Method for preparation of double-phase zirconium alloy EBSD sample by electrolytic polishing

A technology of electropolishing and zirconium alloys, which is applied in the preparation of test samples, material analysis using radiation diffraction, measuring devices, etc., can solve the problems of insufficient research on the dual-phase structure of dual-phase zirconium alloys, and achieve stable polishing effect. Easy to formulate and effective from a wide range of raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

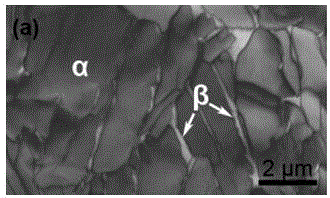

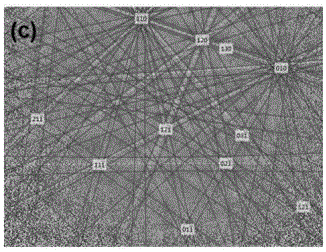

Image

Examples

preparation example Construction

[0020] 1) Preparation of workpiece

[0021] Use a cutting tool (such as a wire cutting tool) to cut a two-phase zirconium alloy bar along the length, width, and thickness directions, and cut a workpiece with a three-dimensional structure according to the process requirements; for example, according to the process requirements, cut a workpiece with a geometric size of 10mm×8mm×3mm The number of workpieces is spare;

[0022] 2) Grinding of the workpiece

[0023] Use metallographic water abrasive paper to polish each surface of the workpiece; for example, use 240# metallographic water abrasive paper for grinding; then use the fixture to clamp the workpiece, and then use sandpaper to polish the LD-TD surface of the workpiece step by step. For example, use sandpaper with smaller sand grains to polish step by step, use 400#~3000# sandpaper to polish the LD-TD surface (the surface in the direction of length and thickness) of the workpiece step by step; finally remove the workpiece a...

Embodiment 1

[0031] Using a wire cutting tool, cut the forged biphase Zr-2.5Nb zirconium alloy bar (strain ε ~ 30%) along the length, width, and thickness directions (represented by LD, WD, and TD) to cut workpieces of 10 mm × 8 mm × 3 mm. First, use 240# metallographic water abrasive paper to polish each surface of the workpiece; then use the fixture to clamp the workpiece, and use 400#, 800#, 1000#, 1200#, 2000# and 3000# sandpaper to grind the LD of the workpiece -TD surface (the surface in the direction of length and thickness) is polished step by step to be smooth and bright; finally, the workpiece is removed, and the surface of the sample is washed with water and ethanol in sequence, and dried with cold air for use.

[0032]The volume ratio of the electrolytic polishing liquid used for preparing the surface treatment of the workpiece is: 10% perchloric acid, 70% methanol, and 20% ethylene glycol monobutyl ether. The dual-phase zirconium alloy workpiece is used as the anode, connected...

Embodiment 2

[0034] Using a wire cutting tool, cut a workpiece of 10 mm × 7 mm × 3 mm along the length, width and thickness directions (represented by LD, WD and TD) of the dual-phase Zr-2.5Nb zirconium alloy forged bar (strain ε~30%). First, use 240# metallographic water abrasive paper to polish each surface of the workpiece; then use the fixture to clamp the workpiece, and use 400#, 800#, 1000#, 1200#, 2000# and 3000# sandpaper to grind the LD of the workpiece -TD surface (the surface in the direction of length and thickness) is polished step by step to be smooth and bright; finally, the workpiece is removed, and the surface of the sample is cleaned with water and ethanol in sequence, and dried with cold air for use.

[0035] The volume ratio of the electrolytic polishing liquid used for preparing the surface treatment of the workpiece is: 8% perchloric acid, 74% methanol, and 18% ethylene glycol monobutyl ether. The dual-phase zirconium alloy workpiece is used as the anode, connected to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com