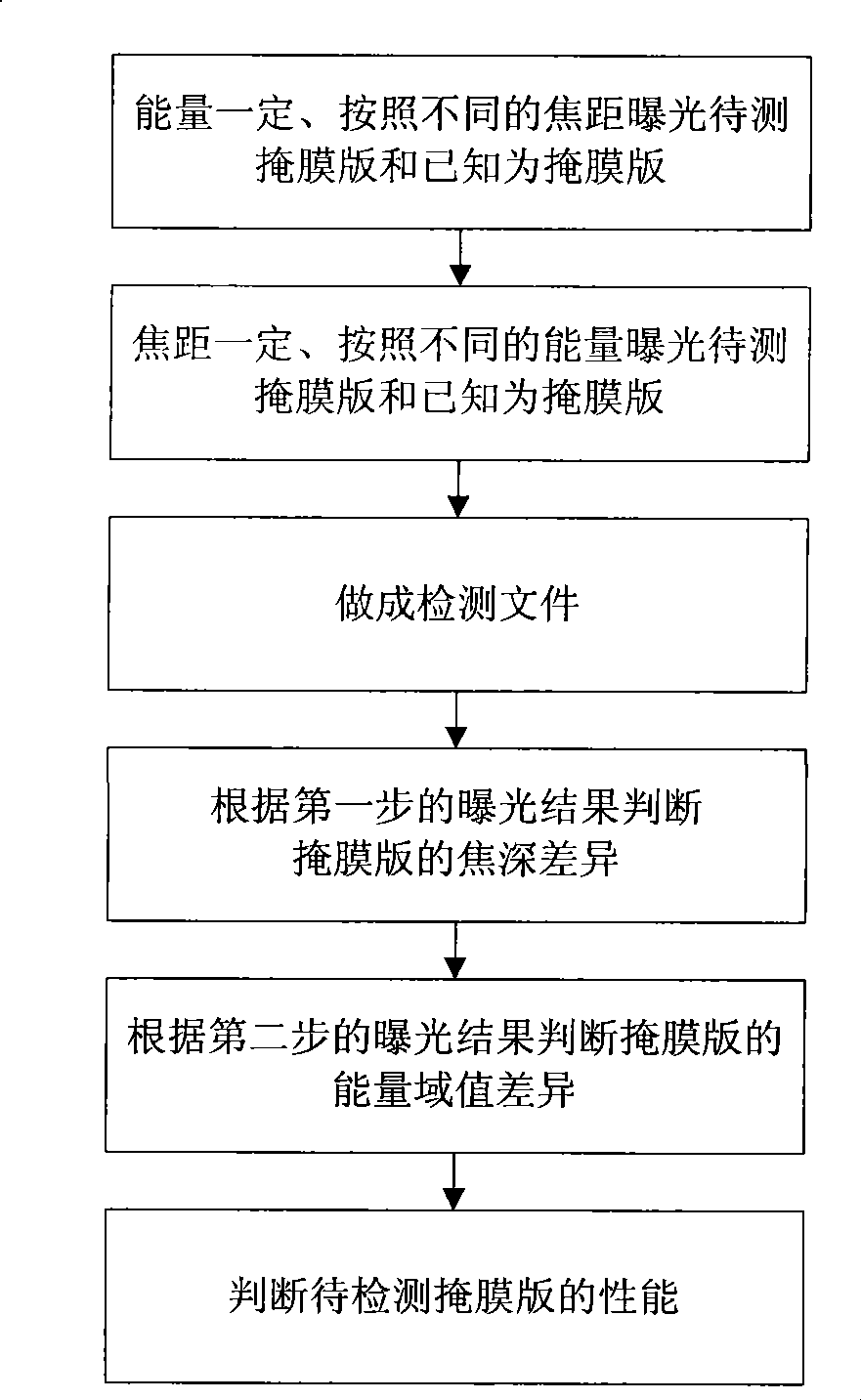

Method for detecting mask printing plate

ActiveCN101452201ANo open circuitNo short circuitSemiconductor/solid-state device testing/measurementSemiconductor/solid-state device manufacturingWorkloadPhysics

The invention discloses a method for detecting a masking plate. The method comprises the following steps: 1, under the condition of unchanged energy, carrying out simultaneous exposure of patterns of a masking plate to be detected and a masking plate known as a non-defective product on an optical piece according to different focal lengths; 2, under the condition of unchanged focal length, carrying out the simultaneous exposure of the patterns of the masking plate to be detected and the masking plate known as the non-defective product on the optical piece according to different energy; 3, making a detection file; 4, according to exposure results of the step 1, judging focal depth difference between the masking plate to be detected and the masking plate known as the non-defective product and the patterns and condition of particles of the two masking plates; 5, according to exposure results of the step 2, judging energy domain value difference between the masking plate to be detected and the masking plate known as the non-defective product and the patterns and the condition of the particles of the two masking plates; and 6, according to results of the step 4 and step 5, judging the performance of the masking plate to be detected. The method can reduce the workload and improve the working efficiency.

Owner:SHANGHAI HUAHONG GRACE SEMICON MFG CORP

Lubricant for drawing spring steel wire

ActiveCN103897787AConsistent colorSignificant change in softening pointLubricant compositionSide effectBorax

The invention provides a lubricant for drawing a spring steel wire. The lubricant for drawing the spring steel wire comprises the following components in percentage by weight: 40-60% of calcium stearate, 35-55% of softening point regulator and 5%-8% of extreme pressure additive, wherein the softening point regulator is one or more selected from calcium hydroxide, titanium dioxide, zinc oxide, sodium carbonate, sodium silicate, borax and paraffin. The lubricant is characterized in that the softening point of the lubricant changes obviously in a drawing process, and in the viscosity-temperature change of the lubricant, the lubricant is brought into a mold during drawing, and therefore, the requirements of the drawing process can be met. The lubricant has the advantages that the protection capacity of the lubricant on the surface of the steel wire is further improved, the subsequent heat treatment is not affected after drawing, no toxic or side effects are produced, a stable lubricating film can be formed on the surface of the steel wire under severe wire drawing conditions, and the wire drawing process is stabilized and the surface of the steel wire is protected against scratch.

Owner:GUANGZHOU ORSA WIRE SCI & TECH

Manufacturing method of matte transparent glazed ceramic sheet

The invention provides a manufacturing method of a matte transparent glaze ceramic sheet. The method comprises the following steps: spraying a biscuit with a ground glaze, printing, spraying with a matte transparent glaze, firing, and edging to obtain the finished product, wherein the matte transparent glaze comprises the following raw materials in percentage by weight: 80-93% of frit, 3-11% of calcined zinc oxide, 4-8% of air knife soil, 0.1-0.4% of methyl cellulose and 0.2-0.6% of sodium tripolyphosphate, and the frit is prepared from calcite, barium carbonate, strontium carbonate, potassiumfeldspar, kaolin, sodium carbonate, quartz sand and dolomite. According to the invention, zirconium dioxide is not added into the obtained matte transparent glazed ceramic sheet, transparency is good, calcined zinc oxide is used for adjusting expansion of glaze to achieve the purpose of adjusting the shape of a brick, and air knife soil improves the suspension property and viscosity of the glaze;and after the matte transparent glaze is sintered, the glossiness is 5-20 degrees, the glaze surface is smooth, a printing layer can be placed below the matte transparent glaze, the printing layer isprevented from being scratched, and the matte transparent glaze layer can also be used for polishing.

Owner:FOSHAN SANSHUI NEW PEARL CONSTR CERAMICS IND +1

Movable and quick-inflation rescue air cushion

The invention provides a movable and quick-inflation rescue air cushion, relates to a rescue air cushion, and solves the problem that the rescuing time is prolonged because a conventional rescue air cushion is long in inflation time, large in volume and hard to transport when being used. A plurality of tank bodies comprise at least one third tank body, a plurality of first tank bodies and a plurality of second tank bodies, wherein when the number of the third tank body is one or more, the plurality of first tank bodies and the plurality of second tank bodies are alternately attached to the periphery of the third tank body or the plurality of third tank bodies and connected to form a tank assembly, and a plurality of inflation hoses are fixedly connected to the upper end face of the tank assembly; the upper cavity in the tank assembly is a pipeline chamber, and the lower cavity of the tank assembly is a gas collection chamber; a plurality of gas inlet pipelines and a plurality of gas exhaust pipelines are arranged in the pipeline chamber; a plurality of rollers are arranged at the bottom of the tank assembly; a buffer face mesh is arranged on the plurality of inflation hoses; an inflation hose coating is coated on each inflation hose; and a plurality of reinforcing wires pass through the inflation hose coatings to form a reinforcing wire mesh. The movable and quick-inflation rescue air cushion is used in rescue work.

