Spot welding general mold

A general-purpose mold and spot welding technology, used in manufacturing tools, welding equipment, auxiliary welding equipment, etc., can solve the problems of wasting labor and inability to adjust, and achieve the effect of saving materials and improving spot welding efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

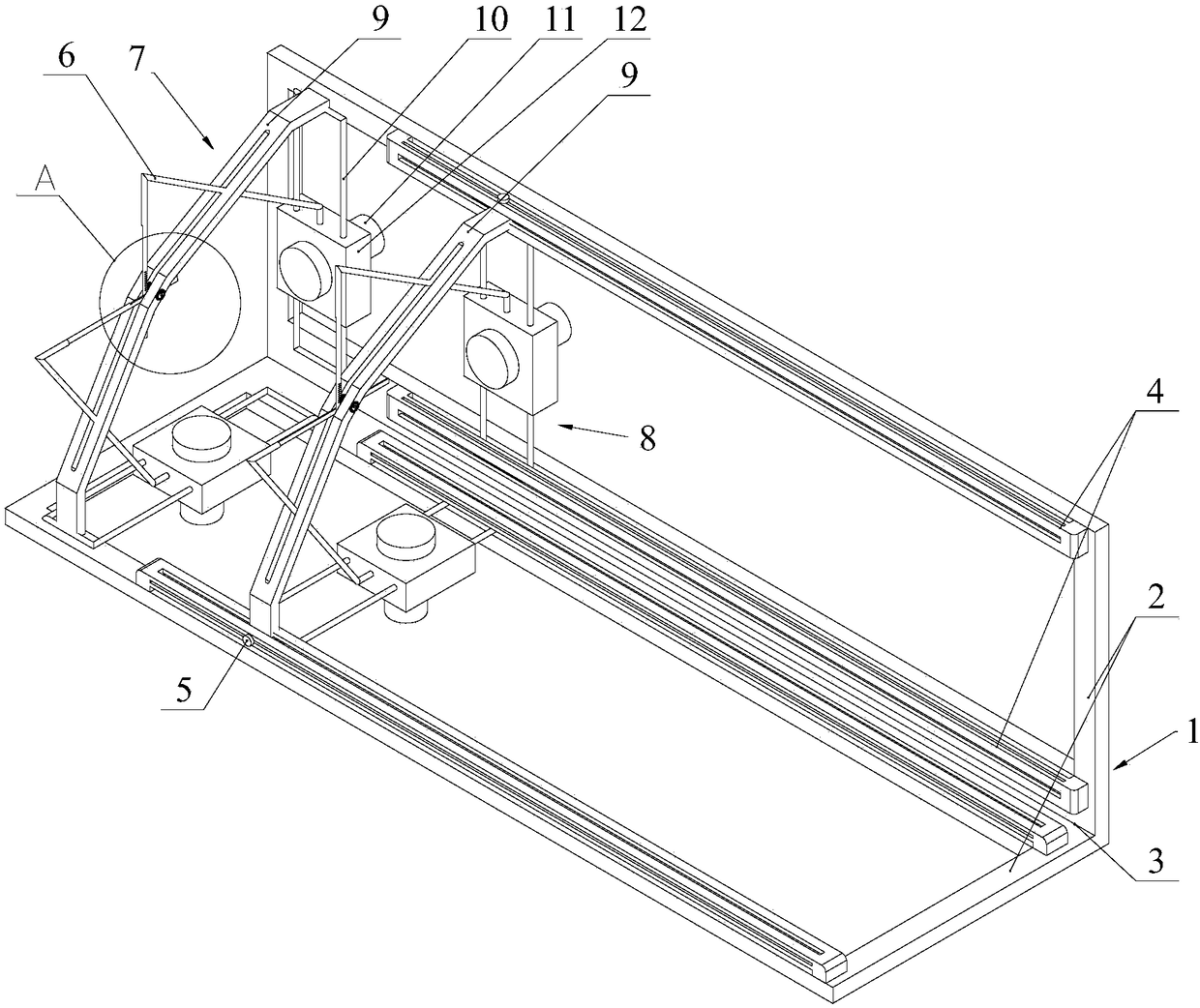

[0027] Such as figure 1 with 2 Shown, a kind of general mold for spot welding comprises a main frame 1, and the main frame 1 includes two sub-frames 2 perpendicular to each other, and the intersection of the two sub-frames 2 is an alignment 3, and each sub-frame 2 is aligned along its length direction. A sliding track 4 with a pitch between holes is provided;

