Method for preparing nano-scale lithium ion battery anode material

A lithium-ion battery, cathode material technology, applied in battery electrodes, circuits, electrical components, etc., can solve the problems of mechanical mixing uniformity, large reaction time and energy consumption, uneven particle size distribution, etc., to achieve excellent processing performance, reaction High biological activity and the effect of increasing tap density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

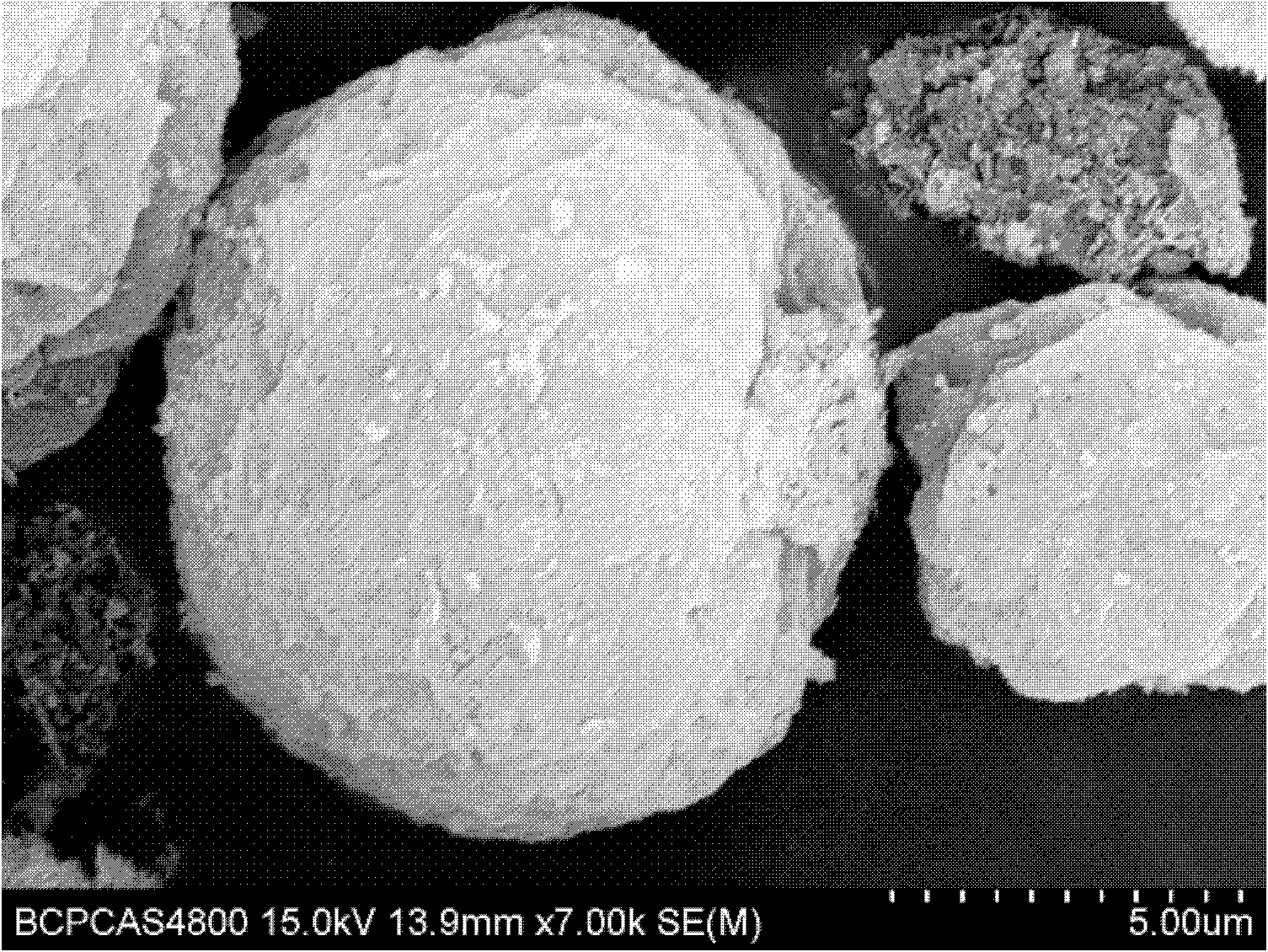

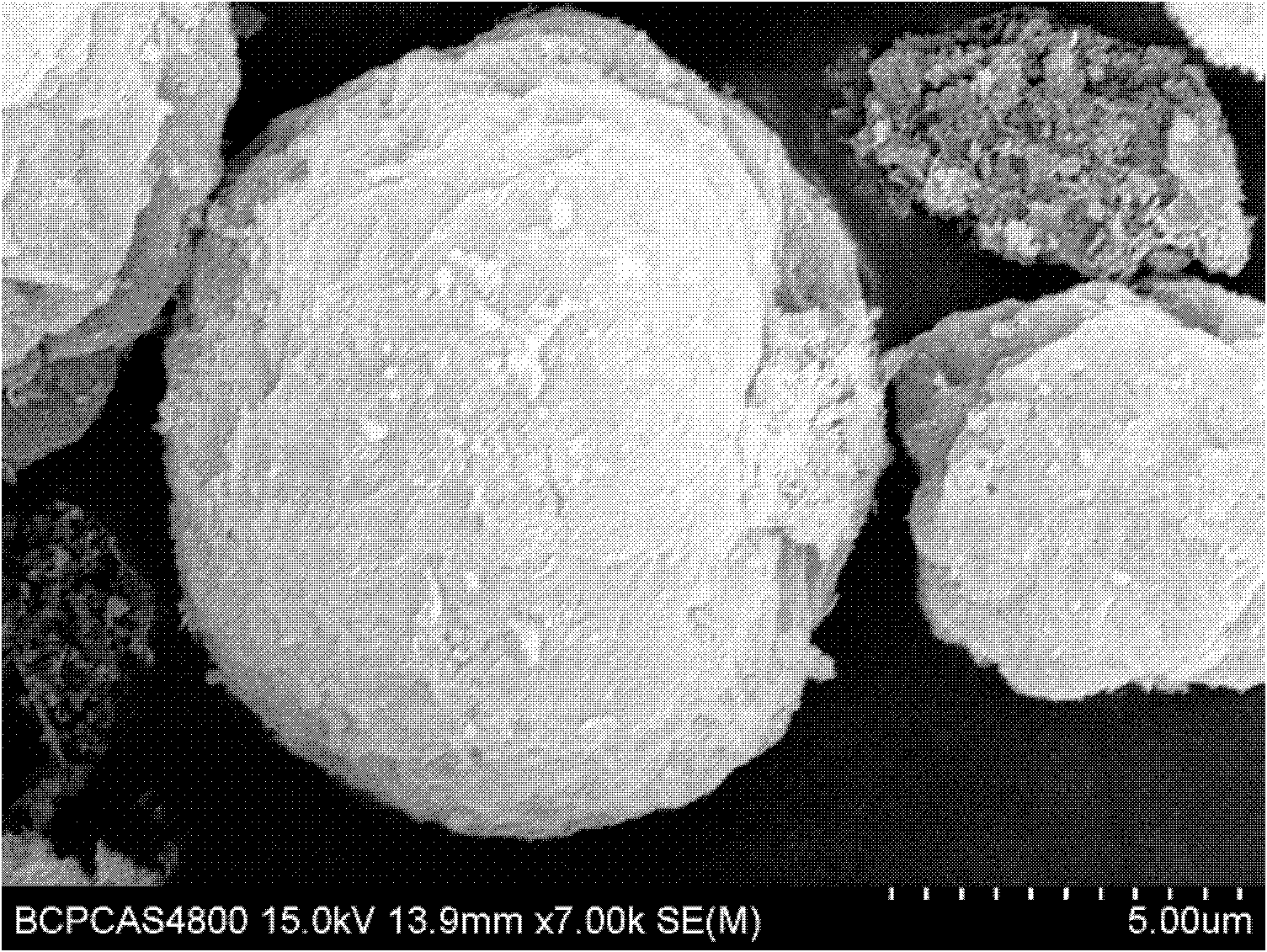

[0016] Example 1: Lithium nitrate, nickel nitrate, cobalt nitrate, and manganese nitrate were dissolved in deionized water respectively to form a homogeneous solution, wherein Li: Ni: Co: Mn molar ratio was 1: 0.3: 0.4: 0.3, and the above solutions were mixed After fully stirring, add urea solution twice the sum of the amount of all metal ion substances to the above mixed solution as a precipitating agent, then move it into a water bath and heat at a constant temperature of 95°C, and obtain LiNi after fully reacting. 0.3 co 0.4 mn 0.3 o 2 Precipitate the precursor, filter and wash 3 times with deionized water 3 times the volume of the precipitate, then spray-dry the suspension. The temperature of the feed port is set to 180°C, and the resulting dried precursor is sintered at 850°C in air 10 hours to get figure 1 The globular aggregate structure α-NaFeO with primary particle size on the order of nanometers shown 2 Type LiNi 0.3 co 0.4 mn 0.3 o 2 Cathode material.

Embodiment 2

