Method for preparing hydrogenated silicon film by utilizing magnetron sputtering

A magnetron sputtering coating and magnetron sputtering technology, applied in the direction of sputtering coating, ion implantation coating, metal material coating process, etc., can solve aggregation, Si-Si bond breaking, movement and density increase, etc. Problems, to achieve the effect of smooth surface, good compactness, and increase crystallization rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

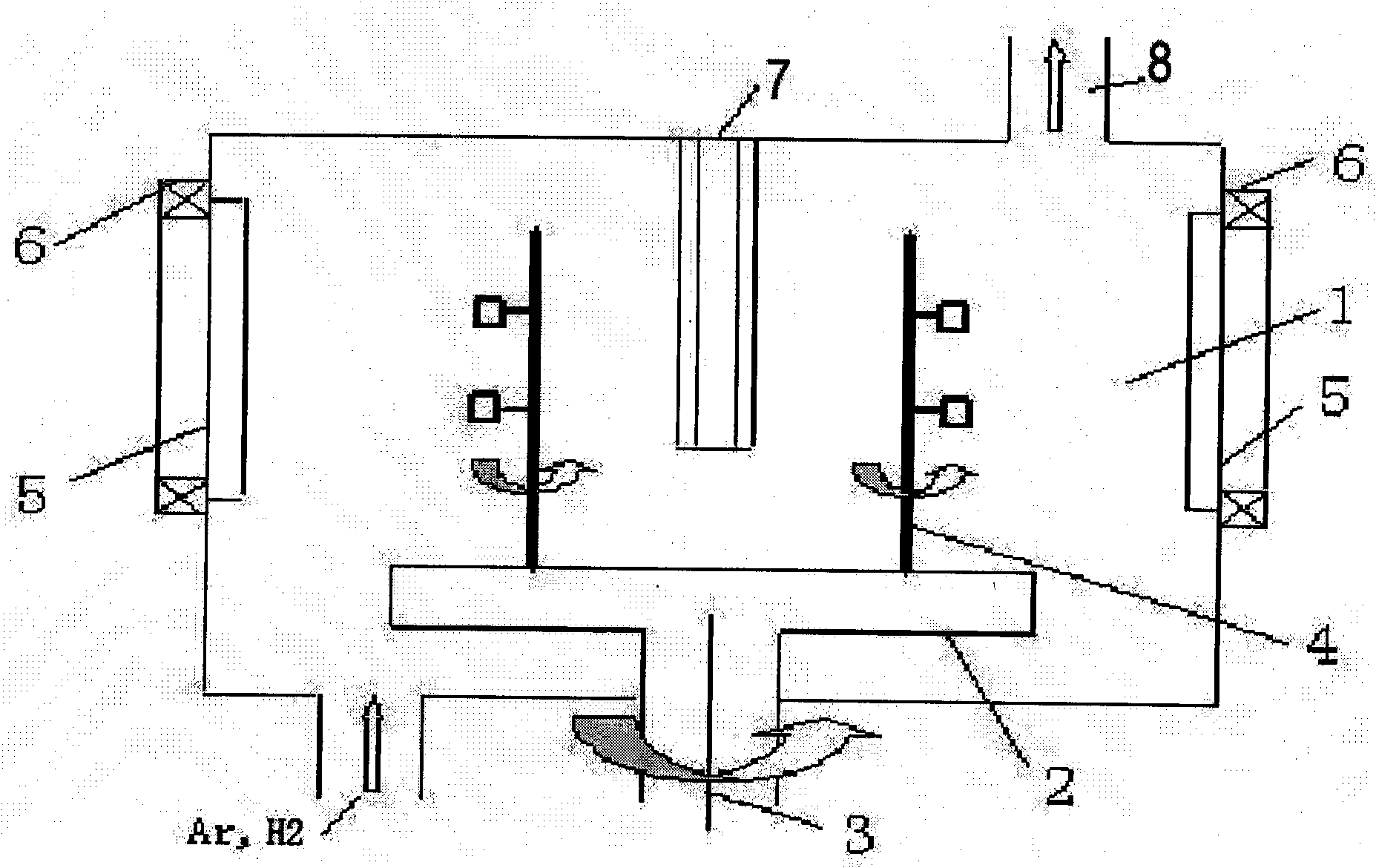

[0030] Evacuate the air pressure of the vacuum chamber to 6×10 -3 Pa, heat the common glass sheet to 250°C; before coating, pass 16sccm of Ar into the vacuum chamber 1 in the furnace, when the pressure in the vacuum chamber reaches 6Pa and keep the pressure stable at 6Pa, open the bias voltage from 3 to -1000V The vacuum chamber and the substrate are bombarded and cleaned for 30 minutes; this can ensure a better bond between the film and the substrate.

