Method for producing traceless quenching and embossing saw blade

A production method and saw blade technology, which are applied to metal sawing equipment, tool manufacturing of sawing machine devices, tool dressing of sawing machine devices, etc., can solve the problems of poor hardenability and unqualified hardness, and achieve good wear resistance. , beautiful appearance, the effect of improving productivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

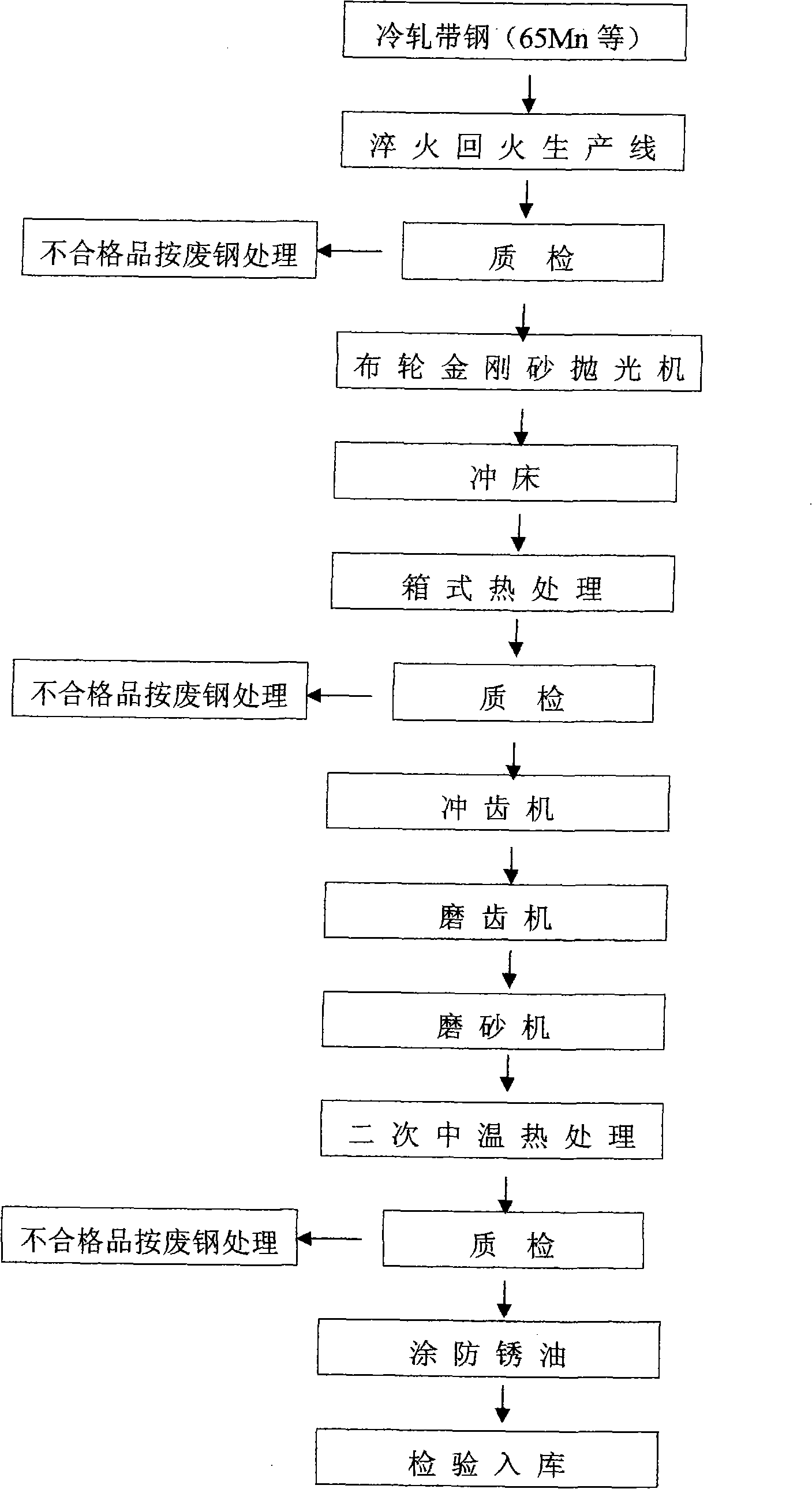

[0016] The production method of the traceless quenching embossed saw blade comprises the following steps: (1) selecting a cold-rolled strip, (2) heating the cold-rolled strip to 800-850°C and then quenching it in a quenching medium at 40-60°C, (3) Temper the strip after quenching at a temperature of 460-480° C., (4) strip quality inspection after tempering, (5) carry out double-surface polishing of the strip with a cloth wheel emery polishing machine, ( 6) Stamp the polished strip into a saw blade blank, (7) heat treat the saw blade blank at 380-400°C, (8) inspect the quality of the saw blade blank, (9) use the stamped saw blade blank Gear punching machine, (10) Install the punched saw blade on the gear grinding machine to grind the teeth, (11) Sand the ground saw blade to deburr, (12) Put the deburred saw blade on the Medium-temperature heat treatment at 380-400°C, (13) quality inspection of finished products, (14) coating with anti-rust oil and packaging after inspection, (1...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com