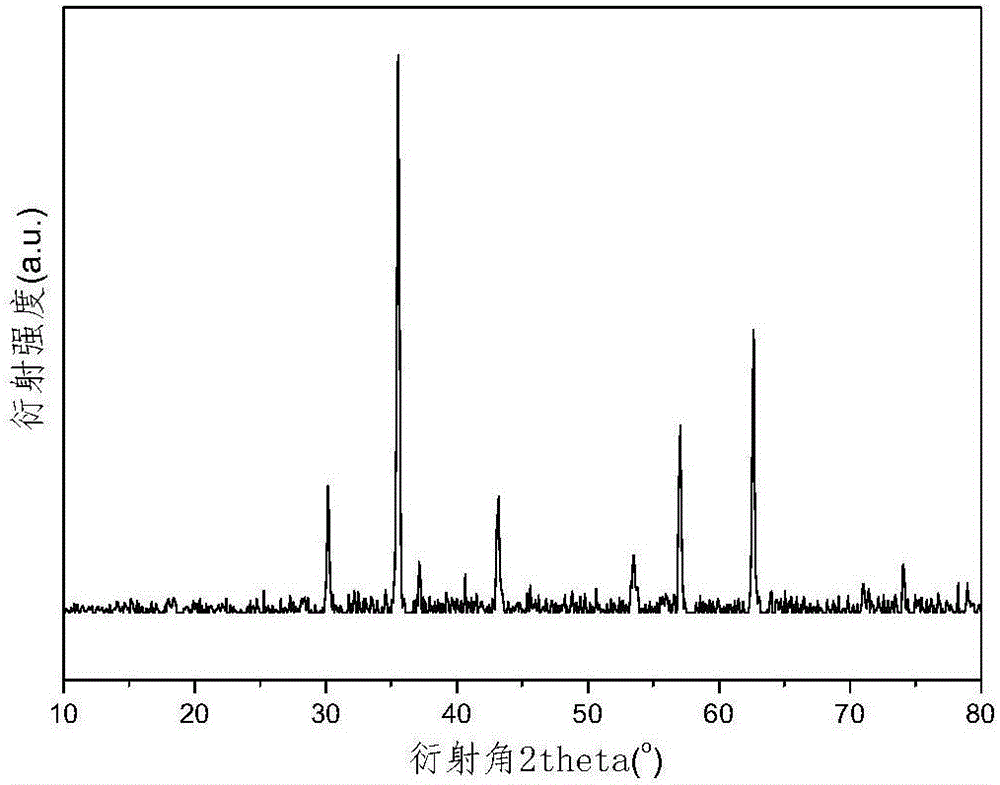

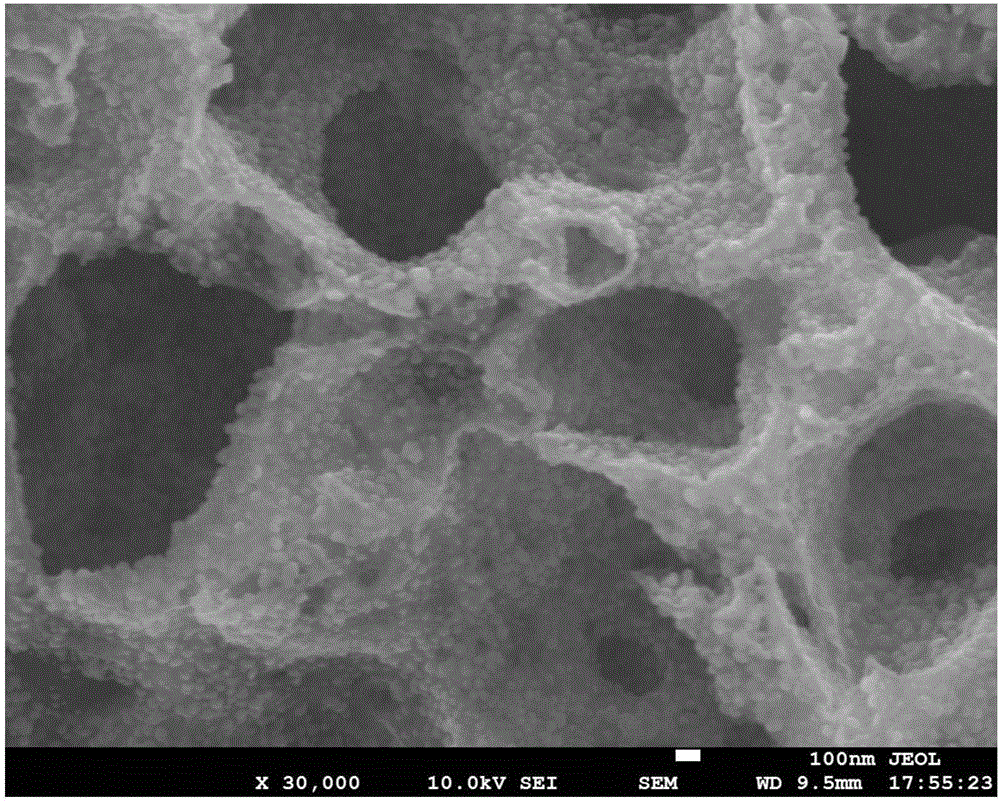

Porous graphene supported carbon coated iron oxide nanoparticle composite material and preparation method thereof

An iron oxide nanometer, porous graphene technology, applied in electrical components, battery electrodes, circuits, etc., can solve the problems of difficult to achieve large-scale production, high cost of graphene, complex equipment, etc., and achieve excellent cycle stability and good rate. performance, the effect of high lithium storage capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] A porous graphene-loaded carbon-coated iron oxide nanoparticle composite material is prepared through the following steps:

[0031] (1) Adopt airtight oxidation method to directly prepare graphene oxide with microcrystalline graphite ore as raw material. In the lined reaction kettle, take 30mL of concentrated sulfuric acid in another container, put the reaction kettle and concentrated sulfuric acid with graphite ore powder and potassium permanganate in the equipment with refrigeration function and refrigerate at low temperature (0°C) for 12h , then, add concentrated sulfuric acid into the reaction kettle with graphite ore powder and potassium permanganate, cover it, tighten the reaction kettle, put it in an oven at 90°C for 2 hours, and slowly pour the reaction product into the reaction kettle with a weight of Add hydrogen peroxide dropwise to water 20 times the weight of concentrated sulfuric acid until all of it turns yellow, then centrifugally wash with dilute hydroc...

Embodiment 2

[0041] A porous graphene-loaded carbon-coated iron oxide nanoparticle composite material is prepared through the following steps:

