Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

85results about How to "Enlarged stomata" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

FFC glaze with high stain resistance, FFC sanitary ceramic and preparation method of FFC sanitary ceramic

ActiveCN111253071AExtended firing temperature rangeReduce glaze porosityPotassium feldsparSodium carboxymethylcellulose

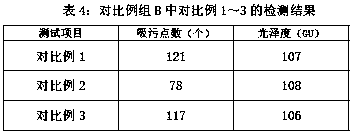

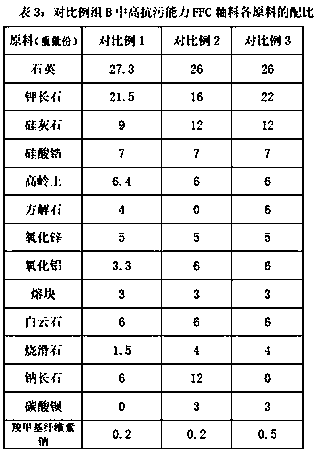

The invention discloses an FFC glaze with high stain resistance, an FFC sanitary ceramic and a preparation method of the FFC sanitary ceramic. The FFC glaze with high stain resistance comprises the following raw materials in parts by weight: 22-29 parts of quartz, 24-28 parts of potassium feldspar, 6-10 parts of wollastonite, 7-8 parts of zirconium silicate, 5-10 parts of kaolin, 0-5 parts of calcite, 5-7 parts of zinc oxide, 5-7 parts of aluminum oxide, 2-3 parts of frit, 4-8 parts of dolomite, 5-8 parts of calcined talc, 1-4 parts of barium carbonate and 0.2-0.5 part of sodium carboxymethylcellulose. According to the FFC glaze with high stain resistance, multi-alkali effect is utilized, barium carbonate is introduced, the use amount of calcined talc is increased, and the use amount of albite is reduced, so venting of a green body is more smooth, the porosity of a glaze surface is reduced, and microcracks of the glaze surface are reduced. Besides, the FFC glaze with high stain resistance also utilizes the principle of like dissolves like to increase the consumption of aluminum oxide and quartz, improve the bonding property of the blank and a glaze, and further reduce the microcracks on the glaze surface of the sanitary ceramic correspondingly.

Owner:江门市东鹏智能家居有限公司

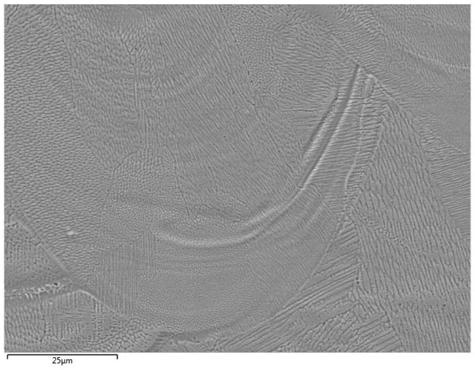

Electro-beam welding method of niobium alloy and titanium alloy thick plate

InactiveCN101274388ASimplify the process stepsSimple and efficient operationWelding/cutting auxillary devicesAuxillary welding devicesSmooth surfaceHigh pressure

The invention discloses an electron-beam welding method for welding niobium alloy and titanium alloy thick plates, which comprises steps of: welding surface processing: the welding surfaces of two welding pieces which need welding are processed into smooth surfaces with the roughness Ra less than or equal to 1.6 Mum and the surface being vertical to each adjacent surface of plate material; washing with acid: HF, HNO3 and H2O or HF, H2SO4, HNO3 and H2O are used for preparing an acid solution in a container resisting acid corrosion, and the two welding pieces are respectively put into the acid solution for being washed at normal temperature; welding: a middle or high voltage vacuum electron-beam welding machine is used for welding one face of the each of the two welding pieces, and the depth of a welding line is one second to three fourths of the thickness of the plate material; after the concreting of the welding line and under the same welding condition, the other faces of the two welding pieces are welded, and the depth of the welding line is one fourth to three fourths of the thickness of the plate material. The process of the method has the advantages of simple steps, convenient operation, high welding quality and good straightness of the welded plate and solving the problem of great warp and deforming of the plate material existing in the welding of the thick plate materials.

Owner:NORTHWEST INSTITUTE FOR NON-FERROUS METAL RESEARCH

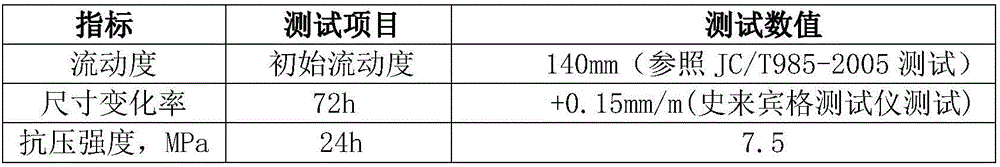

Binary system quick-drying thick-layer cement self-leveling mortar

The invention belongs to the technical field of building materials and specifically discloses binary system quick-drying thick-layer cement self-leveling mortar. The binary system quick-drying thick-layer cement self-leveling mortar is mainly composed of the following ingredients (by weight): 25-30% of ordinary Portland cement, 5-8% of sulfoaluminate cement, 1.5-3% of calcium oxide, 2-5% of fine sinking beads and 40-45% of dried river sand of 12-140 meshes, etc. According to the binary system quick-drying thick-layer cement self-leveling mortar, one-time construction thickness reaches 50 mm, existing ground artificial plaster can be directly replaced, construction speed is fast, construction period is greatly shortened, and flatness is high. After construction, the ground can be directly coated with floor paint, and wooden floorboards and PVC boards can be paved or large-sized flat bricks can be directly paved by the use of a glue for tiles by a thin-layer full adhesion method.

Owner:河南一方建材集团有限公司

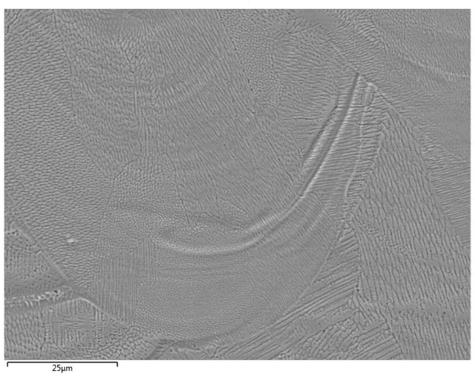

FeCoCrNi series high-entropy alloy selective laser melting in-situ additive manufacturing method and product

ActiveCN111085689AReduce manufacturing costReduce R&D costsAdditive manufacturing apparatusTransportation and packagingSelective laser meltingHigh entropy alloys

The invention provides a FeCoCrNi series high-entropy alloy selective laser melting in-situ additive manufacturing method. The method comprises the following steps: step 1, mixing mixed elemental metal powder with M-X alloy powder and / or N-Y alloy powder, wherein the mixed elemental metal powder at least comprises two of Fe, Co and Ni metal elemental powder, the M element in the M-X alloy powder is the metal element with the highest melting point in a high-entropy alloy, the N metal element in the N-Y alloy powder is the metal element with the lowest melting point in the high-entropy alloy, Xand Y are at least one metal element in the mixed elemental metal powder, and the molar number of each metal element in the mixed metal powder is the same; and step 2, carrying out laser additive manufacturing through laser 3D printing equipment to obtain the FeCoCrNi series high-entropy alloy. The product is good in forming effect and free of air holes and macroscopic cracks.

Owner:TIANJIN UNIV

Ferment bread and preparation method thereof

InactiveCN106942312AEnlarged stomataImprove chewinessPre-baking dough treatmentModified nutritive productsYeastFermentation

The invention discloses ferment bread and a preparation method thereof, and relates to the technical field of food processing. The preparation method of the ferment bread comprises the following steps of mixing fruits with saccharide and water to obtain a mixture, and fermenting the mixture under the condition of 28-30 DEG C for 5-7 days, so as to obtain fruit ferment liquid; adding the fruit ferment liquid to flour, and then performing fermentation at the temperature of 3-5 DEG C for 20-25h, so as to obtain natural ferment leavening dough; and uniformly mixing the flour with the natural ferment leavening dough and the water to obtain new dough, hitting the dough, then performing fermentation and shaping for many times, and then performing baking. The ferment bread made by the method has natural fruity fragrance and wheat fragrance, and besides, natural ferment leavening dough is adopted as yeast, so that the made ferment bread is beneficial for health of human bodies. The ferment bread is prepared by the preparation method of the ferment bread, the air holes of the bread are large, and the bread is chewy and good in mouth feel.

Owner:滕志刚

Preparation method of under-glaze red pottery tableware

InactiveCN101548843AReduce weightLower firing temperatureTable equipmentsClaywaresThermal insulationThermal stability

The present invention provides a preparation method of under-glaze red pottery tableware, including following steps: (1) select materials; (2) producing red ceramic clay; (3) biscuit firing, baking in oxidizing atmosphere with temperature of 950-1000 DEG, time 7.5-8 hours, heat insulation 7-8 hours; (5) cladding glaze, surface decoration processing; (6) baking color and drying in kiln, with a temperature of 740-760 DEG, time 3-4 hours, heat insulation 9-10 hours; (7) cladding transparent glaze, glaze firing with a temperature of 1050-1100 DEG, time 9-10 hours, heat insulation 11-12 hours; (8) checkout, packaging, warehousing. Applying the present invention, the red pottery tableware is provided with advantages of light weight, low baking temperature, low energy consumption, products easily weathering when breakage, reducing pollution to ecologic environment; and thermal stability of products is preferable, better preservation, high manufacturing yield; employing under-glaze decoration art, bright in color, fastness, elegant quality, conforming to life requirement of modern people.

Owner:翁汉荣 +1

Wallpaper foaming pulp

The invention discloses a wallpaper foaming pulp comprising the following components in percentage by weight: 25-45% of PVC resin powder, 20-35% of DOP, 5-15% of titanium dioxide, 10-20% of calcium carbonate, 2-5% of a foaming agent, 2-5% of a viscosity reducer, 0.5-1.5% of a stabilizing agent, 1-3% of a fire-proofing agent, 0.2-0.5% of a sterilizing agent and 1-3% of silicon dioxide. The wallpaper foaming pulp disclosed by the invention can be used for ensuring that foaming wallpaper is high in durability, good in moisture absorption effect and longer in service life.

Owner:ZHEJIANG CARLE KLEI WALLPAPER MFG

Jasminum sambac Ait. Large-leaf sunshine green tea preparation technique

ActiveCN101268793AStrong taste strong tasteFresh tastePre-extraction tea treatmentClimate change adaptationGreen teaTea leaf

The invention relates to a preparation method of a jasmine large-leaf ShaiQing tea which belongs to a tea leaf product, in particular to a tea made by a scenting technique. The tea provided by the invention is a product which is made by adopting the Yunnan large-leaf ShaiQing primary tea, magnolia and fresh jasmine flower to slowly scent for 12 to 14 hours at the low temperature of 36 to 42 DEG C. The made tea of the invention keeps the fine appearance and mouthfeel of the Yunnan large-leaf ShaiQing primary tea, at the same time, adds the fresh degree of fragrant of the jasmine flower and the magnolia, does not lose the fragrant after a long-term storage, and ensures that the strip of the tea keeps thick and large.

