Cf/C-SiC composite material as well as preparation method and application thereof

A composite material and prefabricated technology, applied in mechanical equipment, machines/engines, engine components, etc., can solve problems such as poor high-temperature mechanical properties, difficulty in large-scale production, and no marketization, etc., to achieve small contact angle and good wetting Sexuality, the effect of increasing the penetration speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

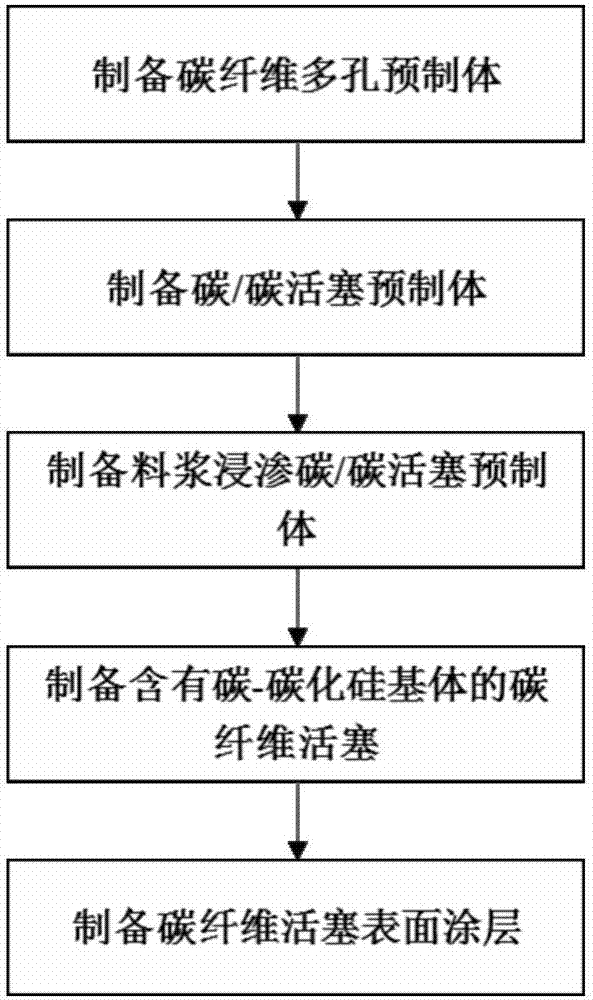

[0056] Such as figure 1 As shown, the preparation method of the silicon carbide fiber reinforced silicon carbide ceramic matrix composite material provided by the embodiment of the present invention comprises the following steps:

[0057] Step 1. Preparation of carbon fiber piston porous prefabricated body:

[0058] The carbon fiber is woven into a piston-shaped preform by a knitting process; the carbon fiber in the carbon fiber piston porous preform is a mesophase pitch-based carbon fiber. The density of the piston shape preform is 0.58g / cm 3 ; The prefabricated body is a three-dimensional and five-directional needle-punched carbon felt porous prefabricated body;

[0059] Step 2. Preparation of carbon / carbon piston preform:

[0060] Using the chemical vapor infiltration method, the carbon fiber piston porous preform is placed in the tooling mold, and then put into the chemical vapor deposition furnace together. On the described carbon fiber piston prefabricated body that ...

Embodiment 2

[0073] Step 1. Preparation of carbon fiber piston porous prefabricated body:

[0074] The carbon fiber is woven into a piston-shaped preform by a knitting process; the carbon fiber in the carbon fiber piston porous preform is a mesophase pitch-based carbon fiber. The density of the piston shape preform is 0.6g / cm 3 ; The prefabricated body is a three-dimensional and five-directional needle-punched carbon felt porous prefabricated body;

[0075] Step 2. Preparation of carbon / carbon piston preform:

[0076] Using the chemical vapor infiltration method, the carbon fiber piston porous preform is placed in the tooling mold, and then put into the chemical vapor deposition furnace together. On the described carbon fiber piston prefabricated body that obtains in step 1 by carbon organic matter precursor, infiltrating carburization, the prepared density is 1.38g / cm 3 carbon / carbon piston preform; when chemical vapor infiltration deposits matrix carbon, the carbon source gas used is ...

Embodiment 3

[0090] Step 1. Preparation of carbon fiber piston porous prefabricated body:

[0091] The carbon fiber is woven into a piston-shaped preform by a knitting process; the carbon fiber in the carbon fiber piston porous preform is a mesophase pitch-based carbon fiber. The density of the piston shape preform is 0.58g / cm 3 ; The prefabricated body is a three-dimensional and five-directional needle-punched carbon felt porous prefabricated body;

[0092] Step 2. Preparation of carbon / carbon piston preform:

[0093] Using the chemical vapor infiltration method, the carbon fiber piston porous preform is placed in the tooling mold, and then put into the chemical vapor deposition furnace together. The carbon-organic precursor is infiltrated on the carbon fiber piston preform obtained in step 1 to prepare a carbon / carbon piston preform; when chemical vapor infiltration deposits matrix carbon, the carbon source gas used is propane, and the diluent gas used is argon Gas and chemical vapor ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Density | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com