[0017] Example 2: Lithium nitrate, nickel acetate, cobalt oxalate, and manganese nitrate were dissolved in deionized water to form a homogeneous solution, wherein Li: Ni: Co: Mn molar ratio was 1: 0.2: 0.6: 0.2, and the above solutions were mixed After fully stirring, add urea solution 3 times the sum of all metal ion substances to the above mixed solution as a precipitating agent, then move it into a water bath and heat at a constant temperature of 90°C, and obtain LiNi after fully reacting. 0.2 co 0.6 mn 0.2 o 2 The precursor is precipitated, filtered and washed twice with deionized water 5 times the volume of the precipitate, and the suspension is spray-dried. The temperature of the feed port is set to 165°C, and the dried precursor is sintered in air at 900°C In 6 hours, the globular aggregate structure α-NaFeO with primary particle size on the order of nanometers was obtained 2 Type LiNi 0.3 co 0.4 mn 0.3 o 2 Cathode material.

Embodiment 3

[0018] Example 3: Lithium nitrate, nickel sulfate, cobalt oxalate, and manganese nitrate were dissolved in deionized water to form a homogeneous solution, wherein Li: Ni: Co: Mn molar ratio was 1: 0.4: 0.2: 0.4, and the above solutions were mixed After fully stirring, add urea solution 3 times the sum of all metal ion substances to the above mixed solution as a precipitating agent, then move it into a water bath and heat at a constant temperature of 85°C, and obtain LiNi after fully reacting. 0.4 co 0.2 mn 0.4 o 2 Precipitate the precursor, filter and wash 5 times with deionized water 2 times the volume of the precipitate, then spray-dry the suspension. The temperature of the feed port is set to 165°C, and the resulting dried precursor is sintered in air at 750°C In 15 hours, the globular structure α-NaFeO with primary particle size in the order of nanometers was obtained 2 Type LiNi 0.4 co 0.2 mn 0.4 o 2 Cathode material.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com