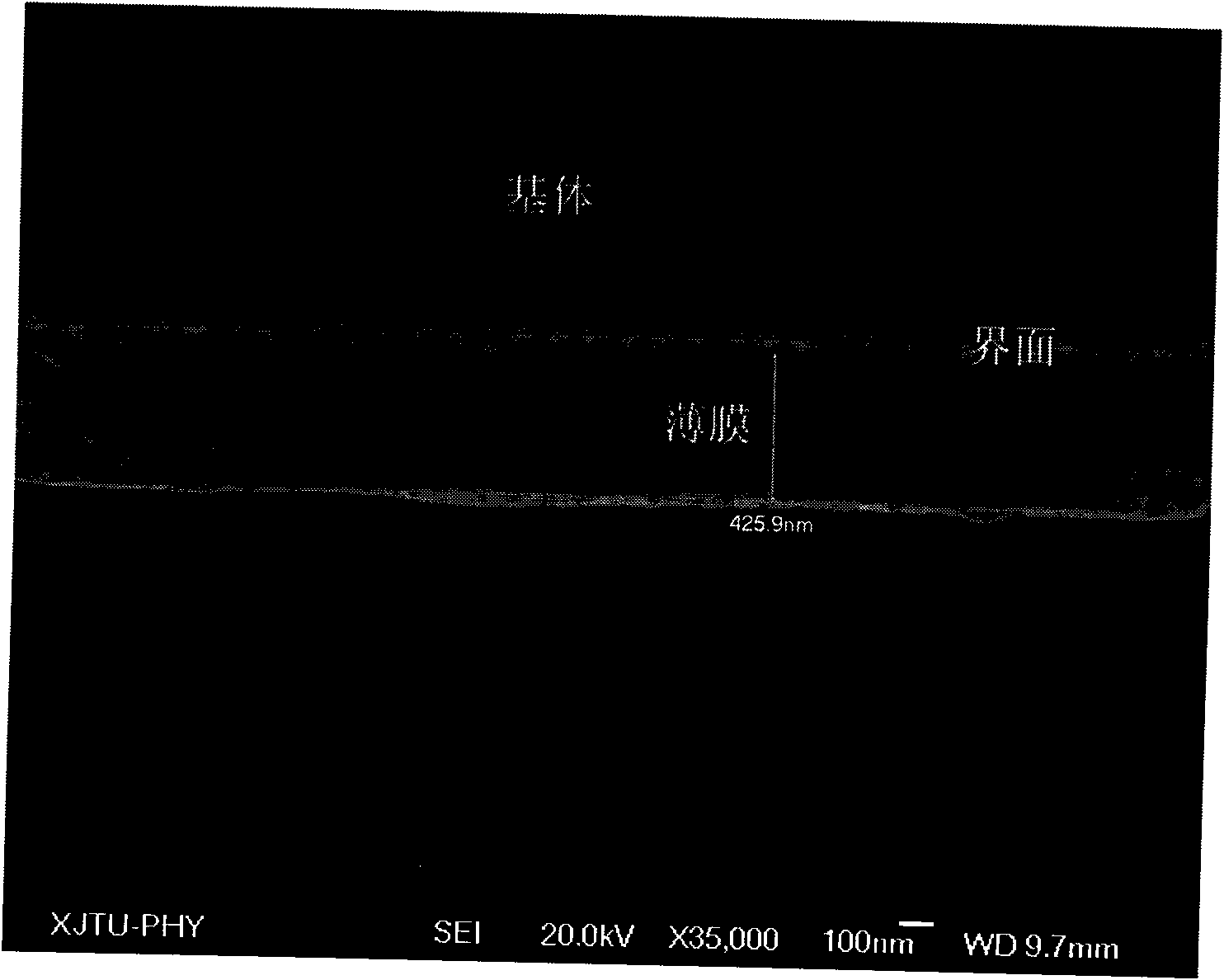

[0031] After the substrate was cleaned, the Ar gas was turned off, and the air pressure in the vacuum chamber was pumped to 6×10 -3 Pa, while feeding Ar gas and H 2 gas to make H 2 The volume percentage of the gas is 60%. When the vacuum chamber pressure rises to 0.5Pa, adjust the negative bias to -100V, turn on the control power of the Si target, adjust the power of the Si target to 2kW, and the deposition time is 120min to obtain hydrogenated silicon. film.

Embodiment 2

[0033] Evacuate the air pressure of the vacuum chamber to 8×10 -4 Pa, heat the quartz glass sheet to 240°C; before coating, pass 24 sccm of Ar into the vacuum chamber 1 in the furnace, when the pressure in the vacuum chamber reaches 8Pa and keeps the pressure stable at 8Pa, open the bias voltage from 3 to -800V The vacuum chamber and the substrate were bombarded and cleaned for 40 min.

[0034]After the substrate was cleaned, the Ar gas was turned off, and the air pressure in the vacuum chamber was evacuated to 8×10 -4 Pa, while feeding Ar gas and H 2 gas to make H 2 The volume percentage of the gas is 20%. When the vacuum chamber pressure rises to 0.3Pa, adjust the negative bias to -100V, turn on the control power of the Si target, adjust the power of the Si target to 4kW, and the deposition time is 60min to obtain hydrogenated silicon. film.

[0035] The thin film grown on the quartz glass plate is vacuum annealed in the later stage to increase the crystallization rate o...

Embodiment 3

[0037] Evacuate the air pressure of the vacuum chamber to 5×10 -3 Pa, heat the single crystal Si(100) sheet to 200°C; before coating, pass 18 sccm of Ar into the vacuum chamber 1 in the furnace, and when the pressure in the vacuum chamber reaches 4Pa and keeps the pressure stable at 4Pa, turn on the bias 3 to -900V to bombard and clean the vacuum chamber and substrate for 20 minutes.

[0038] After the substrate was cleaned, the Ar gas was turned off, and the air pressure in the vacuum chamber was evacuated to 5×10 -3 Pa, while feeding Ar gas and H 2 gas to make H 2 The volume percentage of the gas is 40%. When the vacuum chamber pressure rises to 0.4Pa, adjust the negative bias to -100V, turn on the control power of the Si target, adjust the power of the Si target to 3kW, and the deposition time is 90min to obtain hydrogenated silicon. film.

[0039] The thin film grown on the single crystal silicon wafer is vacuum annealed in the later stage to increase the crystallizati...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com