POM(polyformaldehyde) raw material rod production process

A production process and raw material technology, applied in the field of polyoxymethylene, can solve the problems of insufficient tightness of the product structure, insufficient stability of the extrusion appearance, white cores, pores, etc., and achieve the effects of improved pores, tight product structure, and reduced scrap rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0069] The embodiments of the present invention will be described in detail below with reference to the accompanying drawings, but the present invention can be implemented in many different ways defined and covered by the claims.

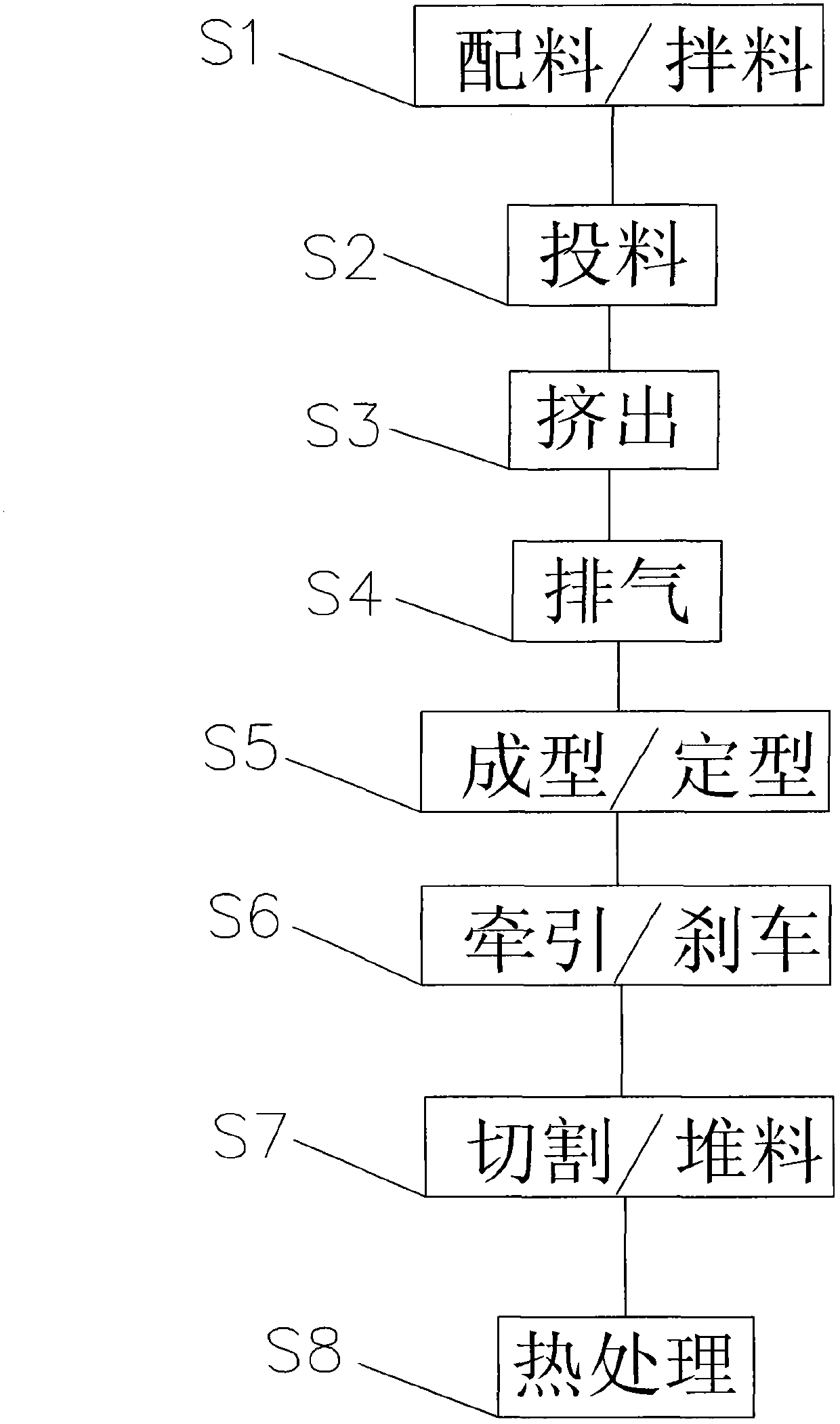

[0070] Such as figure 1 Shown, the POM raw material rod production technology of the embodiment of the present invention, it comprises the following steps:

[0071] The first step, ingredients / mixing process:

[0072] Clean up the surrounding environment at the mixing head and blow off the mixer with an air gun to prevent dirt and impurities from entering the mixer and raw materials; pour 100KG raw materials into the mixer, weigh 2-3KG color masterbatch on the raw materials evenly On the surface, start the mixer, and the mixing time is 10-15 minutes, so that the raw materials and the color masterbatch are evenly mixed.

[0073] The second step, feeding process:

[0074] Feed materials in time to ensure that the hopper is not empty, so as to prevent...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com