Selection method for recycling plastic

A technology for recycling plastics and screening methods, applied in plastic recycling, mechanical material recycling, recycling technology, etc., can solve problems such as difficult to improve work efficiency, reduce manufacturing costs and manpower input, reduce labor costs, and prevent air pollution Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

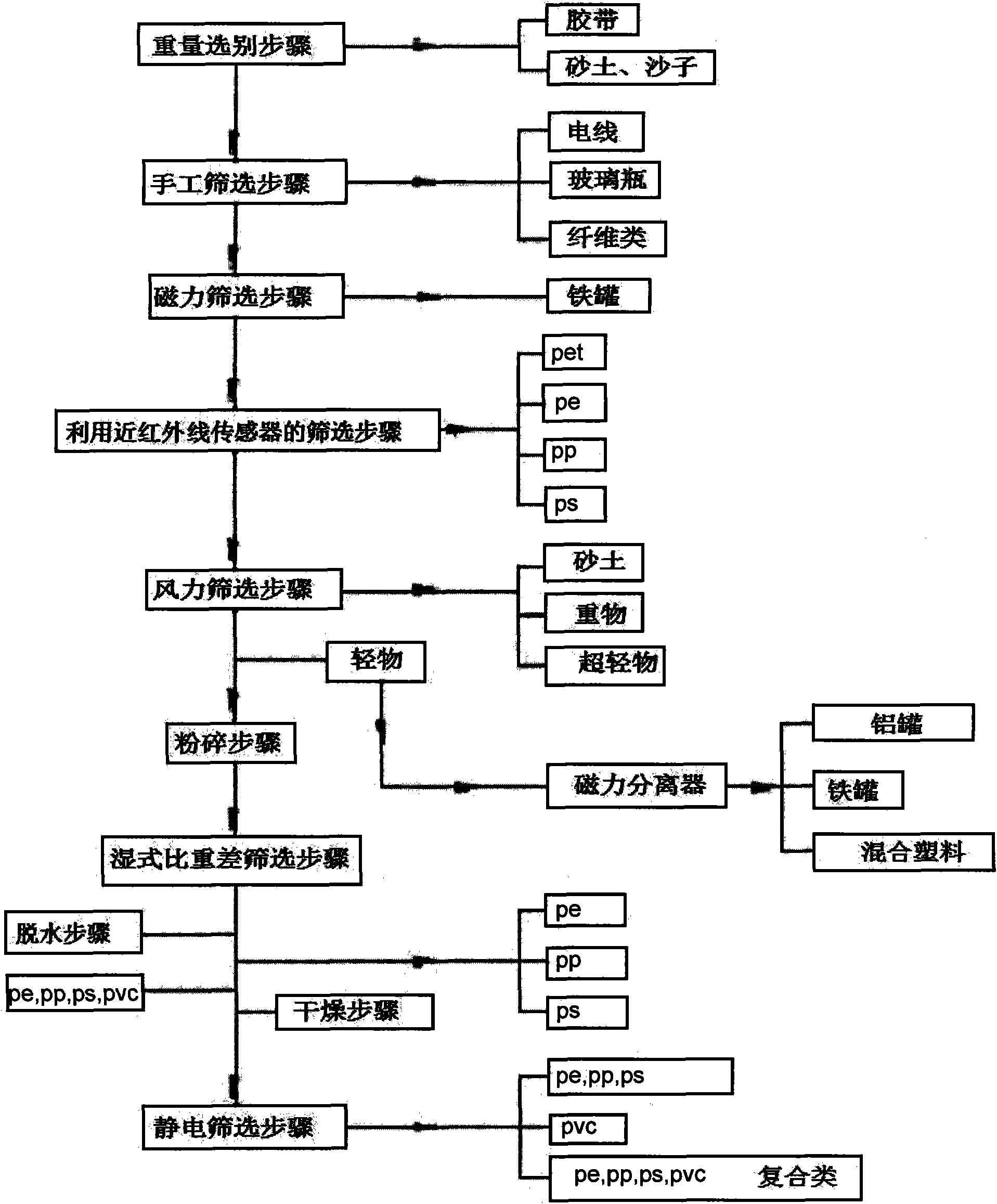

[0078] Screen out mixed plastics (PET, PP, PE, PS, PVC, etc.) from existing domestic waste, and screen PET, PP, PE, PS for recycling. Since PET, PP, PE and PS cannot be completely screened out in different categories from mixed plastics (PET, PP, PE, PS, PVC, etc.), there are limitations in the use and recycling of recycled plastics.

[0079] The present invention provides a method for screening out PVC from mixed plastics (PET, PP, PE, PS, PVC, etc.) most accurately in order to fully recycle the above-mentioned wasted plastic resources.