Owner:昆明七彩云南庆沣祥茶业股份有限公司

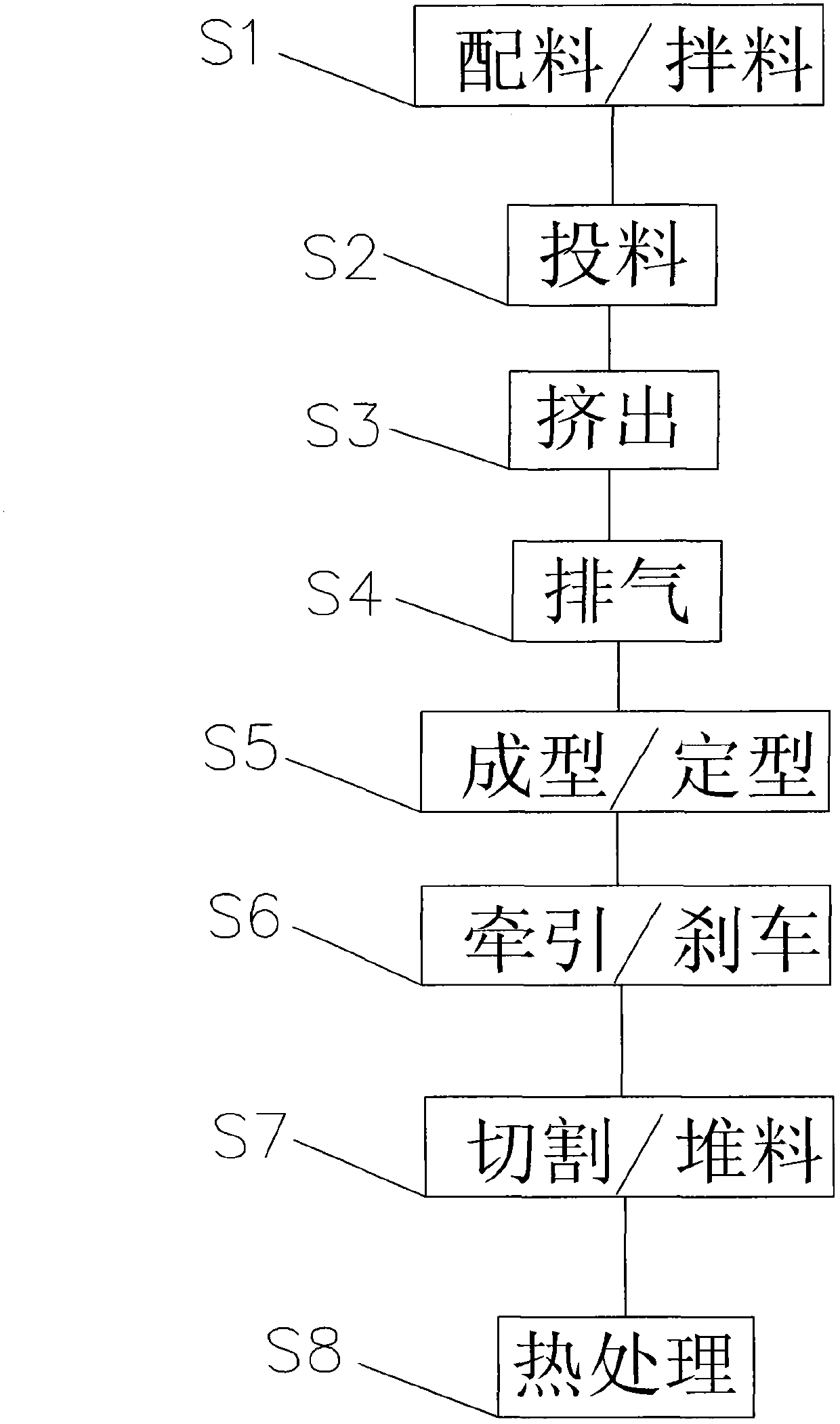

POM(polyformaldehyde) raw material rod production process

The invention relates to the technical field of polyformaldehyde, and particularly discloses a POM (polyformaldehyde) raw material rod production process. The POM raw material rod production process comprises the following steps of: a burdening / material mixing process, a material charging process, an extruding process, an exhaust process, a shaping / sizing process, a traction / brake process, a cutting / stockpiling process, and a heat treatment process. The POM raw material rod production process provided by the invention has the advantages that the extruding product is stable, the continuous production is realized, the qualification rate of a product is greatly improved, and the rejection rate is reduced; and meanwhile, the production efficiency is greatly improved, the energy is saved, the consumption is saved, the manufacturing cost is saved, the product structure is tight, an inner white core and an air hole are greatly improved, and the POM raw material rod production process has application and popularization values.

Owner:深圳市恩欣龙特种材料股份有限公司

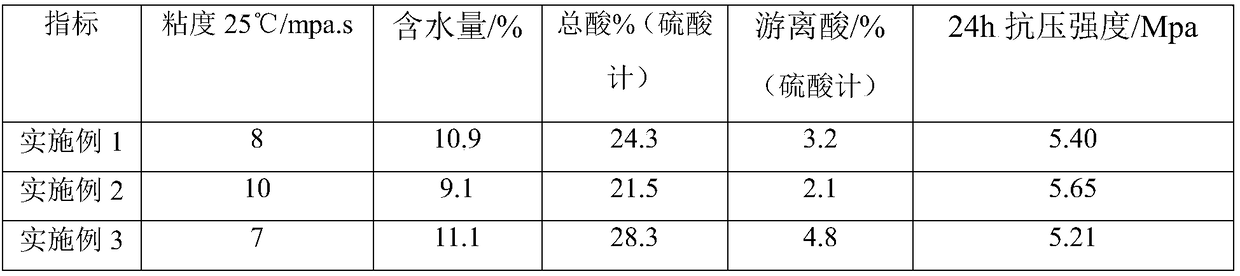

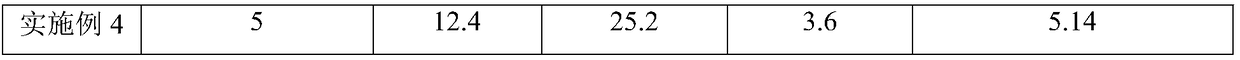

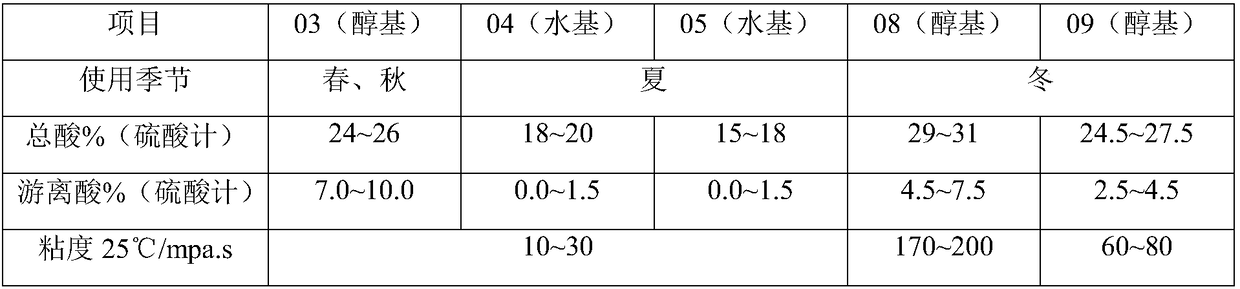

3D sand mold printing furan resin curing agent and preparing method thereof

ActiveCN108543908AAdvanced technologyEnlarged stomataAdditive manufacturing apparatusFoundry mouldsOrganic acidFuran

The invention relates to a 3D sand mold printing furan resin curing agent and a preparing method thereof. The curing agent is prepared through concentrated sulfuric acid, benzene series, organic acid,ethanol and a wetting agent, and has excellent properties that viscosity and the water content are low, free acid is low, and rapid curing can be achieved, wherein at the temperature of 25 DEG C, theviscosity is smaller than or equal to 10 mPa.s, the water content is smaller than or equal to 15%, and the free acid is smaller than or equal to 10%. Rapid hardening can be achieved, and the sand mold ink jetting printing usage requirement is met.

Owner:SUZHOU XINGYE MATERIALS TECH

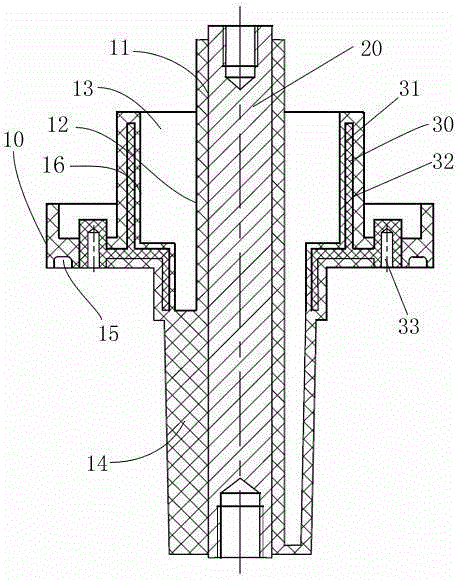

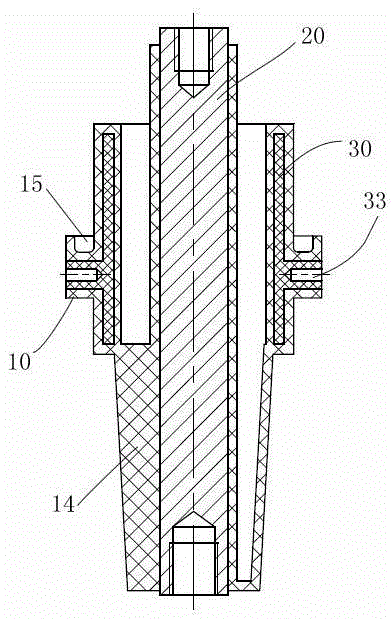

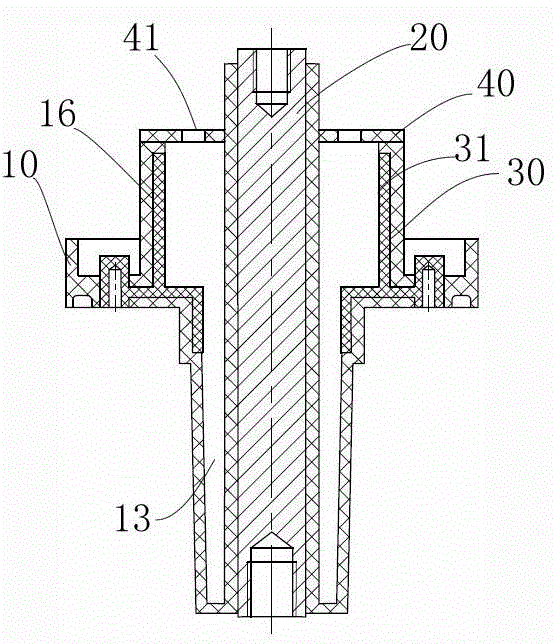

Insulating bush made of thermoplastic material and production method thereof

InactiveCN104916377AFast cooling and solidificationImprove structural strengthInsulating bodiesElectrical conductorPlastic materials

The invention relates to an insulating bush made of thermoplastic material and a production method thereof. The insulating bush comprises an insulting housing, a center conductor, and a shielding mesh. The insulating housing is formed based on casting by using a thermoplastic material; a through hole is formed in the center along the axial direction; and an annular inner cavity of the insulating bush is formed between the outer side surface of the through hole of the insulating bush and the inner side surface of the insulating bush. The center conductor is embedded into the through hole of the insulating housing. The shielding mesh is arranged inside the annular inner cavity of the insulating bush and is encircled by the insulating bush completely or partially. The shielding mesh encircles the center conductor. According to the invention, the structure is compact; the weight is light; and the bush can be installed conveniently. Because of the insulating housing made of the thermoplastic material, pores and small cracks can be eliminated; and the plastic material has a fast cooling and solidification speed. Moreover, the thermoplastic material can be repeatedly used after heating again, thereby realizing the good recycling property and eliminating the solidification process. Therefore, the production time is substantially reduced and the production efficiency is improved.

