Method for showing 6082 aluminum alloy structure

A technology of aluminum alloy and structure, which is applied in the field of metallographic sample preparation, can solve the problems such as the difficulty of displaying the structure of 6082 aluminum alloy, and achieve the effect of simple implementation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0016] a Deformation: Make 60% compression deformation of 6082 aluminum alloy sample at room temperature.

[0017] b Annealing: Anneal the deformed sample at 540°C and cut it with a grinding wheel cutting machine.

[0018] c Rough grinding and polishing: Roughly grind the sample with water sandpaper, and replace the next sandpaper when there are no scratches perpendicular to the grinding direction on the surface. Wash and polish the sample ground by No.1200 water sandpaper, and observe the polished surface with a microscope to ensure that there are no large scratches.

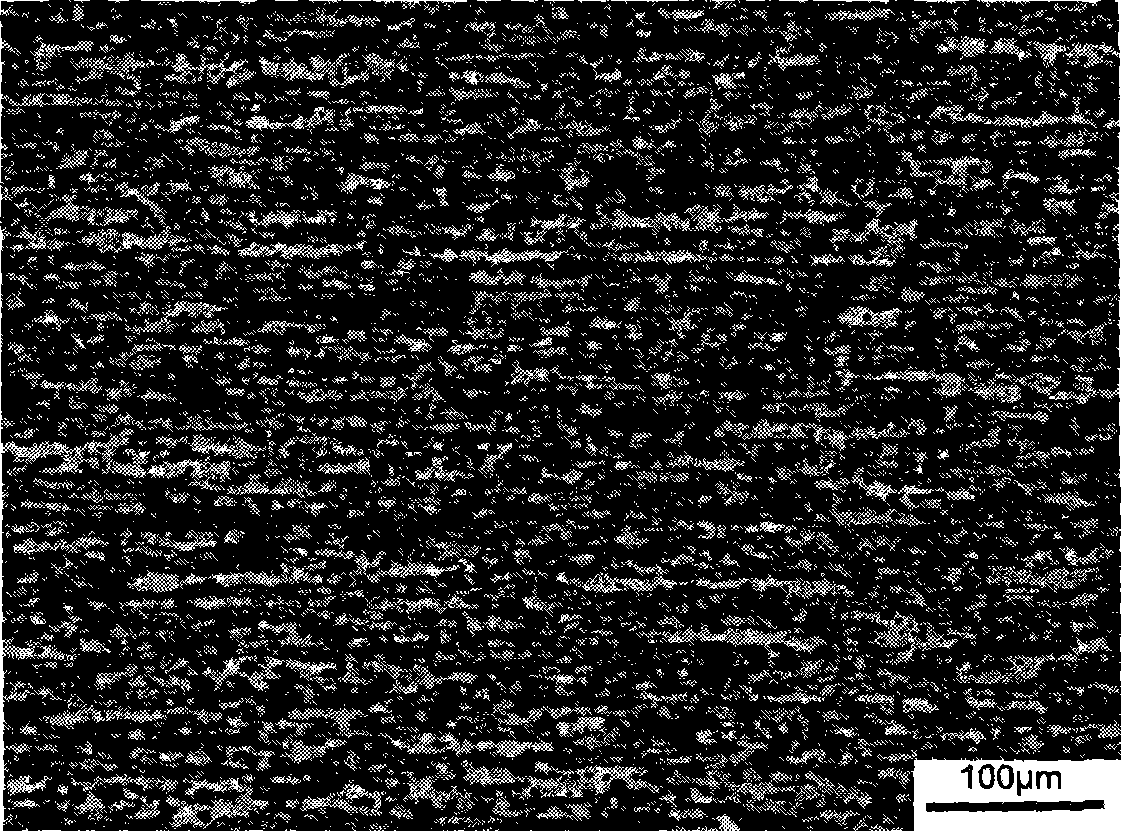

[0019] d Anodizing: Coating the polished sample on the NO.70-1730 ELECTROMET III POLISH / ETCHER electrolytic polishing machine, the voltage is 30V, the anodizing time is 90s, washed with alcohol and dried; Observed under a microscope, a relatively clear recrystallized structure of 6082 was obtained.

[0020] Anodizing solution formula and preparation process

[0021] (1) The formula of the anodic oxidation so...

Embodiment 2

[0027] a Rough grinding and polishing: Roughly grind the hot-extruded sample on water sandpaper, and replace the next sandpaper when there are no scratches perpendicular to the grinding direction on the surface. Wash and polish the sample ground by No1200 water sandpaper, and observe the polished surface under a microscope to ensure that there are no large scratches.

[0028] b Anodizing: The polished sample is coated on the NO.70-1730 ELECTROMET III POLISH / ETCHER electrolytic polishing machine, the voltage is 30V, the anodizing time is 90s, washed with alcohol, and dried; Observation under a microscope shows a clearer structure of 6082 after extrusion.

[0029] Anodizing solution formula and preparation process

[0030] (1) The formula of the anodic oxidation solution is:

[0031] 50mL of 46% hydrofluoric acid (HF),

[0032] 14g boric acid (H 3 BO 3 ),

[0033] Add distilled water to dilute to 1L.

[0034] (2) The configuration process of the anodic oxidation solution ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com