Mesh welding machine with functions of simultaneously pressing multiple electrodes down and respectively welding single electrode

A welding wire mesh machine and electrode technology, applied in the field of wire mesh welding machines, can solve the problems of increasing the capacity of the transformer, poor flatness of the metal mesh, high power consumption, etc., to ensure the welding quality, the flatness, and the low power consumption. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] Embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

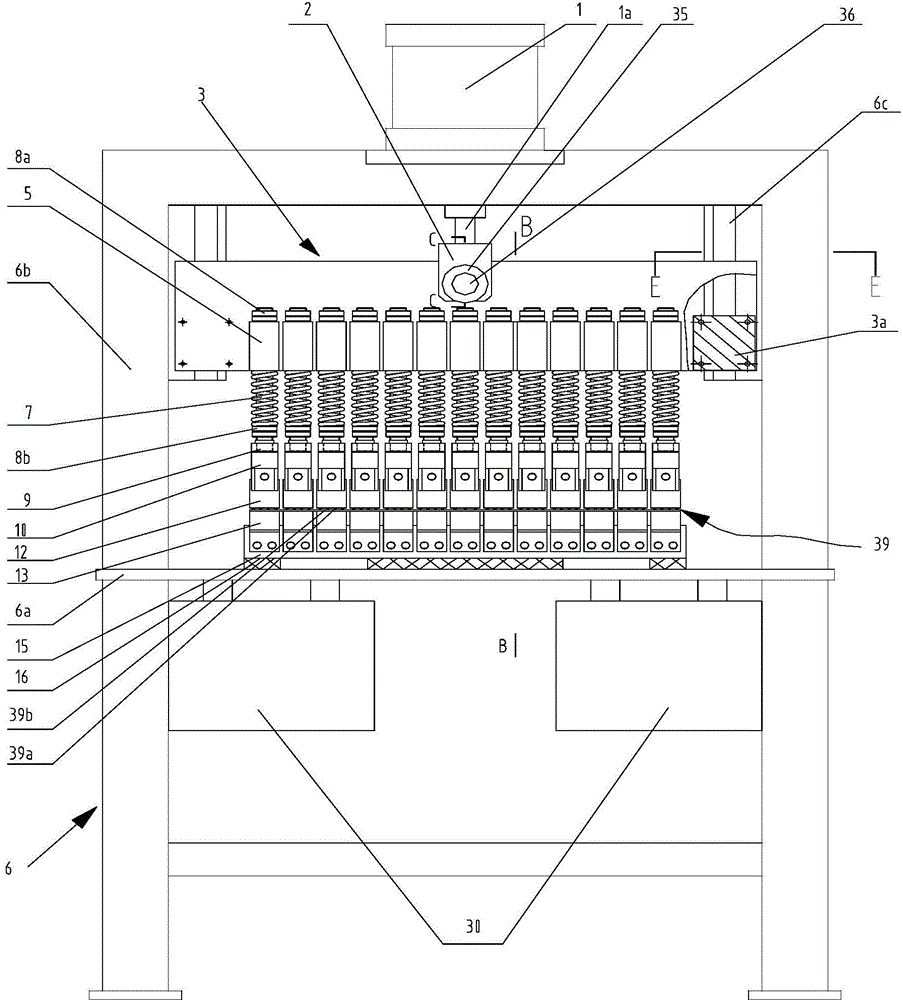

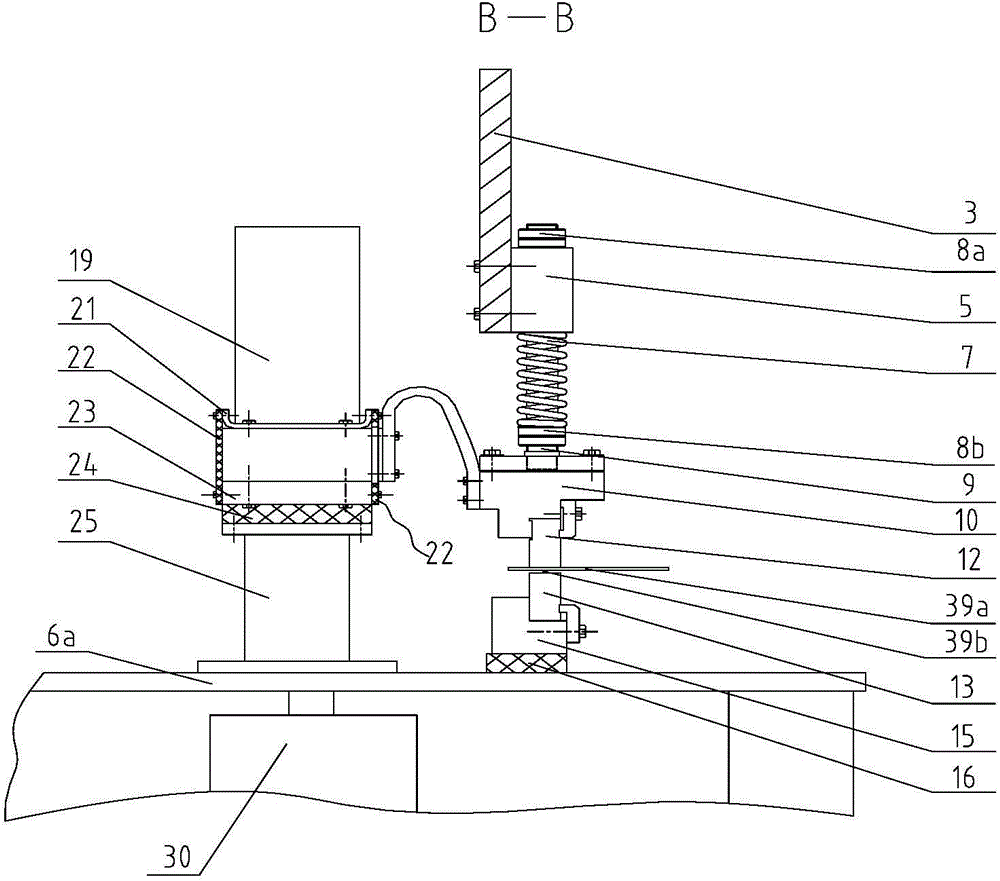

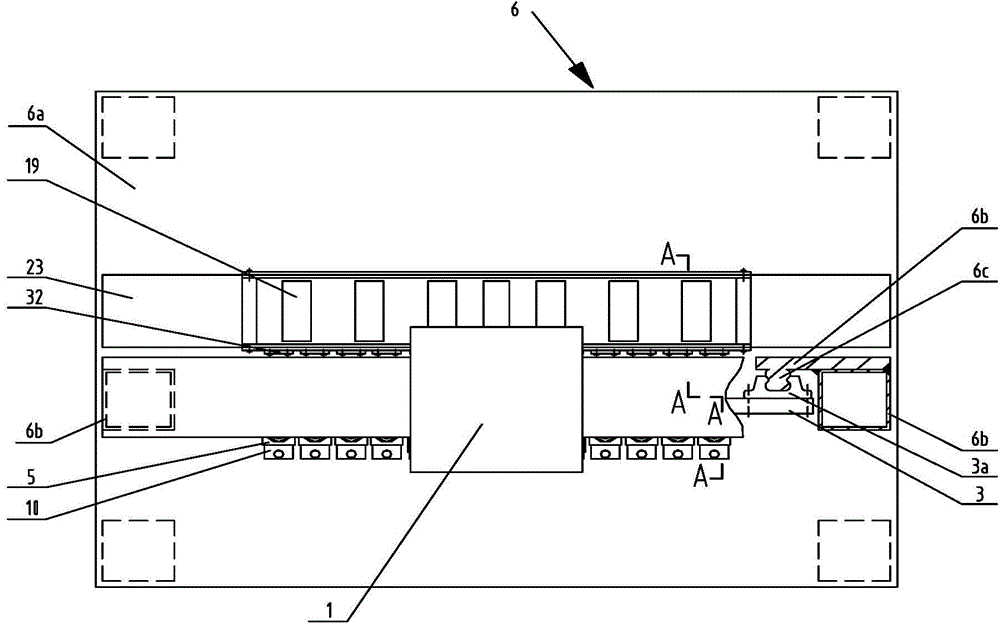

[0030] The invention discloses a mesh welding machine which has a plurality of electrodes and simultaneously presses down a single electrode to weld respectively. electrode 13.

[0031] like Figure 1 to Figure 1c As shown, the frame 6 includes four uprights supporting a frame plate 6a, two transformers 30 are arranged below the frame plate 6a, and a U-shaped upper frame 6b is supported in the middle of the left and right sides above the frame plate 6a. The electrode 12 and the lower electrode 13 are located in the upper frame 6b above the frame plate 6a.

[0032] The lower electrodes 13 have a plurality of spaced and arranged side by side, and the plurality of lower electrodes 13 are mounted on a lower electrode holder 15, and the lower electrode holder 15 is fixed on the frame 6 through the first insulating plate 16. The upper part of the integrated...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com