Owner:HARBIN INST OF TECH

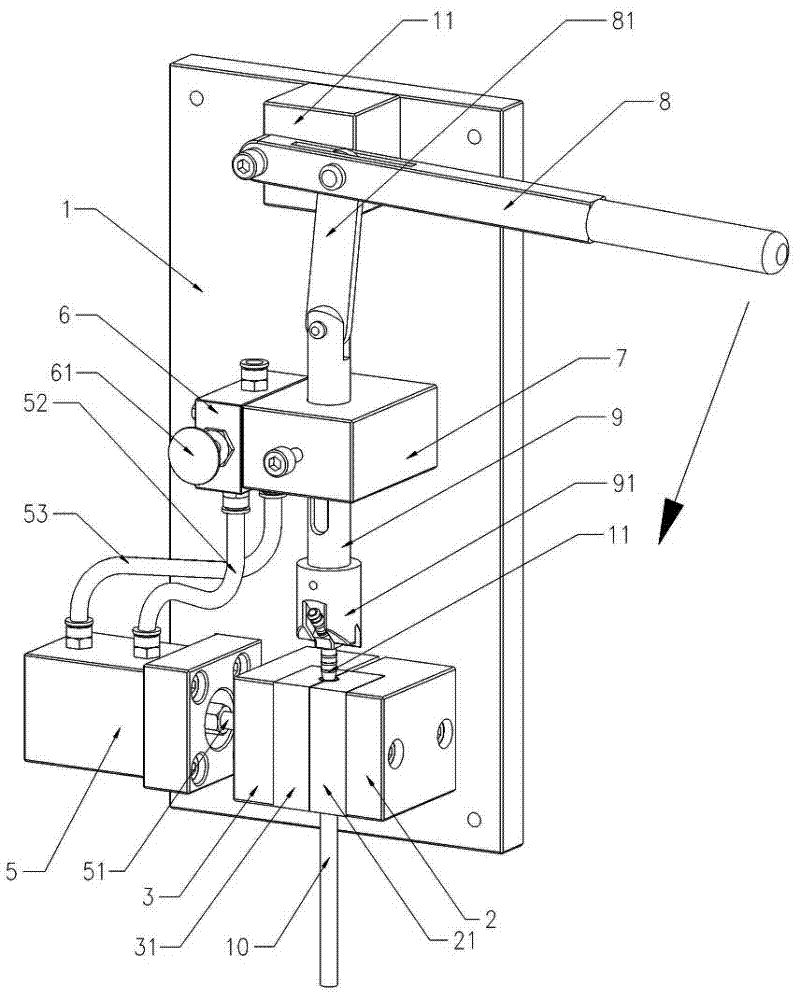

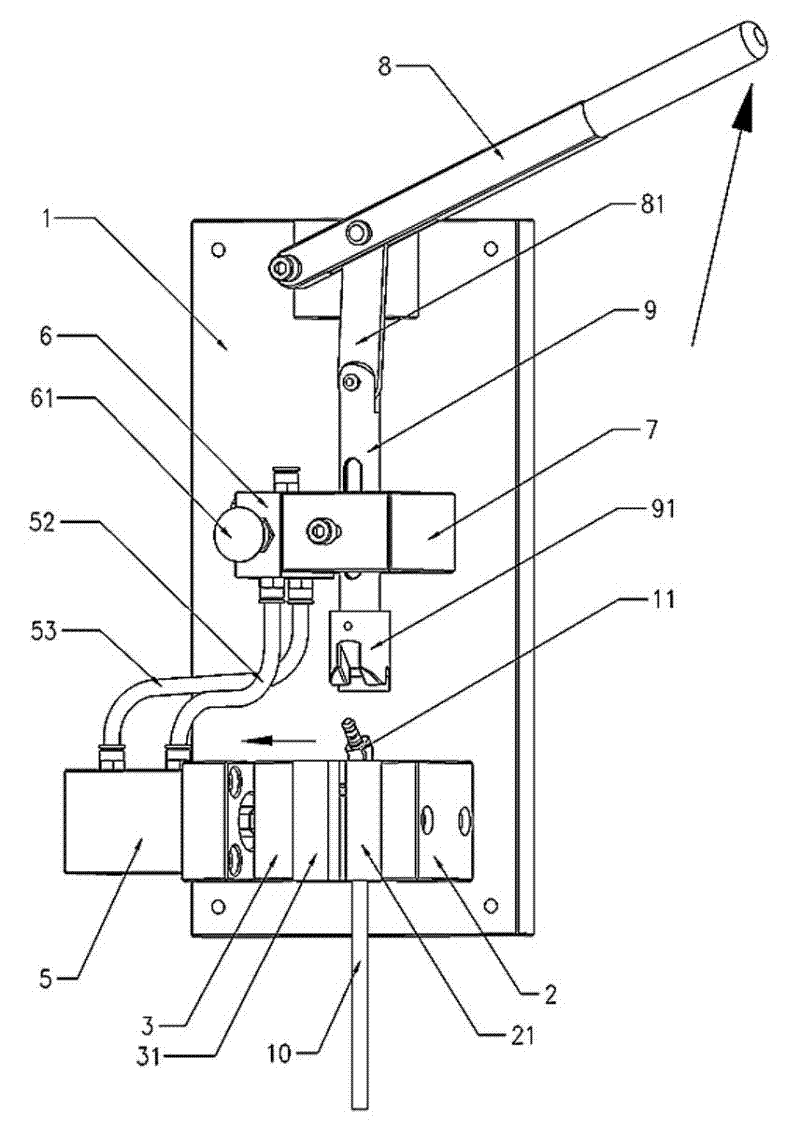

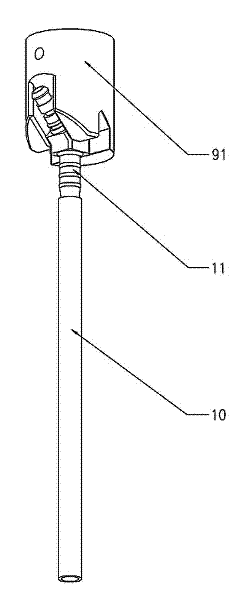

Hose fitting assembly station

InactiveCN102267122AAdvance and retreat smoothlyAccurate directionMetal-working hand toolsInterference fitPunch press

The hose joint assembly platform is fixed with a fixed block, cylinder, two-way valve, and support plate on the bottom plate; the two-way valve controls the advance and retreat of the piston push rod through the intake pipe; the sliding clamping block is pulled by the piston push rod. The fixed block is closed and separated; soft cushion blocks are respectively set on the mating surfaces of the fixed block and the sliding clamping block, and the corresponding parts have semicircular grooves, which are convenient for clamping the hose; the push-pull handle connects the push rod together with the punch Press against the pipe joint, rigidly insert the pipe joint into the inner wall of the rubber hose, and use the interference fit to fix the two tightly together. Equipping corresponding series of punches for pipe joints of different shapes and sizes can expand the scope of application, convenient and quick assembly, good sealing performance of joints, and high production efficiency.

Owner:ZHEJIANG BOSHITE MECHANICAL CO LTD

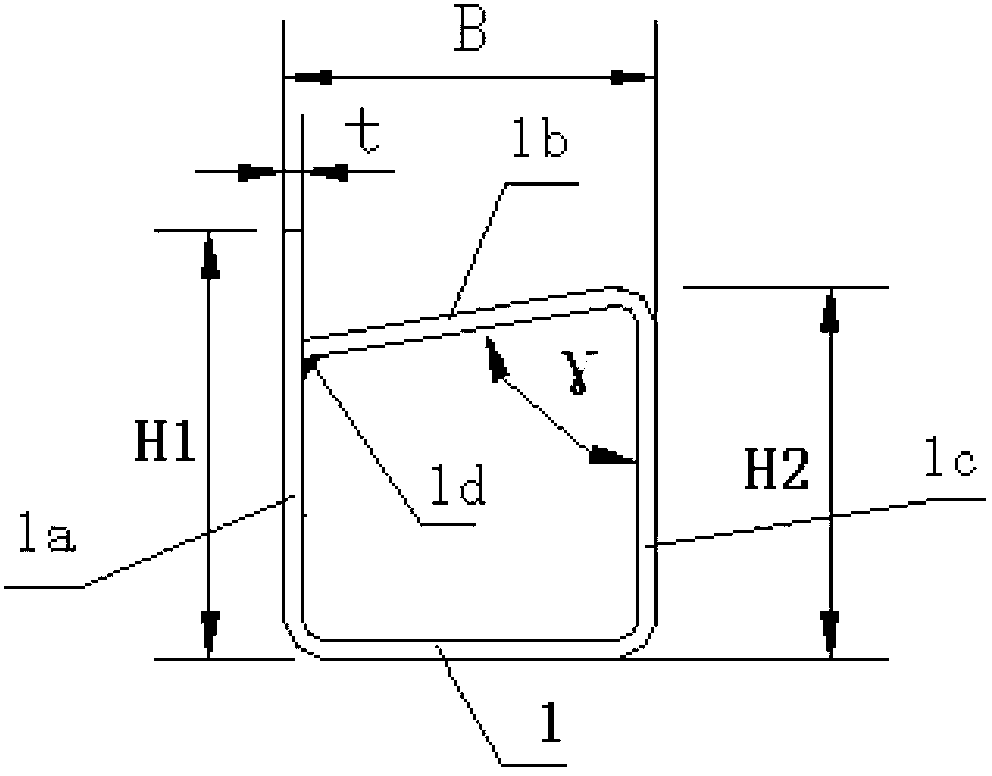

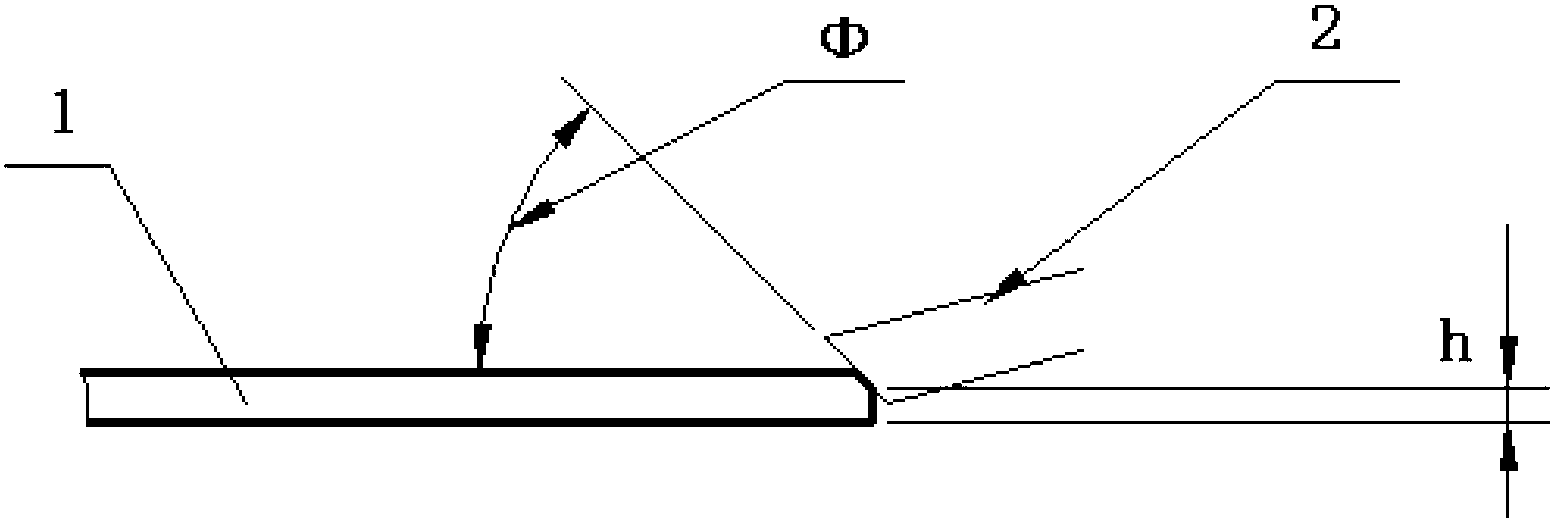

Method for manufacturing finned square rectangular steel tube

The invention provides a method for manufacturing a finned square rectangular steel tube. The method comprises the following steps: (1) carrying out trimming on the inner angle of the end face of a welding edge, wherein the trimming angle phi is 45+ / -2 degrees, and the trimming left root h meets the equation: h=1 / 2 thickness of a plate+ / -0.5mm; (2) carrying out pre-profiling of cold bending on strip steel through a die, and forming the shape and corresponding size of a product preliminarily; (3) carrying out extruding welding through four rollers: using an upper extrusion roller, a lower extrusion roller, a left extrusion roller and a right extrusion roller for extrusion, and bending a side extrusion roller of a finned edge by 3-6 degrees for carrying out high-frequency welding on the end face of the welding edge and the surface of the inner side of the finned edge; (4) planning welding burrs: planning outer burrs through an arc blade and avoiding the finned edge, and regulating the angle of a planer tool until the included angle alpha 1 between the planer tool and the vertical direction of the finned edge is 6 degrees, wherein the angle alpha 2 of the bottom of a planer tool is 18 degrees; (5) carrying out sizing shaping: when the four rollers are sized and shaped in an extrusion mode, bending the side extrusion roller of the finned edge by 2-3 degrees, and enabling the angle of the finned edge to meet the standard requests. The product produced through the method is good in shape of the cross section, good in surface quality, free of scratch, good in planeness, and stable and qualified in welding.

Owner:HANKOU STEEL ROLLING MILL WUHAN IRON & STEEL CORP

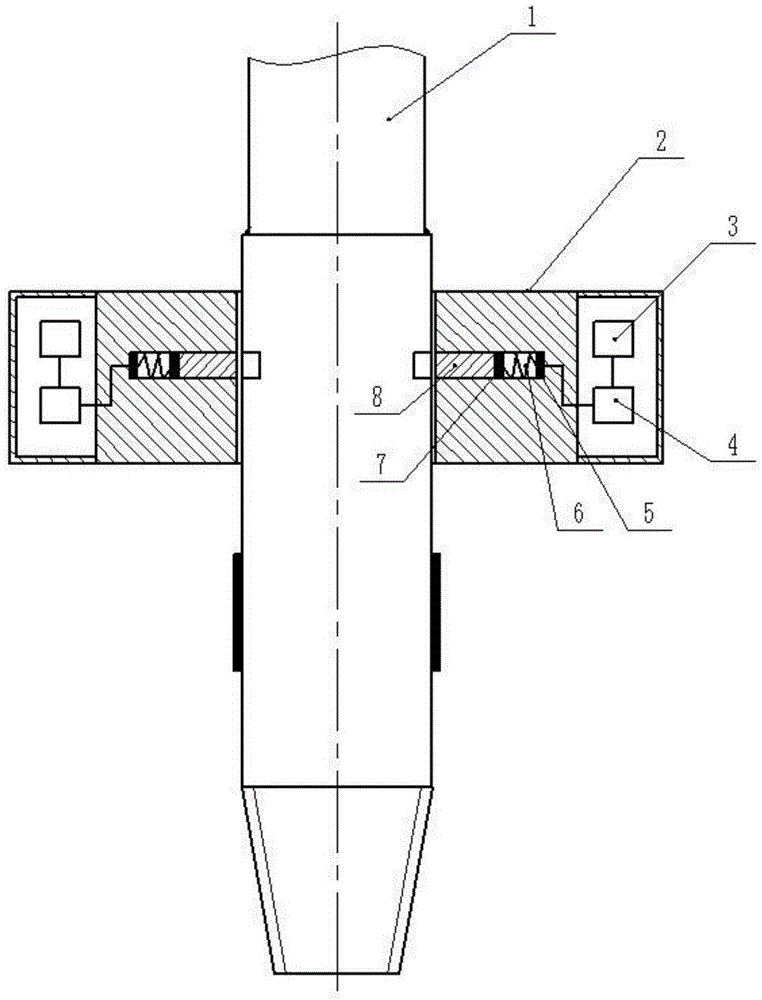

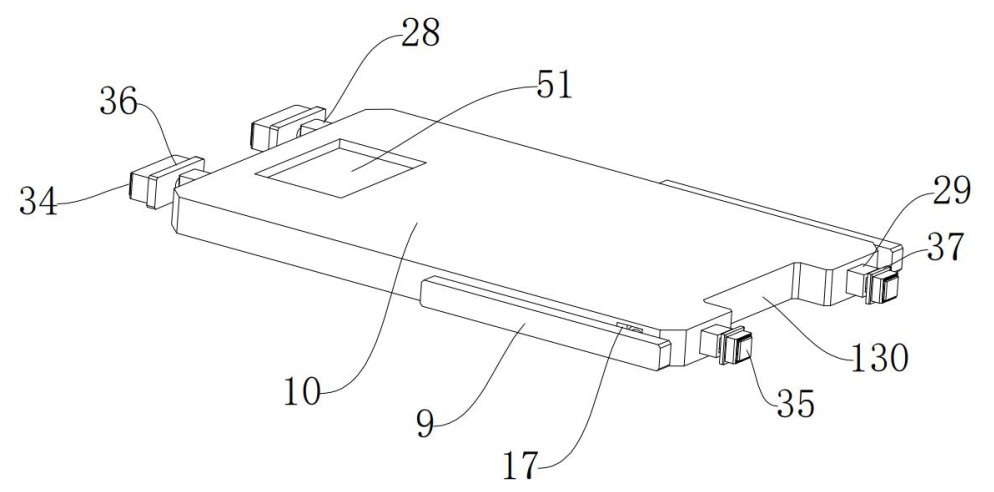

Permanent-magnet surface-mounting magnetic steel assembly tool and application method thereof

