Method for preparing alkaline-earth silicate fluorescent powder activated by rare earth elements

An alkaline earth silicate, rare earth element technology, applied in chemical instruments and methods, electrical components, luminescent materials, etc., can solve the problems that mixing cannot be uniform enough, product particle size distribution is uneven, product synthesis temperature difference, etc. Avoid agglomeration and cracking, shorten the production cycle, the effect of short production cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

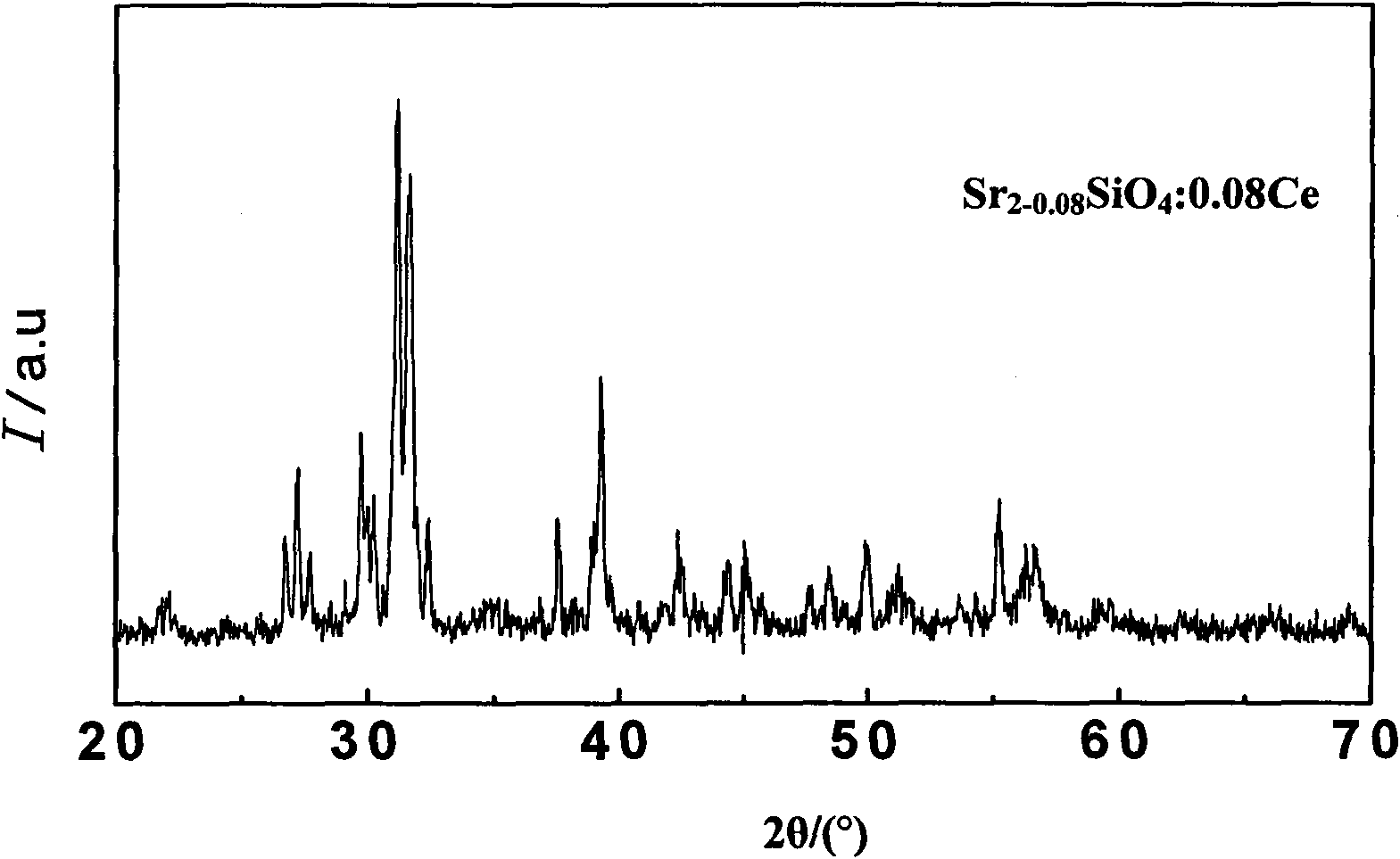

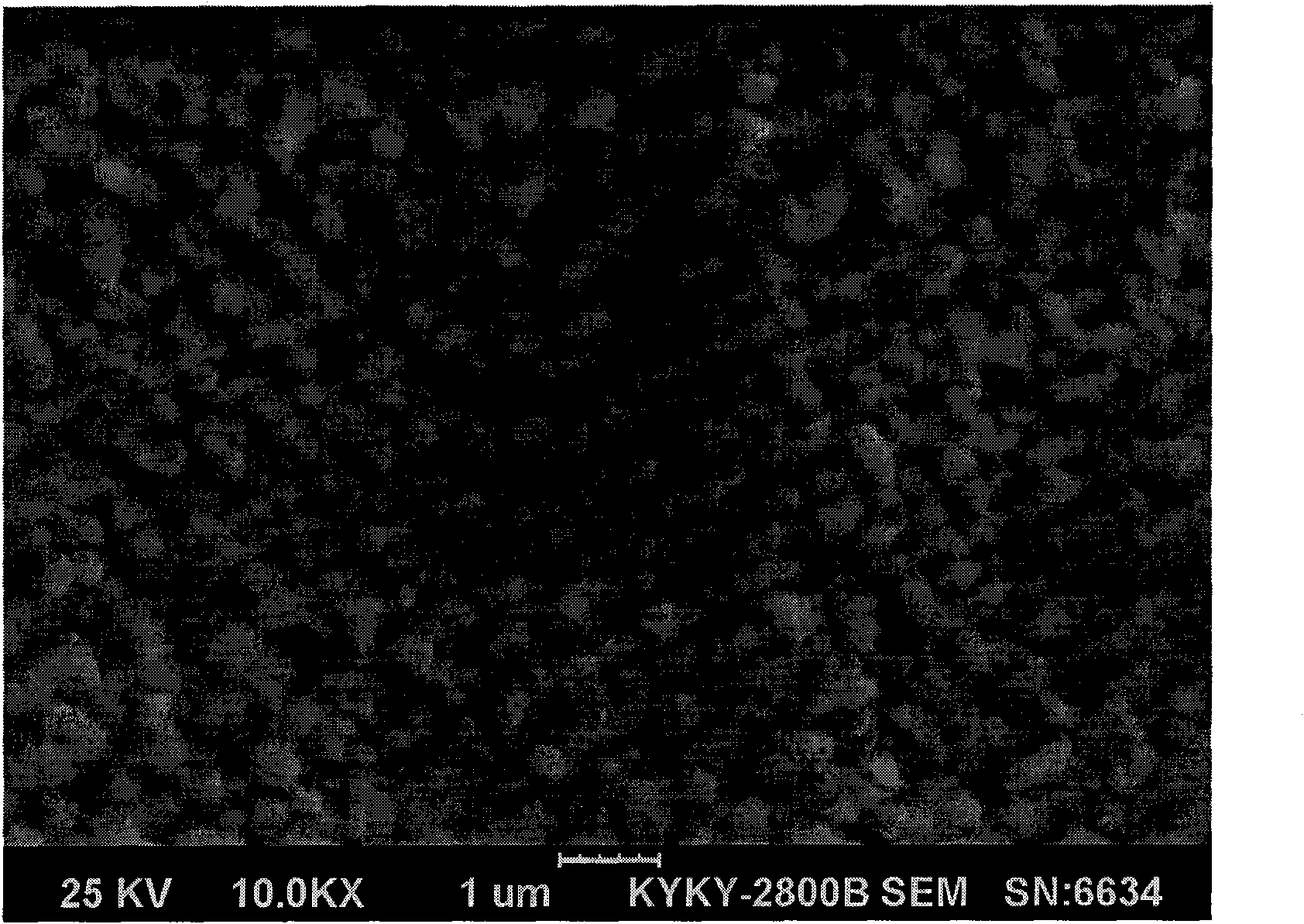

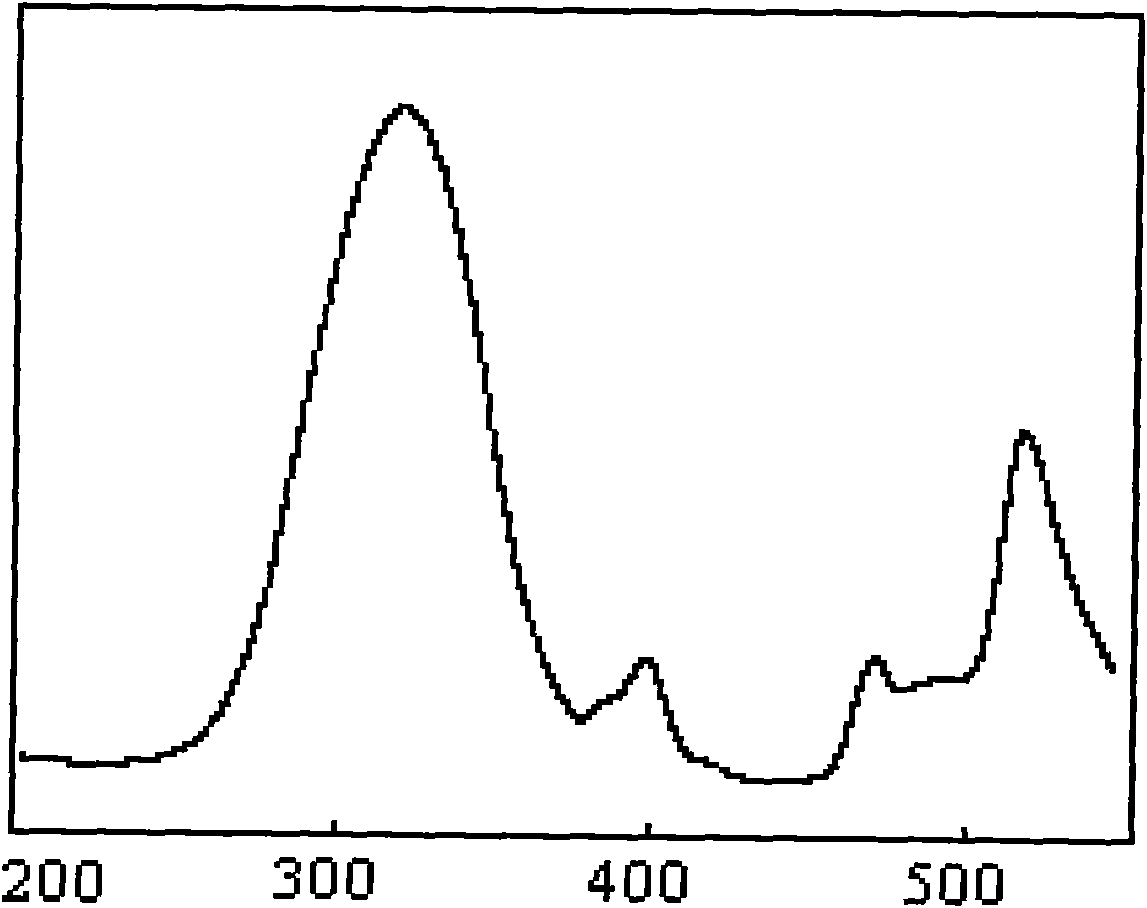

[0025] Example 1: Sr 1.92 SiO 4 : Preparation of 0.08Ce Phosphor Powder

[0026] Weigh Sr(NO 3 ) 2 6.095g, Ce(NO 3 ) 3 ·6H 2 O 0.521g was dissolved in 50ml of deionized water, and was stirred to obtain a homogeneous solution; then, 7.386ml of tetraethyl orthosilicate (TEOS) was dissolved in 20ml of absolute ethanol and then dropped into the above-mentioned homogeneous solution, and fully stirred to obtain a homogeneous solution A;

