Carbon intercalation layer V2O3 nanometer material and preparation method and application thereof

A nanomaterial and nanotechnology, applied in structural parts, electrical components, battery electrodes, etc., can solve the problems of low cycle life, low energy density, poor rate performance, etc., and achieve the effect of improving cycle stability and alleviating volume changes.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0038] The carbon intercalation V 2 o 3 A method for preparing a nanomaterial, comprising the steps of:

[0039] (1) Add vanadium pentoxide and organic amine liquid into water, mix uniformly to obtain a mixed solution, place it in a reactor for hydrothermal reaction, and obtain a hybrid precursor; wherein the concentration of vanadium pentoxide in the mixed solution 0.02-0.04g / mL;

[0040] (2) After drying the hybrid precursor obtained in step (1), pass through inert gas for carbonization to obtain carbon intercalation V 2 o 3 nanomaterials.

[0041] Wherein the organic amine described in step (1) is one or more of 3-phenylpropylamine, ethylenediamine, aniline or octylamine, the mixing method is ultrasonic mixing, and the hydrothermal reaction temperature is 180-200°C, The hydrothermal reaction time is 40-48 hours.

[0042] The inert gas in step (2) is nitrogen or argon, preferably argon, and the heating rate during carbonization is 3°C / min-20°C / min, preferably 3°C / min-5...

Embodiment 1

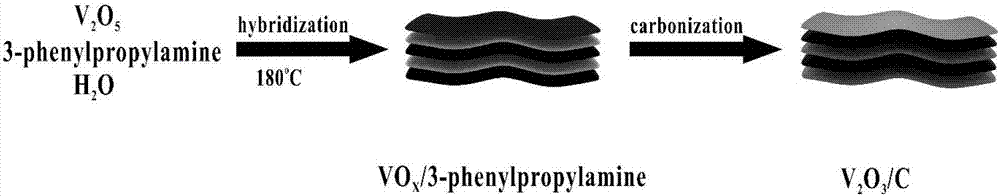

[0049] The schematic diagram of the preparation method of this embodiment is as follows figure 1 shown, including the following steps:

[0050] The first step is to synthesize VO x / 3-phenylpropylamine nanoribbon precursor.