Owner:MOTIC XIAMEN ELECTRIC GRP

Epoxy waterproof paint

ActiveCN104327677AReduce internal stressImprove toughnessConjugated diene hydrocarbon coatingsEpoxy resin coatingsGlass fiberEmulsion

The invention discloses epoxy waterproof paint. The epoxy waterproof paint is prepared from the following raw materials in percentage by weight: 30%-40% of bisphenol A epoxy resin, 8%-15% of fluorocarbon emulsion, 5%-10% of organic silicon, 5%-10% of nano hollow glass fibers, 10%-18% of nitrile rubber, 10%-17% of sheet-shaped highly wear-resistant pigment filler, 0.5%-0.9% of a dispersant, 0.4%-0.8% of a defoaming agent, 0.4%-0.8% of a preservative, 0.2%-0.5% of a leveling agent and 15%-23% of deionized water. The epoxy waterproof paint disclosed by the invention is good in impact resistance and good in water resistance.

Owner:GUANGDONG TAISHI IND CO LTD

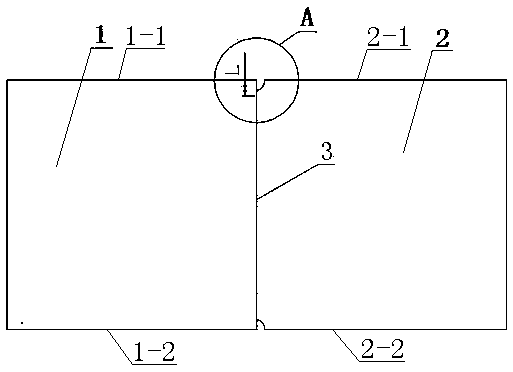

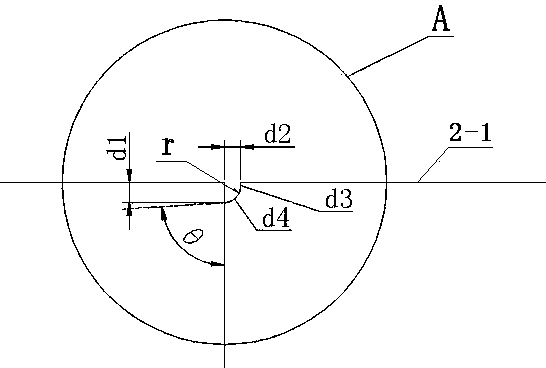

Welding method of laser tailor-welded plate

ActiveCN110480154AImprove stamping crackingImprove problems such as fatigue crackingLaser beam welding apparatusNotchingLaser

The invention discloses a welding method of a laser tailor-welded plate. The welding method of a laser tailor-welded plate comprises the following steps of, A, blanking, firstly blanking a first steelplate blank and a second steel plate blank into a first steel plate and a second steel plate; and the two ends of one longitudinal side edge of the second steel plate are correspondingly blanked by one process gap; B, tailoring plates, tailoring the first steel plate and the second steel plate to obtain tailoring welding edges, and enclosing the process gaps at the two ends of the first steel plate and the second steel plate into two tailor welding gaps; C, laser welding, firstly, making the laser travel 0.5mm along the welding direction at one end of the gap side edge of the first steel plate of the tailor welding gap, starting the laser arc, then carrying out the welding along the tailoring welding edge of the first steel plate and the second steel plate to form a welding joint, and finally, moving the laser to the other tailor welding gap, and stopping welding when the laser advances to the other tailor-welding gap and is 0.5mm away from the other end of the gap side edge of the first steel plate. Compared with the prior art, the welding method of a laser tailor-welded plate can solve the problem that defects are easy to occur at both ends of the welding joint of the existing laser tailor-welded plate.

Owner:DONGFENG LIUZHOU MOTOR

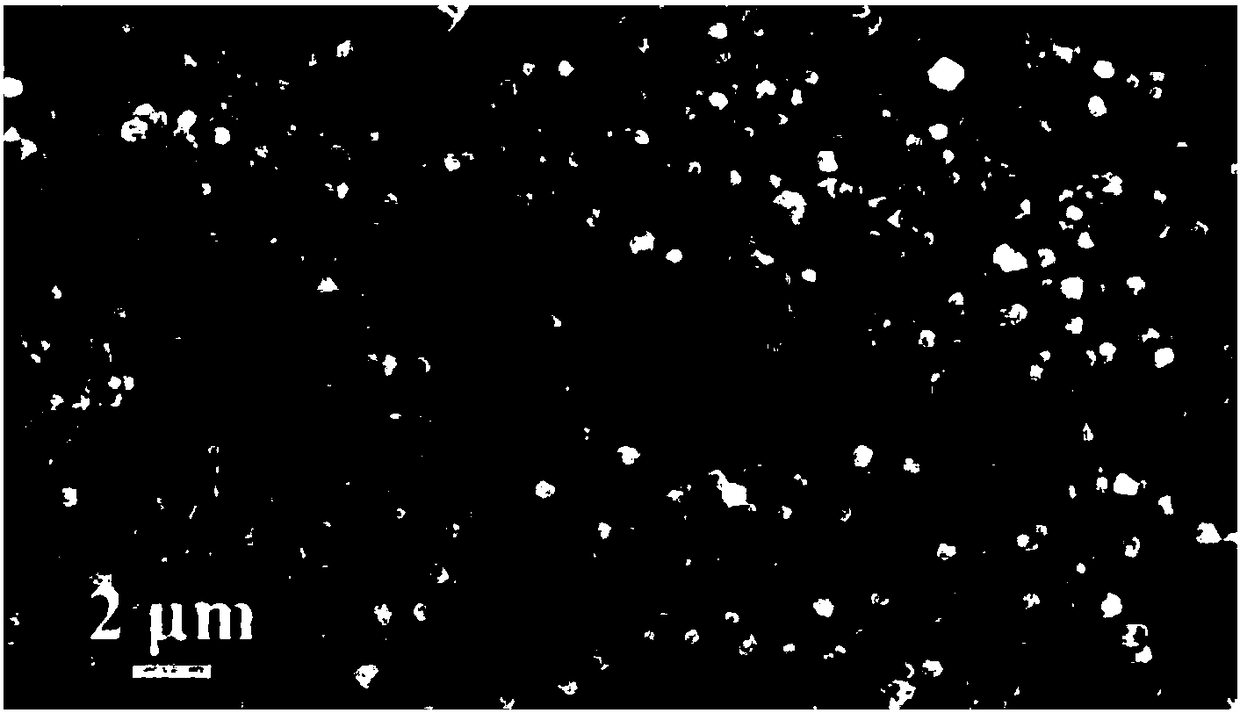

Preparation method of raw material powder for high-entropy alloy selective laser melting additive manufacturing

ActiveCN111168053AImprove molding efficiencyAchieve near net shapeAdditive manufacturing apparatusIncreasing energy efficiencySelective laser meltingHigh entropy alloys

The invention provides a preparation method of raw material powder for high-entropy alloy selective laser melting additive manufacturing. According to the technical scheme, through a raw material mixing method, alloy powder or simple metal powder is matched with alloy powder to obtain high-entropy alloy powder, so that melting points of all the composition powder in the high-entropy alloy powder tend to be similar, and wherein the mole numbers of all metal elements in the high-entropy alloy powder are the same. The invention further discloses the application of the preparation method of the raw material powder for high-entropy alloy selective laser melting additive manufacturing in a high-entropy alloy selective laser melting in-situ additive manufacturing process, and an obtained high-entropy alloy product is good in forming effect and free of pores and macroscopic cracks.

Owner:TIANJIN UNIV

Preparation method for sodium carboxymethylcellulose degradation product and purpose of working as frozen dough modifier

ActiveCN107041399AControl growth rateReduce sizeDough treatmentPre-baking dough treatmentBiotechnologyFood additive

The invention discloses a preparation method for sodium carboxymethylcellulose degradation products and belongs to the field of food additives. Sodium carboxymethylcellulosewith substitute degree of 0.9 to 1.5 and then dissolved into phosphate buffer with a pH value of 5.0 to prepare a sodium carboxymethylcellulose solution with weight concentration of 2%; and then cellulose is added for degradation and a sodium carboxymethylcellulose degradation product with viscosity of 100 to 700mPa.s can be achieved. The degradation product is applied for a frozen dough modifier and the addition amount is 0.3 to 1% of the flour; the dough structure can be protected during the refrigeration by the use of the degradation product; content of water capable of being frozen can be reduced for the dough; a finished product volume can be increased and a tissue structure can be improved; and bread taste and flavor can be improved.

Owner:HUAZHONG AGRI UNIV

Novel plant growth regulator composition and preparation method thereof

InactiveCN107624760ABreak growth dormancyImprove developmentBiocidePlant growth regulatorsDiseaseSolvent

The invention relates to a novel plant growth regulator composition. The novel plant growth regulator composition contains the following components: 0.2-0.5 part of a brassinolide compound, 1-3 partsof 5-aminolevulinic acid salt, 300-500 parts of sodium salicylate and 500-700 parts of an auxiliary material. A preparation method of the novel plant growth regulator composition comprises the following steps: uniformly stirring sodium salicylate and the auxiliary material to obtain a mixture, dissolving the brassinolide compound into a solvent, adding octyl phenol-10, adequately and uniformly stirring to obtain a second mixture, uniformly spraying the second mixture to the mixture, airing, and crushing, so as to obtain powder. According to the novel plant growth regulator composition, the growth and dormancy of crops can be broken through, the seed germination can be promoted, the survival rate of plants can be increased, the differentiation of adventive roots of calluses can be induced;the allocation of nutrients is adjusted, the sugar content of fruits is increased, and the disease resistance and stress resistance are improved; and the plant photosynthesis is improved. The preparation method has the advantages of simplicity, convenience in use, low cost and no pollution.

