Electrode system for improving performances of steel-aluminum dissimilar metal resistance spot welding head

A technology of dissimilar metals and electrode systems, applied in resistance welding equipment, welding media, welding equipment, etc., can solve the problems of deterioration of mechanical properties of welded joints, intermetallic compounds, easy cracks, etc., and improve the interface structure and bonding form of joints. , the effect of reducing the degree of atomic diffusion and reducing the growth rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

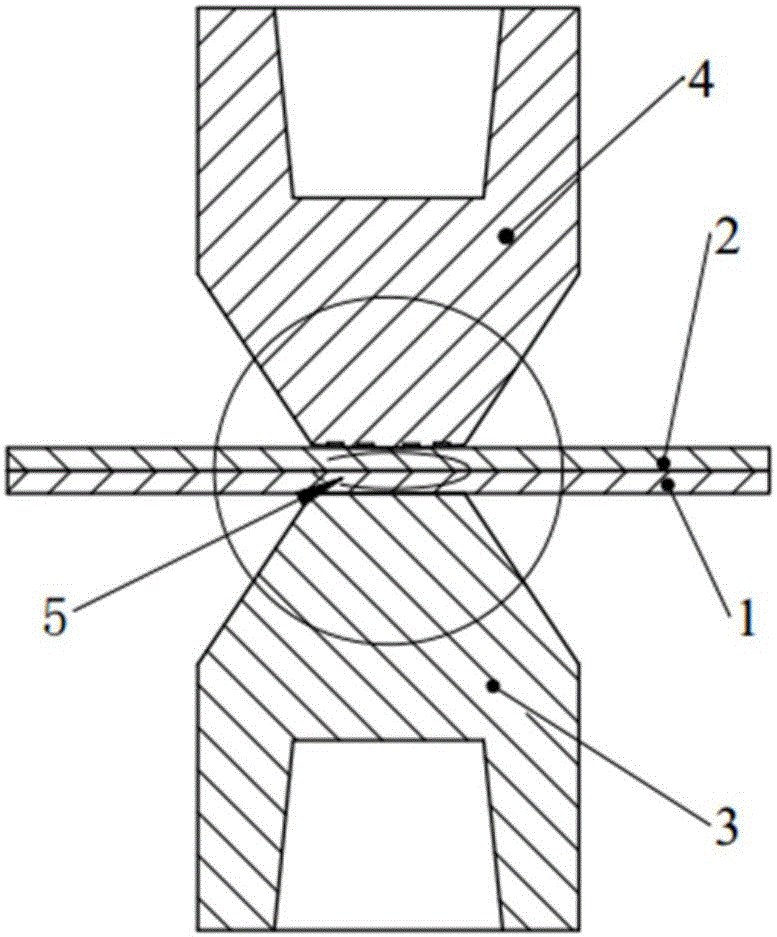

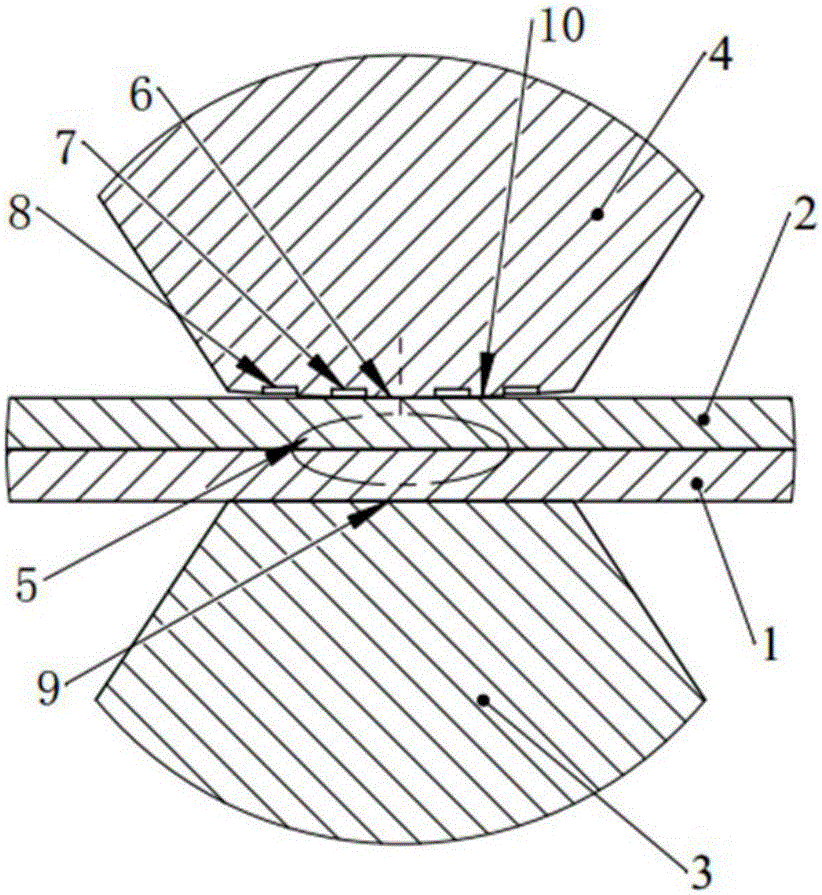

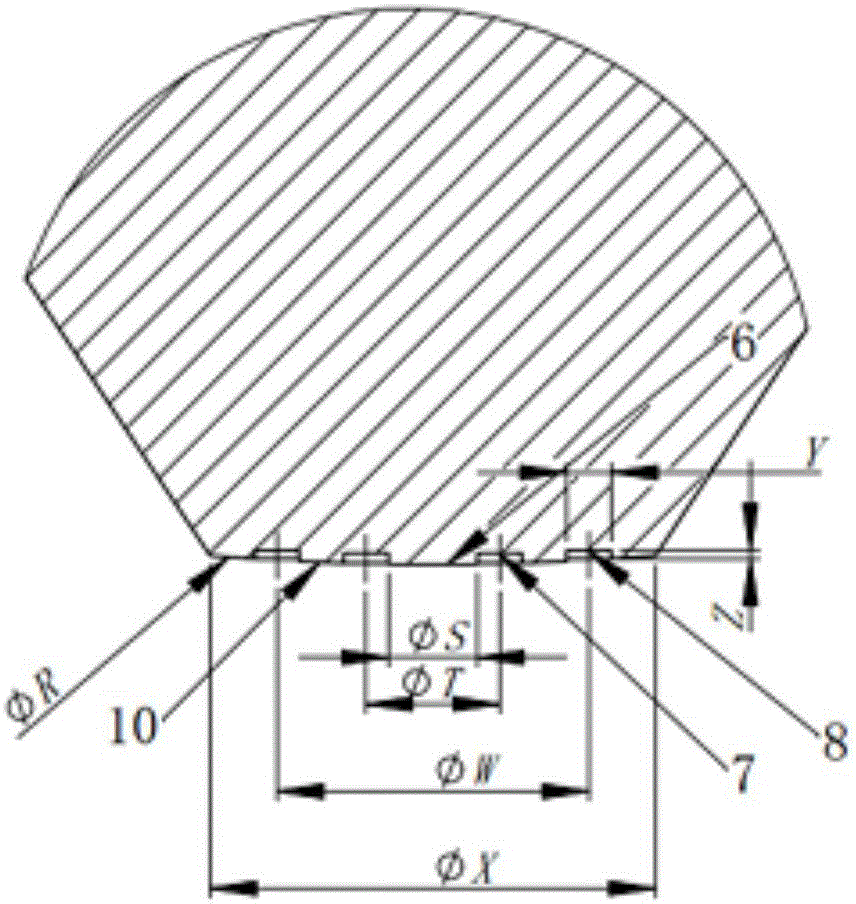

[0044] An electrode system used to improve the performance of spot welding joints of steel and aluminum dissimilar metals, in which the positive electrode is a ring electrode, and the negative electrode is a flat electrode. Their overall shape is a cylindrical structure, and the diameter of the end face is The electrode end face of the flat electrode is a flat end face, and the end face of the ring electrode has an outer circular groove and an inner circular groove. The diameter of the spot welding electrode is 20mm, and the diameter of the spherical surface is 50mm. The distance from the axis at the flat end face is and Each position has an annular groove with a depth of 200um and a width of 0.8mm. The diameter of the central circular platform 6

[0045] During spot welding, the positive electrode touches the surface of the aluminum plate, and the negative electrode touches the surface of the high-strength steel, resulting in a small indentation. At this time, the spo...

Embodiment 2