PendingCN108923600AReduce impact forceEasy to useManufacturing stator/rotor bodiesSurface mountingMagnetic poles

The invention belongs to the technical field of motor manufacturing, and particularly relates to a permanent-magnet surface-mounting magnetic steel assembly tool and an application method thereof. Thepermanent-magnet surface-mounting magnetic steel assembly tool comprises a rotor core, a plurality of magnetic steel positioning devices, a plurality of magnetic steel press blocks and a magnetic steel push device, wherein the rotor core is arranged on a rotor rack, the plurality of magnetic steel positioning devices can be detachably fixed on the rotor core, the plurality of magnetic steel pressblocks can be fixedly arranged on the rotor core, the magnetic steel push device can be matched with the rotor core to push a magnetic steel block to a magnetic steel installation region, a pluralityof magnetic steel installation grooves are formed in a peripheral surface of the rotor core, each magnetic steel installation groove is corresponding to a magnetic pole to be installed, and the magnetic pole to be installed comprises a plurality of magnetic steel blocks. According to the permanent-magnet motor surface-mounting magnetic steel assembly tool and the application method thereof, provided by the invention, no damage to a surface of the magnetic steel during the large-size permanent-magnet motor assembly process can be ensured, the magnetic steel collision force is reduced, so thatthe application performance and the lifetime of the motor are ensured, moreover, the magnetic steel assembly efficiency of an assembly person also can be improved, and the safety of an operator duringthe magnetic steel assembly process is ensured.

Owner:青岛海西电气有限公司

Drill rod clamping device

ActiveCN105221086ASimple structureEasy to operateDrilling rodsDrilling casingsControl circuitSolid core

The invention discloses a drill rod clamping device. The drill rod clamping device comprises a drill rod and a clamping device body. The drill rod is composed of a drill rod connector and a steel pipe. The drill rod connector is welded to the steel pipe. The drill rod connector is composed of a taper thread section, an anti-abrasion section and a non-anti-abrasion section. An outer arc groove is formed in the circumference of the non-anti-abrasion section of the drill rod connector. The clamping device body comprises a clamping box. The clamping box is composed of a cavity part and a solid core part. The cavity part is provided with an infrared receiving circuit and a control circuit. The infrared receiving circuit is electrically connected with the control circuit. The solid core part is provided with a groove. An electromagnet is fixed to the bottom of the groove and sequentially and fixedly connected with a magnet and a sliding block through a spring. The magnet is fixed to the sliding block. The sliding block can move leftwards and rightwards along the groove. The drill rod clamping device is simple in structure, convenient to operate, reliable in clamping, long in service life, low in manufacturing cost, free of abrasion and scratches to the drill rod and free of slipping.

Owner:CHTC JOVE HEAVY IND

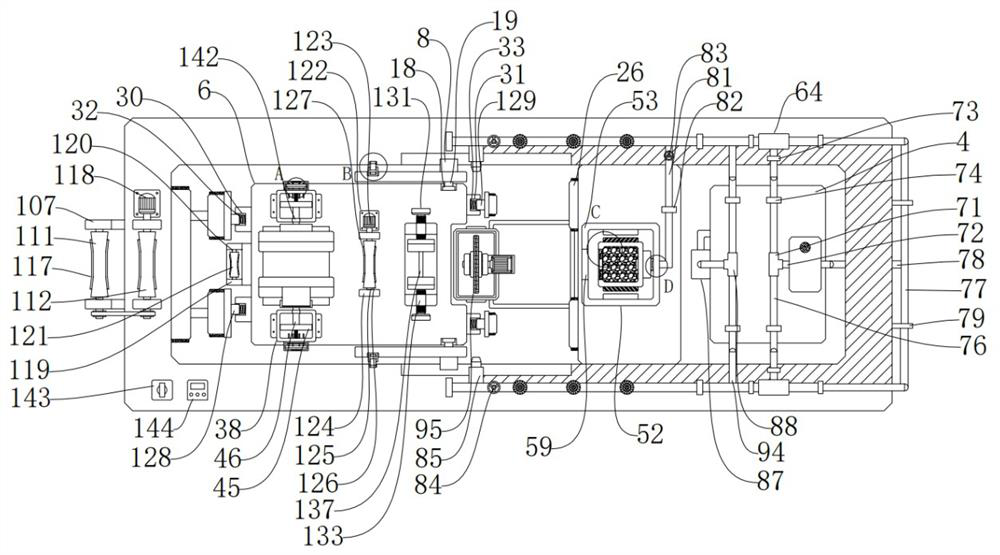

All-dimensional dust suppression expansion type pipe clamping and machining all-in-one machine of three-phase rotating structure

ActiveCN113385964AGuaranteed accuracyEasy to adjustOther manufacturing equipments/toolsMetal working apparatusStructural engineeringMachine

The invention discloses an all-dimensional dust suppression expansion type pipe clamping and machining all-in-one machine of a three-phase rotating structure. The all-dimensional dust suppression expansion type pipe clamping and machining all-in-one machine comprises a base, a supporting column, a machining frame, a cooling water mist box, a grinding plate, a magnetic attraction type moving mechanism, an expansion type clamping mechanism, an unpowered grinding mechanism, a vortex separation type cooling mechanism, an all-dimensional atomization dustproof mechanism, a high-precision cutting device, a linkage feeding mechanism, a positioning material moving mechanism and a positioning clamping mechanism. The invention belongs to the technical field of pipe cutting and grinding devices, and particularly provides the all-dimensional dust suppression expansion type pipe clamping and machining all-in-one machine of the three-phase rotating structure, so that integration of pipe cutting, grinding and scrap iron adsorption treatment is achieved, all-around scrap collection is facilitated, self-adaptive clamping and fixing on pipes can be carried out according to different cross section shapes and sizes of the pipes through the arrangement of an expansion type clamping mechanism, and due to the arrangement of the linkage feeding mechanism, the labor intensity of workers can be reduced conveniently, and therefore the all-dimensional dust suppression expansion type pipe clamping and machining all-in-one machine of the three-phase rotating structure can machine the pipes efficiently.

Owner:徐州中顺尚奕机械制造有限公司

Technology for producing aluminum alloy section bar for ships

ActiveCN103589922AExcellent physical and chemical propertiesSmall dimensional toleranceAluminium alloyExtrusion

The invention discloses a technology for producing an aluminum alloy section bar for ships. The technology orderly comprises component optimization, pouring blank-making, extrusion molding, quenching, stretching straightening and aging treatment. The optimal aluminum alloy comprises, by mass, 0.27-0.37% of Si, 0.16-0.20% of Fe, 0.02-0.04% of Cu, 0.22-0.33% of Mn, 1.35-1.65% of Mg, 0.04-0.06% of Cr, 0.09-0.11% of Zn, 0.09-0.11% of Ti and the balance Al. In the extrusion molding, an extrusion rate is in a range of 1.3-2.2m / min, a bar casting temperature is in a range of 515-545 DEG C, a mold temperature is in a range of 450+ / -15 DEG C and an extrusion cylinder temperature is in a range of 460+ / -15 DEG C. The aluminum alloy section bar obtained by the technology has excellent physical and chemical performances, small dimensional tolerance and high product surface quality.

Owner:CHINA ZHONGWANG

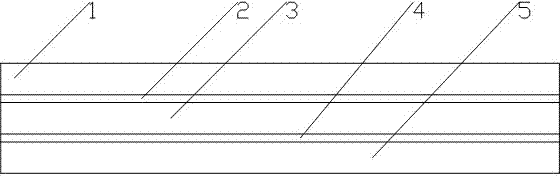

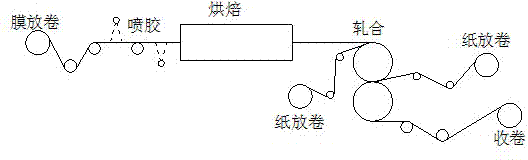

Manufacturing method of flexible composite material

ActiveCN103085441ASolve the problem of appearance defects of traditional production processSolve the problem of cosmetic defectsLamination ancillary operationsLaminationFiberPolyurethane adhesive

The invention discloses a manufacturing method of a flexible composite material. The manufacturing method comprises the steps of unwinding a base material film, respectively spraying a polyurethane adhesive solution on the front and back of the unwound base material film to form polyurethane adhesive layers, baking a solvent and then respectively carrying out hot pressing, rolling and winding on the adhesive layers and fiber papers, carrying out aftertreatment and slitting to obtain a finished product. By adopting the manufacturing method disclosed by the invention, the problem of apparent defects caused by the traditional manufacturing technique is solved, performance indexes of a produced product are up to the standard while appearance of the produced product is good, no scratch is produced, and export requirements are met.

Owner:ZHUZHOU TIMES NEW MATERIALS TECH

Semiconductor material polishing method and polishing solution for polishing gallium antimonide substrate

PendingCN112701037AImprove surface roughnessGuaranteed stabilitySemiconductor/solid-state device manufacturingPolishing compositions with abrasivesGallium antimonideOrganic acid

In order to overcome the defects that when a soft semiconductor material such as gallium antimonide is polished by adopting a CMP (Chemical Mechanical Polishing) process in the prior art, metal ions and the like contained in a polishing abrasive and a polishing solution are easily attached to the surface of a polished object, scratches are generated on the surface of the polished object, and the service life of the polishing solution is short, the invention provides a semiconductor material polishing method and a polishing solution for polishing a gallium antimonide substrate. According to the method, a semiconductor material with the Mohs hardness of 1.5-6 is polished. A first step is rough polishing, and a polishing solution containing a hard abrasive is adopted to conduct mechanical polishing on a semiconductor material substrate slice. A second step is medium polishing, and a medium polishing solution comprises a soft polishing abrasive, a weak acid oxidizing agent, organic acid, a hydrophilic nonionic surfactant and deionized water. A third step is fine polishing, and a fine polishing solution comprises a weak acid oxidizing agent, organic acid and deionized water. When the polishing method is adopted for polishing a semiconductor material, corrosion pits and scratches are eliminated, pits are reduced, and a material with good surface roughness is obtained.