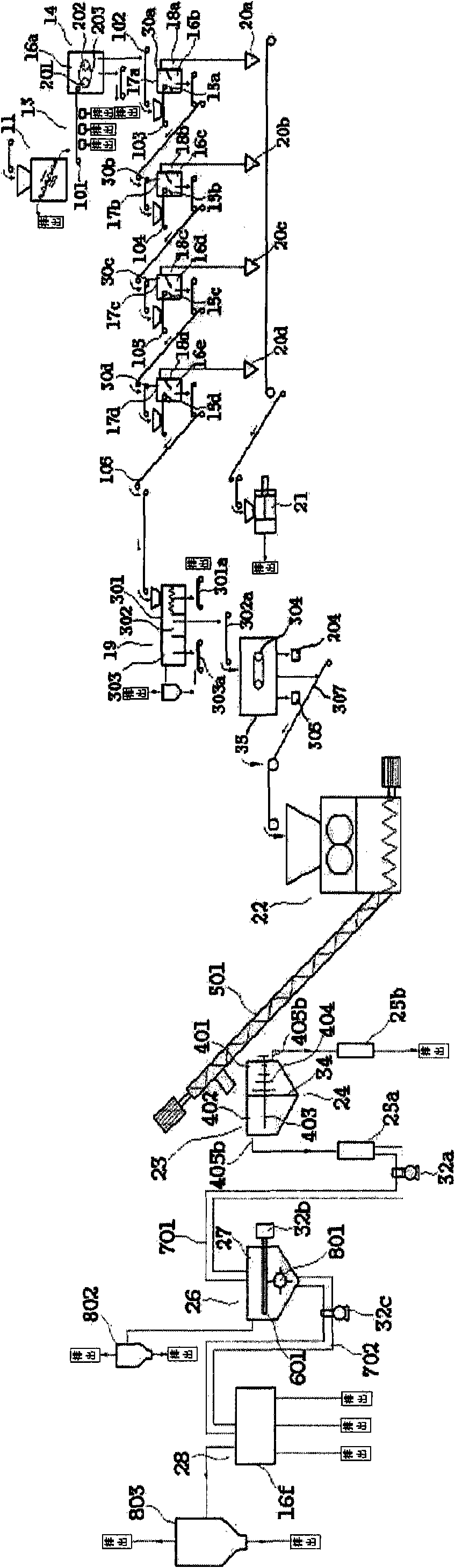

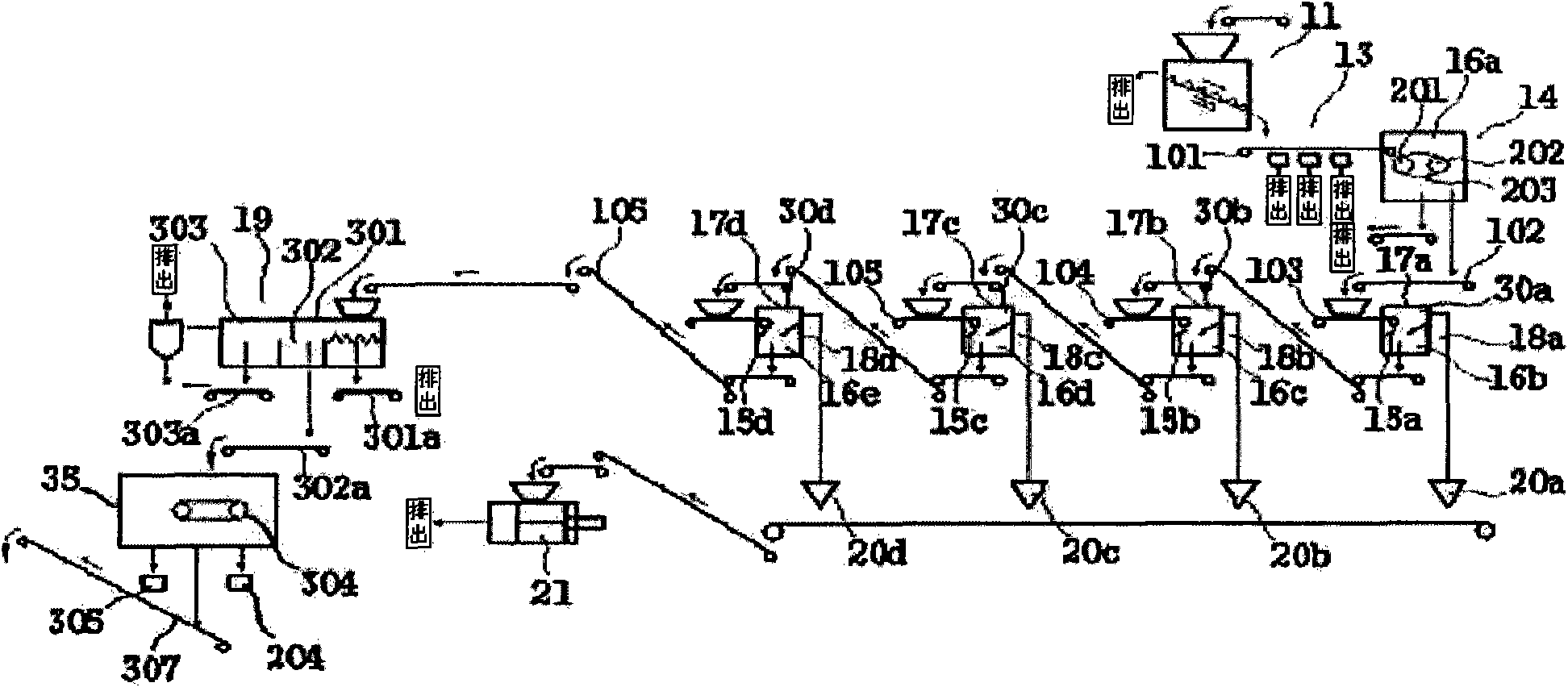

[0080] According to the present invention, under the state of power input to each device, when domestic waste flows into the weight sorting machine (11) through the conveyor belt (101), the weight sorting plate (12) sorts the weight in an inclined state. Therefore, foreign matter (sand, sand, etc.) is discharged through the hole (not shown) below the weight sorting plate (12), while most of the heavy things (solid plastics) and light things ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com