Gantry-type automatic spot welding system for battery pack

An automatic spot welding and gantry technology, applied in resistance welding equipment, welding equipment, metal processing equipment, etc., can solve the problems of high welding labor intensity, unreliable welding, enterprise loss, etc., to improve the efficiency and quality of spot welding, Reduce the labor intensity of workers, increase the number of installations and the effect of

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

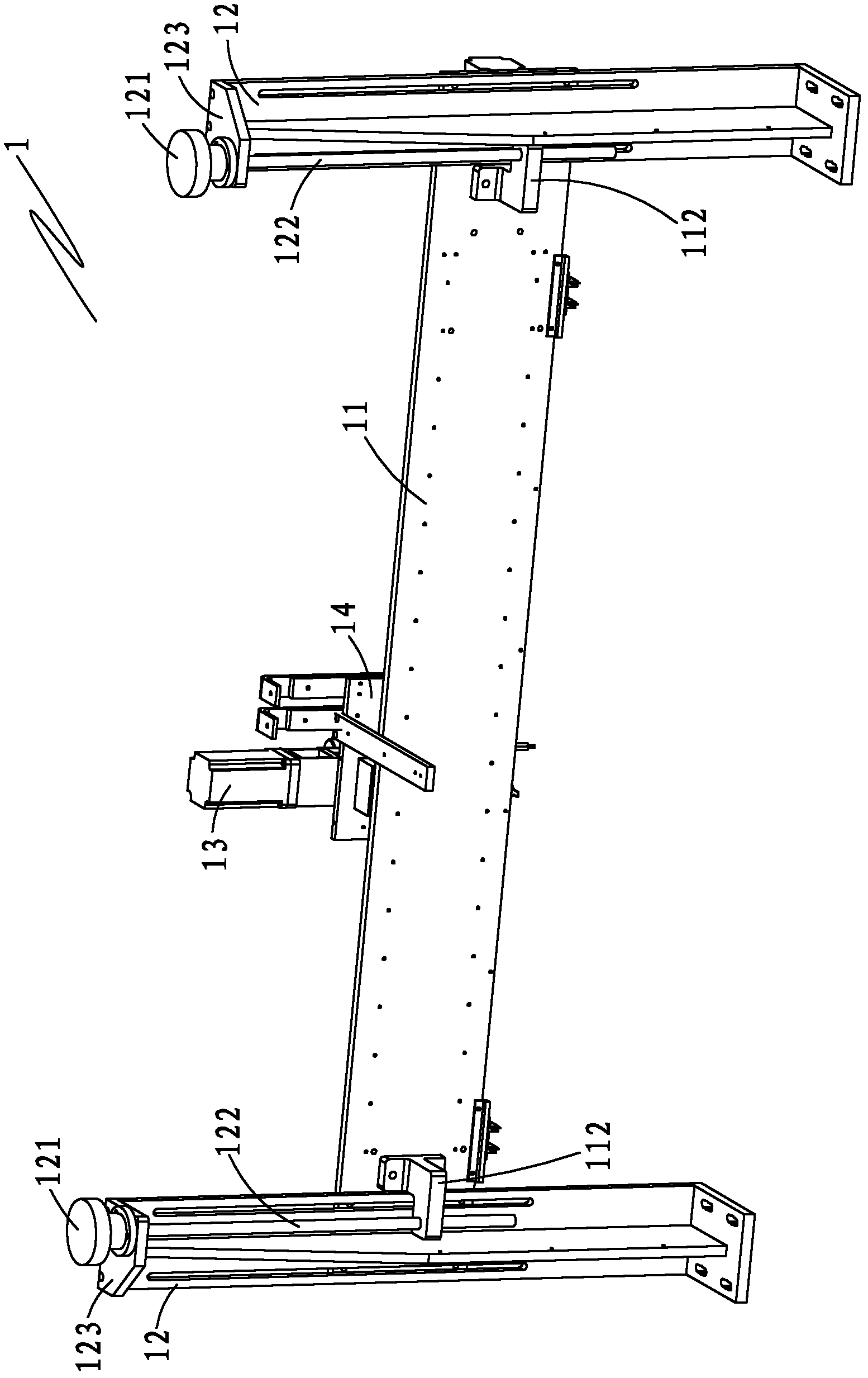

