Plate processing system and plate processing method

A technology for sheet metal processing and processing tools, applied in metal processing equipment, manufacturing tools, welding equipment, etc., can solve the problems of large setting space, workpiece offset, workpiece time consumption, etc., and achieve the effect of high-speed processing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

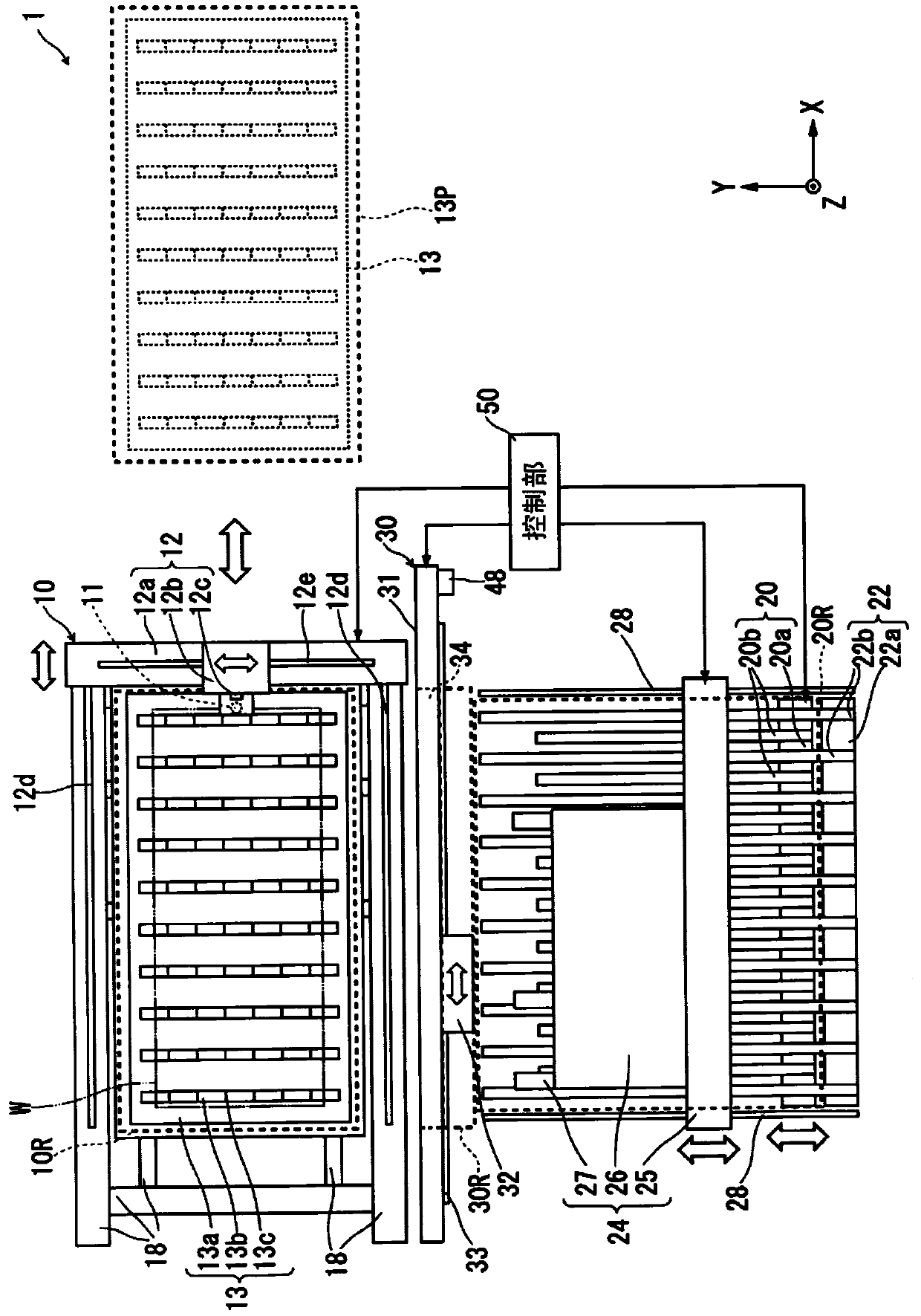

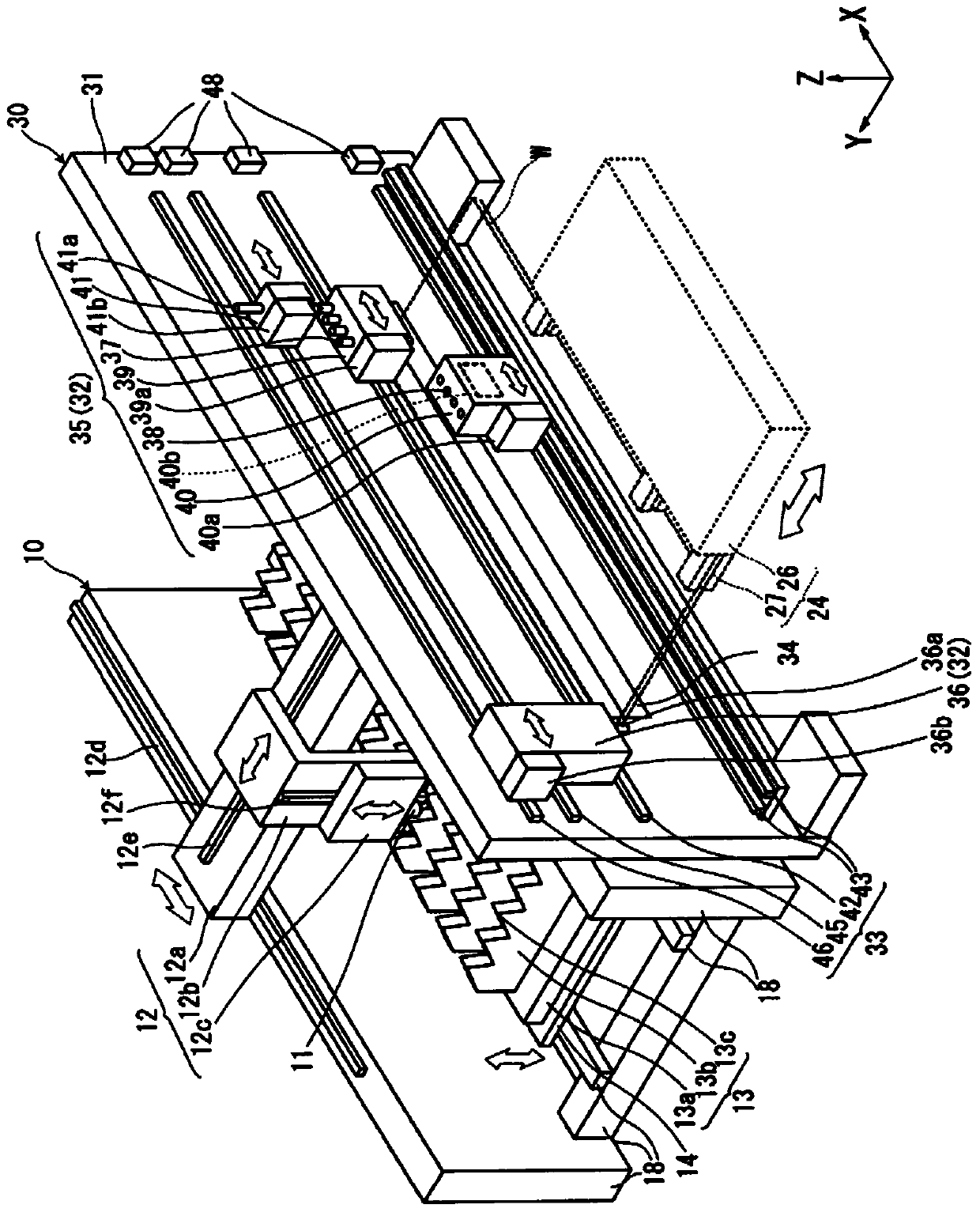

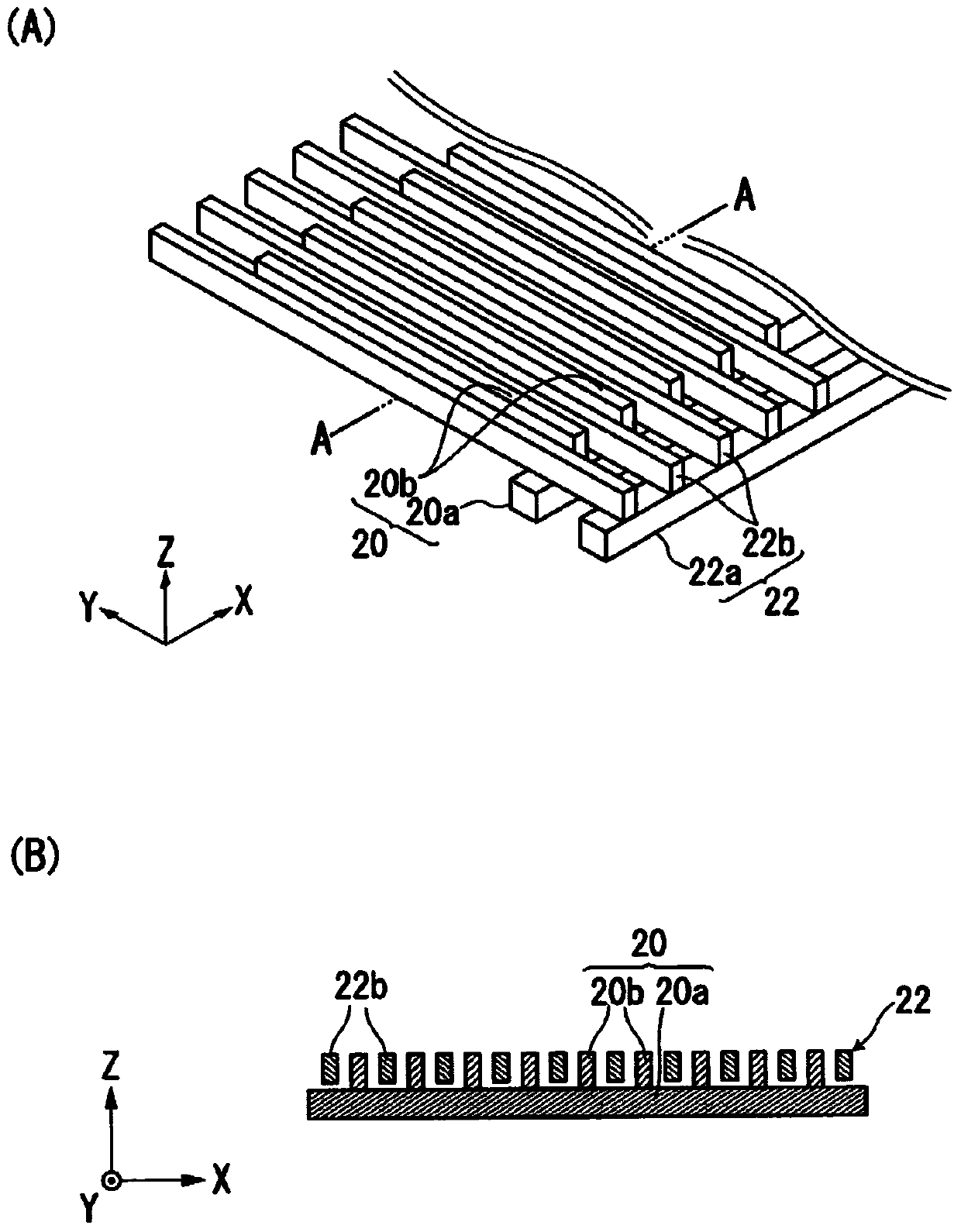

[0067] Hereinafter, embodiments of the present invention will be described with reference to the drawings. However, the present invention is not limited thereto. In addition, in the drawings, in order to describe the embodiment, a part is enlarged or highlighted and described, and the scale is appropriately changed and expressed. In each of the following figures, directions in the figures will be described using an XYZ coordinate system. In this XYZ coordinate system, a plane parallel to the horizontal plane is defined as an XY plane. An arbitrary direction parallel to the XY plane is referred to as an X direction, and a direction perpendicular to the X direction is referred to as a Y direction. In addition, the advancing and retreating direction (the conveyance direction of the workpiece|work W) of the arm part 20b mentioned later is a Y direction. In addition, the direction perpendicular to the XY plane is referred to as an up-down direction or a Z direction. In addition...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com