Owner:郑州卓越农业科技有限公司

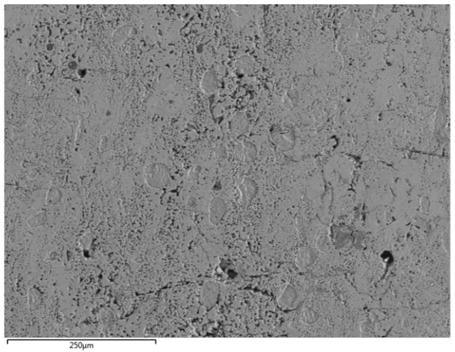

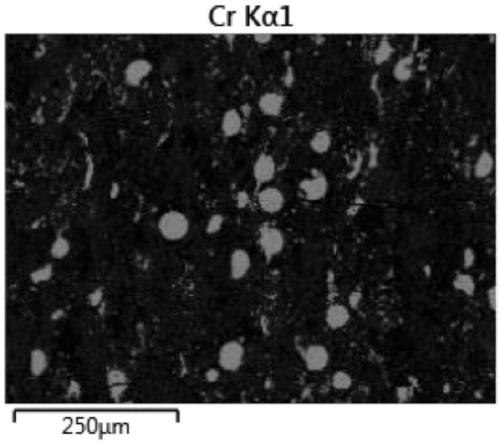

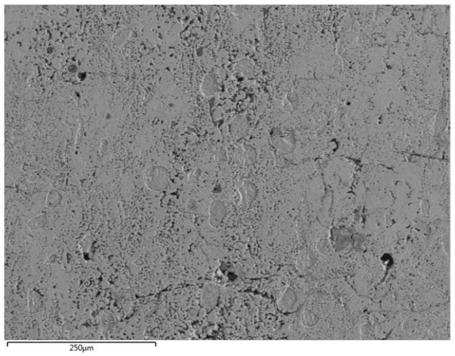

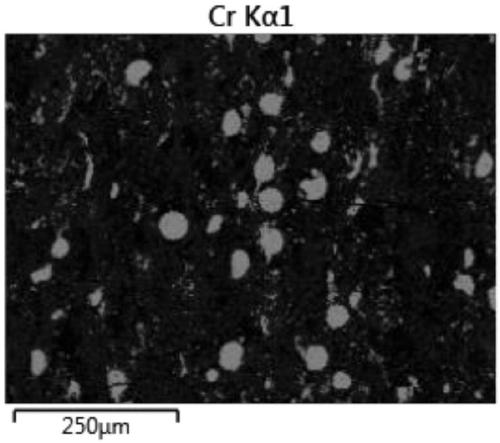

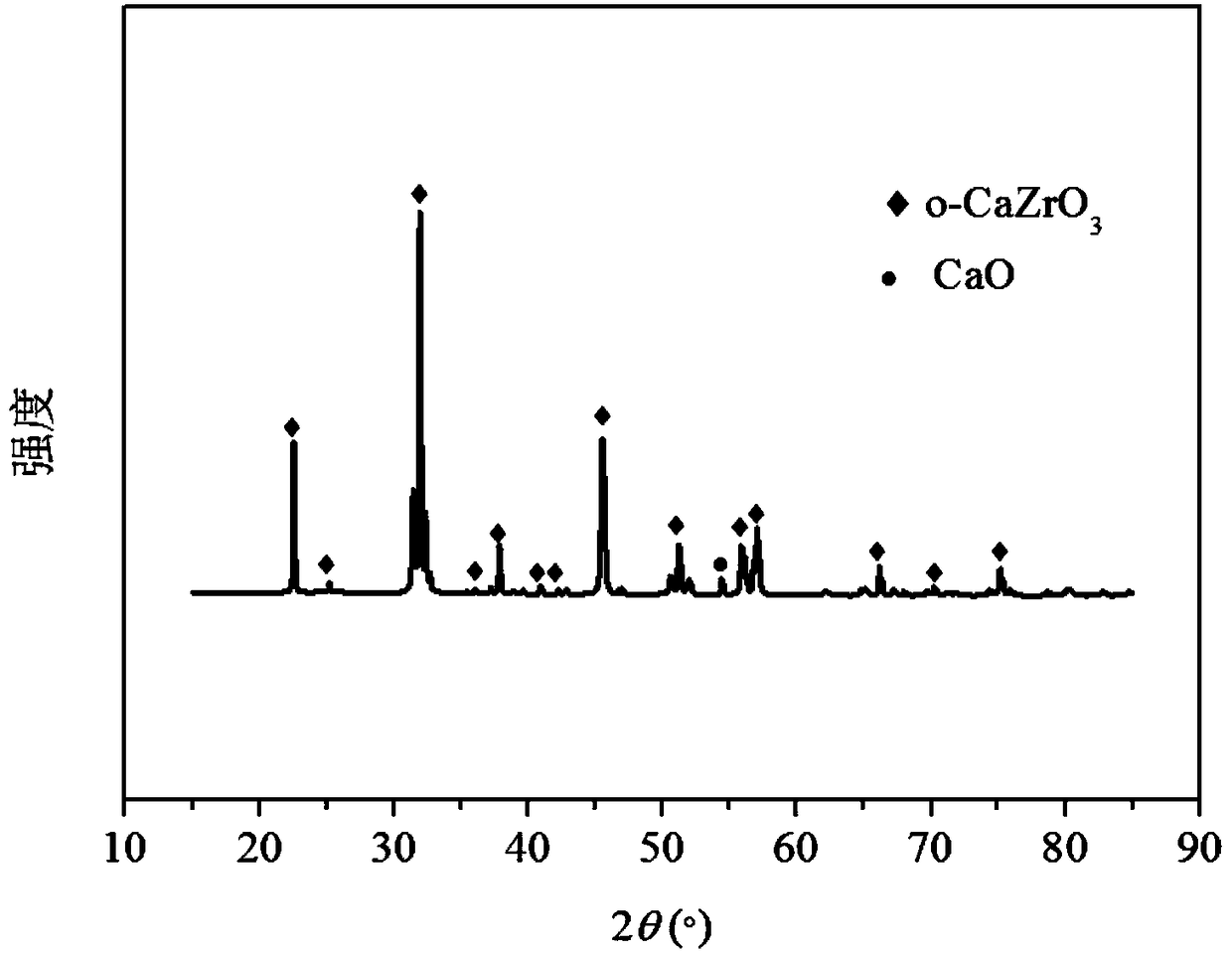

Calcium zirconate material doped with metal and preparation method and application of calcium zirconate material

InactiveCN108529671APossess electronic conductivityLow costCell electrodesZirconium compoundsOxygen ionsZirconate

The invention relates to a calcium zirconate material doped with metal and a preparation method and application of the calcium zirconate material. The calcium zirconate material doped with metal comprises the following raw materials of: calcium carbonate powder, zirconia powder and chromium oxide powder, wherein the molar ratio of the total of the zirconia powder and chromium oxide powder to the calcium carbonate powder is 1:1, and the chromium oxide powder accounts for 0.05-0.15, by mole, of the total of the zirconia powder and chromium oxide powder. The calcium zirconate material doped withchromium has both oxygen ion conductivity and electron conductivity at the same time, and has low price, excellent mechanical properties and stability. The preparation method of the calcium zirconatematerial doped with chromium has a simple process and low cost, the prepared calcium zirconate material doped with chromium has few pores, and the compactness and mechanical properties are improved greatly; the calcium zirconate material doped with chromium can be applied to a dense diffusion barrier layer in an oxygen sensor, a cathode of a solid oxide fuel cell or an oxygen separation membrane.

Owner:NORTHEASTERN UNIV

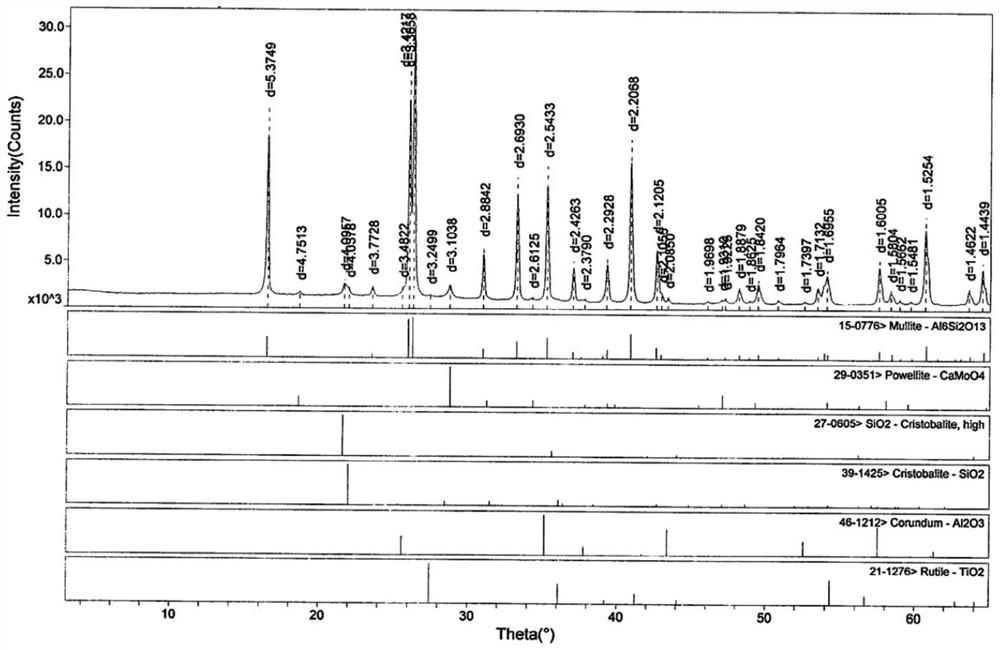

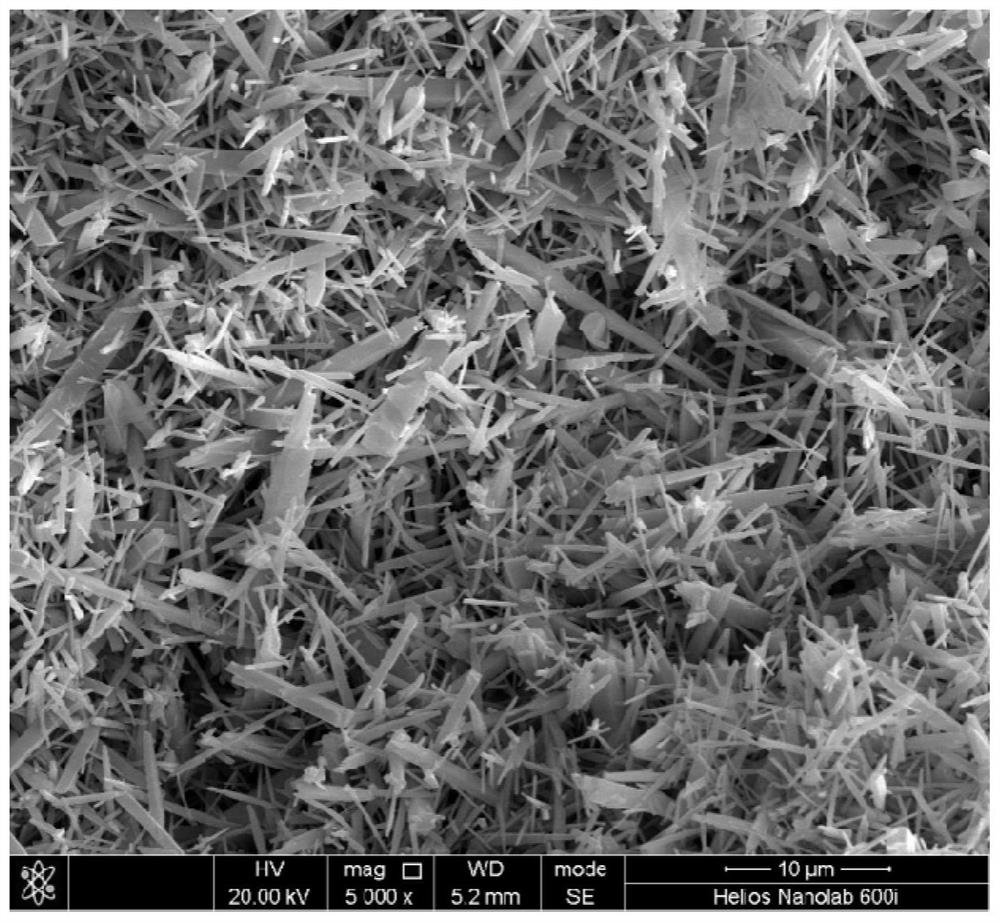

Lightweight and high-strength ceramic decorative plate and preparation method thereof