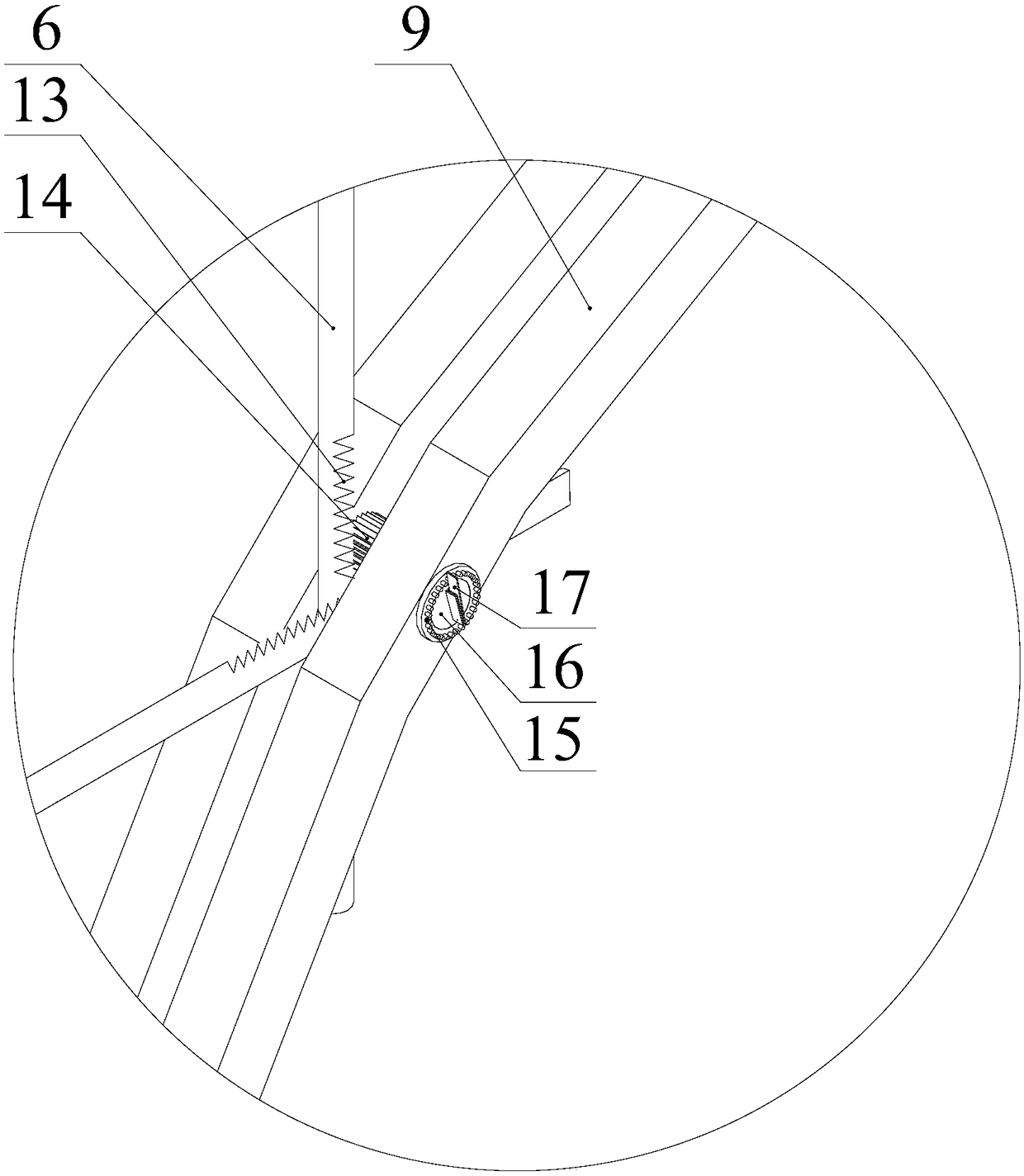

[0028] The universal mold for spot welding also includes a set of fixed end hole position control assemblies 7 and at least one set of movable end hole position control assemblies 8. The fixed end hole position control assemblies 7 and the movable end hole position control assemblies 8 all include two The alignment sliding track 10 on the sub-frame 2, the alignment control block 12 slidably installed on the alignment sliding track 10, the first limit mechanism that limits the alignment control block 12 after the alignment control block 12 moves into place, and The two alignment slide rails 10 are arranged symmetricall...

