Hadifield steel with excellent mechanical property and manufacturing method thereof

A manufacturing method and technology of high manganese steel, which is applied in the field of high manganese steel, can solve problems such as increasing alloy cost, affecting alloy platability, and casting difficulties, and achieves the effects of high plasticity, improved safety, and high-strength plasticity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

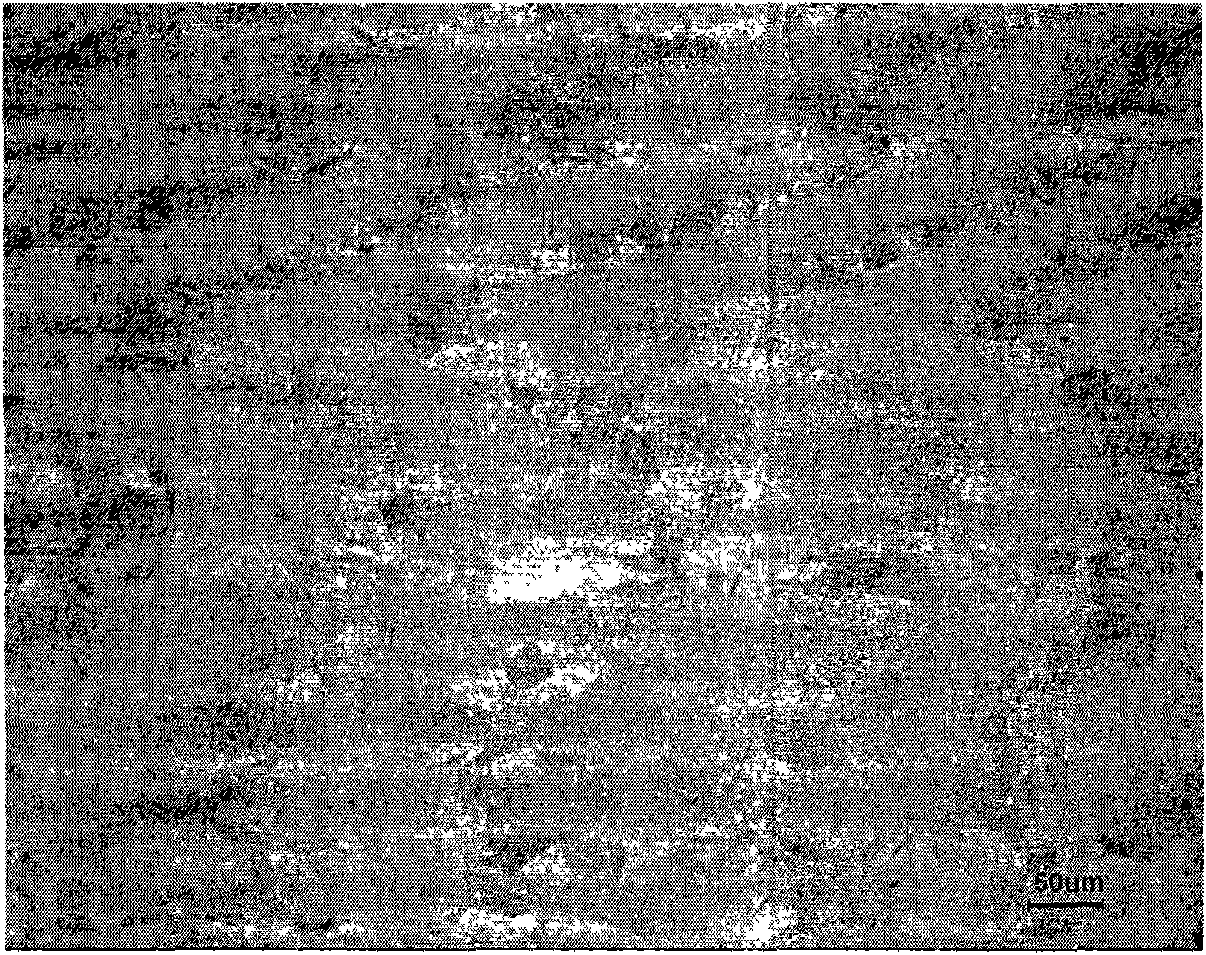

Image

Examples

Embodiment 1~10

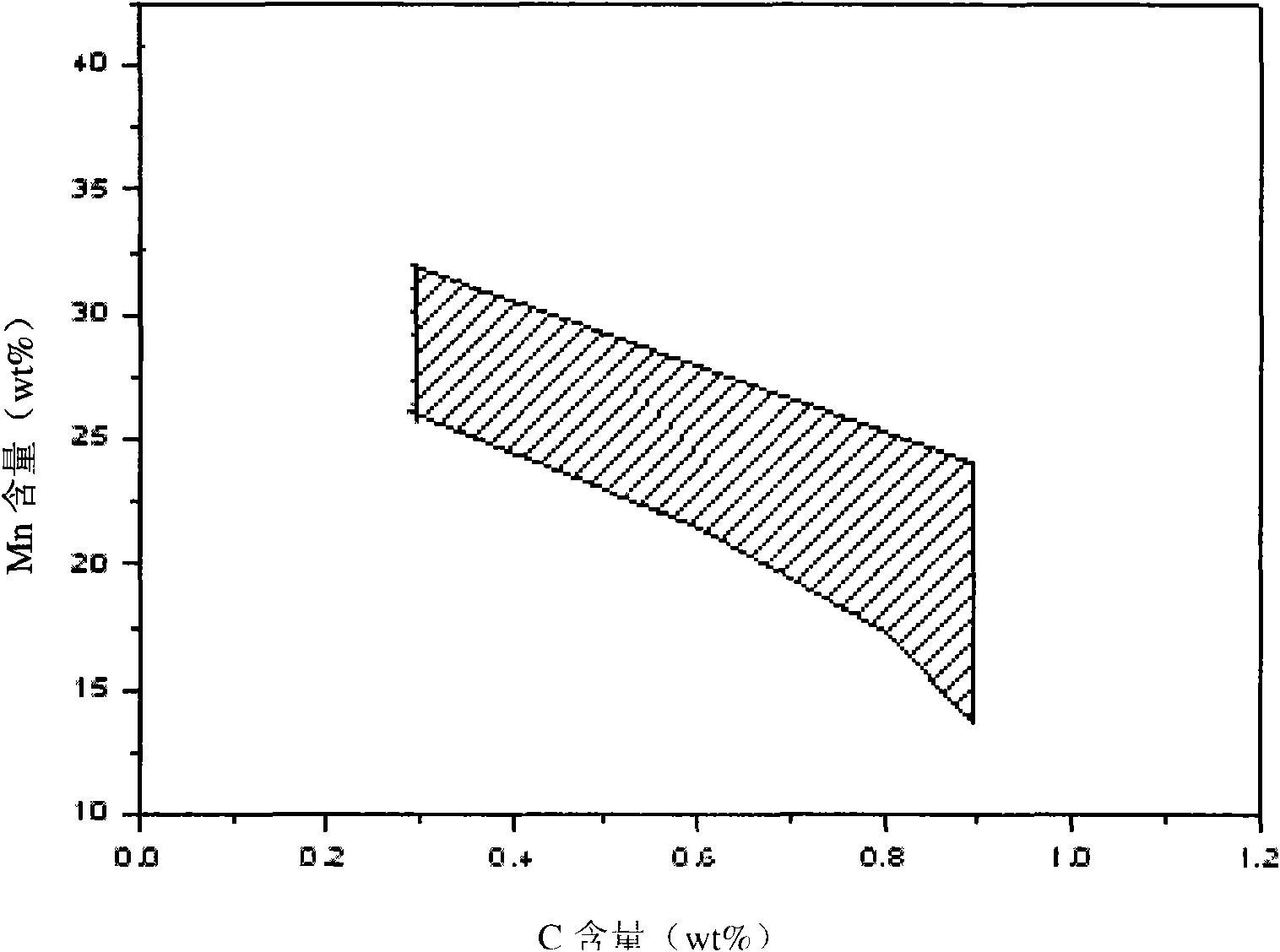

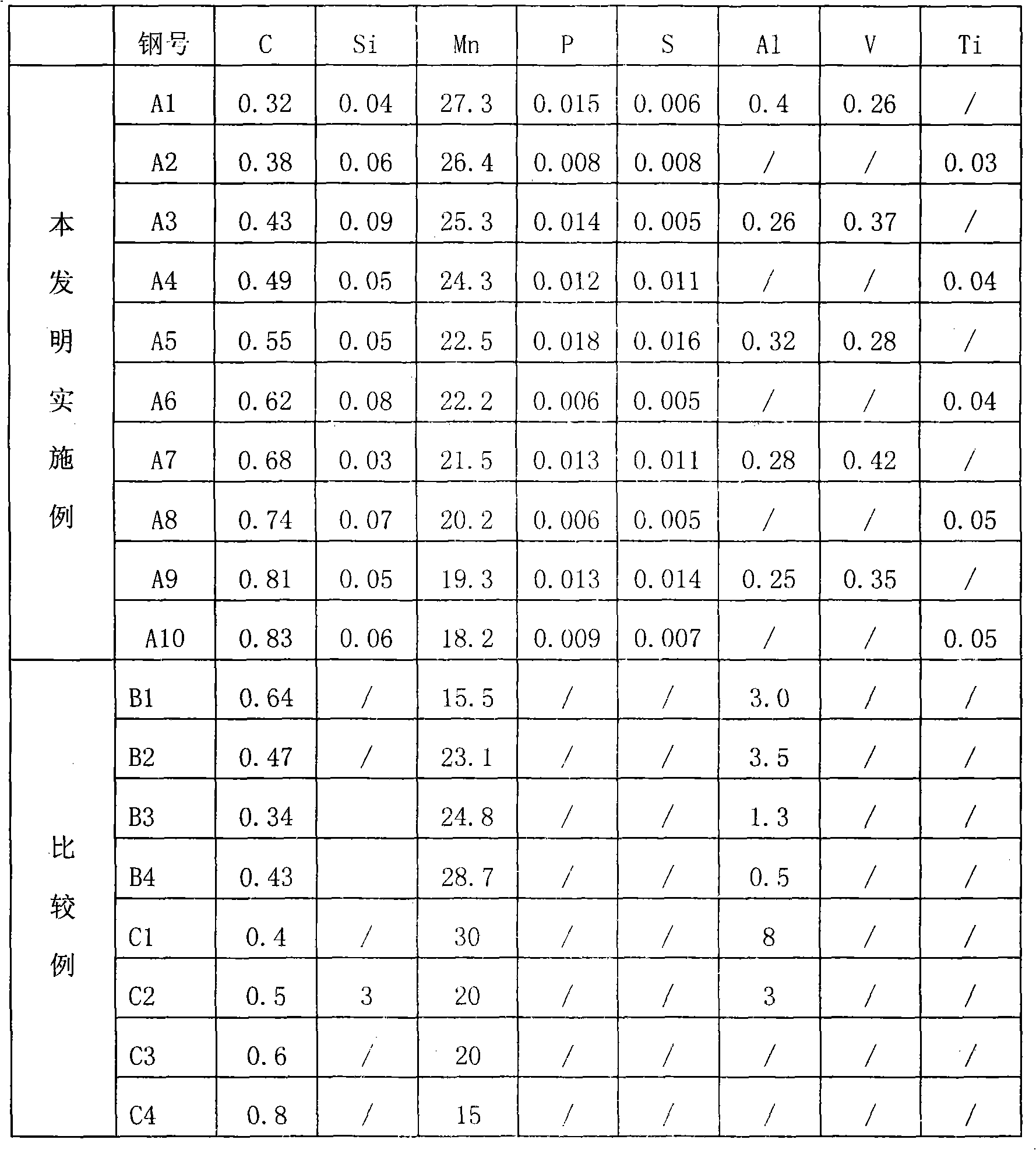

[0035] Table 2 shows the chemical composition of the examples and comparative examples of the steel of the present invention, wherein A1~A10 respectively represent the examples of the present invention, B1~B4, and C1~C4 respectively represent the comparative examples, which are patent documents US5,431,753A and patent documents respectively Steel in CN200480044461.3. Table 3 lists the mechanical properties of the examples of the present invention and comparative examples.

[0036] The chemical composition of table 2 embodiment and comparative example, wt%

[0037]

[0038] Table 3 The mechanical properties of steel of the present invention and comparison steel

[0039]

[0040] Continued Table 3

[0041]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com