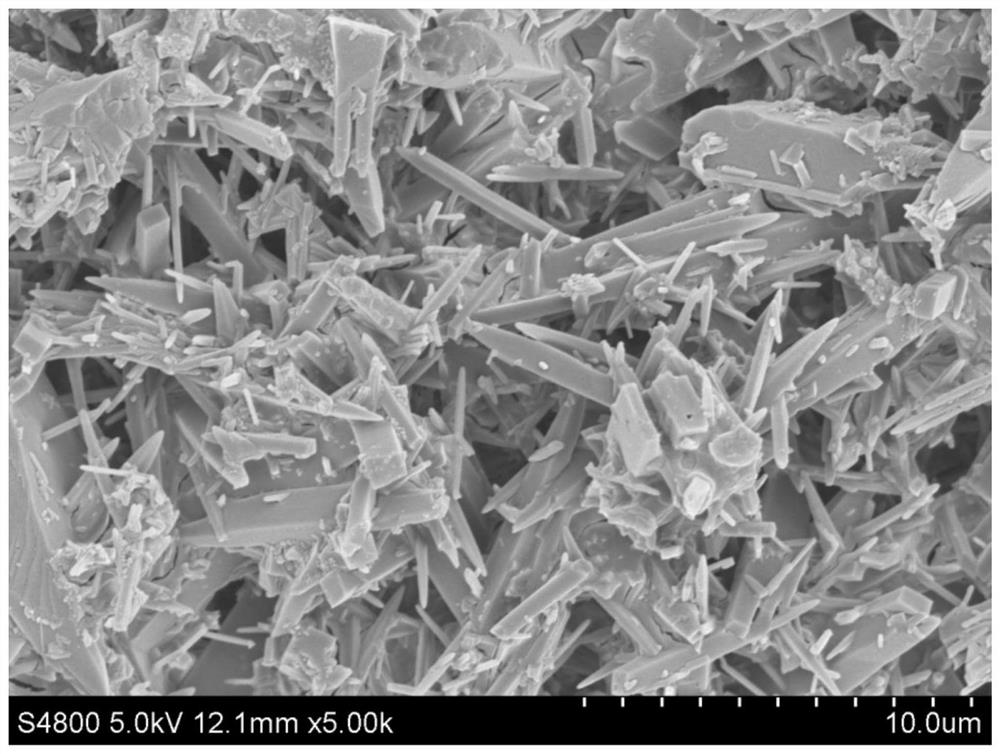

ActiveCN111807812AHigh strengthEnlarged stomataCeramic materials productionCeramicwareCompression moldingMullite

The invention provides a lightweight and high-strength ceramic decorative plate and a preparation method thereof. The lightweight and high-strength ceramic decorative plate is prepared by taking ballclay and calcined bauxite as raw materials and a mineralizer, a sintering aid, a reinforcing agent and a dispersing agent as auxiliary materials through the procedures of ball milling, spray drying, compression molding, ink-jet printing and glazing, two-time sintering, polishing and hole sealing. A large number of mullite whiskers are generated in situ in a ceramic body under the low-temperaturecatalytic action of the mineralizer and the sintering aid, so the strength of the lightweight ceramic plate is improved; and meanwhile, due to the scattering effect of a plurality of micropores in thelightweight and high-strength ceramic decorative plate on light, a green body has high whiteness, the procedure of applying whitening ground coat in the conventional procedure is omitted, the technological process is simplified, and the lightweight and high-strength ceramic decorative plate has a good decorative effect. In addition, through the hole sealing procedure of the side face and the bottom face of a ceramic tile, the moisture absorption expansion phenomenon in the using process of a traditional porous ceramic plate is avoided.

Owner:GUANGDONG SUMMIT CERAMIC CO LTD +2

Fuel cell pore sealing method

The invention belongs to the technical field of graphite fuel cell pore sealing, and particularly relates to a technology for conducting pore sealing on graphite bipolar plates in a vacuum pressing mode. According to the technical scheme, the fuel cell pore sealing method includes the steps that a graphite bipolar plate is put into vacuum equipment, an epoxy resin solution is infused into the graphite bipolar plate in a vacuum pressing mode, standing is conducted in an environment with the vacuum degree of 0.8-1.5 MPa and the pressure of 0.5-1 MPa, the epoxy resin residual amount in the graphite plate is increased with the passing of time, and after the epoxy resin solution infused into the graphite bipolar plate is completely solidified, fuel cell pore sealing is completed. The porosity of the graphite plate is reduced, and by means of the impregnation technology, the porosity of the graphite plate is reduced by 95% or above.

Owner:浙江纽能新能源科技有限公司

Jun porcelain sintering process

InactiveCN106336203AEnlarged stomataStrong glaze absorption abilityClaywaresFree coolingRoom temperature

The invention relates to a jun porcelain sintering process. The jun porcelain sintering process comprises the steps of bisque firing, glazing and glaze firing. The bisque firing step comprises the following sub-steps that 1, green body inspection is performed: finished green bodies to be put in a kiln is inspected according to the standard, and the qualified can be put in the kiln after inspection; 2, kiln charging is performed: the qualified finished green bodies are loaded on a supported kiln car shed plate according to different categories in a classified mode; 3, access to the kin is performed: a charged kiln car is slowly pushed into the kiln at a constant speed, and a kiln door is closed; 4, firing is performed: the temperature in the kiln gradually rises from normal temperature to 900 DEG C within 4 hours, and then fire is ceased; 5, cooling is performed: the temperature in the kiln is naturally reduced to 100 DEG C, then the kiln door is opened to avoid the phenomenon that the green body suddenly cracks due to too quick temperature reduction, the kiln car is pulled out at the moment, and the fired green body is taken. The jun porcelain sintering process has the advantages of being reasonable in technological process, low in production cost and high in finished product pass percent.

