Drill rod clamping device

A drill pipe clamping and clamping device technology, applied to drill pipes, drill pipes, drilling equipment, etc., can solve the problems of high production cost, troublesome replacement, clamping failure, etc., and achieve long service life, low manufacturing cost, Reliable clamping effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

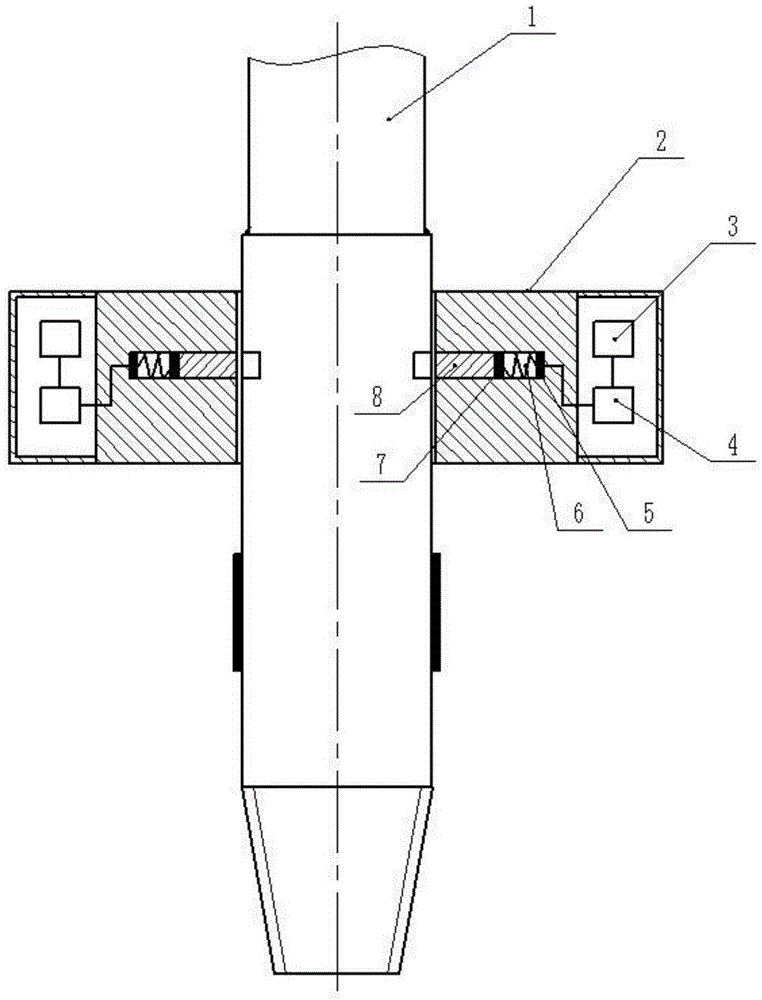

[0030] Such as Figure 5 As shown, a drill pipe clamping device provided by the present invention includes a drill pipe 1, the drill pipe 1 is composed of a drill pipe joint and a steel pipe 12, the drill pipe joint is welded with the steel pipe 12, and the drill pipe joint Conical thread section 16, wear-resistant section 15, and non-wear-resistant section 13. The circumference of the non-wear-resistant section 13 of the drill pipe joint is provided with an outer arc groove 14, and the non-wear-resistant section 13 of the drill pipe joint The maximum depth of the outer arc grooves 14 on the circumference of the section 13 is smaller than the wall thickness of the drill pipe joint. Evenly distributed along the circumference.

[0031] The function of the wear-resistant section 15 of the drill pipe joint: the drill pipe joint wears quickly because the drill pipe joint is subjected to erosion and wear while undergoing severe wear. In order to improve the wear resistance of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com