Owner:SUZHOU KUNYUAN OPTOELECTRONICS CO LTD

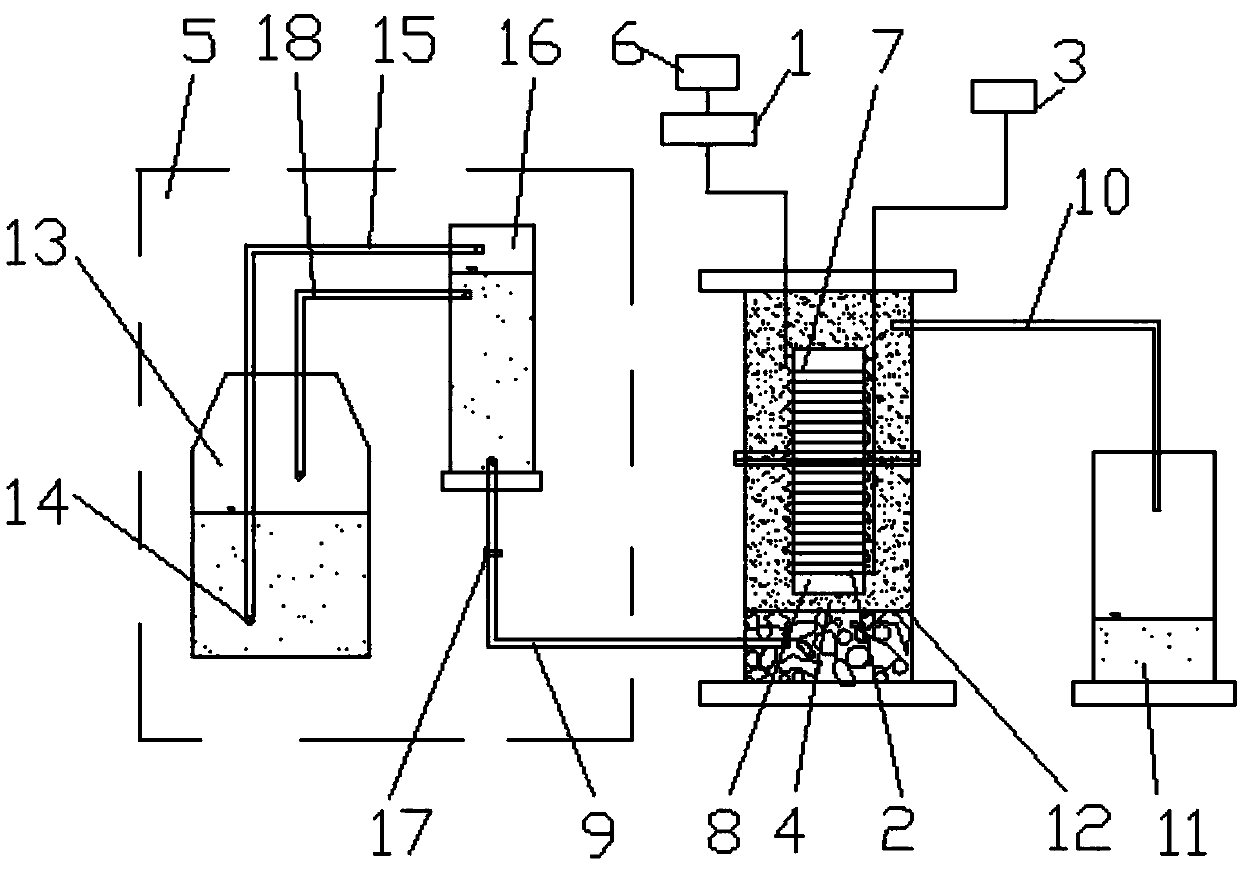

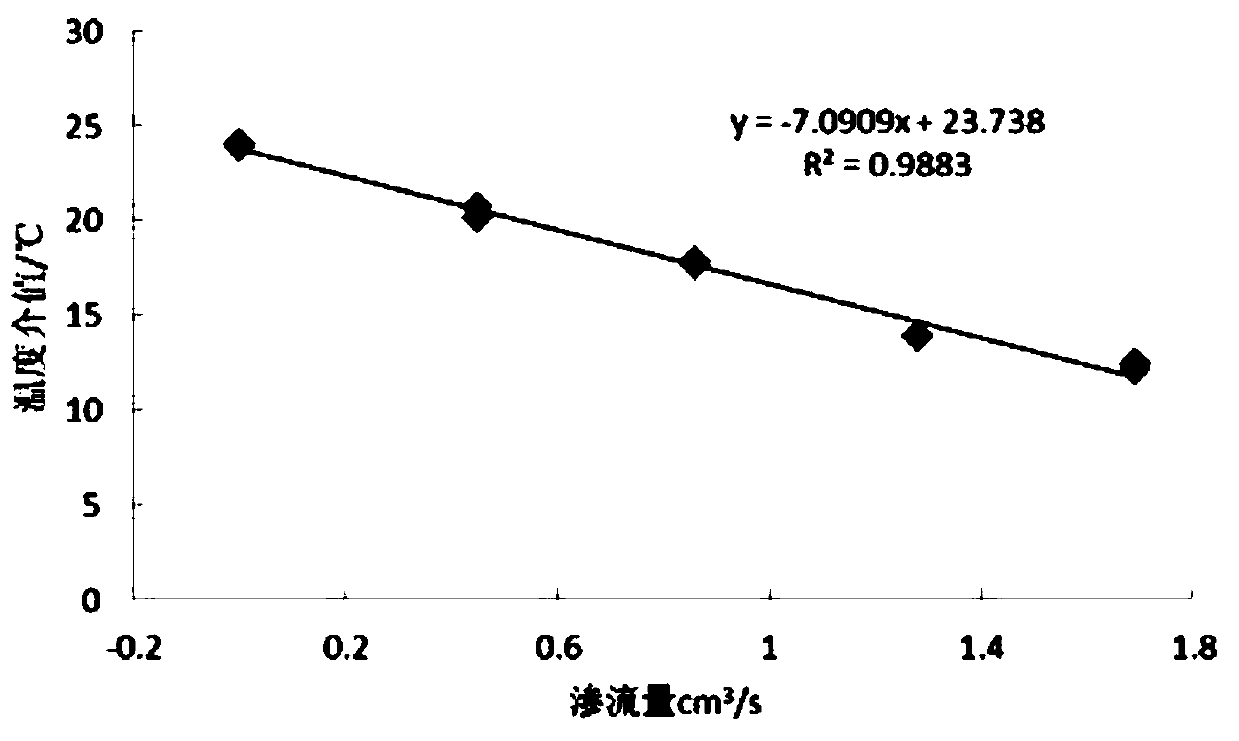

Si-DTS-based sandy soil seepage quantity monitoring platform

InactiveCN109596496AImprove monitoring accuracyIncreased sensitivityThermometers using physical/chemical changesPermeability/surface area analysisEngineeringStreamflow

The invention discloses a Si-DTS-based sandy soil seepage quantity monitoring platform. The platform comprises a heating system, a seepage system and a distributed optical fiber temperature measurement system, wherein the heating system comprises a silicone rubber heating band and an AC power supply; the seepage system comprises a model pipe and a water supply system for providing seepage for sandy soil in the model pipe; the distributed optical fiber temperature measurement system comprises a temperature measurement optical fiber and a DTS demodulator and a distributed optical fiber temperature measurement main control computer, which are connected with the temperature measurement optical fiber in sequence; the temperature measurement optical fiber is wound on the outer wall of a PVC pipe; the silicone rubber heating band is wound outside the temperature measurement optical fiber to form a measurement pipe; and the distributed optical fiber temperature measurement main control computer is used for acquiring and analyzing corresponding position and temperature information of the temperature sensing optical fibers. The platform is capable of testing a relative relationship between atemperature intermediate value of the measurement pipe in the sandy soil and a seepage quantity through the heating system, the seepage system and the distributed optical fiber temperature measurement system, so as to obtain a seepage quantity of a seepage field in the sandy soil, and is simple to operate and high in correctness.

Owner:XIAN UNIV OF TECH

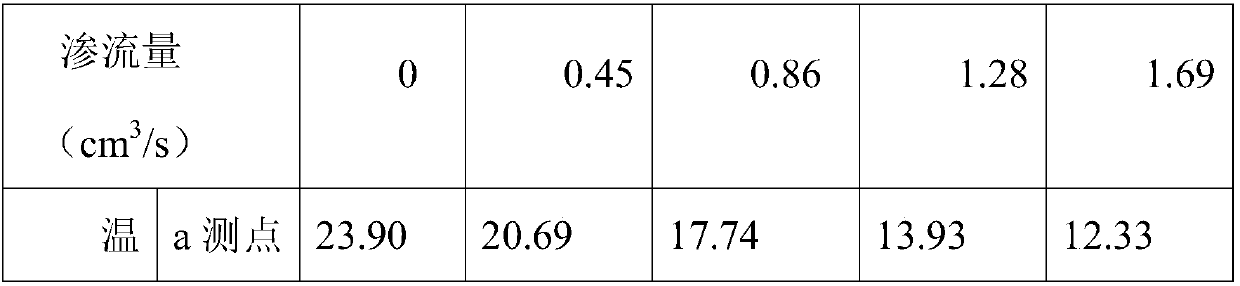

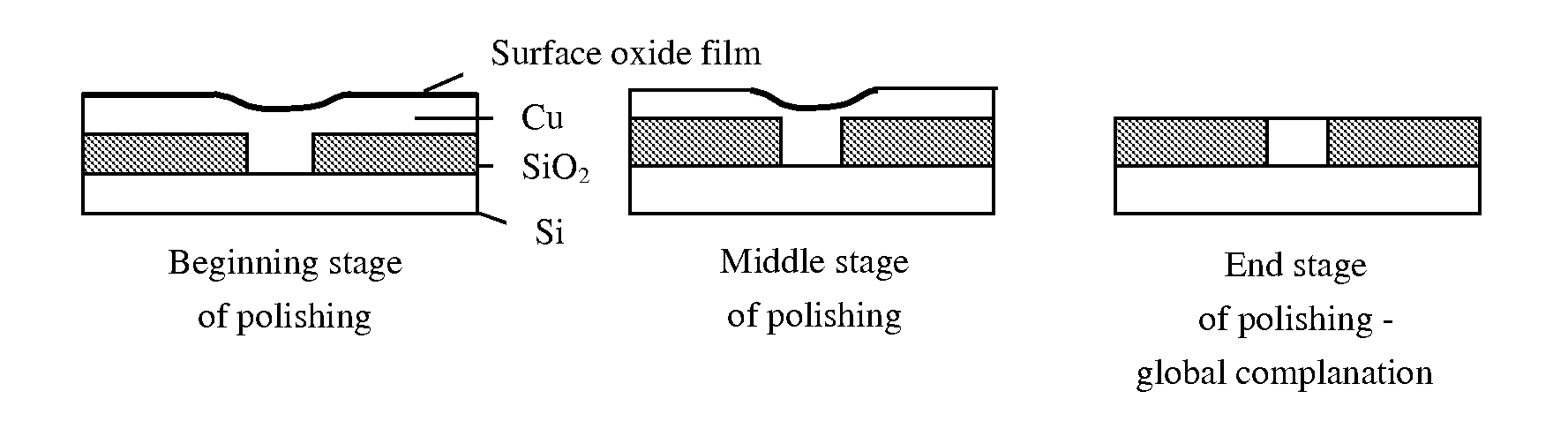

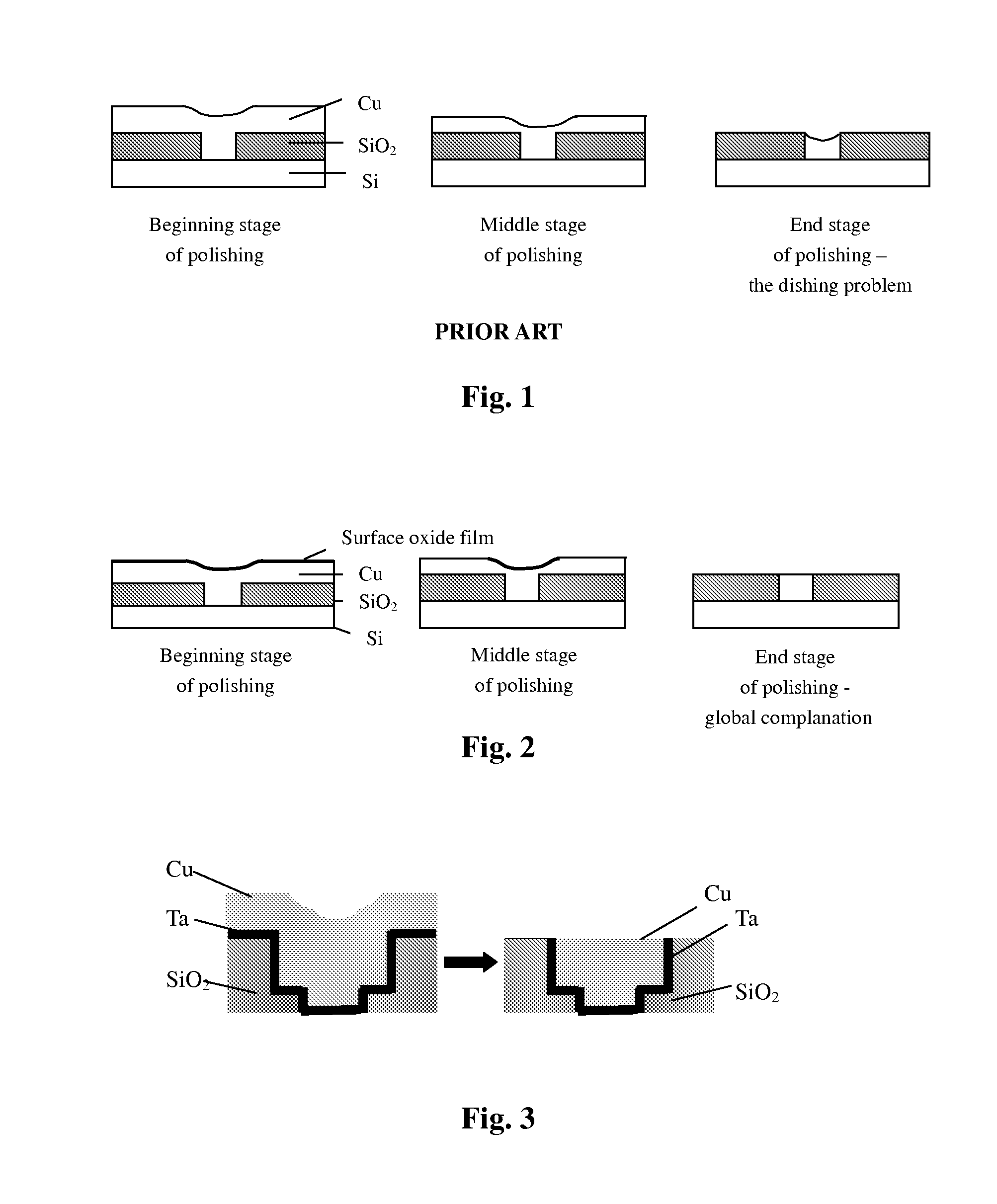

Method for controlling the dishing problem associated with chemical-mechanical planarization (CMP) during manufacture of copper multilayer interconnection structures in ultra large-scale integrated circuits (ULSI)