Owner:温书强

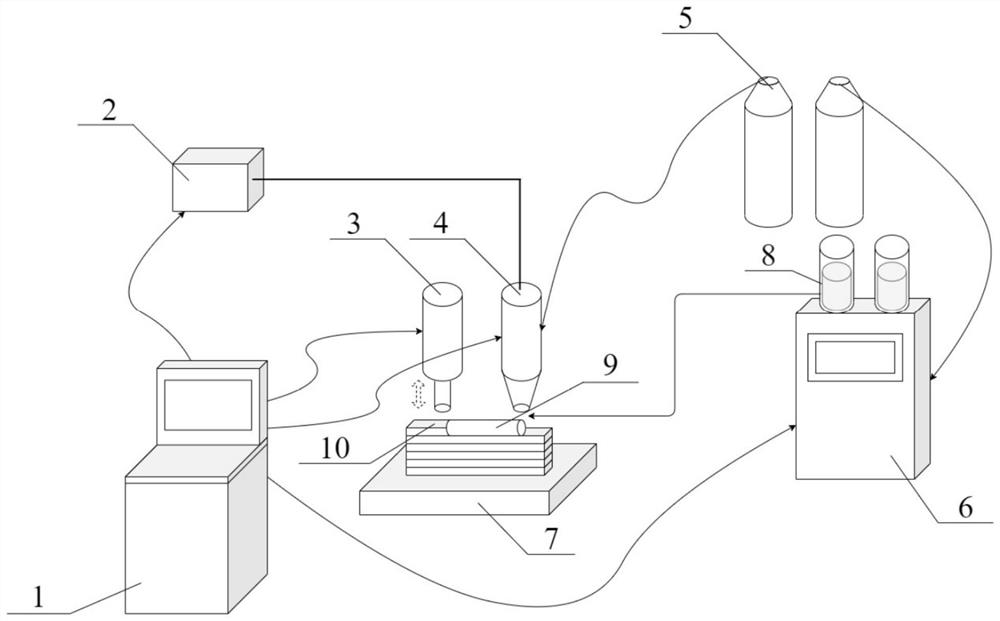

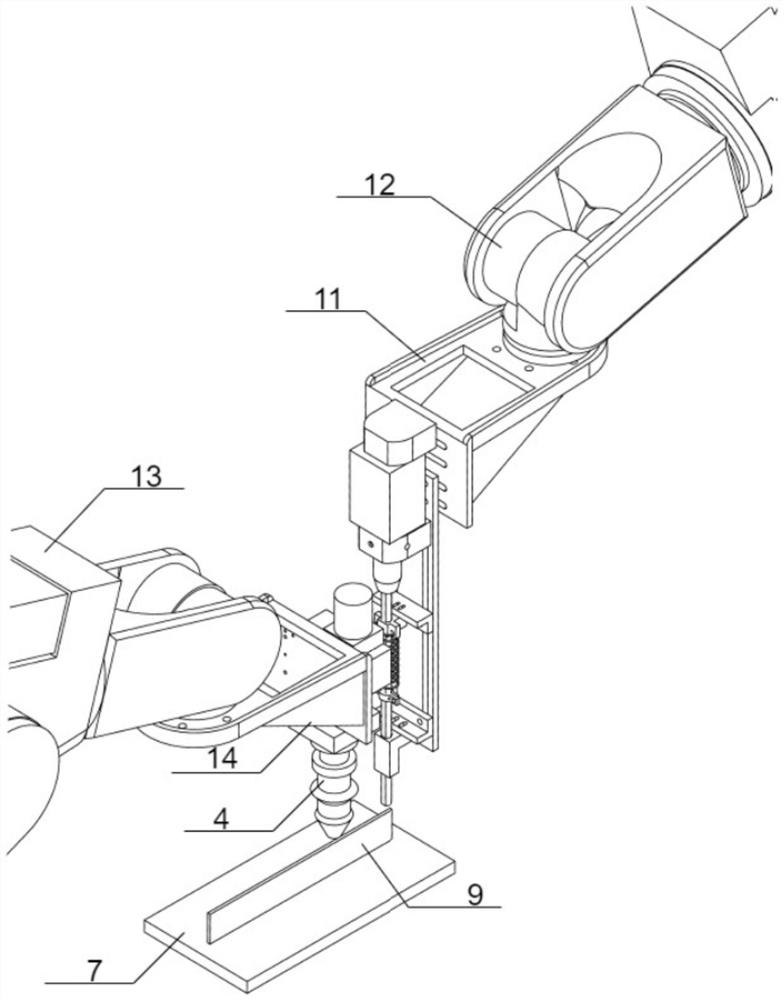

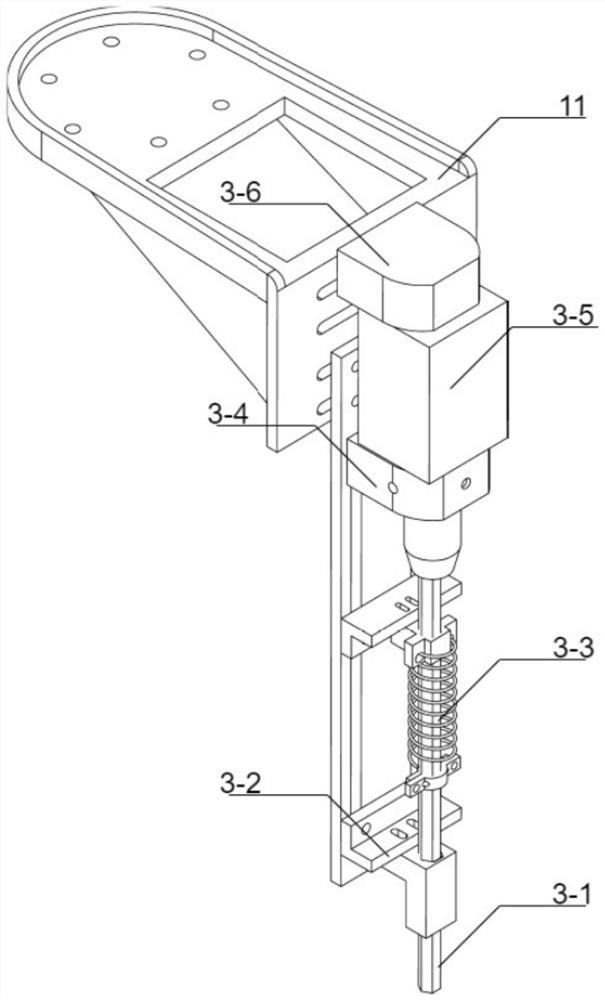

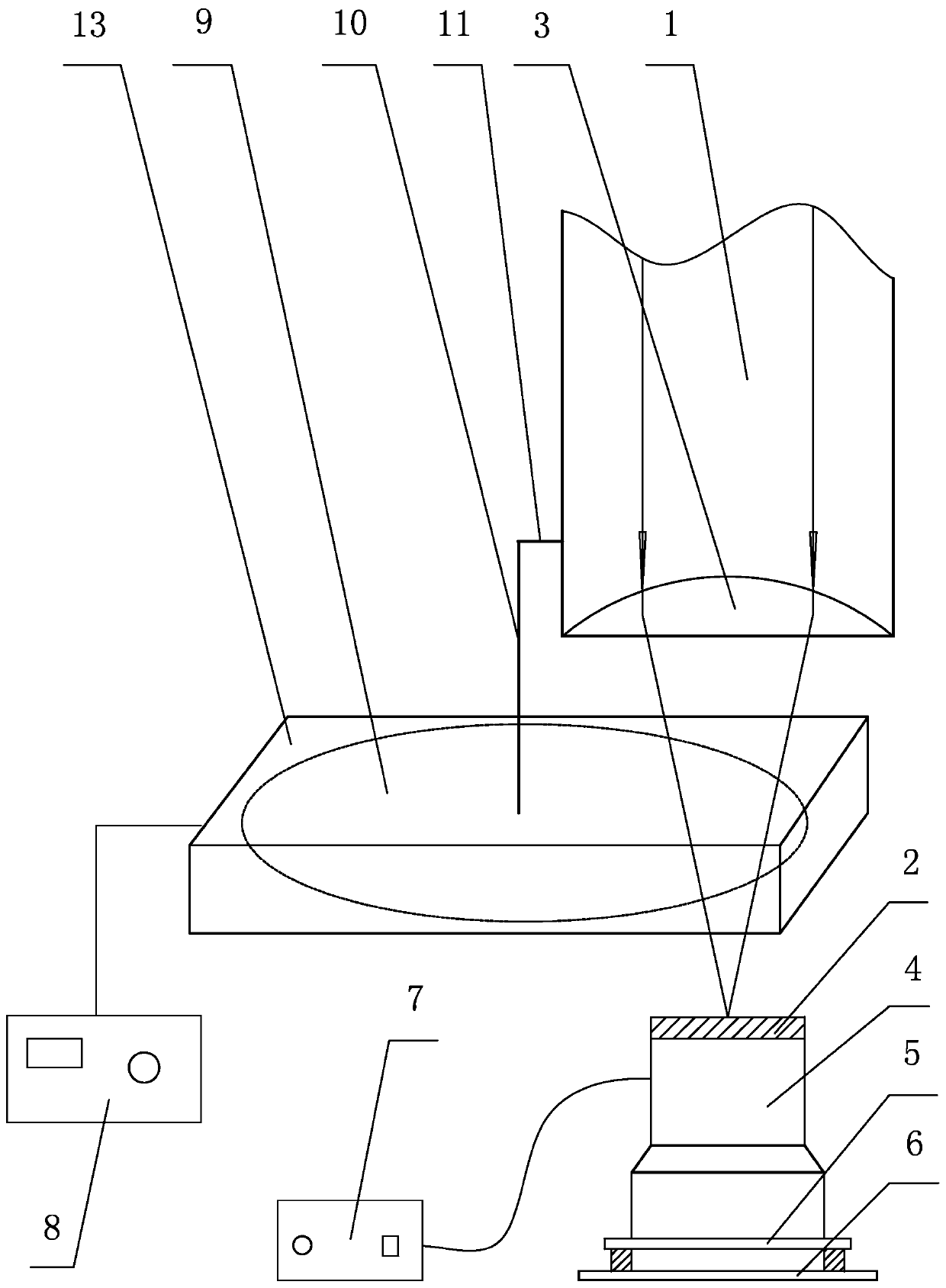

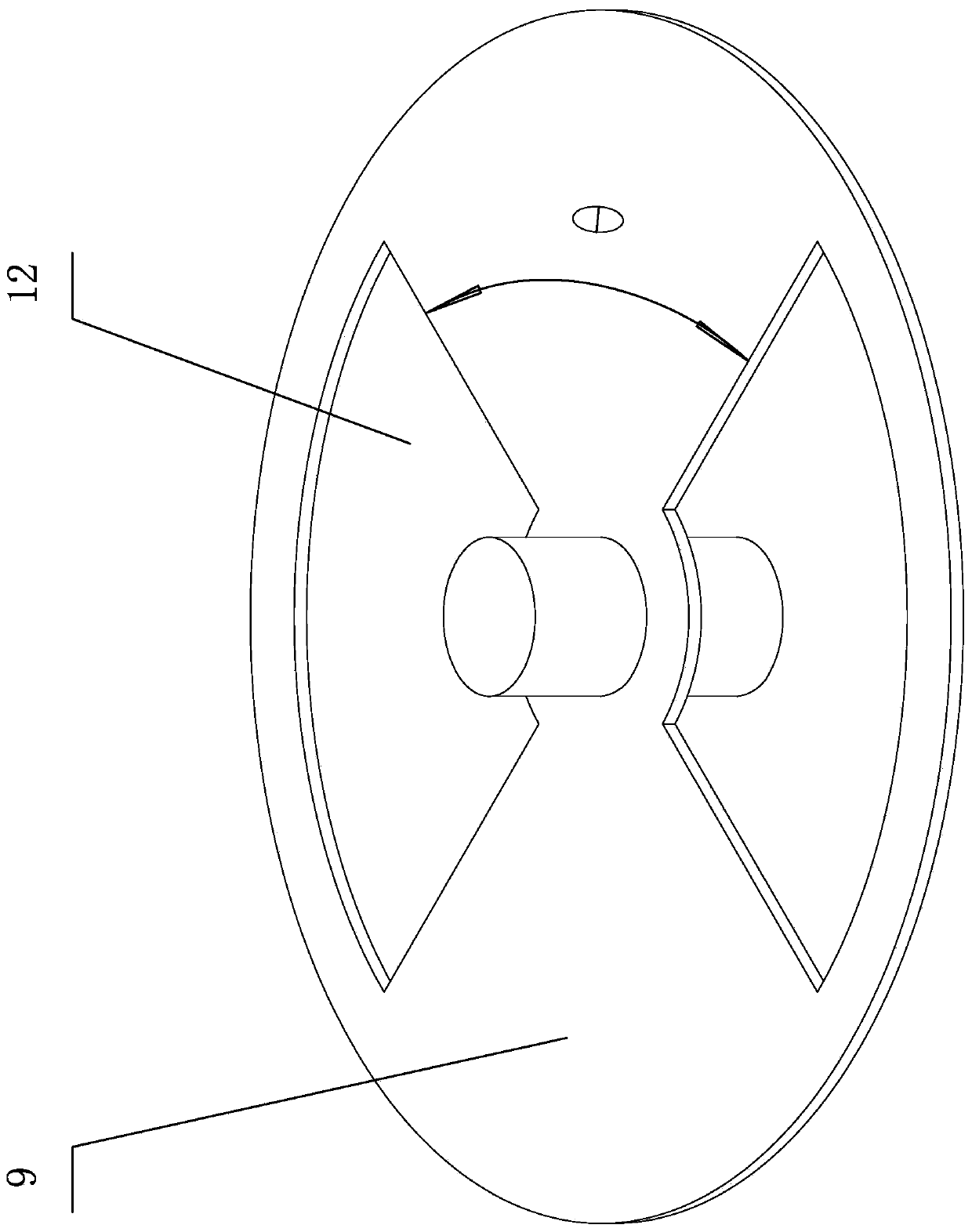

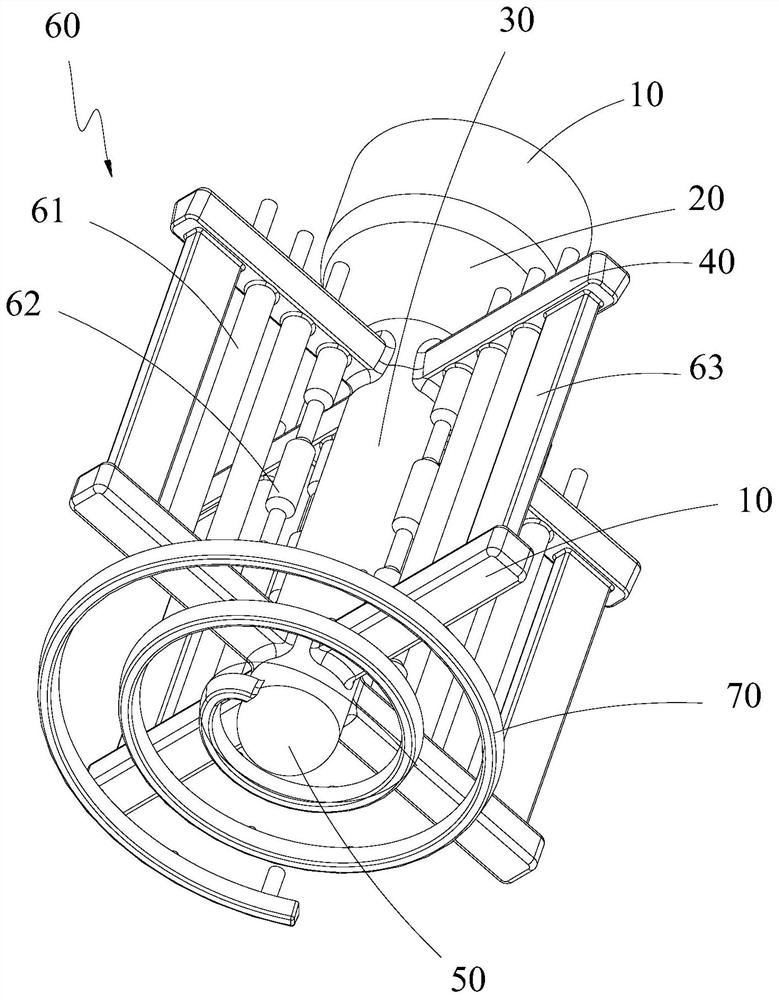

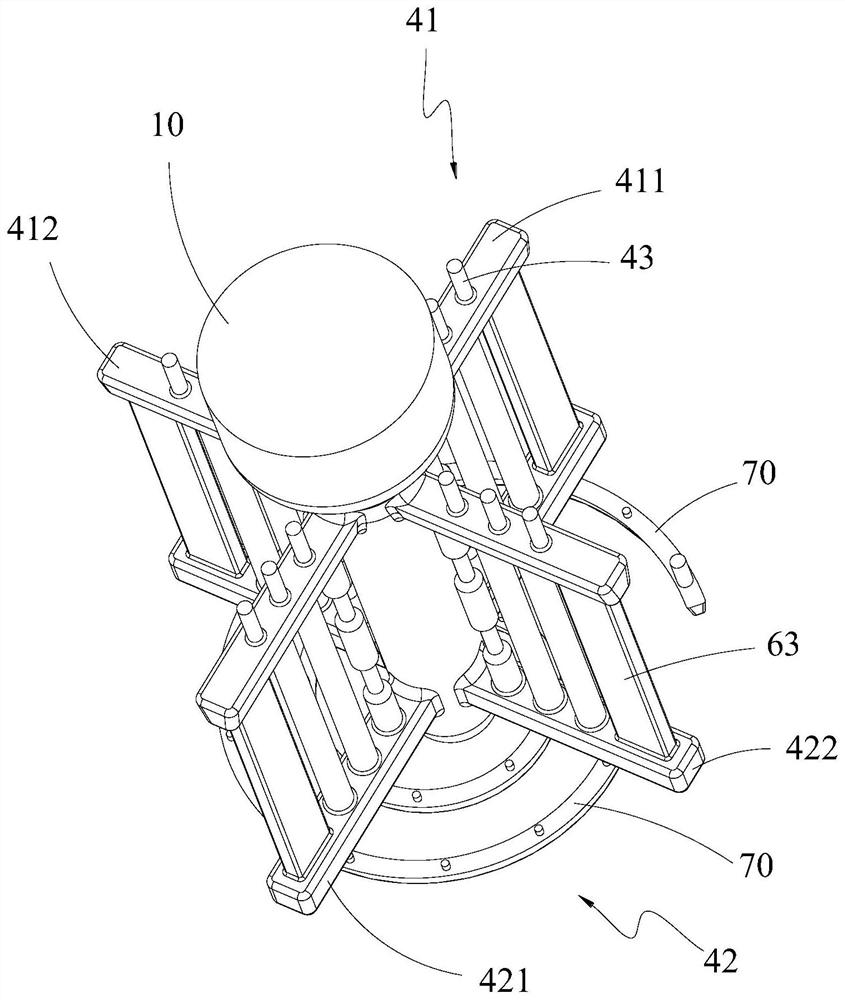

Synchronous hammering shape control device and method for metal component additive manufacturing

ActiveCN113145861ARefining solidified tissueEnlarged stomataAdditive manufacturing apparatusIncreasing energy efficiencyProcess engineeringAdditive layer manufacturing

The invention discloses a synchronous hammering shape control device and method for metal component additive manufacturing. The device comprises a control device body, an additive deposition device, a synchronous hammering device, a clamping device and a moving device. The device is characterized in that the synchronous hammering device is installed on a synchronous hammering moving device through the clamping device and keeps synchronous hammering movement with an additive deposition head. The method is characterized in that the synchronous hammering moving device and the additive deposition head keep synchronous hammering movement. The device and the method have the beneficial effects that a solidification structure of an additive manufacturing metal component can be obviously refined, air hole and crack defects of the additive manufacturing metal component can be obviously improved, the residual stress of the additive manufacturing technical component can be obviously eliminated, deformation generated in the forming process of the additive manufacturing metal component can be controlled, the density of the additive manufacturing metal component can be improved, pollution is avoided, and the process application range is wide.

Owner:DALIAN UNIV OF TECH

Ni-Zn high-strength cupronickel alloy and preparing method thereof

InactiveCN106086517AImprove performanceThe tensile strength corrosion degree meetsCupronickelColor intensity

The invention discloses Ni-Zn high-strength cupronickel alloy and a preparing method thereof. The Ni-Zn high-strength cupronickel alloy is prepared from, by weight, 20-40 parts of Ni, 30-35 parts of Zn, 20-30 parts of Mn, 12-18 parts of P, 4-7 parts of Fe, 5-15 parts of Al and the balance Cu. The performance of the cupronickel alloy is higher, tensile strength and corrosion resistance can better meet the requirement of artware, the specific color intensity and hardness of cupronickel alloy can be maintained for artware produced in the later stage, and environment friendliness is higher and daily use requirements of people are better met. The cupronickel alloy contains zinc which can be dissolved in copper nickel in a solid state to generate a solution strengthening effect, and corrosion resistance is also realized. The cupronickel alloy has high strength and corrosion resistance, high elasticity, attractive appearance and low price, and cost can be saved.

Owner:WUHU CHUJIANG ALLOY COPPER

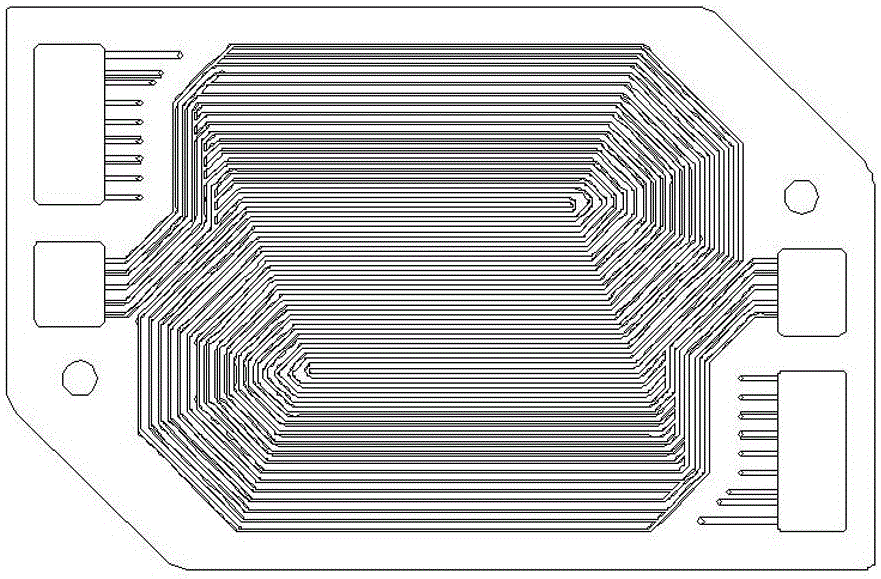

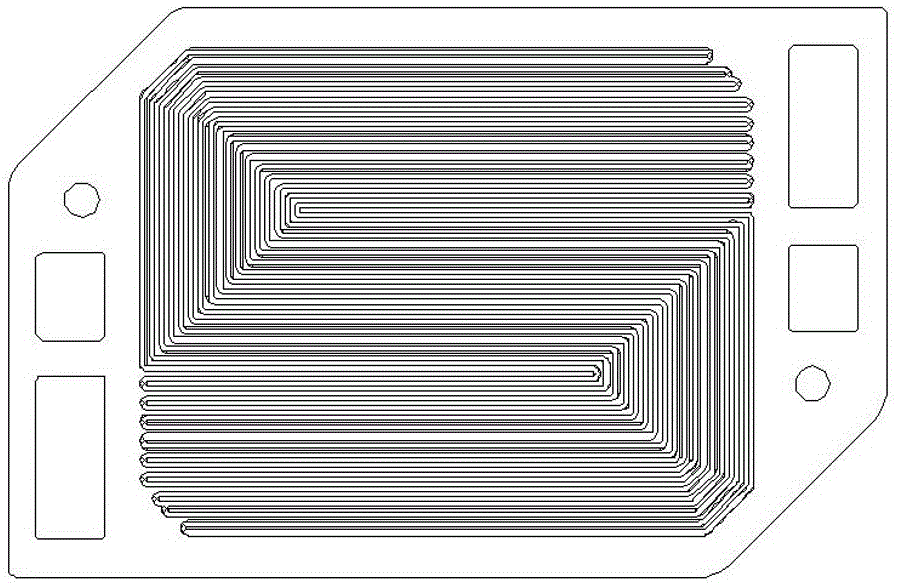

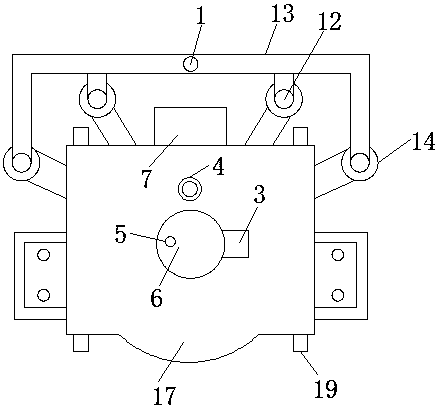

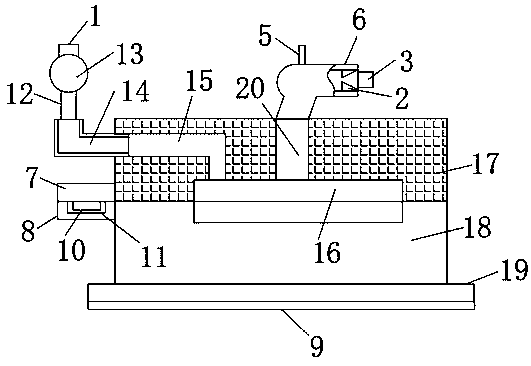

Continuous laser and ultrasonic composite surface micromachining system and method

PendingCN110052703AImprove surface propertiesEnhanced convective heat transferLaser beam welding apparatusVibration amplitudeNumerical control