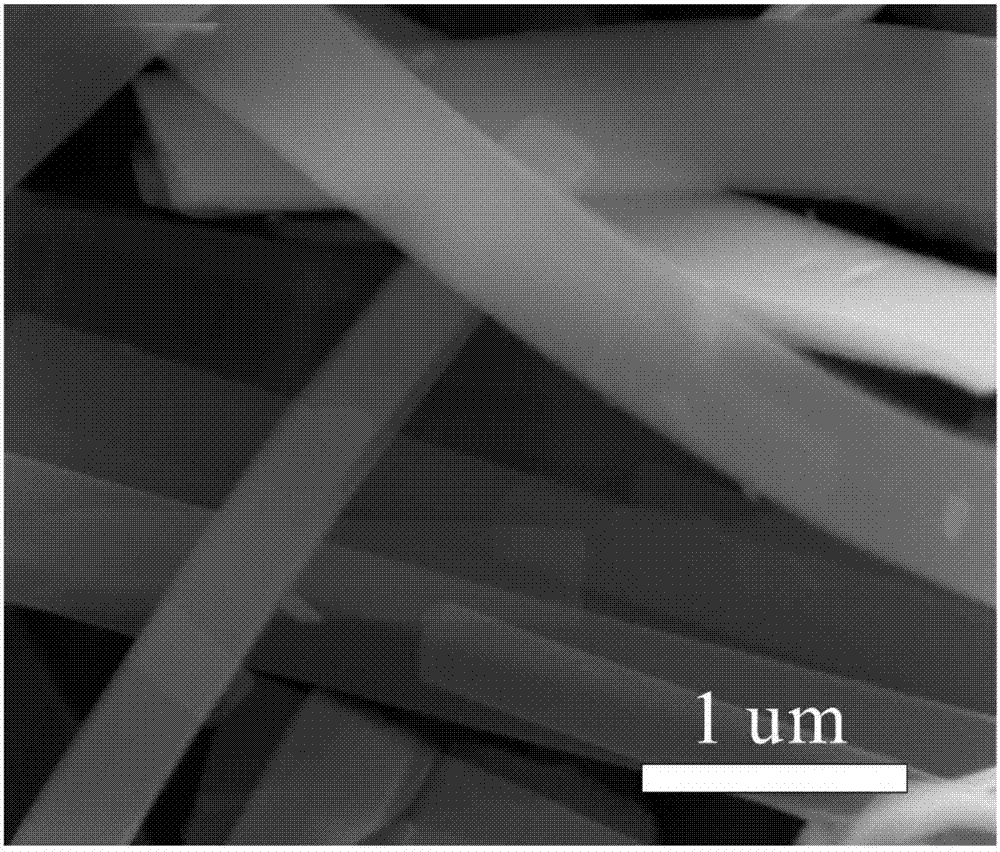

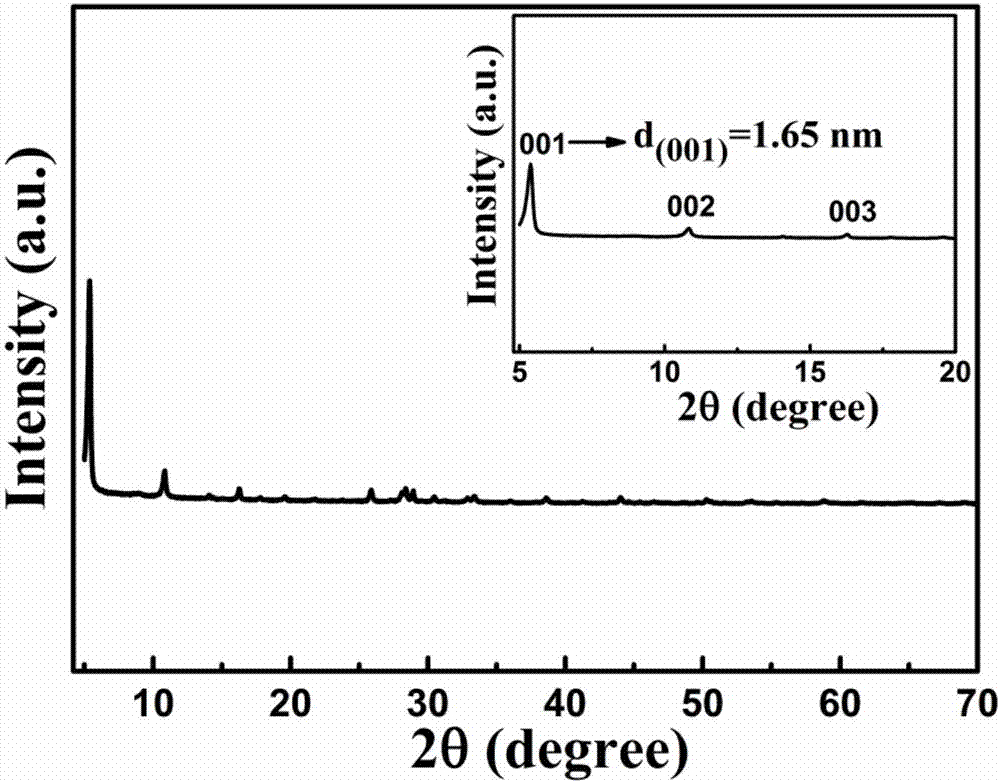

[0051] Will 0.81g V 2 o 5 The powder and 0.6 g of 3-phenylpropylamine liquid were added to 30 mL of water and stirred for 3 hours while being assisted by ultrasound to make the reaction mixture uniformly mixed. Afterwards, the reaction mixture was transferred to a reaction kettle and kept at 180° C. for 48 hours. After naturally cooling to room temperature, the product was removed with acetone to remove 3-phenylpropylamine that did not participate in the reaction, and then dried at 80° C. for 12 hours. A hybrid nanoribbon was obtained with the morphology as figure 2 shown. image 3 is the XRD pattern of the nanobelt precursor. The hydrothermal generation of the layered nanoribbon precursor was confirmed by XRD.

[0052] The second step, the syn...

Embodiment 2

[0060] The first step is to synthesize VO x / aniline precursor.

[0061] Will 0.6g V 2 o 5 The powder and 0.614 g of aniline were added to 30 mL of water and stirred for 3 hours while assisting with ultrasound to make the reaction mixture homogeneous. Afterwards, the reaction mixture was transferred to a reaction kettle and kept at 180° C. for 40 hours. Allow to cool to room temperature and then dry.

[0062] The second step, the synthesis of carbon intercalation V 2 o 3 nanomaterials.

[0063] VO x / aniline precursor, placed in an argon atmosphere, first heated to 400°C at a rate of 20°C / min, pre-carbonized at 400°C for 1 hour, and then raised to 600°C at a rate of 20°C / min , holding for 3 hours to obtain carbon intercalation V 2 o 3 nanomaterials. The length of the material obtained in this embodiment is 10-20 microns, the width is 0.5-1 microns, and the thickness is 60-90 nanometers, wherein V 2 o 3 The mass percentage of is 75.5%, and the content of C-N laye...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Width | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com