Spot welding device for power battery pack electrode slice

A technology for power battery packs and spot welding equipment, applied in resistance welding equipment, welding equipment, electrode features, etc., can solve the problems of high welding labor intensity and low welding efficiency, and achieve the effect of avoiding the reduction of spot welding efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0049] The present invention will be described in further detail below in conjunction with the accompanying drawings.

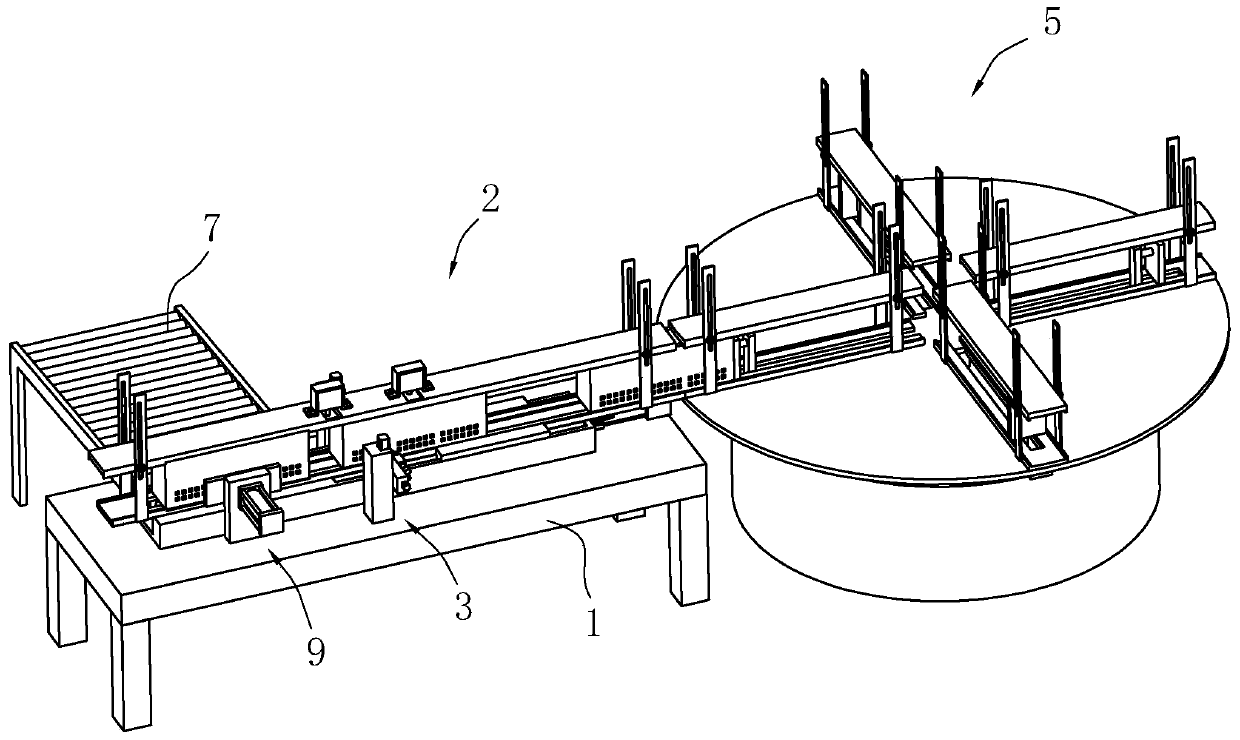

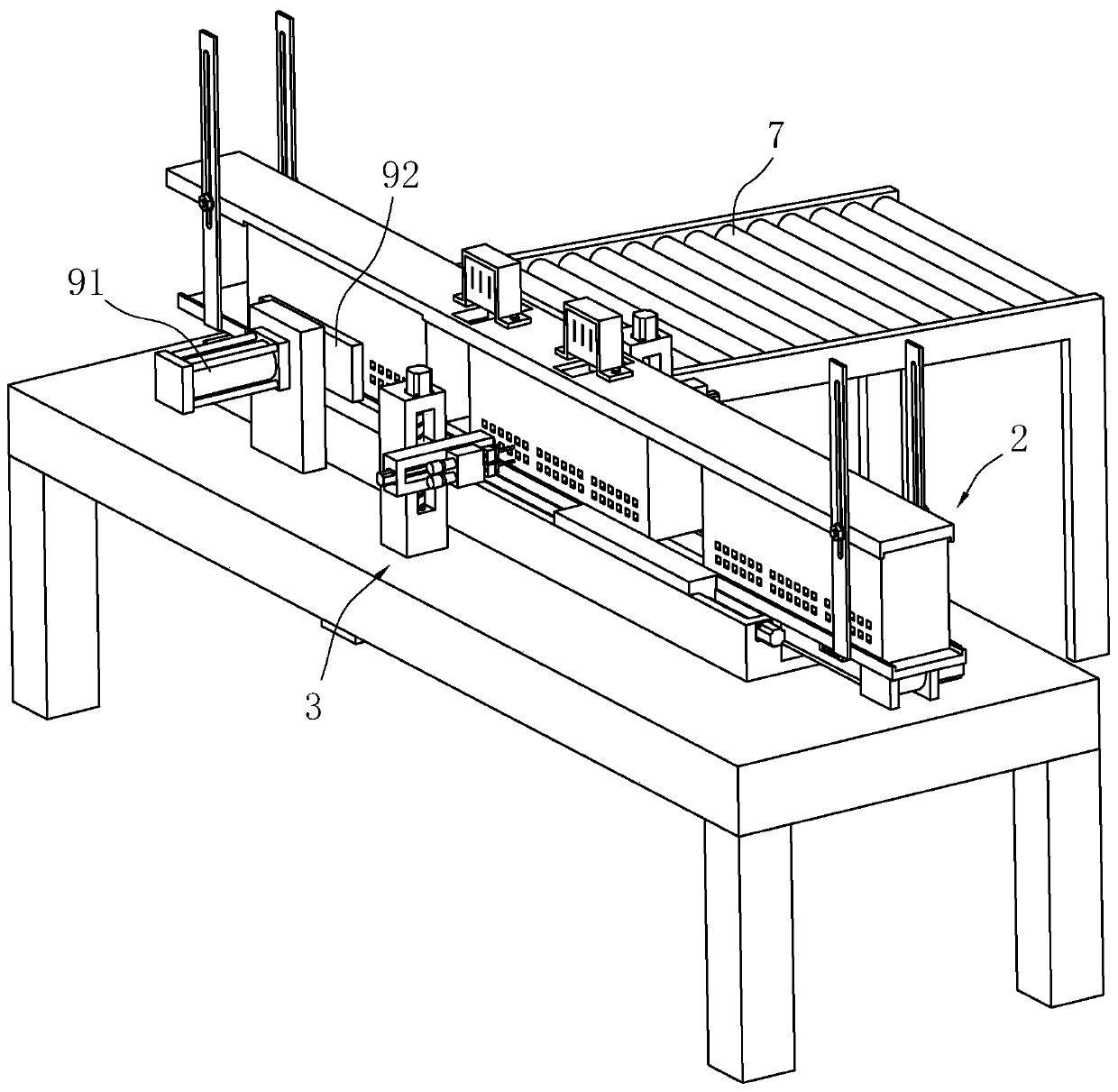

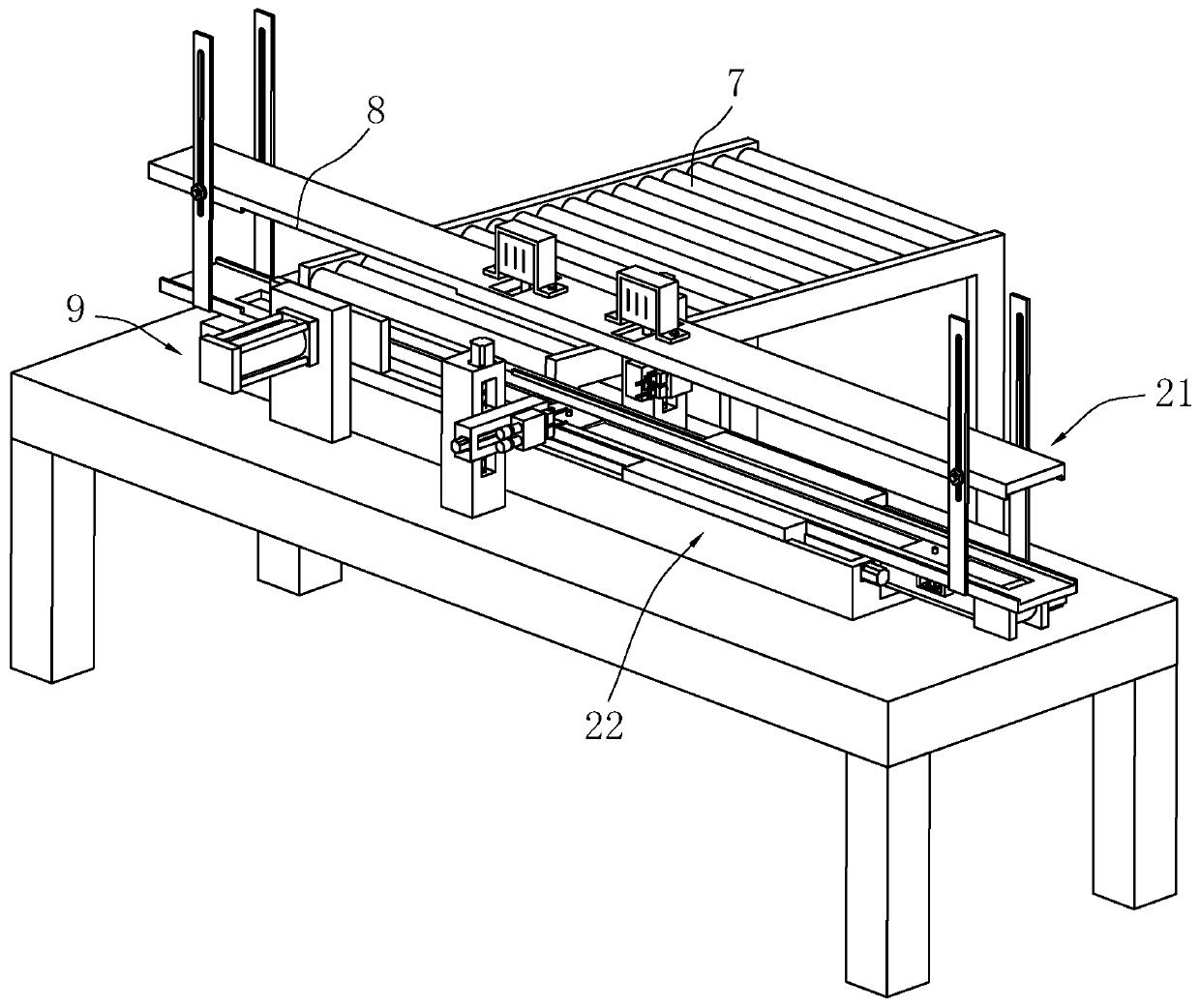

[0050] combine figure 1 and figure 2 As shown, a spot welding device for electrode sheets of a power battery pack includes a frame 1 , a conveying assembly 2 arranged on the frame 1 , two sets of spot welding assemblies 3 , a transfer assembly 4 and a rotary feeding assembly 5 . The power battery pack carries the electrode sheet into the spot welding jig 6, the spot welding jig 6 is loaded into the rotary feeding assembly 5, and the spot welding jig 6 is sent into the conveying assembly 2 through the rotary feeding assembly 5 , the spot welding assembly 3 completes the spot welding process of the electrode sheet of the power battery pack in the spot welding jig 6 on the conveying assembly 2 .

[0051] Specifically, combined with Figure 11A and Figure 11B As shown, the spot welding fixture 6 comprises a base plate 61, a front baffle plate 62 fixed on th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com