British standard B500B ribbed thread steel bar and production method thereof

A threaded steel bar and production method technology, applied in the British standard B500B ribbed threaded steel bar and its production field, can solve the problems of large deviation of yield strength index, inconspicuous yield point of coil screw, deterioration of steel bar welding performance, etc., so as to improve tensile strength Excellent strength, solderability, and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

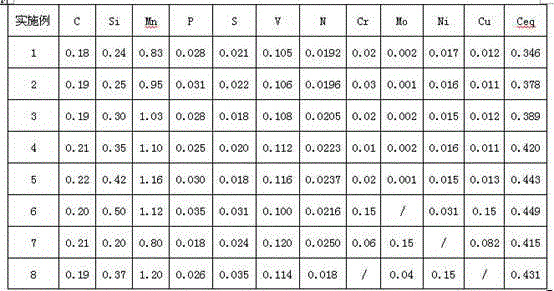

Examples

Embodiment 1

[0020] Example 1: The British standard B500B ribbed threaded steel bar is prepared by the following specific process, and the rolling specification is Φ6.0mm.

[0021] Put the billet into a heating furnace with a temperature of 1120-1140° C. in the soaking section and heat it. The holding time in the soaking section is 55 minutes, so that the billet reaches 1067° C. before being released from the furnace. After the heated billet is descaled by high-pressure water, it is subjected to rough, intermediate and pre-finish rolling. The starting temperature of rough rolling is 1032°C; the rolled piece is cooled to 880°C by passing through water, and then finish rolling is started, and the finishing temperature is controlled at 1005°C. ℃; through water cooling to 912 ℃ spinning. After silk spinning, the method of strong cooling at the front end and air cooling at the rear end is adopted. The cooling speed in the strong cooling zone is controlled at 8.5°C / s, and the coils are collected...

Embodiment 2

[0022] Example 2: The British standard B500B ribbed threaded steel bar is prepared by the following specific process, and the rolling specification is Φ8.0mm.

[0023] Put the billet into a heating furnace with a temperature of 1110-1130° C. in the soaking section and heat it. The holding time in the soaking section is 50 minutes, so that the billet reaches 1050° C. before being released from the furnace. After the heated billet is descaled by high-pressure water, it is subjected to rough, intermediate and pre-finish rolling. The starting temperature of rough rolling is 1017°C; the rolled piece is cooled to 894°C by passing through water, and the finish rolling is started, and the finishing temperature is controlled at 1002°C. ℃; through water cooling to 904 ℃ spinning. After spinning, the method of strong cooling at the front end and air cooling at the rear end is adopted. The cooling speed in the strong cooling zone is controlled at 8.0°C / s, and the coils are collected after...

Embodiment 3

[0024] Example 3: The British standard B500B ribbed threaded steel bar is prepared by the following specific process, and the rolling specification is Φ10.0mm.

[0025] Put the steel billet into a heating furnace with a temperature of 1115-1135° C. in the soaking section and heat it. The holding time in the soaking section is 45 minutes, so that the steel billet reaches 1045° C. before being released from the furnace. After the heated billet is descaled by high-pressure water, it is subjected to rough, medium and pre-finish rolling. The starting temperature of rough rolling is 1000°C; the rolled piece is cooled to 907°C by passing through water, and then finish rolling is started, and the finishing temperature is controlled at 1012°C. ℃; through water cooling to 897 ℃ spinning. After spinning, the method of strong cooling at the front end and air cooling at the rear end is adopted. The cooling speed in the strong cooling zone is controlled at 7.8°C / s, and the coils are collect...

PUM

| Property | Measurement | Unit |

|---|---|---|

| yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com