Hose fitting assembly station

A technology of hose joints and assembly tables, which is applied in the direction of hand-held tools and manufacturing tools, which can solve the problems of easy leakage, tearing, and unsuitability for assembly line production at the end of the joint, and achieve the effect of stable advance and retreat, and accurate direction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

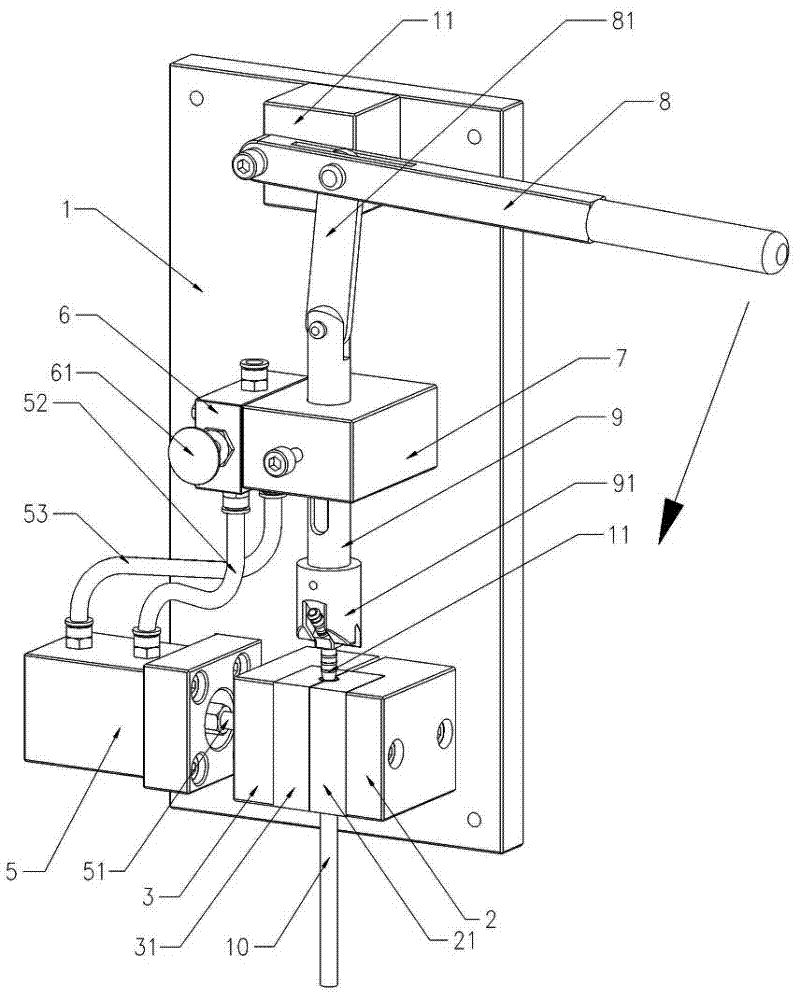

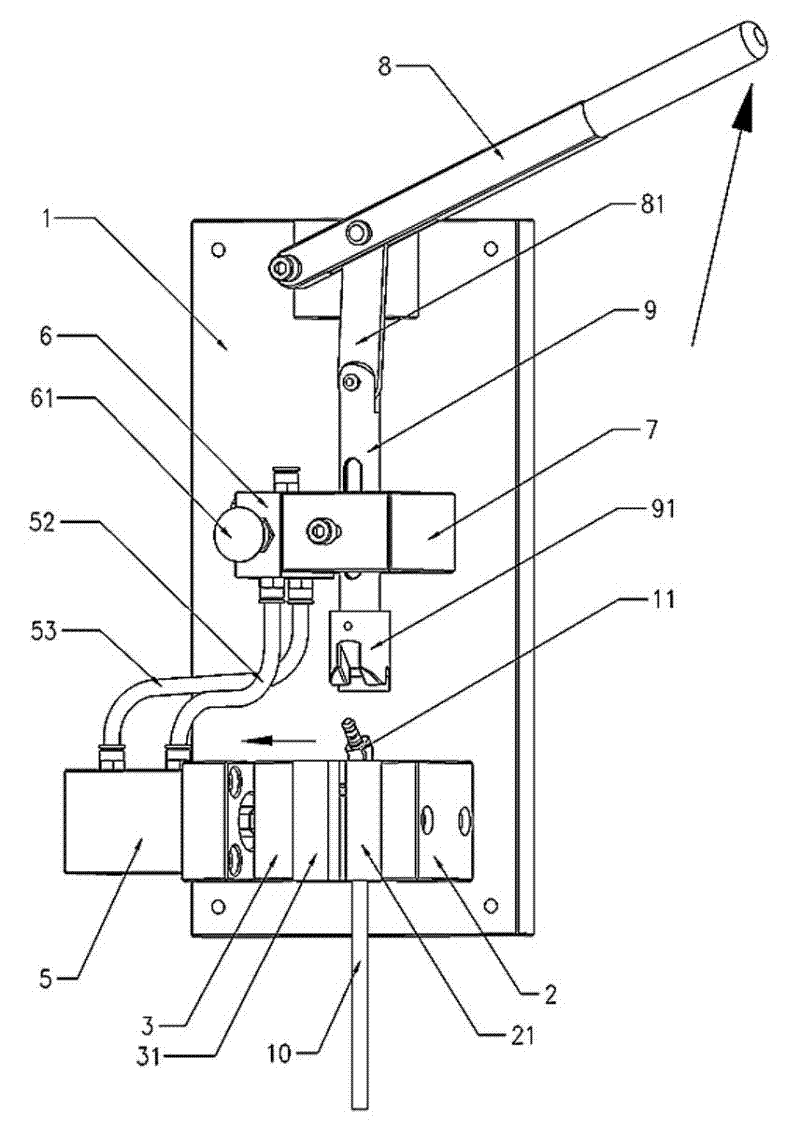

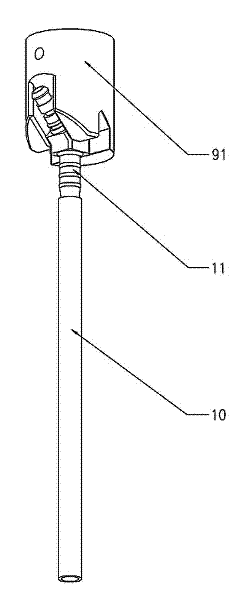

[0029] The structure of the hose joint assembly table is as follows: Figure 1 to Figure 5 As shown, the operation process is as follows: the operator places the rubber hose 10 in the groove of the fixed block 2, the end surface of the rubber hose 10 is flush with the side of the fixed block 2, and presses the button 61 of the two-way valve 6 to let the high-pressure air flow from the cylinder The rear air inlet 53 of 5 is input, and the piston push rod 51 is pushed forward together with the sliding clamping block 3, and the rubber hose 10 is clamped and fixed with the fixing block 2, and a pipe joint 11 is held in the left hand and placed on the top of the punch 91, and the right hand plate Move the handle 8, press the push rod 9 together with the punch 91 to the pipe joint 11 through the connecting piece 81, force the pipe joint 11 into the inner wall of the rubber hose 10, and use the interference fit to tightly fix the two together. Press the button 61 of the two-way valve...

Embodiment 2

[0031] Embodiment 2: The basic structure is the same as that of Embodiment 1, if the assembly structure is relatively simple straight pipe joint 112, such as Figure 6 Shown; Then the punch 91 that uses among the embodiment 1 is changed into the cylindrical punch 92 and gets final product, and operation method is identical with embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com