Spot welding machine for batteries

A spot welding machine and battery technology, applied in welding equipment, auxiliary welding equipment, welding/cutting auxiliary equipment, etc., can solve the problems of unstable quality of battery solder joints, no automation of spot welding operations, and low assembly efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

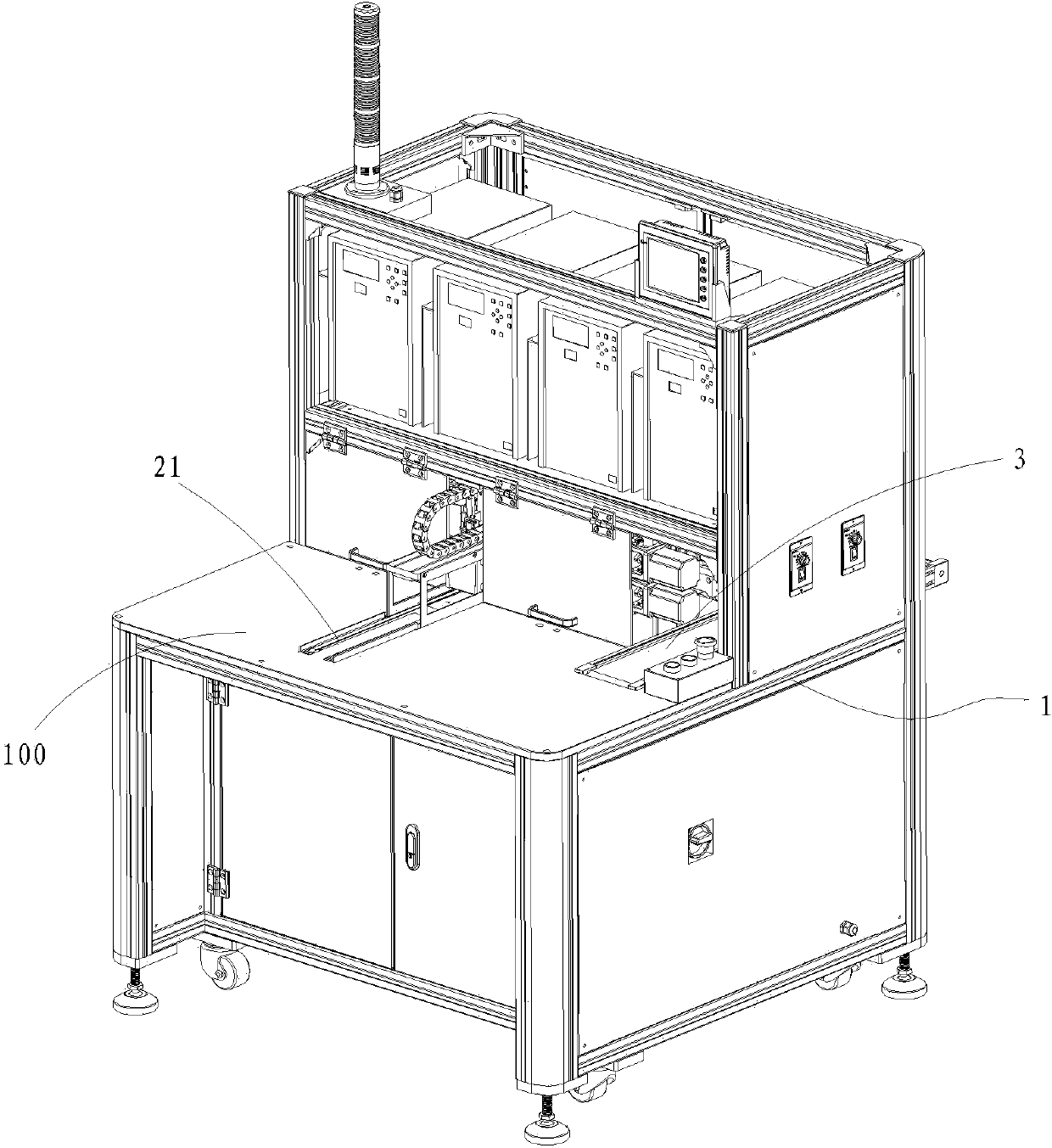

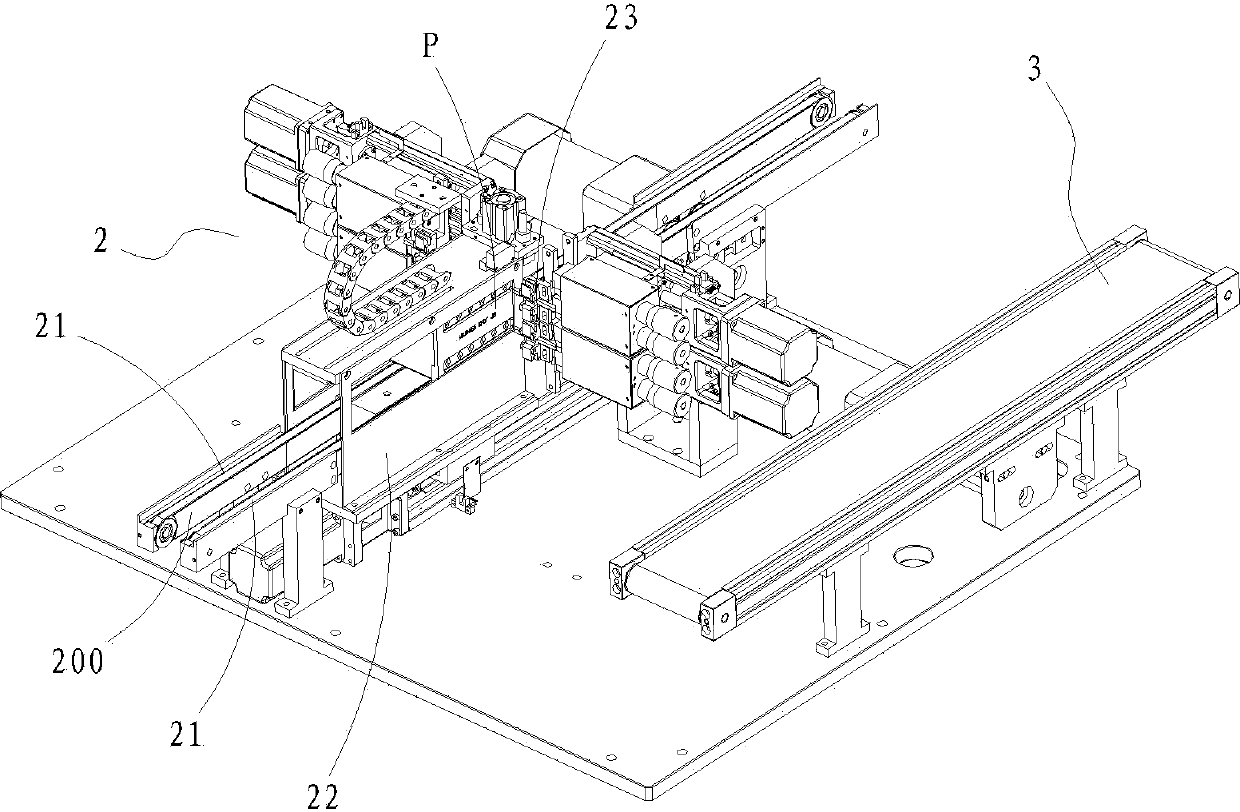

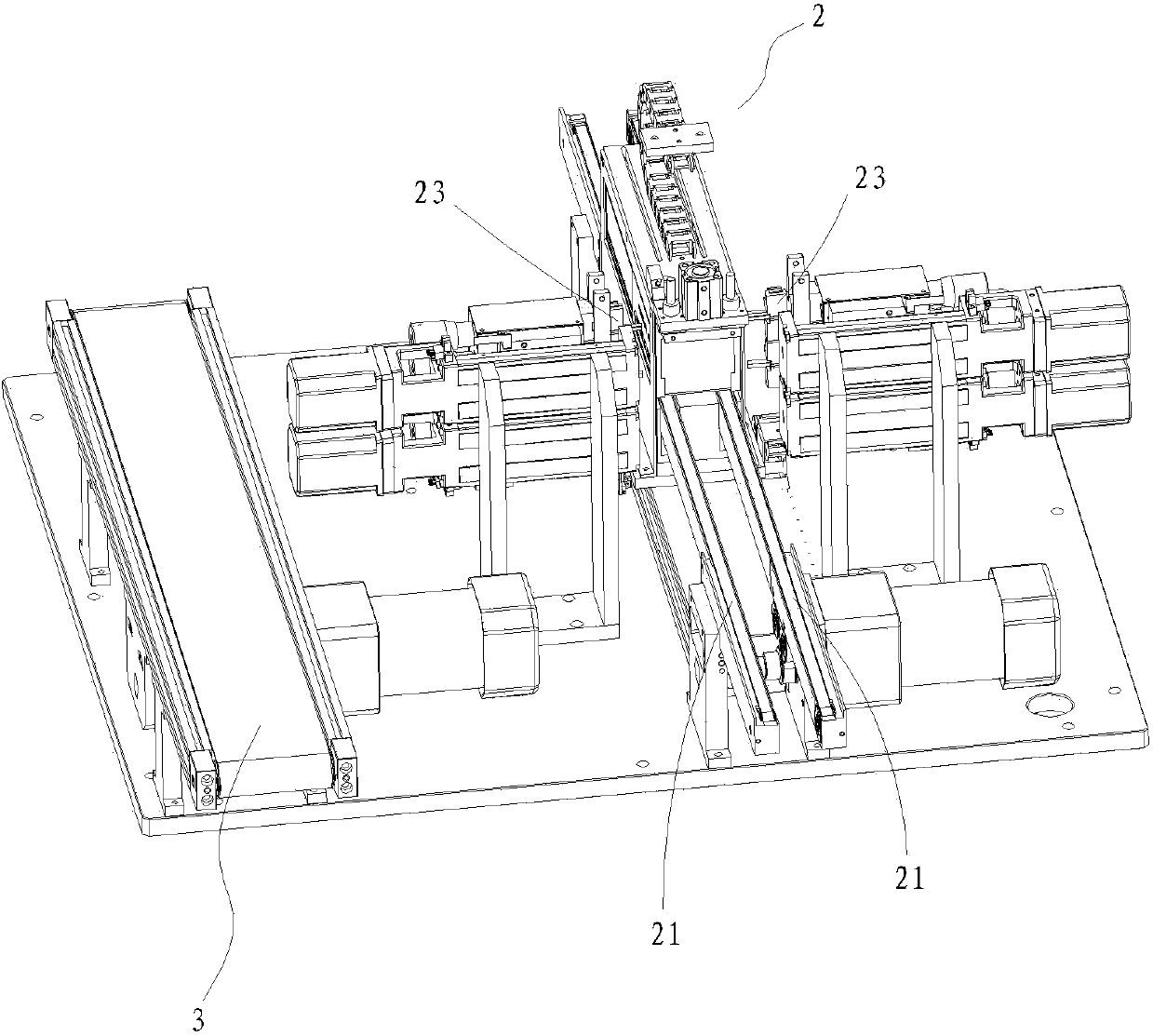

[0024] Example: see Figure 1 to Figure 5 , a battery spot welding machine, comprising a frame 1 and a spot welding device 2 mounted thereon, said spot welding device 2 comprising a conveyor belt 21, a spot welding frame 22 and a spot welding machine welding head 23:

[0025] Conveyor belt 21, which passes through the spot welding frame 22, the conveyor belt 21 has a gap 200 in the middle along the conveying direction, and the conveyor belt is used to convey the battery pack P;

[0026] Spot welding frame 22, it has a battery pack passage, and sensor is installed on this spot welding frame and is used for the battery pack that induction conveyer belt conveys, and the spot welding frame at battery pack channel end is provided with movable block 24, and described spot welding frame 22 two The sides are all opened with spot welds, and the position corresponding to the spot welds is provided with a spot welder welding head 23, and the tray assembly is housed on the spot welder and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com