InactiveUS20080032606A1Good effectStrong complexationOther chemical processesSemiconductor/solid-state device manufacturingVery large scale integrated circuitsSlurry

Provided is a method of chemical-mechanical planarization of copper multilayer interconnection structures and of controlling the dishing problem associated therewith comprising: (a) preparing a slurry by (i) diluting SiO2 hydrosol with deionized water; (ii) admixing a chelating agent and adjusting the pH to between 9.5 to 11.5; and (iii) admixing nonionic surfactant(s) and oxidant(s); (b) applying said slurry to said copper multilayer interconnection structures; and (c) polishing said copper multilayer interconnection structures with polishing pad(s). The flow speed is 200-5000 ml / min, the temperature is 20-40° C., the rotation speed is 60-120 rpm, the pressure is 100-250 g / cm2, and the polishing speed can be 200-1100 nm / min. The process involves 1-5 min for polishing the copper and then 30-60 sec for polishing the copper, the barrier layer, and the dielectric layer. Consistent polishing speeds for the copper, the barrier layer, and the dielectric layer are achieved, which effectively reduces the dishing problem. At the same time, the method reduces the contamination of the surface with metal ions.

Owner:LIU YULING +5

High-precision ultrathin cold-rolled steel strip for electronic component and production method thereof

The invention discloses a high-precision ultrathin cold-rolled steel strip for an electronic component and a production method thereof. The thickness of the high-precision ultrathin cold-rolled steelstrip is 0.14 to 0.16mm; the high-precision ultrathin cold-rolled steel strip is prepared by carrying out acid washing of a hydrochloric acid acid-washing machine set, one-rolling-path rolling of a single-rack and six-roller HC rolling machine, unwinding and edge cutting of a slitting machine set, primary annealing of a bright cover type annealing furnace, flattening of a single-rack and four-roller flattening machine, and plate-shaped defect elimination of a bending and straightening machine set on a hot-rolled steel strip in sequence. The high-precision ultrathin cold-rolled steel strip disclosed by the invention has the advantages of short flow and high product rate, secondary rolling and secondary annealing procedures are omitted and the production cost is reduced; meanwhile, the high-precision ultrathin cold-rolled steel strip for the electronic component has the characteristics of low impurity content, ultrathin thickness, high size precision, flat and straight plate shape, highsurface reflection rate, high roughness uniformity, low yield ratio, uniform performance and good stamping performance, and is applicable to electronic basic components including a battery shell, a communication cable, a television color tube, a carbon membrane resistor and the like.

Owner:山东泰山轧钢有限公司

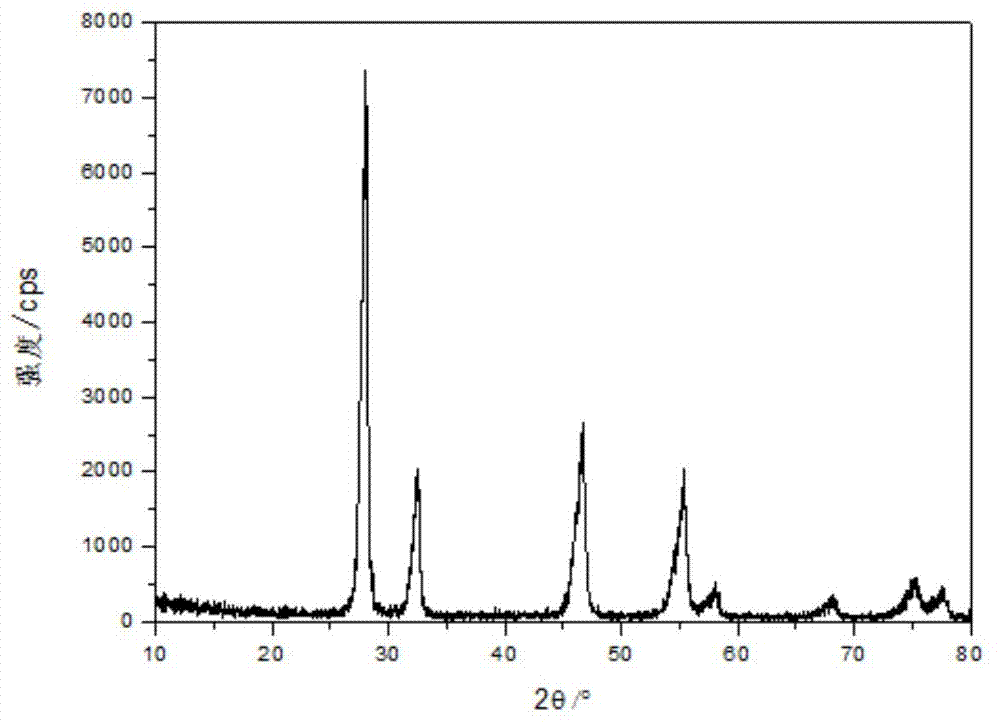

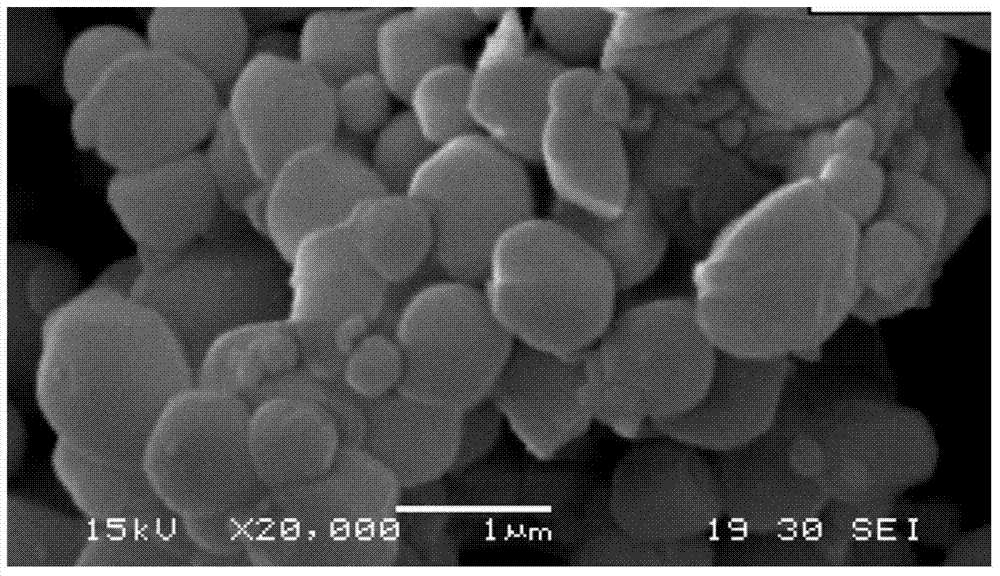

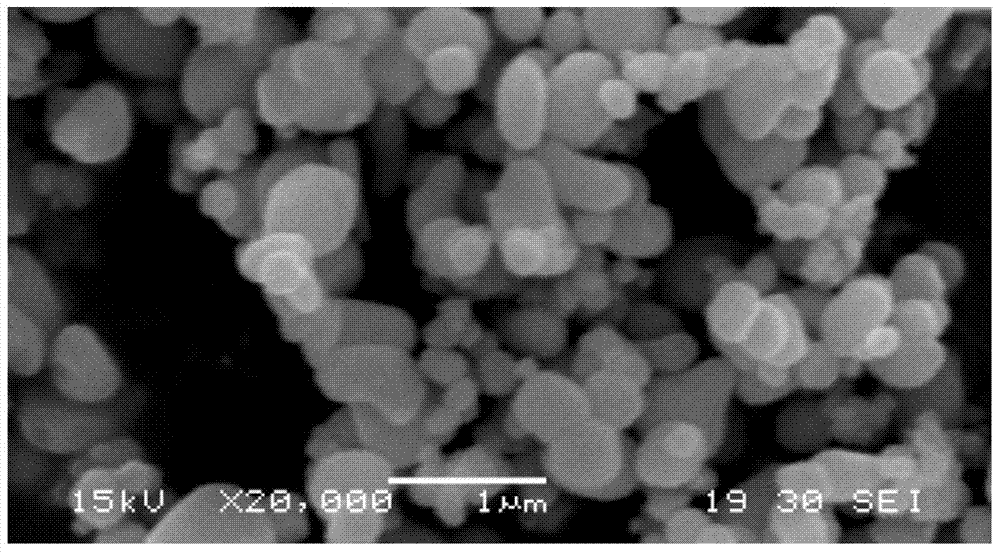

Cerium oxide polishing powder and preparation method thereof

ActiveCN103571334ASimple processLow costOther chemical processesRare earth metal compoundsCubic crystal systemWastewater

The invention discloses cerium oxide polishing powder. The purity TREO of cerium oxide CeO2 is more than or equal to 99.95%; cerium oxide is CeO2 powder with crystal form being a uniphase cubic crystal system; cerium oxide is shaped like a round cake with the average particle size of 1mum. The invention further discloses a preparation method for the cerium oxide polishing powder. The preparation method comprises the steps of preparation of cerium chloride, precipitation, dehydration, roasting, smashing and the like. Compared with the existing preparation method, the polishing powder prepared by adopting the method is cerium oxide powder, F is not required for introduction in the preparation process, and the preparation method has the advantages of being simple in process, low in cost, and free from waste water; the cerium oxide polishing powder has the advantages of having no scratch in the polishing process of products, being high in polishing precision and the like.

Owner:方复(上海)新材料科技有限公司

Feeding and finishing system and process of aluminum and plastic caps

ActiveCN104444292AAchieve the purpose of organizingReduce mutual frictionConveyor partsEngineeringHigh pressure

The invention discloses a feeding and finishing system of aluminum and plastic caps. The system comprises an aluminum cap feeding and finishing portion, a plastic cap feeding and finishing portion, a pneumatic control portion, a photoelectric control portion and an automatic controller. The invention further discloses a feeding and finishing process of aluminum and plastic caps employing the system. By the use of the centrifugal separation mode with a unique tray structure, friction of the aluminum or plastic caps is greatly reduced, and loss is reduced; by the use of a pneumatic mode with a unique screening rail and the use of high-pressure air as power to finish the caps, the caps run faster on the rail, the cap finishing process is stable and is better than mechanical finishing, product yield can be evidently increased, the surfaces of the caps have no scratch or deformation after finishing, and fewer caps are jammed or deformed; the fishing and moving speeds are higher, above 900 caps per minute; finishing and arrangement of the aluminum and plastic caps is achieved, and feeding for a next procedure is achieved.