The invention discloses a continuous laser and ultrasonic composite surface micromachining system and method. The system comprise a lens for focusing a laser beam of a continuous laser on a target material, a laser action time adjusting device and a target material up-down vibration amplitude adjusting device; the target material up-down vibration amplitude adjusting device comprises an ultrasonicamplitude transformer controlled by an ultrasonic generator, the amplitude transformer is mounted on a CNC numerical control platform through a fixing clamp, and the target material is mounted on theamplitude transformer; and the laser action time adjusting device comprises a light blocking turntable which controls the rotating speed of a speed regulator, light transmission ports for adjusting the laser passing ratio are uniformly distributed on the upper circumference of the light blocking turntable, and the position of the light blocking turntable between the lens and the target material is adjusted by a lifting mechanism and a left-right moving mechanism. According to the continuous laser and ultrasonic composite surface micromachining system and method, the surface performance of thetarget material is improved by utilizing the laser melting quenching principle, the target material is fixed on the ultrasonic amplitude transformer, the convection heat exchange of the surface of the target material is accelerated, the cooling effect is enhanced, the molten slag is thrown out, the processing area is homogenized, and grains are refined.

Owner:GUILIN UNIV OF ELECTRONIC TECH

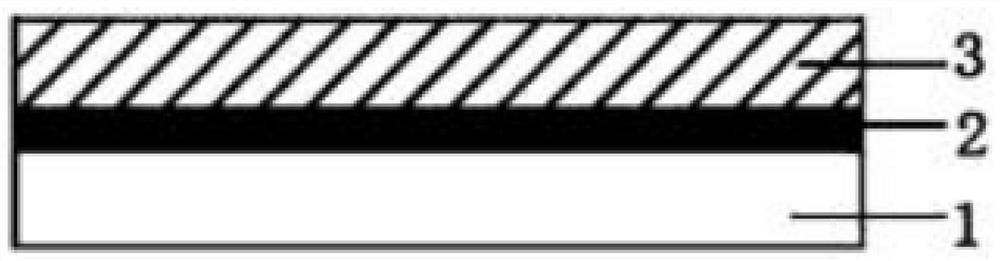

Intelligent temperature-adjusting decorative ceramic plate and preparation method thereof

ActiveCN111792911AHigh strengthEnlarged stomataSynthetic resin layered productsCeramicwareInsulation layerGraphite

The invention discloses an intelligent temperature-adjusting ceramic decorative plate and a preparation method thereof. The intelligent temperature adjustment ceramic decorative plate comprises a ceramic phase change composite decorative layer, a graphene heating film and a heat insulation layer, the ceramic phase change composite decorative layer is formed by compounding a phase change material and a whisker reinforced porous ceramic decorative plate through a melt infiltration process, and phase change temperature adjustment, bearing and decoration functions are integrated. The preparation method comprises the following steps: preparing the high-strength high-porosity whisker reinforced porous ceramic decorative plate; melting and infiltrating the phase change material to prepare the ceramic phase change composite decorative layer; and the ceramic phase change composite decorative layer, the graphene heating film and the heat insulation layer are bonded and compounded. Compared withthe prior art, the preparation method has the following advantages: the phase change material and the decorative plate are compounded into a whole, so the structure is simplified, the thickness is reduced, and efficient heat transfer is facilitated; and meanwhile, the graphene heating film is assisted, so efficient heating can be achieved when the air temperature is cold, the indoor temperature stability is improved, and the heating power utilization cost is saved.

