Silicon carbon composite material, preparation method thereof as well as lithium ion battery

A technology of silicon-carbon composite materials and carbon layers, which is applied in battery electrodes, secondary batteries, circuits, etc., can solve the problems of complex preparation process, fast specific capacity decay, and high raw material cost, so as to alleviate volume changes, prolong cycle life, Facilitate the effect of quick exchange

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

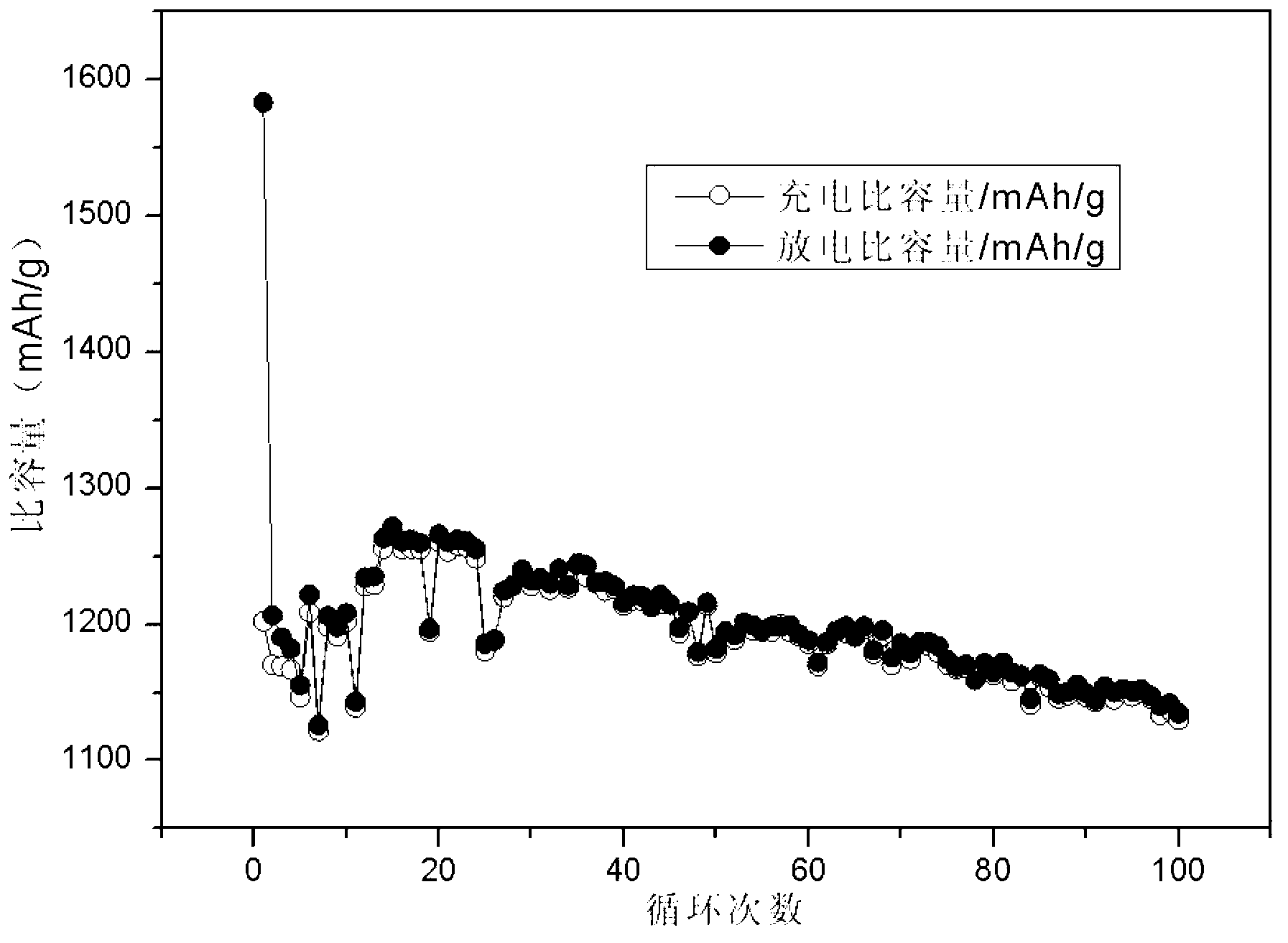

Image

Examples

Embodiment 1

[0033] Such as figure 1 As shown, this embodiment provides a method for preparing a silicon-carbon composite material, comprising the following steps:

[0034] (1) Weigh 5.6g of amorphous silicon 1 (particle size is 800 mesh), then add 1M solution of polymer polyvinyl alcohol 2, ultrasonically disperse for 30 minutes, evaporate the solvent under stirring, and obtain the organic carbon precursor polyethylene The composite of amorphous silicon 1 coated with alcohol 2 is then kept at 800° C. for 1 hour under the protection of nitrogen, the organic carbon precursor polyvinyl alcohol 2 is carbonized at high temperature, and the porous carbon layer 3 is coated on the amorphous silicon 1 .

[0035](2) Add a hydrofluoric acid solution with a concentration of 5wt% to the above product, and the molar ratio of hydrogen fluoride to amorphous silicon 1 in the added hydrofluoric acid solution is 10:1. 20mmol / L chloroplatinic acid solution was added dropwise under stirring, the platinum in ...

Embodiment 2

[0043] This embodiment provides a method for preparing a silicon-carbon composite material, comprising the following steps:

[0044] (1) Weigh 5.6g of amorphous silicon (particle size: 100 mesh), add 3M glucose and sucrose solution, ultrasonically disperse for 30 minutes, evaporate the solvent under stirring, and obtain the organic carbon precursor glucose and sucrose-coated The composite of shaped silicon is then kept at 600°C for 2 hours under the protection of argon, the organic carbon precursors glucose and sucrose are carbonized at high temperature, and a porous carbon layer is coated on the amorphous silicon.

[0045] (2) Add a hydrofluoric acid solution with a concentration of 12wt% to the above product, and the molar ratio of hydrogen fluoride to amorphous silicon in the added hydrofluoric acid solution is 3:1. 60mmol / L silver nitrate solution was added dropwise under stirring, the silver in the added silver nitrate solution was 0.5% of the mass of the amorphous silico...

Embodiment 3

[0049] This embodiment provides a method for preparing a silicon-carbon composite material, comprising the following steps:

[0050] (1) Weigh 5.6g of amorphous silicon (particle size: 200 mesh), add 2.5M starch solution, disperse ultrasonically for 30 minutes, evaporate the solvent under stirring, and obtain organic carbon precursor starch-coated amorphous silicon. The composite is then kept at 700°C for 3 hours under the protection of hydrogen, the organic carbon precursor starch is carbonized at high temperature, and the porous carbon layer is coated on the amorphous silicon.

[0051] (2) Add hydrofluoric acid with a concentration of 1wt% to the above product, and the molar ratio of hydrogen fluoride to amorphous silicon in the added hydrofluoric acid is 5:1. 40mmol / L chloroauric acid solution was added dropwise under stirring, the gold in the added chloroauric acid solution was 2% of the mass of amorphous silicon in step (1), and the reaction was stirred for 2 hours.

[0...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com