Method for producing sludge modifier by utilizing coal gangue

A technology of sludge conditioning and coal gangue, which is applied in dehydration/drying/concentrated sludge treatment, solid waste removal, ferric halide, etc., can solve the problems of reducing production costs, reduce production costs, realize full utilization, cheap effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment 1

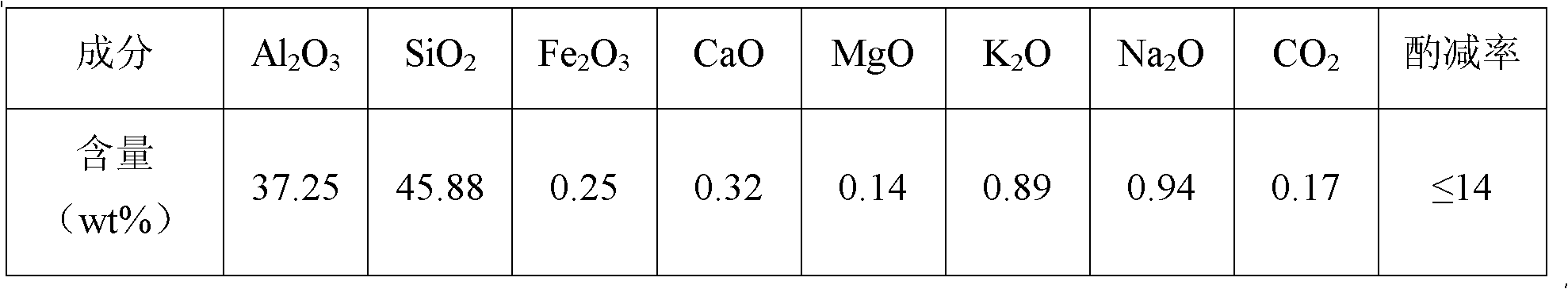

[0026] The sludge conditioning agent was prepared by using coal gangue samples from Huairen County, Shaanxi Province. The composition and content (wt%) of coal gangue samples are shown in the table below:

[0027]

[0028] Use 0.25-0.4mm coal gangue and sodium carbonate powder to mix and calcinate, wherein the temperature is 900°C, the time is 50min, and the mass ratio of coal gangue to sodium carbonate is 2:1; the calcined solid matter is soaked in water and filtered to obtain Filter residue and alkaline filtrate.

[0029] Adopt the mixed acid solution of concentrated sulfuric acid (mass fraction 98%) and concentrated hydrochloric acid (mass fraction 36%), the concentrated sulfuric acid and the concentrated hydrochloric acid mass ratio are 1: 5, then add the water dilution of 3 times volume to obtain mixed acid; Dissolve the filter residue, feed the mixed acid and the calcined solid at a volume ratio of 4:1, and filter to obtain an acidic filtrate. The dissolution tempera...

Embodiment 2

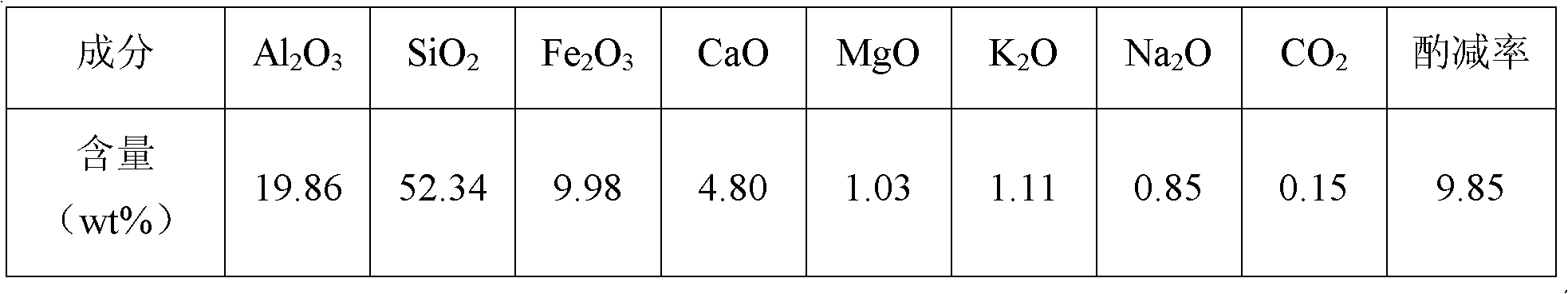

[0032] The sludge conditioning agent was prepared by using the coal gangue samples from Jiaozi Mountain, Anshun City, Guizhou Province. The composition and content (wt%) of coal gangue samples are shown in the table below:

[0033]

[0034] Use 0.25-0.4mm coal gangue and sodium carbonate powder to mix and calcinate, wherein the temperature is 900°C, the time is 40min, and the mass ratio of coal gangue to sodium carbonate is 3:1; the calcined solid matter is soaked in water and filtered to obtain Filter residue and alkaline filtrate.

[0035] Adopt the mixed acid solution of concentrated sulfuric acid (mass fraction 98%) and concentrated hydrochloric acid (mass fraction 36%), the concentrated sulfuric acid and the concentrated hydrochloric acid mass ratio are 1: 5, then add the water dilution of 3 times volume to obtain mixed acid; Dissolve the filter residue, feed the mixed acid and the calcined solid at a volume ratio of 4:1, and filter to obtain an acidic filtrate. The d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com