Polishing solution and polishing method of silicon carbide crystals

The technology of polishing liquid and grinding liquid is applied in the polishing field of polishing liquid and silicon carbide crystal, which can solve the problems of low polishing rate, poor polishing effect, and difficult to crystallize, and achieve the effect of improving polishing rate, avoiding loss and firm adhesion.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0100] The first step, coarse grinding

[0101] Prepare the abrasive liquid that coarse grinding is used: by weight percentage, boron carbide micropowder 20.0%, median particle diameter is 20 μ m, thixotropic agent silane modified polyurea and polyhydroxy carboxylic acid amide altogether 2.0% (both weight ratio 1: 1), wetting and dispersing agent polyacrylate ammonium salt 1.0%, rust inhibitor fatty acid alkanolamide 0.5%, water balance;

[0102] Rough grinding of silicon carbide crystal surface: traditional flat grinding equipment, 4-inch silicon carbide wafer, pressure 300g / cm 2 , the rotating speed is 50rpm, the supply rate of circulating grinding liquid is 500mL / min, and the grinding time is 30min.

[0103] The second step, fine grinding

[0104] Preparation of grinding liquid for fine grinding: by weight percentage, polycrystalline diamond micropowder 0.5%, median particle size is 2 μm, solvent 95% (ethylene glycol and purified water, weight ratio 9:1), wetting and disp...

Embodiment 2-8

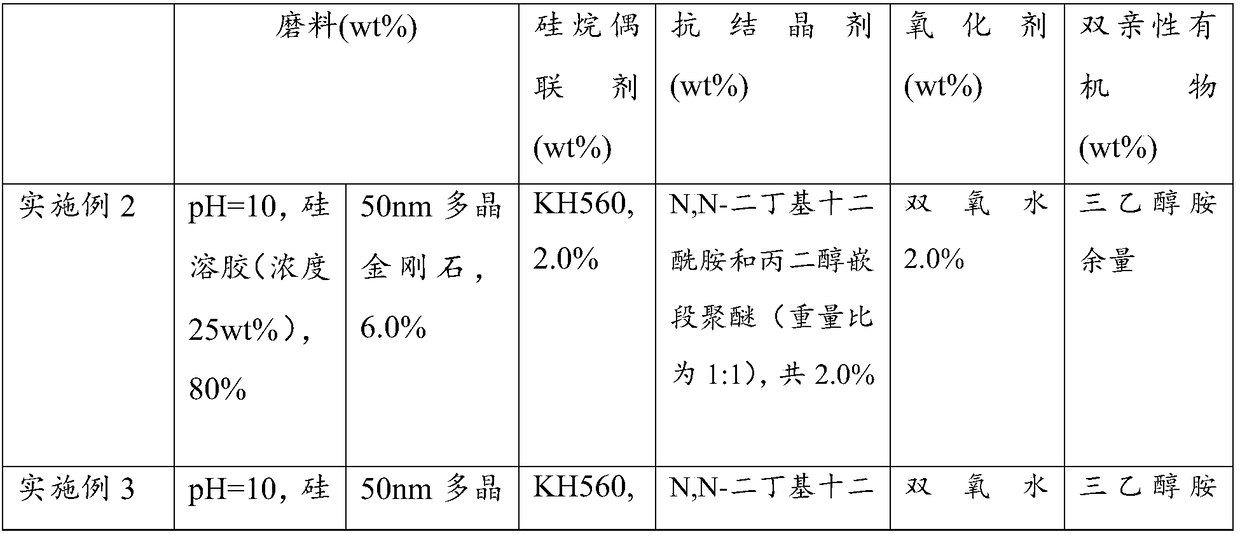

[0110] The polished material is the same as in Example 1, the only difference from Example 1 is that the formulation of the polishing liquid used for fine grinding changes, and the rest of the raw materials and process conditions are the same as in Example 1. The specific formula is shown in Table 1.