Embodiment 2

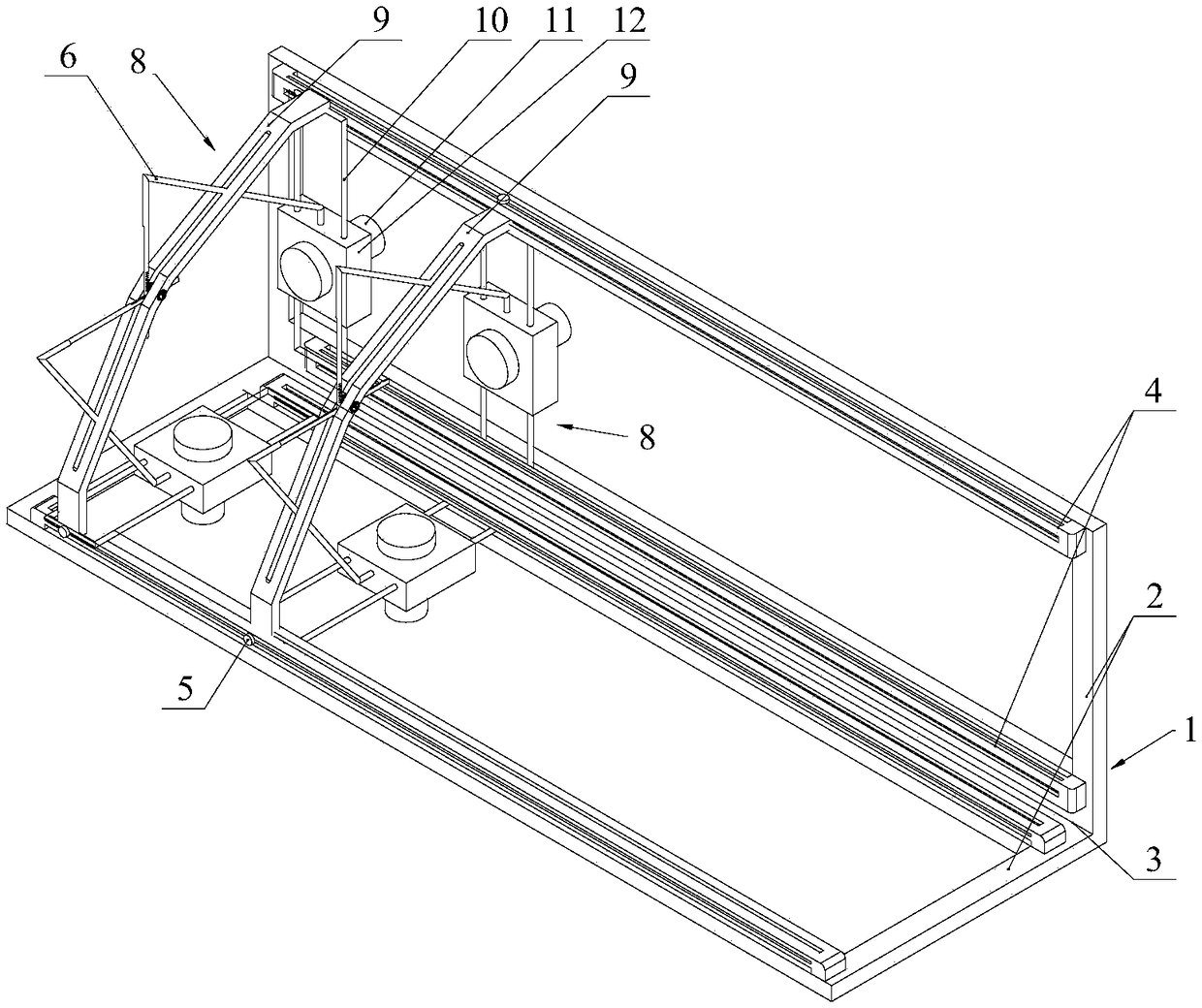

[0038] Such as image 3 As shown, the difference between this embodiment and Embodiment 1 is that this embodiment does not include the hole position control assembly 7 at the fixed end, but has at least two groups of hole position control assemblies 8 at the movable end.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com