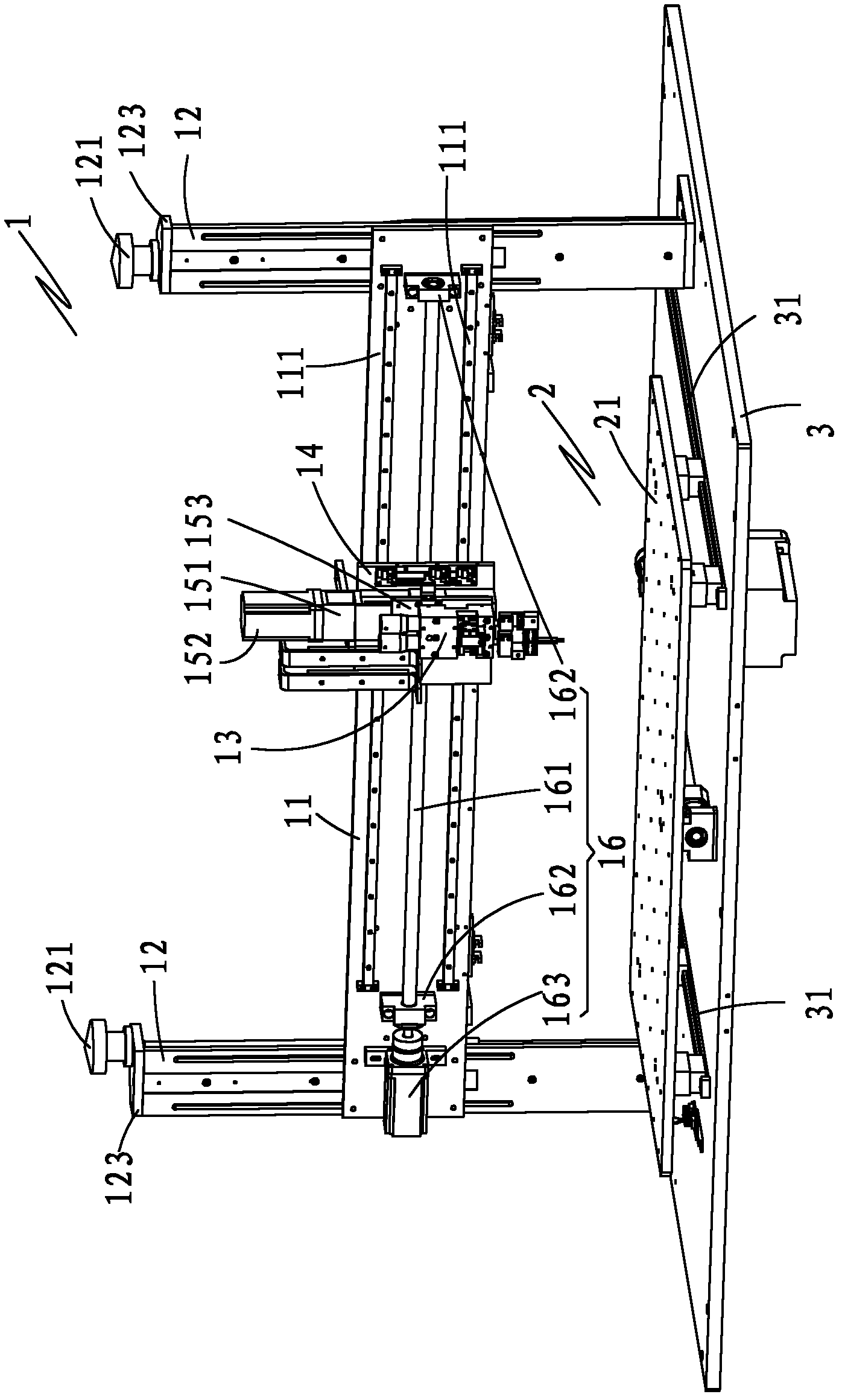

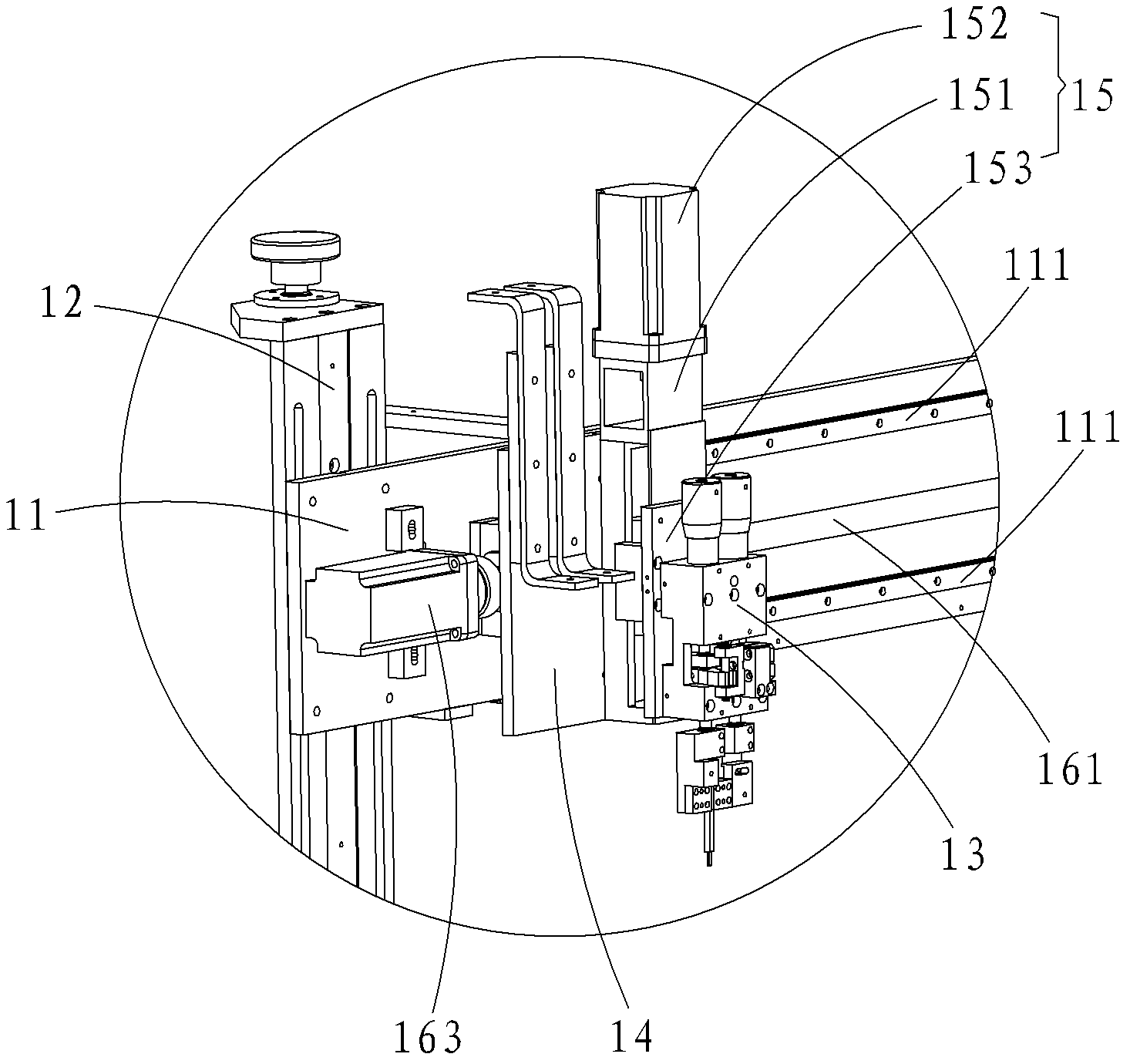

[0021] see figure 1 and figure 2 As shown, a gantry type automatic spot welding system for a battery pack of the present invention includes a spot welding device 1 and a spot welding fixture fixture 2 ( figure 1 The middle spot welding fixture fixture is not drawn); Described spot welding device 1 comprises crossbeam 11, one group is arranged side by side relatively and is used for regulating the column 12 of described crossbeam 11 height, spot welding mechanism 13, is used to fix described point The X-axis slide table 14 of the welding mechanism 13, the Y-axis motion mechanism 15 that moves the spot welding mechanism 13 laterally, and the X-axis motion mechanism 16 that makes the X-axis slide table 14 laterally move; the bottom of the beam 11 is arranged in parallel There are two guide rails 111, and a group of symmetrical beam fixing seats 112 are arranged on the surface of the beam 11, and the two beam fixing seats 112 are respectively slidably embedded in the column 12 t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com