[0049] Same as Example 1, the difference is that the positive electrode 4 adopts a traditional ball electrode, the negative electrode 3 adopts a flat end face electrode, spot welding 1.2mm 6061 aluminum alloy + 1.2mm galvanized dual-phase steel, and the nugget after welding with the same heat input 5 has a diameter of 6.9 mm. Compared with the ring electrode of Comparative Example 1, more air hole defects are generated in the center of the nugget 5 .

[0050] Figure 7 As shown, the joint IMC welded by the ball electrode consists of heterogeneous iron-aluminum compound near the steel side and needle-like compound near the aluminum side. Its thickness is less than 3 μm.

Embodiment 3

[0052] Same as in Example 2, the positive electrode 4 is a traditional spherical electrode, the negative electrode 3 is a flat end electrode, spot welding 1.2 mm 6061 aluminum alloy + 1.2 mm galvanized dual-phase steel, and adjusting the welding parameters to obtain the same nugget diameter as in Example 1.

[0053] Table 1 is a comparison of the joint tensile shear performance (N) and fracture mode obtained by using the traditional ball electrode and the electrode with a circular groove on the ball end surface of the present invention (the data in Table 1 are the average value of multiple tests).

[0054] Table 1 Tensile shear performance (N), comparison of fracture modes

[0055] Nugget diameter (mm) Tensile shear performance (N) fracture mode ball electrode 7.4 4647 interface fracture ring electrode 7.4 5270 button break

[0056] As shown in Table 1, under the same nugget diameter, the tensile shear strength of the ball electrode is 464...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com