Thin and extremely thin ore body mining method

A mining method and technology for ultra-thin ore, which are applied in surface mining, underground mining, special mining, etc., can solve the problems of inability to meet mining needs, large dilution of mining methods, restricting mine development, etc., and achieve low ore loss and dilution. The effect of low mining cost and high production capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The implementation of the present invention will be described in detail below in conjunction with the drawings and examples.

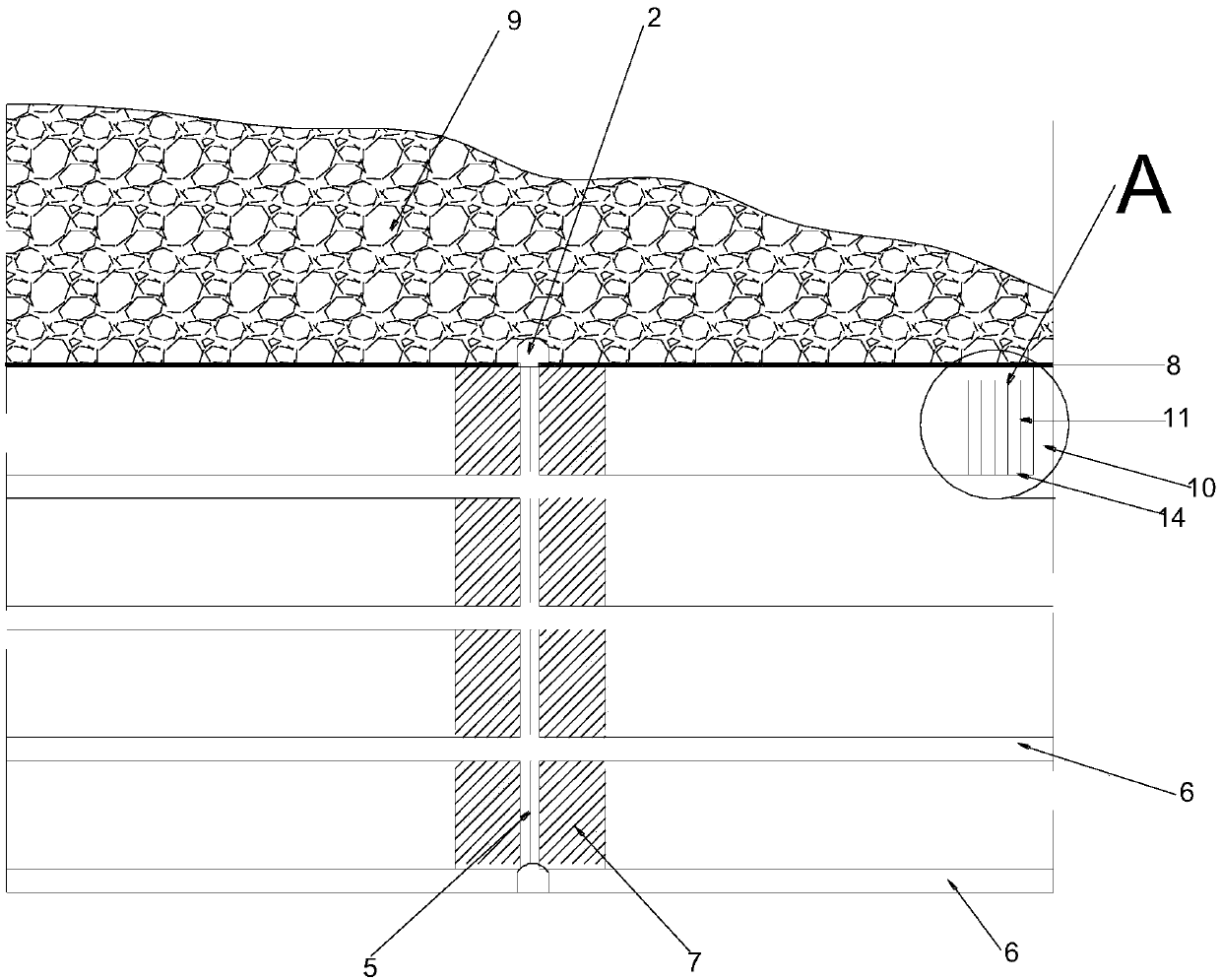

[0025] Such as figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 , Figure 6 As shown, the present invention is a mining method for thin and extremely thin ore bodies, without leaving top and bottom pillars, and without bottom structure, and does not use ore drawing under overburden rock. This mining method is suitable for mining unstable to moderately stable surrounding rocks on the hanging wall. Steeply inclined orebody without deformation. It is suitable for ore bodies with relatively regular shape, small thickness changes, few or no interlayers, ore non-spontaneous combustion and non-bonding; subsidence of the surface and surrounding rocks is allowed, the ore-rock boundary is obvious, and the mining conditions are complex.

[0026] 1. Block layout

[0027] The layout of ore blocks in a gold mine is arranged along the veins, and...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com