Owner:HEBEI JINHUAN PACKAGING

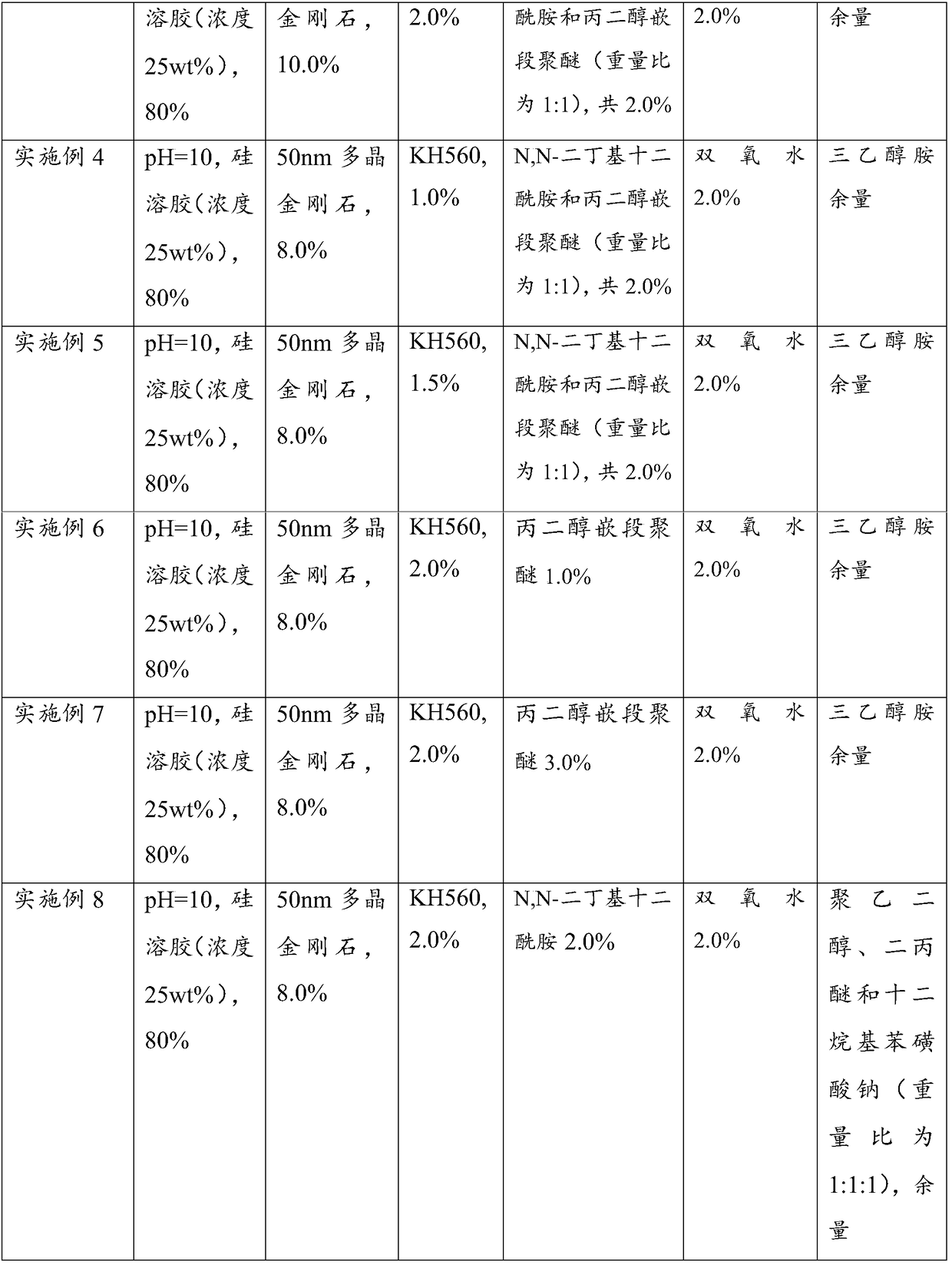

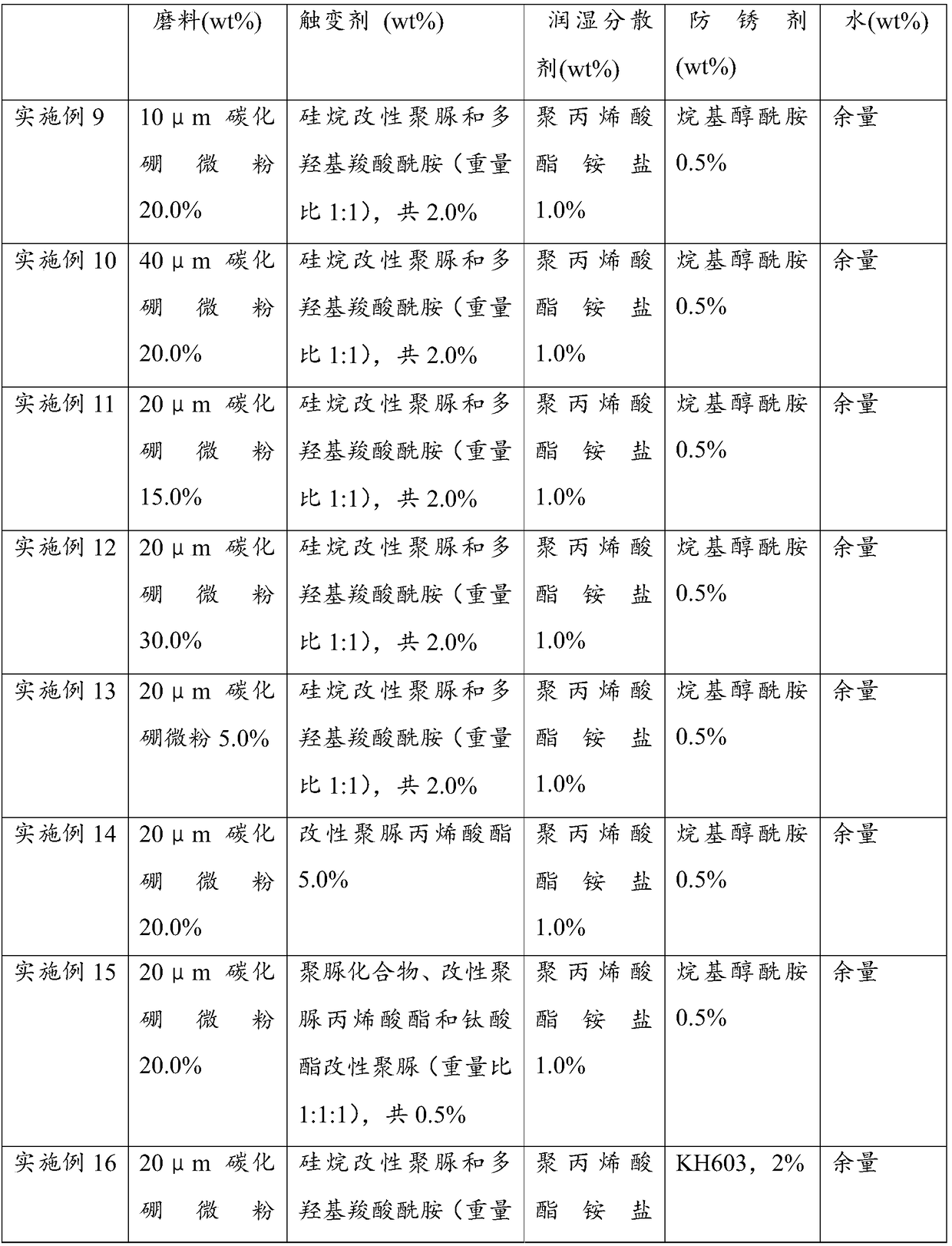

Polishing solution and polishing method of silicon carbide crystals

ActiveCN108949036ASmall scratchSmall roughnessPolishing compositions with abrasivesSoft layerOrganic matter

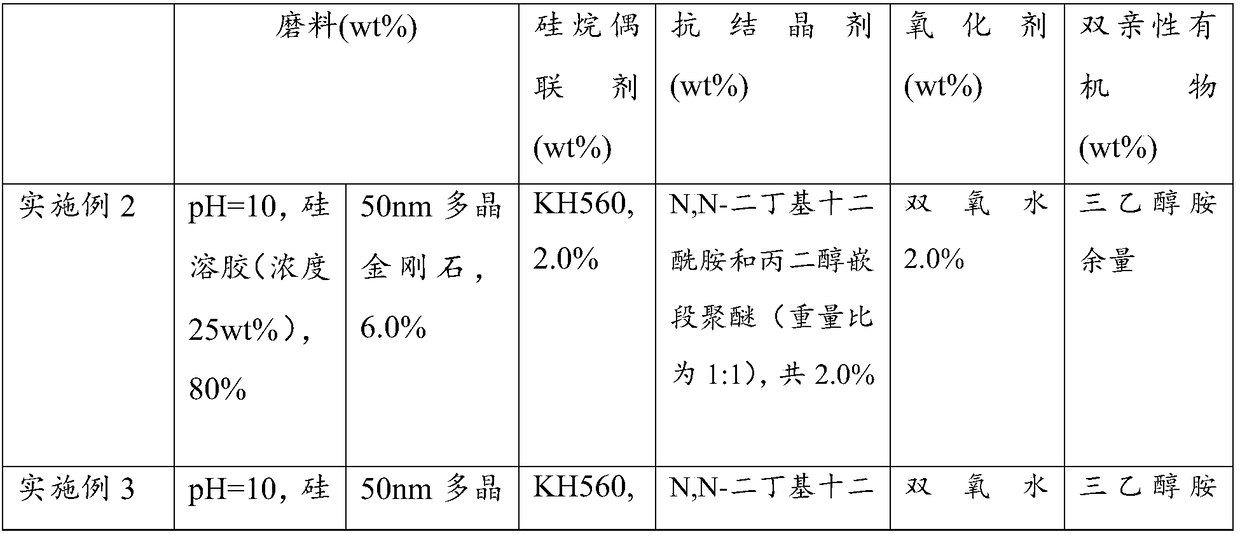

The invention relates to a polishing solution and a polishing method of silicon carbide crystals. The polishing solution comprises the following components in percentage by weight: 6-10% of nanoscalepolycrystalline diamond, 75-87% of alkaline silica sol, 1-2% of a silane coupling agent, 1-3% of an anti-crystallization agent, 1-2% of an oxidant, and the balance of amphiphilic organic matter. The polishing solution of the invention has the advantages of good wet spreading performance, high soft layer removal rate, being not prone to crystallization, and the like, and therefore polishing for silicon carbide solves the problems of low polishing rate and poor polishing effect. In addition, as the polishing solution is used in combination with a coarse grinding fluid and a fine grinding fluid,a high-speed, high-flatness, high-gloss, low-roughness polishing effect can be achieved.

Owner:BEIJING POLYSTAR HITECH CO LTD

Preparation technology of supporting block for grinding outer ring channel electromagnetic coreless gripping device

InactiveCN1556234ASuperiorImprove wear resistanceRevolution surface grinding machinesGraphiteMaterials processing

Owner:LUOYANG BEARING SCI & TECH CO LTD

Metal can cap separating mechanism

The invention discloses a metal can cap separating mechanism, which comprises a framework, a feeding passage and a discharging passage, wherein the feeding passage and the discharging passage are arranged on the framework. A feeding conveying belt and a discharging conveying belt which are identical in conveying direction and driven by the same power mechanism are arranged below the feeding passage and the discharging passage, the moving speed of the discharging conveying belt is higher than that of the feeding conveying belt, a can cap separating section is arranged between the feeding conveying passage and the discharging conveying passage, the front end of the feeding conveying belt and the rear end of the discharging conveying belt form a staggering structure in the can cap separating section, and metal can cap toppling preventing devices are arranged on two sides of the passage where the discharging conveying belt is located. The metal can cap separating mechanism solves the problem that existing metal can cap separating equipment is poor in separating effect, has requirements for product materials and affection on product quality effectively, is suitable for separation of metal can caps made of different materials and applicable to high-speed production lines of metal can caps.

Owner:YIWU EASY OPEN END INDAL CORP

Double-surface polishing method for silicon carbide chip

InactiveCN105666300AReduce processing timeConsistent surface qualityPolishing machinesSemiconductor/solid-state device manufacturingWater solubleCopper

The invention relates to a double-surface polishing method for a silicon carbide chip. The double-surface polishing method comprises the steps that the silicon carbide chip is subjected to rough polishing, semi-finishing polishing and finishing polishing sequentially on a double-surface polishing machine; during rough polishing, water-soluble diamond polishing liquid is used, the diameter of diamond particles is 5-15 microns, the polishing pressure is 40-100 kg, and a polishing disc is a resin copper disc or a resin tin disc or a polishing pad of a polyurethane structure; during semi-finishing polishing, water-soluble diamond polishing liquid is used, the diameter of diamond particles is 0.25-3 microns, the polishing pressure is 60-120 kg, and a polishing disc is a resin copper disc or a resin tin disc or a polishing pad of a polyurethane structure; and during finishing polishing, alkali silicon dioxide polishing liquid is used, an oxidizing agent with a proper proportion is added, the PH value of the finishing polishing liquid is adjusted to be 9-13, the polishing pressure is 80-140 kg, and a polishing pad is of a fluff structure. By means of the double-surface polishing method, the processing time can be shortened by a half, the flatness of the silicon carbide chip is improved, the surface quality is consistent after polishing, and the silicon carbide chip has no defects of orange peel, scratching damage, matte and the like.

