Grinding and polishing process for repair of aluminum alloy hub

A technology of aluminum alloy wheels and craftsmanship, which is applied in the field of repairing aluminum alloy wheels and can solve problems such as waste and surface damage of aluminum alloy wheels

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

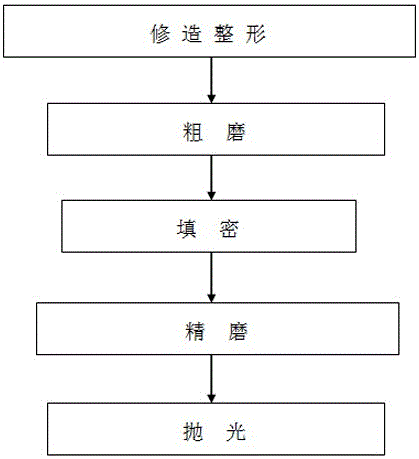

[0022] refer to figure 1 , the present invention proposes a grinding and polishing process in aluminum alloy wheel hub repair, comprising the following steps:

[0023] S1. Repairing and shaping: First, use an aluminum file or a grinding head to trim the scratched part of the wheel hub or the raised part of the welded part to the proper shape. Each curved surface should be inspected with a curved surface ruler, and the error is less than 0.5MM;

[0024] S2. Coarse grinding: Use No. 80~400 dry grinding sandpaper to firstly polish and repair the surface in turn. The curved arc or special-shaped parts need to be carefully polished with cushion supporting sandpaper. It is required to be slightly higher than the base surface as a fine grinding allowance;

[0025] S3. Filling: Check whether there are pores and depressions on the polished surface, and fill the pores and depressions with putty or aluminum putty;

[0026] S4. Fine grinding: For the refurbished surface that passes the i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com