High-safety power lithium ion secondary battery composite positive material and preparation method thereof

A composite positive electrode material and secondary battery technology, which is applied in the direction of secondary batteries, battery electrodes, batteries, etc., can solve the problems of battery cycle performance degradation, and achieve improved safety and cycle performance, large discharge capacity, and good cycle performance. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

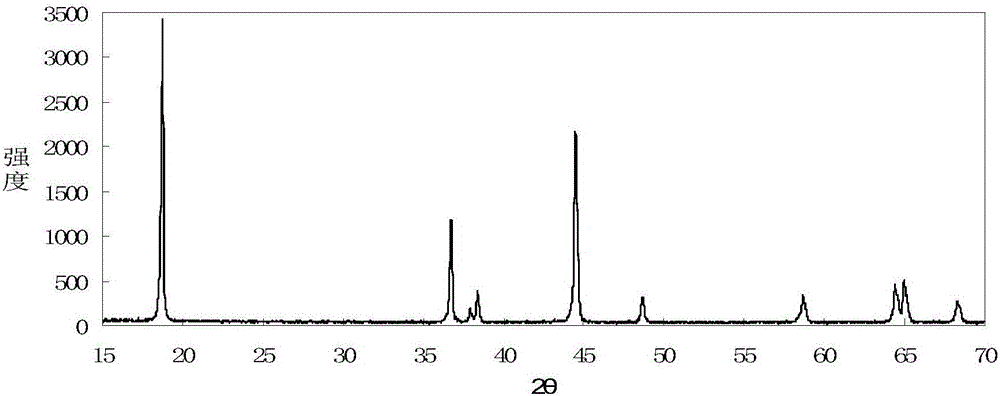

Embodiment 1

[0030] Nickel sulfate, cobalt sulfate and manganese sulfate are made into mixed solution according to Ni:Co:Mn molar ratio is 0.6:0.2:0.2 and mixes evenly, the total number of moles of Ni, Co, Mn three kinds of transition metal ions is 2mol / L, then Add 4 mol / L NaOH solution, transition metal ion solution and 4 mol / L ammonia water into the reaction vessel at the same time, control the pH value of the reaction system to 11.5, and the reaction temperature to 60°C. Then, the obtained precipitate was filtered, washed, and dried at 120° C. for 12 hours. Lithium carbonate and Ni 0.6 co 0.2 mn 0.2 (OH) 2 According to Li / M=1.12 (M is Ni 0.6 co 0.2 mn 0.2 (OH) 2 ), mixed in a high-speed mixer, calcined in a muffle furnace at 900°C for 12 hours, the atmosphere was 3L / min of air, the material was cooled with the furnace, crushed and passed through a 400-mesh sieve. Add 30mL of deionized water into the mixing tank, add 0.07g of aluminum isopropoxide and stir to dissolve, keep the t...

Embodiment 2-6

[0033] Pure phase LiNi obtained based on embodiment 1 0.6 co 0.2 mn 0.2 o 2 , adding aluminum isopropoxide of different quality, so that the coating amount of final aluminum is respectively 0.1%, 0.5%, 1%, 3%, 5%, other steps are the same as embodiment 1.

Embodiment 7-9

[0035] The Al oxide-coated Li-Ni composite positive electrode material was prepared similarly to Example 1, except that after Al coating, the sintering temperatures were 400°C, 600°C, and 700°C, respectively.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com