Metal can cap separating mechanism

A separation mechanism, metal can technology, applied in the direction of conveyor objects, transportation and packaging, can solve problems affecting product quality, requirements for product materials, poor separation effect, etc., to achieve high product quality, small occupied space, good separation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

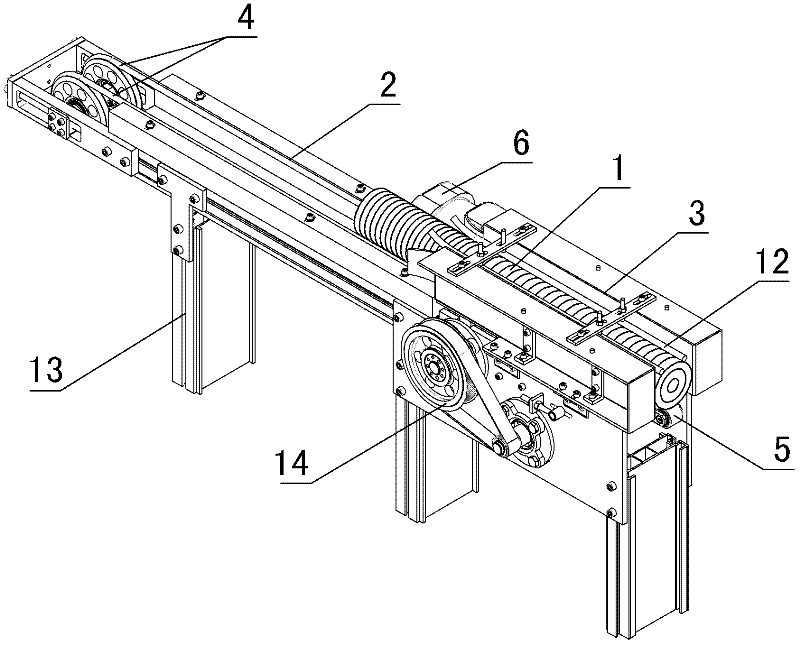

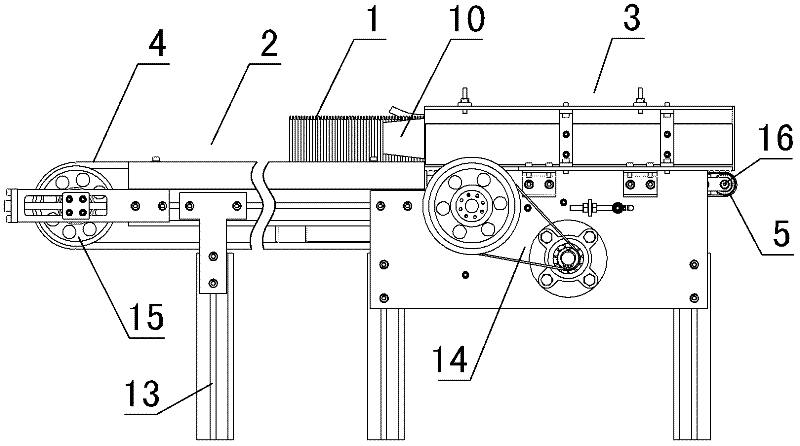

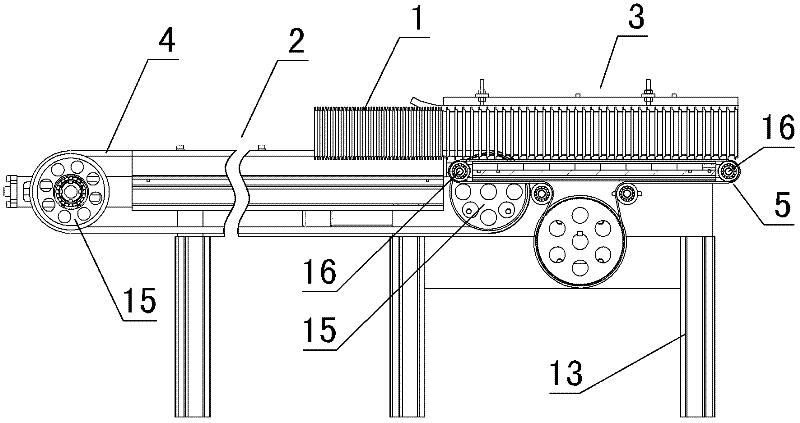

[0027] in such as figure 1 figure 2 In the shown embodiment, a separation mechanism for a metal can lid includes a frame 13 and a can lid separation channel arranged on the frame, and metal can lid limit structures are provided on both sides of the can lid separation channel. The tank cover separation channel comprises a feed channel 2 and a discharge channel 3, the lower part of the feed channel is provided with a feed conveyor belt 4, and the lower part of the discharge channel is provided with a discharge conveyor belt 5, and the feed conveyor belt is two with a cross section of A circular linear conveyor belt, the feed conveyor belt is driven by the feed conveyor wheels 15 arranged at both ends, and its transmission part is symmetrically arranged on the lower part of both sides of the feed channel; the discharge conveyor belt is a rectangular cross-section Ribbon conveyor belt, the discharge conveyor belt is driven by the discharge transmission wheel 16 that is arranged ...

Embodiment 2

[0029] The feeding conveyer belt of embodiment 2 is a strip-shaped conveyer belt with a rectangular cross section, and its conveying part is arranged at the middle position at the bottom of the feed passage. Symmetrically arranged at the lower part of both sides of the discharge channel, the width of the feed conveyor belt is smaller than the interval width between the two discharge conveyor belts, and the moving speed ratio of the discharge conveyor belt and the feed conveyor belt is 10 to 1; the feed channel The center line of the feeding channel is inclined, the height of the center line of the feeding channel decreases gradually along the conveying direction of the metal can cover, and the center line of the discharging channel is horizontally set; the metal can cover anti-dumping devices on both sides of the channel are vacuum devices, so Described vacuum device is arranged on the suction hole on both sides of the channel and the suction mechanism connected with the sucti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com