[0042] (1) Adopt airtight oxidation method to directly prepare graphene oxide with flake graphite ore as raw material, the specific steps are as follows: directly take 0.6g flake graphite ore powder (graphite content 60%), 3g potassium permanganate, place in polystetrafluoroethylene successively In the reaction kettle lined with vinyl fluoride, take 30mL of concentrated sulfuric acid in another container, put the reaction kettle with graphite ore powder and potassium permanganate and concentrated sulfuric acid in the equipment with refrigeration function at low temperature (-5 ℃ ) refrigerated for 12 hours, then, add concentrated sulfuric acid into the reaction kettle with graphite ore powder and potassium permanganate, cover it, tighten the reaction kettle, place it in a 90°C oven for 2 hours, and pour the reaction product slowly under vigorous st...

Embodiment 3

[0047] A porous graphene-loaded carbon-coated iron oxide nanoparticle composite material is prepared through the following steps:

[0048] (1) Adopt airtight oxidation method to directly prepare graphene oxide with flake graphite ore as raw material, concrete steps are as follows: directly take 0.5g flake graphite ore powder (graphite content 60%), 10g potassium permanganate, place in polystetrafluoroethylene successively Take 100mL of concentrated sulfuric acid in another container in the reaction kettle lined with vinyl fluoride, and place the reaction kettle with graphite ore powder and potassium permanganate and concentrated sulfuric acid in a device with refrigeration function at low temperature (-2°C) ) refrigerated for 12 hours, then, add concentrated sulfuric acid into the reaction kettle with graphite ore powder and potassium permanganate, cover it, tighten the reaction kettle, place it in a 100°C oven for 1 hour, and slowly pour the reaction product under vigorous sti...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com