Method for manufacturing finned square rectangular steel tube

A manufacturing method, square and rectangular technology, applied in the field of column forming and welding, can solve the problems of difficult induction heating and difficult welding control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The production process flow of the present invention: edge trimming→cold bending primary forming→four-roll extrusion→welding→outer burr planing→sizing and shaping→flying saw sawing→collection and packing into storage.

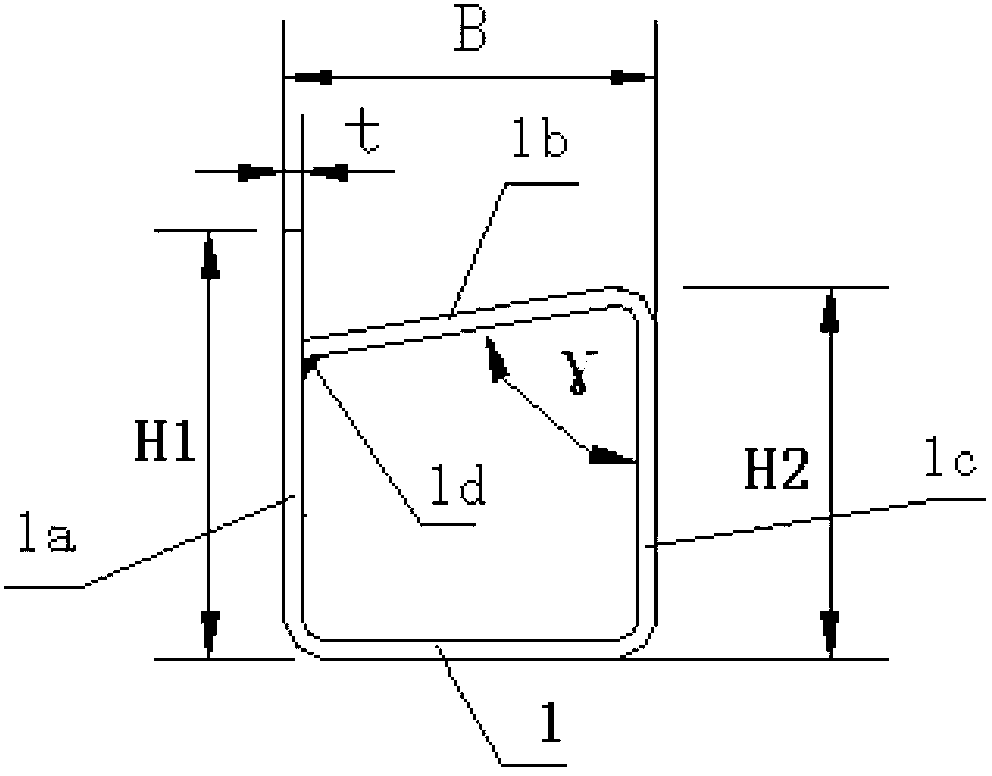

[0028] figure 1 It is a schematic diagram of an embodiment of the present invention:

[0029] Plate 1 thickness t=6mm, H1=115, H2=100, B=100, R=12~15, two bottom angles are right angles, upper right angle γ=80°±5°. 1a is a winged edge, 1b is a welded edge, 1c is a waist edge, and 1d is a welded point.

[0030] The manufacturing steps are as follows:

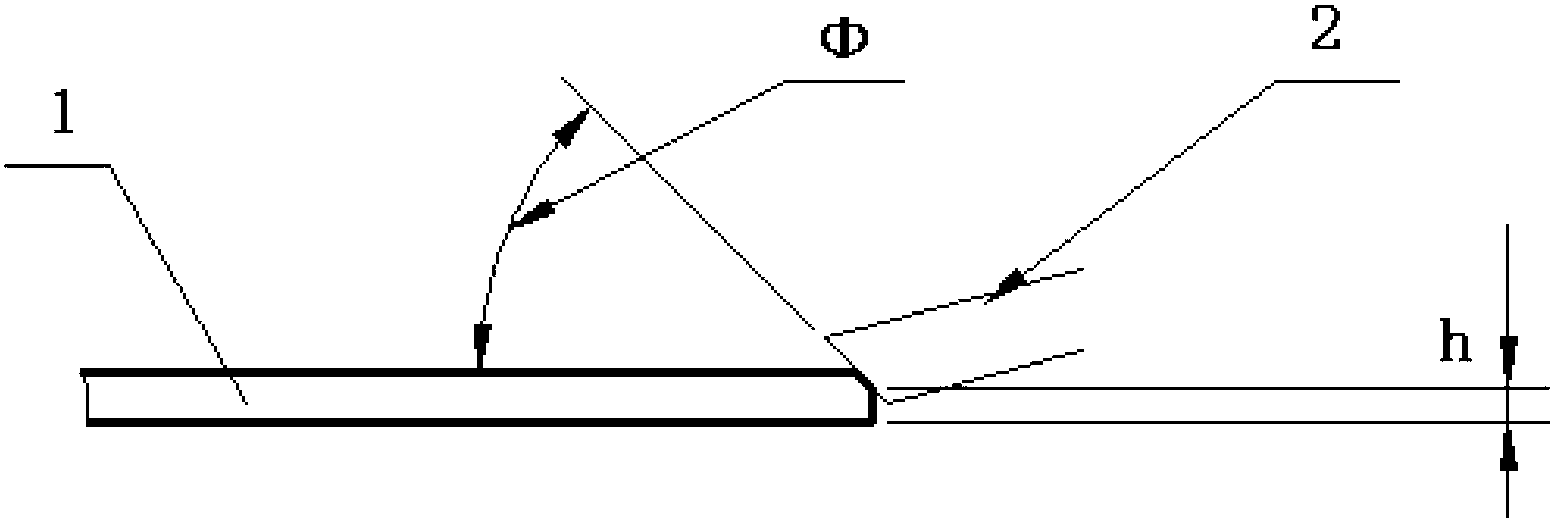

[0031] 1) Trim the inner corner of the welding edge of the plate 1: trimming angle Φ = 45° ± 2°, leaving root h = 1 / 2 thickness of the plate ± 0.5mm; figure 2 : 2 is a trimming knife. Trim the inner angle of the welded end face of the plate 1, so that the inner angle of the welded end face and the winged edge after bending has a welding gap of Φ=45°±2°, so as to ensure the welding quality.

[0032] 2)...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com