Solvent-free epoxy self-leveling system free of epoxy mortar structural layer

A technology free of epoxy sand and structural layer, applied in building structure, on-site coagulation pavement, floor and other directions, can solve the problems of waste of technical materials, unqualified technology, and inability to make according to demand, etc. Inexpensive, smooth surface finish

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

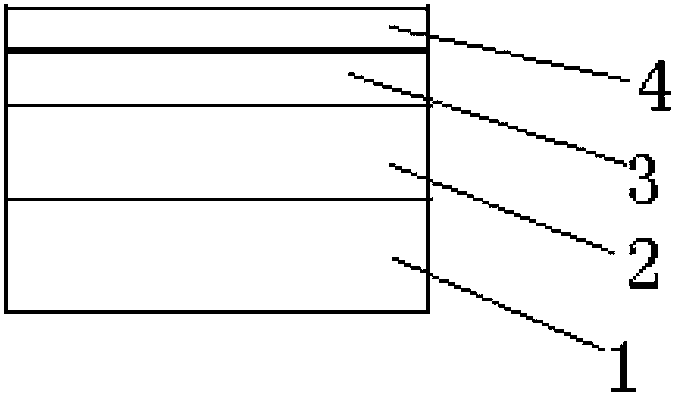

[0008] The structural principle and working principle of the present invention will be described in detail below in conjunction with the accompanying drawings.

[0009] With reference to accompanying drawing, a kind of solvent-free epoxy self-leveling system of free epoxy mortar construction layer is characterized in that, comprises concrete foundation layer 1, is epoxy sealing layer 2 on concrete foundation layer 1, and epoxy sealing layer 2 is Epoxy fine sand sealing layer 3, epoxy fine sand sealing layer 3 is an epoxy surface layer 4.

[0010] The working principle of the present invention is: the present invention is suitable for highly clean, dust-free, sterile pharmaceutical workshops, tobacco industry, electric power, electronics, electrical appliances, food, printing and packaging, computer rooms, airports, offices, stadiums, schools, etc. In places with high requirements, the surface is smooth, beautiful, and mirror effect; acid and alkali resistance, especially alkal...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com