Owner:BEIJING CENTURY GOLDRAY SEMICON CO LTD

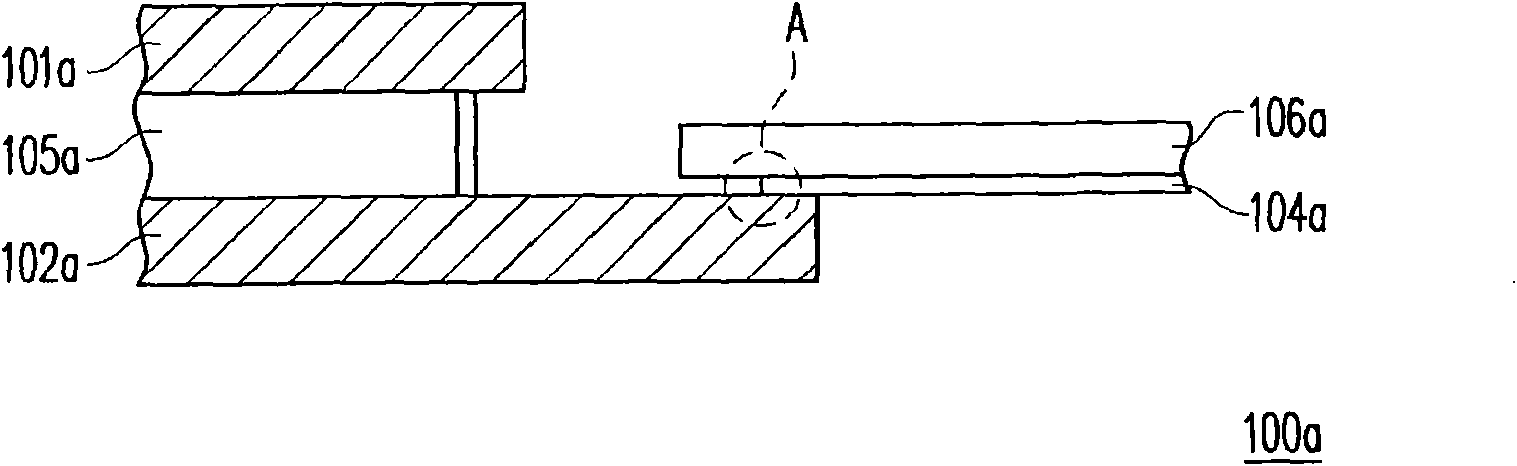

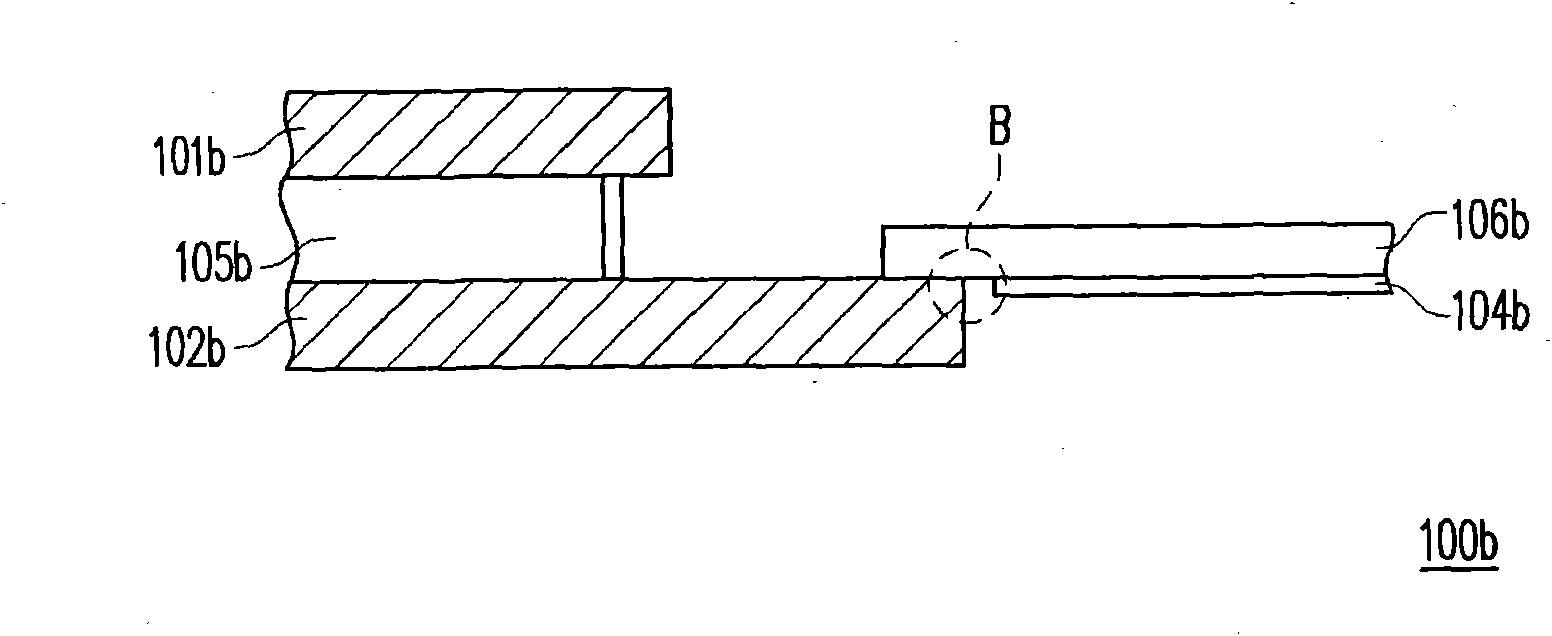

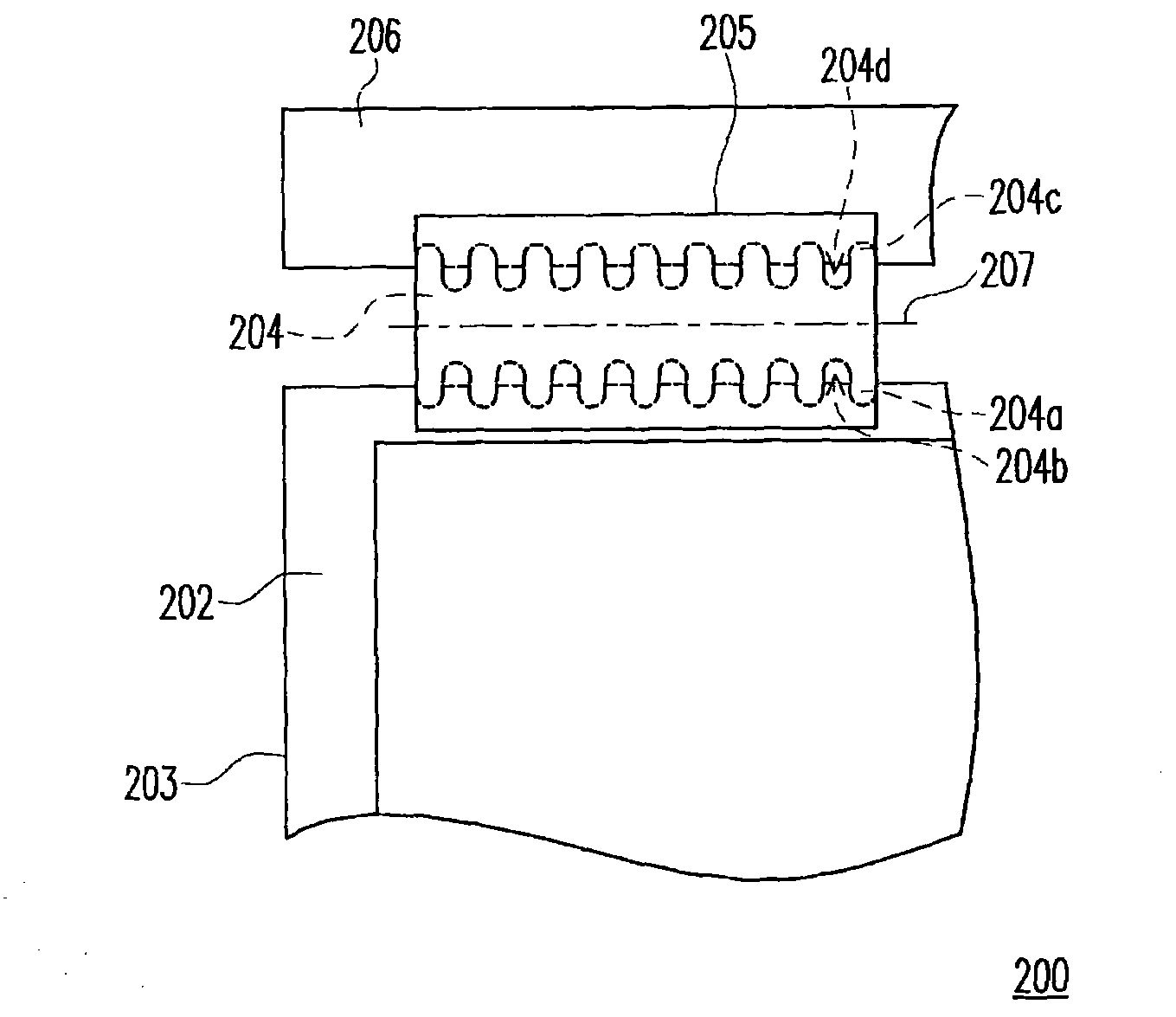

Liquid crystal display

The invention relates to a liquid crystal display, which comprises a display panel with a substrate and a flexible substrate with a plurality of leads and a protective layer, wherein the protective layer covers on the leads, and the flexible substrate is jointed together with the substrate by a fit technology; part of protective layer at the joint of the display panel and the flexible substrate is provided with a plurality of first regular or irregular salients; part of first salients extends into the substrate and is overlapped with the substrate to form a plurality of first overlap regions; and part of first salients does not extend into the substrate, and thereby, a plurality of first gaps are formed at the joint of the substrate and the flexible substrate.

Owner:HANNSTAR DISPLAY CORPORATION

Technology of directly producing low-hydroxyl quartz tube

The present invention discloses a technology of directly producing low-hydroxyl quartz tube. Materials are added into a tungsten crucible. Quartz sand is subjected to a high temperature melting in the tungsten crucible. The high-temperature melted liquid flows out of the furnace mouth of the tungsten crucible vertically along a former arranged at the end of a central core rod within the tungsten crucible. The liquid passes through a drawing quartz tube by a drawing machine and is subjected to a second hydroxyl group content lowering via a nitrogen gas supply system and a heating device, and then a quartz tube semi-product is obtained. The quartz tube semi-product enters into a cooling device at a cooling temperature of 100-160 DEG C. The cooled quartz tube semi-product is cut to obtain a quartz tube product. The one-time directly produced low-hydroxyl quartz tube technology is time-saving, labor saving, and energy saving. The produced low-hydroxyl quartz tube is free of scratches and rubs, does not damage tube materials, pipe, is free of secondary pollution, reduces a lot of production costs, is stable in quality, and can absolutely reach standards and meet customer requirements.

