Automatic assembling device and automatic assembling method for welded steel bar truss deck

A technology of automatic assembly device and steel truss, applied in auxiliary devices, welding equipment, welding equipment and other directions, can solve the problems of increasing construction labor costs and a large number of labor, and achieve simplified operation, automatic positioning and centering, and safe operation. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

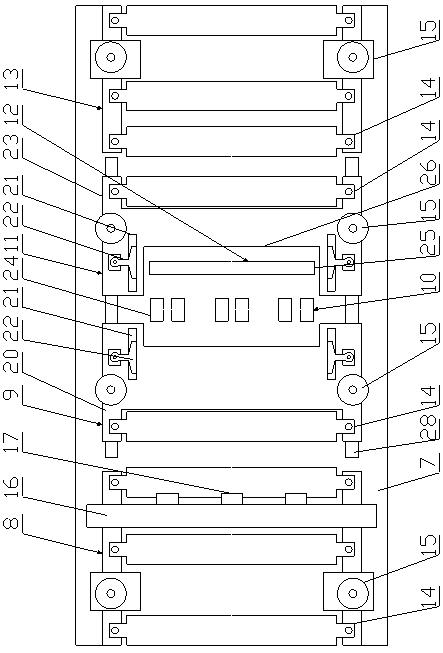

[0050] Embodiment 2 provides an automatic assembly method for a welded reinforced truss floor deck, the method comprising:

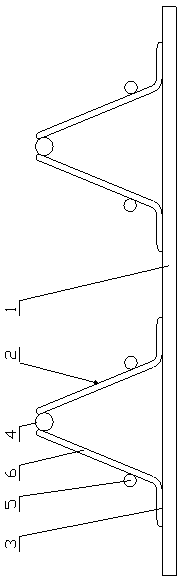

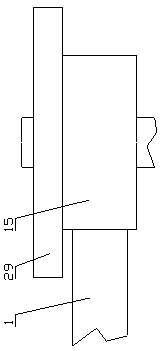

[0051] (1) The positioning cylinder drives the baffle plate 26 to rise above the rear slide plate 23, and at the same time, each guide wheel 15 and guide roller 14 rotate to send the bottom formwork 1 to the baffle plate 26 (the rear end of the bottom formwork 1 leans against the baffle plate 26, This place can be provided with contact switch), guide wheel 15 and guide roller 14 stop rotating.

[0052] (2) Manually place a plurality of steel bar trusses 2 along the pressing block 18 (through the inverted V-shaped groove 19 and guide roller 27) on the bottom template 1, and after placing them in place (manual control or delay control), the pressing cylinder 17 drives The pressing block 18 descends to compress and position the steel bar truss 2 on the bottom formwork 1 .

[0053] (3) The clamping structure 22 on the front feeding slide 9 (located at the r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com