Automatic spot welding machine for welding capsule

A spot welding machine and welding film technology, applied in welding equipment, welding equipment, auxiliary welding equipment, etc., can solve the problems of waste of manpower, low spot welding efficiency, and high labor intensity of operators, so as to improve welding efficiency and liberation. Human labor, the effect of improving spot welding efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

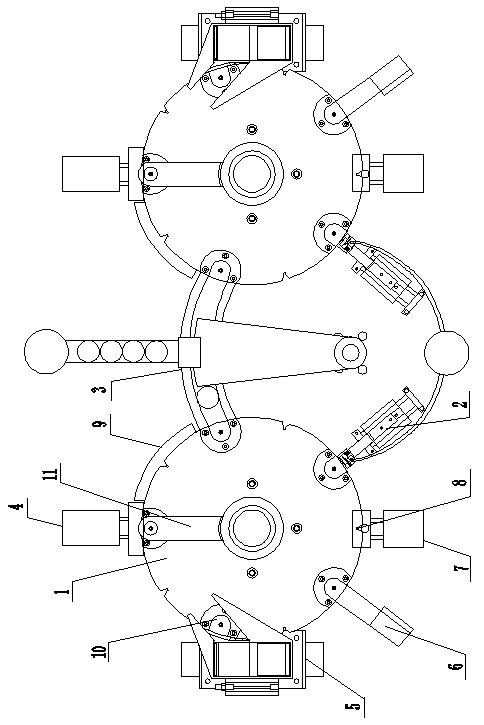

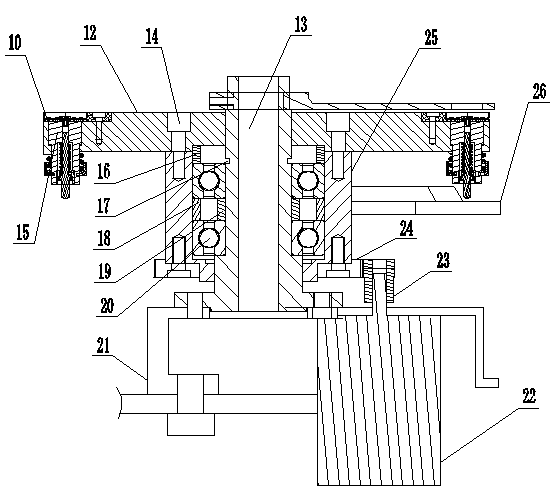

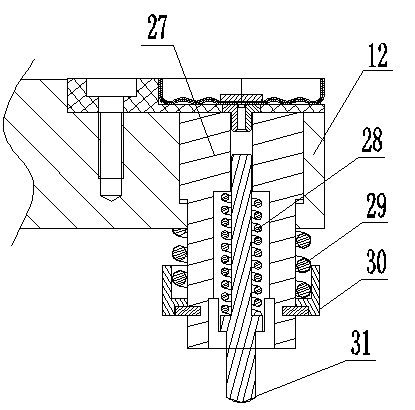

[0039] As shown in the figure, an automatic spot welding machine for welding film boxes, including a turntable device 1, a handle device 2, a sheet feeding device 3, a welding device 4, an unloading device 5, a mold cleaning device 6 and a turntable positioning device 7;

[0040]Described turntable device 1 is provided with two, and is distributed in the both sides of film feeding device 3, and film feeding device 3 is provided with the film feeding guide groove 44 that can convey bellows film to the rotating disk device 1 of both sides respectively, surrounds each A handle device 2, a welding device 4, a discharge device 5, a mold cleaning device 6 and a turntable positioning device 7 are evenly distributed around a turntable device 1; The card slot 8 matched with the turntable positioning device 7, on the upper surface of the turnt...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com