Owner:新明珠(广东)新材料有限公司 +2

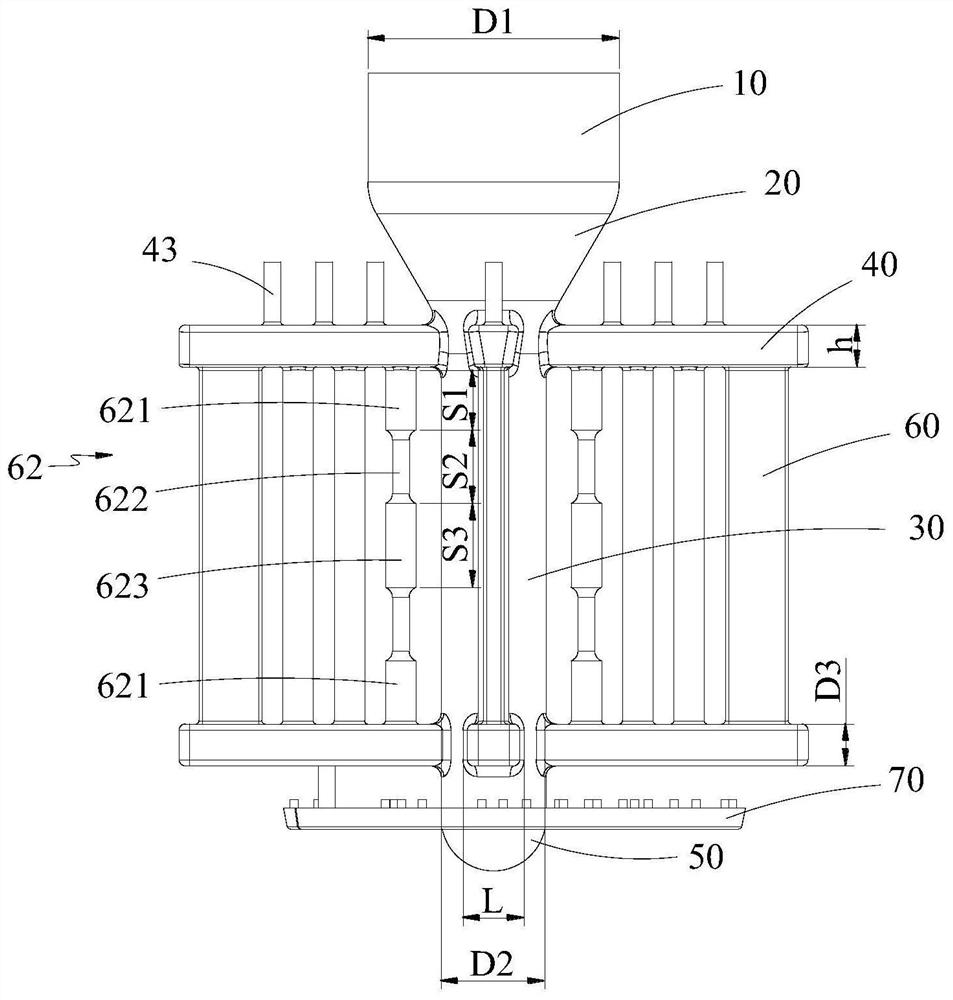

Gating system for casting alloy standard samples and manufacturing method of mold shell

ActiveCN112317692AEnlarged stomataImprove loose defectsAdditive manufacturing apparatusFoundry mouldsMold fillingMetallic materials

The invention is applicable in the technical field of precision casting of metal materials, and provides a gating system for casting alloy standard samples. A sprue cup, a feeding structure connectedwith the sprue cup, a sprue connected with the feeding structure, a cross gate perpendicular to the sprue and multiple ingates connected with the cross gate are arranged, the shapes of the ingates areconsistent with the shapes of prefabricated standard samples, and the sectional areas of the sprue cup, the feeding structure, the sprue and the cross gate are sequentially and progressively decreased, so that when molten metal is poured from the sprue cup, the gravity difference can be generated, stable mold filling can be achieved, the defects of pores and looseness of castings can be overcome,grains can be refined and equiaxed grains can be increased through improvement of a liquid metal temperature field in the solidification process of the molten metal, defects such as segregation are reduced, the standard samples with relatively-uniform structures are obtained, the multiple standard samples can be obtained through one-time pouring, the casting efficiency is greatly improved, and the production and time costs are saved.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

Check valve body steel casting tool and manufacturing process thereof

PendingCN110216244AShorten flushing timeImprove high temperature strengthFoundry mouldsFoundry coresCheck valveSteel casting

The invention relates to the technical field of valve body casting, in particular to a check valve body steel casting tool. The steel casting tool comprises an upper mold and a lower mold, wherein a group of positioning mechanisms are further arranged between the upper mold and the lower mold; molding chambers with the same size are formed in the middles of the opposite sides of the upper mold andthe lower mold; the middle of the upper end of the upper mold is obliquely provided with a ventilating seat; one side of the interior of the ventilating seat is provided with a sand concealed head; four inner runners penetrating through the upper mold are formed in one side of the inner of the upper mold; one end of each inner runner is fixedly inserted with a L-shaped supporting pipe, L-shaped supporting pipes communicate with the molding chambers through the inner runners; the upper ends of the L-shaped supporting pipes are inserted with connecting pipes; the L-shaped supporting pipes communicate with a cross runner through connecting pipes; and the middle of the upper end of the cross runner is provided with a earthenware pipe runner penetrating through the cross runner. With the casting tool, the structure is stable, and the defects of sand holes, air holes, shrinkage holes and cracks casing in casting are overcome.

Owner:福建大通互惠精密铸造有限公司

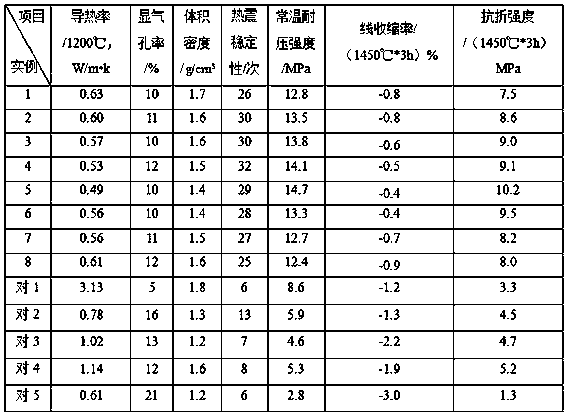

Refractory castable used for steel ladle and preparation method thereof

The invention belongs to the technical field of refractory materials, in particular to a refractory castable used for steel ladle and a preparation method thereof. The refractory castable is preparedfrom the following raw materials in parts by weight: 40-60 parts of micropore corundum aggregate, 10-30 parts of mullite, 10-20 parts of kieselguhr, 3-5 parts of attapulgite clay, 30-40 parts of cement, 1-5 parts of silicon carbide, 5-15 parts of silica powder, water reducer and polypropylene fiber, wherein the water reducer occupies 0.2-0.5% of total mass of the above raw materials, and the polypropylene fiber occupies 0.03-0.1% of total mass of the above raw materials; the particle size of the micropore corundum aggregate is 1-5mm, the bore diameter of the micropore corundum aggregate is 0.5-1.2mu m, the apparent porosity of the micropore corundum aggregate is 4-10%, and the volume density of the micropore corundum aggregate is 2-3.2g / cm<3>. The refractory castable disclosed by the invention has the advantages of low thermal conductivity, proper apparent porosity, high intensity, light weight and high thermal shock stability.

Owner:黎文泰

Heat insulating material and preparation method thereof

The invention discloses a heat insulating material and a preparation method thereof. The material is prepared from the following components in parts by weight: 40-50 parts of silicate cement, 6-12 parts of polyurethane, 4-8 parts of expanded perlite, 10-16 parts of lightwight ceramisite, 5-10 parts of borax, 8-12 parts of gypsum, 10-15 parts of modified attapulgite, 5-15 parts of glass fibers, 5-15 parts of ceramic fibers, 2-8 parts of flame retardant and 3-9 parts of an antibacterial agent. The heat insulating material is reasonable in raw material compatibility and low in cost, has excellentfracture resistance and tensile resistance, excellent flame retardance and antibacterial performance, and has simple preparation process and wide application.

Owner:徐州金盛贸易有限公司

Hybridized aramid silicone aerogel modified flame-retardant polypropylene foaming plate and preparation method thereof

The invention discloses a hybridized aramid silicone aerogel modified flame-retardant polypropylene foaming plate and a preparation method thereof. A hybridized aramid silicone aerogel filler in foaming materials is obtained by mixing an aramid pulp solution with a silica sol system, an aerogel compound with a porous network structure and high in toughness, heat resistance and flame retardant is finally obtained. Melt strength can be effectively increased by adding the aerogel compound into a resin system, effects of reinforcement, flame retardance, nucleation and the like are achieved, usage amount of a traditional flame retardant is reduced, porosity of the system can be effectively increased, resin foaming is facilitated, traditional flame retardant materials of molybdenum disulfide, diethyl phosphonate aluminum and the like are combined, and the lightweight polypropylene foaming composite material with good flame-retardant effect is finally prepared; the composite material is even in porosity, crush and heat resistant, resistant to wear corrosion, economic and durable and quite promising in application.

Owner:阜阳市三郁包装材料有限公司

Polyploid breeding method for eucalyptus camaldulensis 201-2

InactiveCN103548688AProlonged induction timeGood effectHorticulture methodsPlant tissue cultureCell buddingToxicity

The invention discloses a polyploid breeding method for eucalyptus camaldulensis 201-2. The polyploid breeding method comprises the following steps: (1) placing leaves of a tissue culture seedling of the eucalyptus camaldulensis 201-2 into colchicine with the mass concentration being 0.2% and immersing for 24 hours; and (2) inoculating the leaves which are immersed by the colchicine in the step (1) into a proliferation culture medium for culturing; and carrying out subculture on differentiated adventitious buds and inoculating the adventitious buds to a rooting culture medium for culturing to obtain eucalyptus camaldulensis 201-2 polyploid plants. According to the polyploid breeding method for the eucalyptus camaldulensis 201-2, a colchicine immersing method is used for inducing and treating to carry out polyploid induction and a tissue culture technology is combined to culture; a suitable induction scheme is obtained by analyzing through different concentrations and different processing times of the colchicine on the polyploid induction, and the eucalyptus camaldulensis 201-2 polyploid plants are cultured. The method disclosed by the invention not only has the characteristics of economy, convenience, strong specificity on an induction effect, reduction of the toxicity and the like, but can also improves the generation frequency of polyploids and reduces the appearance of chimeras.

Owner:CHONGQING UNIV OF ARTS & SCI

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com