Preparation method of isostatic pressing formed graphite of ultra-thin structure

A technology of isostatic pressing and fine structure, applied in the field of static pressing graphite, can solve the problems of harsh production environment, poor product homogeneity, long production cycle, etc. low effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

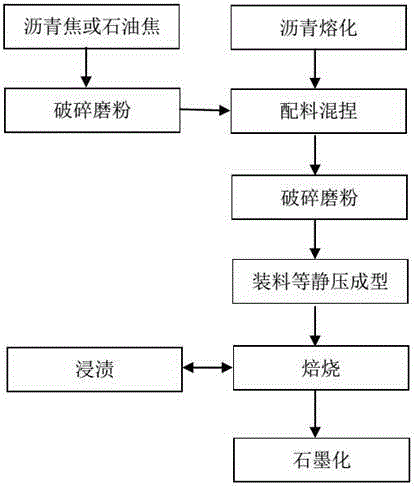

[0025] Such as figure 1 Shown, a kind of preparation method of ultrafine structure isostatic graphite, comprises following multiple steps:

[0026] S1: The calcined petroleum coke or pitch coke is roughly crushed to 1mm or less by a hammer crusher, and then crushed by a jet mill into 5-10μm coke powder as aggregate;

[0027] S2: Preheat the coke powder used as aggregate to 100-150°C, and then mix it with the binder coal tar pitch at an ambient temperature of 150-180°C for 1-3 hours, and pass it through a hammer crusher after natural cooling Crushed to less than 3mm, and then mechanically milled to obtain compressed powder less than 60μm;

[0028] S3: Put the compressed powder into a rubber mold, seal it and perform isostatic pressing under a pressure of 100-140MPa to form a green body;

[0029] S4: heating the green body to 950-1150°C at a heating rate of 1-5°C / h to obtain a carbon body;

[0030] S5: impregnating the carbon body, the impregnation temperature is 260-350°C, t...

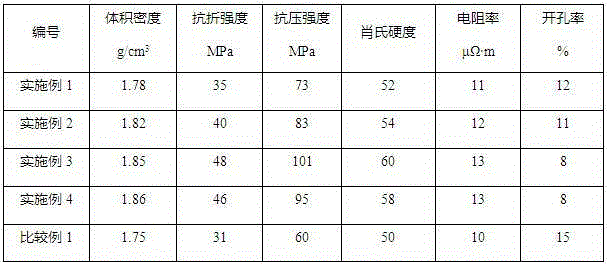

Embodiment 1

[0037] ① First, crush the petroleum coke calcined at 1300℃ to 1mm or less with a hammer crusher;

[0038] ②Use a jet mill to grind to 10 μm to obtain aggregate coke powder, preheat the coke powder to 110°C, and then knead strongly at 160°C for 1.5 hours with the binder coal tar pitch whose softening point is 92°C and has a coking value of 48%. Among them, the aggregate coke powder content is 72%, and the binder pitch content is 28%. After the mixture is cooled, it is crushed with a hammer crusher to less than 3mm, and then mechanically ground to obtain pressed powder;

[0039] ③Put the pressed powder into the rubber mold sleeve to seal, and isostatically press under 110MPa pressure to make a green body;

[0040] ④Heating the formed green body to 950°C at a heating rate of 5°C / h to obtain a carbon body;

[0041] ⑤Impregnate the carbon body. The impregnating agent is low-quinoline medium-temperature coal tar pitch, the impregnating temperature is 280°C, the impregnating pressur...

Embodiment 2

[0045] ① First, crush the pitch coke calcined at 1300℃ to 1mm or below with a hammer crusher;

[0046] ②Use a jet mill to grind to 8 μm to obtain aggregate coke powder. Preheat the coke powder to 120°C with a softening point of 101°C and a binder coal tar pitch with a coking value of 54% at 170°C for 2 hours. Among them, The coke powder content of the aggregate is 69%, the binder pitch content is 31%, after the mixture is cooled, it is crushed with a hammer crusher to less than 3mm, and then pressed powder is obtained by mechanical grinding;

[0047]③Put the pressed powder into the rubber mold sleeve to seal, and isostatically press under 120MPa pressure to make a green body;

[0048] ④Heating the formed green body to 1050°C at a heating rate of 3°C / h to obtain a carbon body;

[0049] ⑤Impregnate the carbon body. The impregnating agent is low-quinoline medium-temperature coal tar pitch, the impregnating temperature is 300°C, the impregnating pressure is 2.0MPa, and the impreg...

PUM

| Property | Measurement | Unit |

|---|---|---|

| softening point | aaaaa | aaaaa |

| coking value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com