[0027] Weigh citric acid (the molar ratio of citric acid to Sr is 2.5:1) and polyethylene glycol HO-(CH 2 CH 2 O) n -H (molecular weight = 6000, A.R., the molar ratio of polyethylene glycol to tetraethyl orthosilicate is 0.015: 1) is co-dissolved in 40ml ethanol aqueous solution (volume fraction is 25%), mix well and add dropwise to the homogeneous Solution A and adjust the Ph value to be equal to 5, stir well to make it evenly mixed to obtain a homogeneous solution B;

[0028] Put the homogeneous solution B in a water bath and heat at a...

Embodiment 2

[0031] Example 2: Ca 1.88 Mg 0.06 SiO 4 : Preparation of 0.06Eu Phosphor Powder

[0032] Weigh Ca(NO 3 ) 2 4.627g, Mg(NO 3 ) 2 ·6H 2 O 0.231g, Eu(NO 3 ) 3 ·6H 2 O 0.402g was dissolved in 50ml of deionized water, and was stirred to obtain a homogeneous solution; then, 7.386ml of tetraethyl orthosilicate (TEOS) was dissolved in 50ml of absolute ethanol and dropped into the above homogeneous solution, and fully stirred to obtain a homogeneous solution A ;

[0033] Weigh citric acid (the molar ratio of citric acid to Ca and Mg is 4:1) and polyethylene glycol HO-(CH 2 CH 2 O) n-H (molecular weight=6000, A.R., molar ratio of polyethylene glycol to tetraethyl orthosilicate is 0.02:1) is co-dissolved in 200ml ethanol aqueous solution (volume fraction is 35%), mixed well and added dropwise to the homogeneous solution A and adjust the Ph value to be equal to 4, fully stir to make it evenly mixed to obtain a homogeneous solution B;

[0034] Put the homogeneous solution B i...

Embodiment 3

[0037] Example 3: Ca 1.94 SiO 4 : Preparation of 0.06Eu Phosphor Powder

[0038] Weigh Ca(NO 3 ) 2 4.775g, Eu(NO 3 ) 3 ·6H 2 O 0.402g was dissolved in 100ml of ionized water, and was stirred to obtain a homogeneous solution; then, 7.386ml of tetraethyl orthosilicate (TEOS) was dissolved in 30ml of absolute ethanol and then dropped into the above-mentioned homogeneous solution, and fully stirred to obtain a homogeneous solution A ;

[0039] Weigh citric acid (the molar ratio of citric acid to Ca is 3:1) and polyethylene glycol HO-(CH 2 CH 2 O) n -H (molecular weight = 6000, A.R., molar ratio of polyethylene glycol to tetraethyl orthosilicate is 0.03:1) is co-dissolved in 250ml ethanol aqueous solution (volume fraction is 50%), mixed well and added dropwise to the homogeneous solution A and adjust the Ph value to be equal to 7, fully stir to make it evenly mixed to obtain a homogeneous solution B;

[0040] Put the homogeneous solution B in a water bath and heat at a c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com