Owner:JIANGSU XINYIDING QUARTZ TECH CO LTD

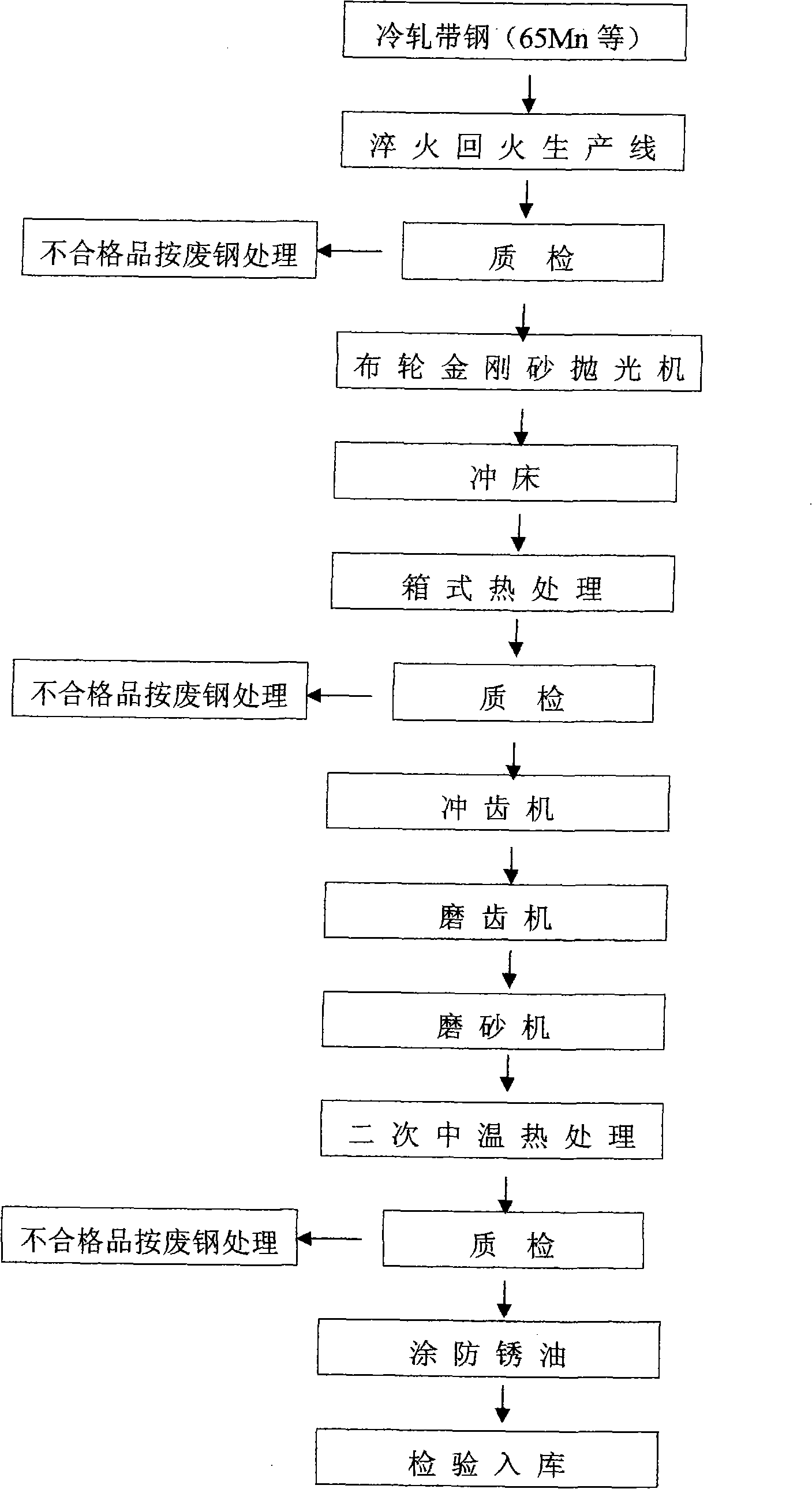

Method for producing traceless quenching and embossing saw blade

InactiveCN101333688AQuality improvementStable hardnessVegetable fibre separation from seedsMetal sawing tool makingProduction lineHardness

The invention discloses a production method of cotton ginning saw-blade, which directly uses the strip steel to firstly quench and temper and then subsequently process the strip steel. The process steps are as follows: selecting the strip, quenching the strip, inspecting the quality of the strip, polishing the surface of the strip, punching the strip into a blank of the saw-blade, heat treating the blank of the saw-blade, inspecting the quality of the blank, punching teeth on the blank by a sawtooth punching machine, grinding teeth, burring, heat treating the blank in moderate temperature, inspecting the quality of the finished product, packaging the finished product after coating antirust oil on the finished product, and inspecting and warehousing the finished product. The production method continuously produces the strip steel of 350mm and 430mm on quenching and tempering production lines, so the produced saw-blade has stable hardness, good toughness, good wear resistance and long service life.

Owner:HANDAN HANWU COTTON MACHINERY

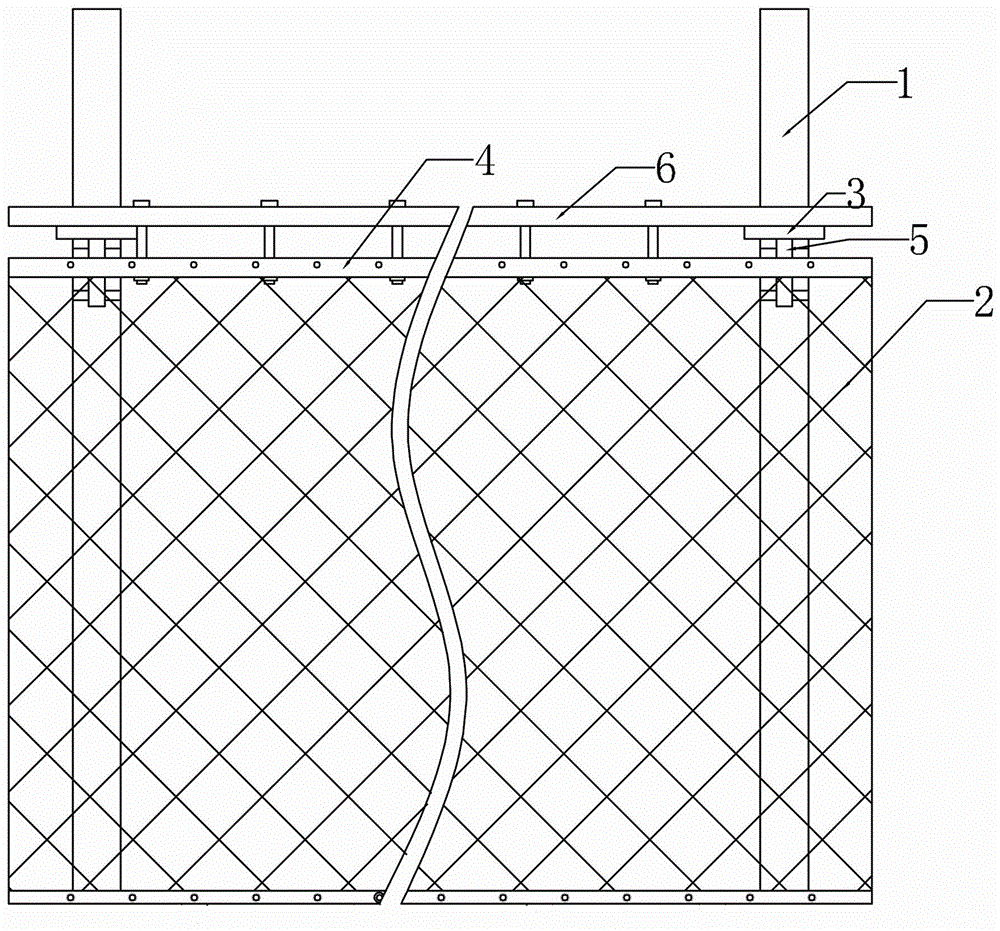

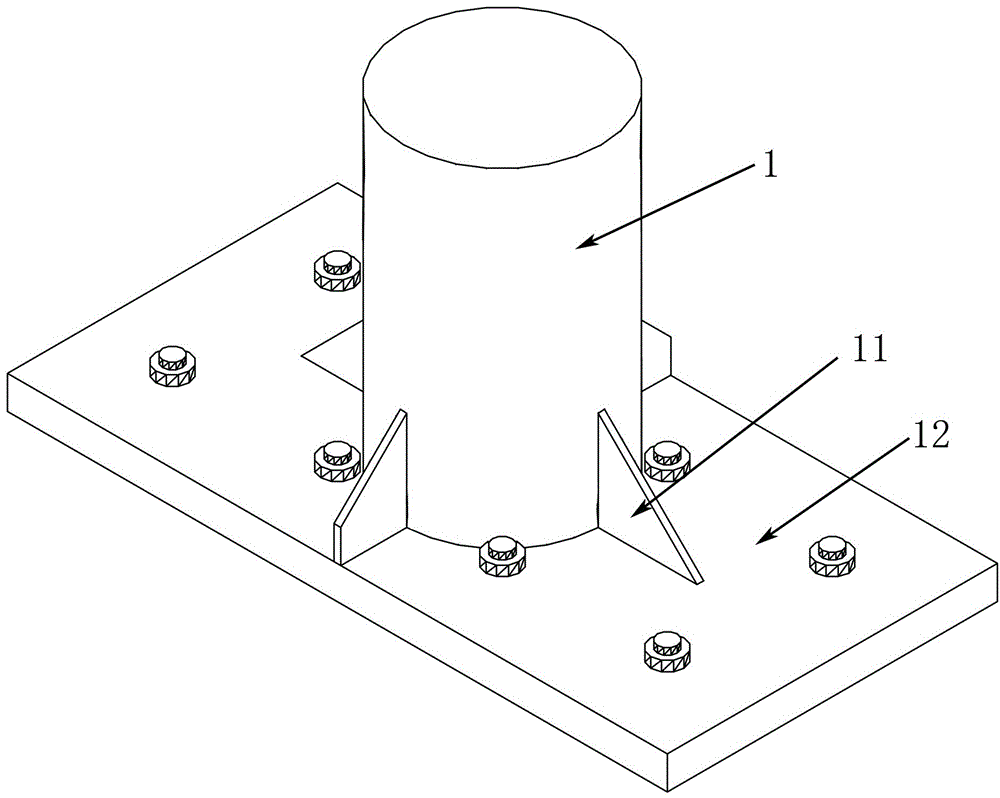

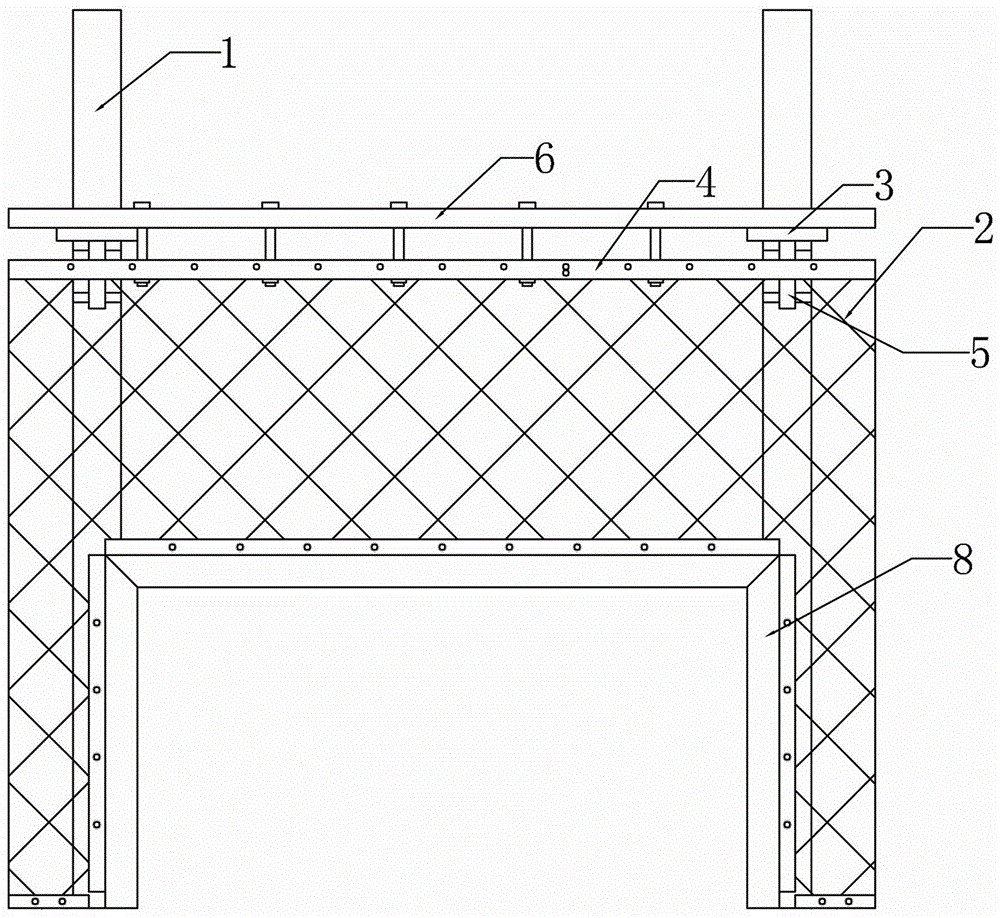

External fixing device of protective net body, protective net fixed externally and application of protective net

The invention discloses an external fixing device of a protective net body. The external fixing device comprises stand columns with the lower ends fixed to the ground on the periphery of the net body. A suspension arm is fixed to the upper portion of each stand column, extends in the normal direction of one joint point of the upper end of the net body and enables a safety distance to exist between the stand column and the net body, and the other end of each suspension arm is used for being detachably and fixedly connected with the upper end edge of the net body. The invention further provides a corresponding protective net and application thereof. The protective net body is reliably supported and fixed; the horizontal safe distance between a supporting element and the net body can be determined according to needs, and it is guaranteed that the supporting element cannot cause any damage to personnel or animals in the net; and the protective net has the characteristics of being simple in structure, convenient to mount and dismount, safe and firm. The external fixing device of the protective net body, the protective net and the application of the protective net are applicable to occasions which have requirements for trampoline enclosures, net enclosing protection of livestock and poultry farms, net separation of sporting venue areas, enclosing of prisoner activity spaces, defining of animal and bird venues of zones, interpopulation isolation of animal parks and the like.

Owner:SHIJIAZHUANG DIAOKANG SPORTS FACILITIES CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com