[0111] Table 1 Proportion of Polishing Fluid for Fine Polishing

[0112]

[0113]

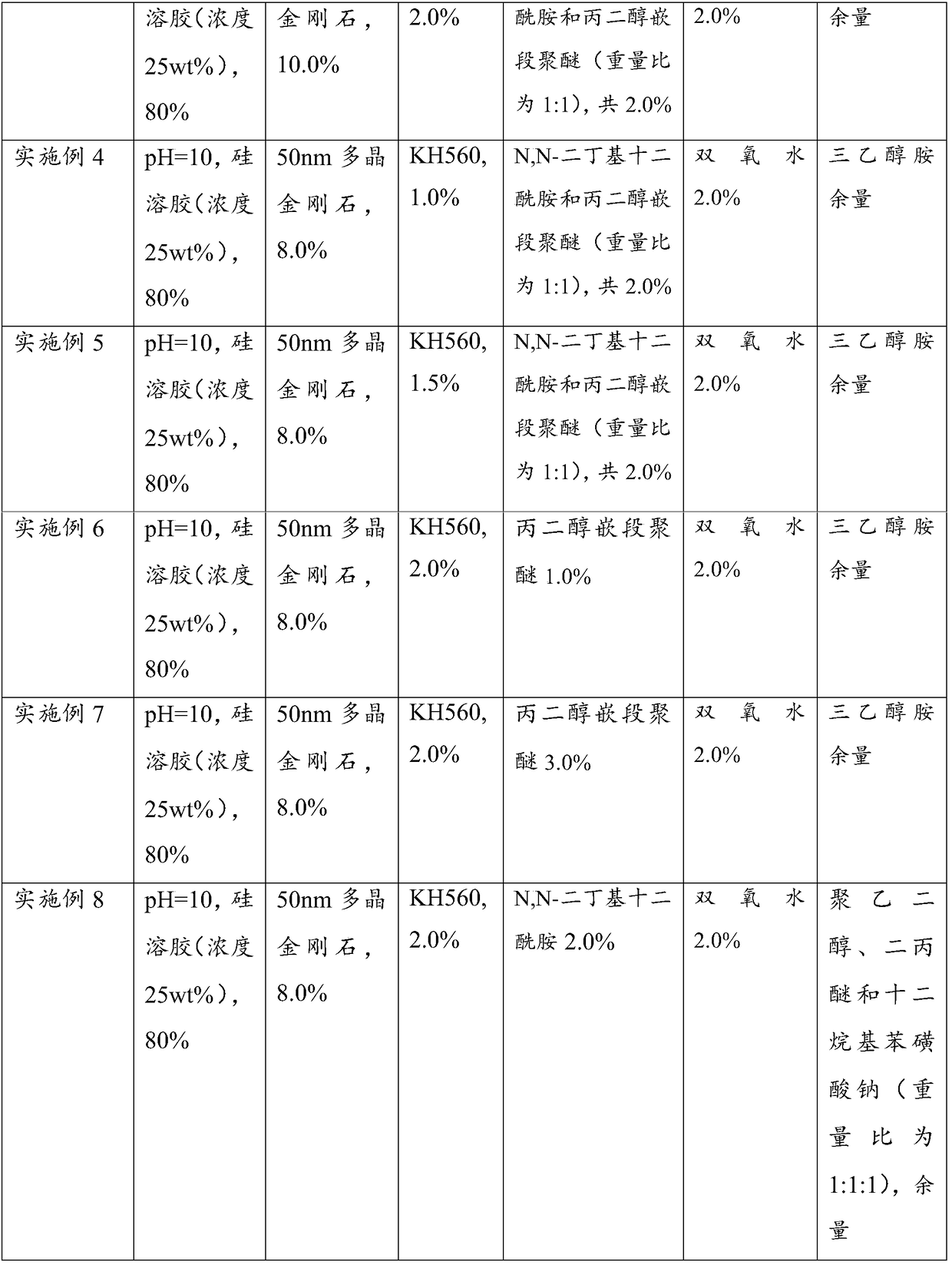

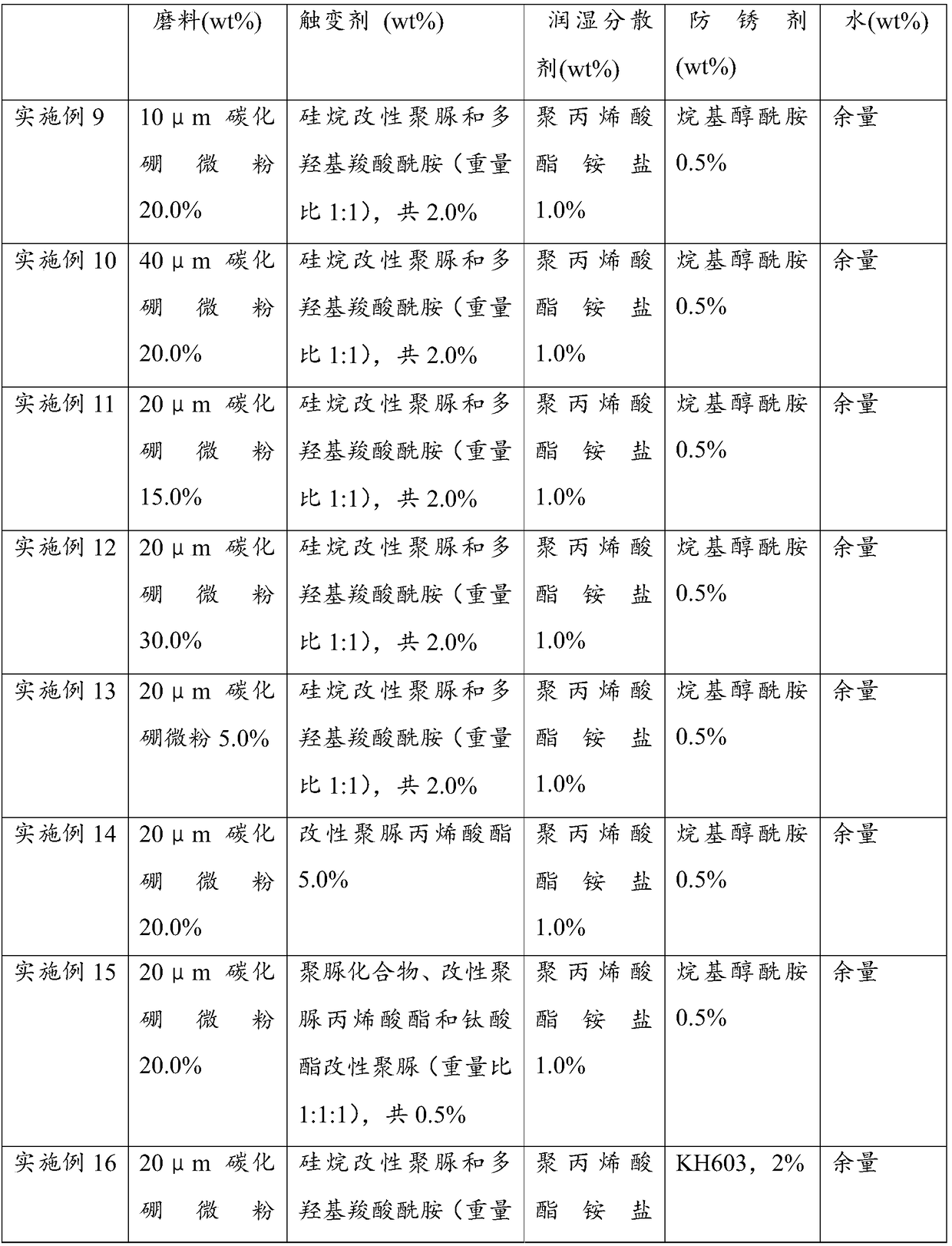

Embodiment 9-17

[0115] The polished material is the same as in Example 1, and the only difference from Example 1 is that the formulation of the abrasive liquid used for rough grinding changes, and the rest of the raw materials and process conditions are the same as in Example 1. The specific formula is shown in Table 2.

[0116] The proportioning of grinding liquid used in table 2 coarse grinding

[0117]

[0118]

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com