Numerical control flange assembly special welding machine

A flange assembly and welding machine technology, applied in welding equipment, welding equipment, auxiliary welding equipment, etc., can solve the problems of high skill requirements for welders, unstable welding quality, unsightly welding, etc., to reduce personnel investment and easy operation , the effect of reducing training costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The embodiments of the present invention are described in detail below. This embodiment is implemented on the premise of the technical solution of the present invention, and detailed implementation methods and specific operating procedures are provided, but the protection scope of the present invention is not limited to the following implementation example.

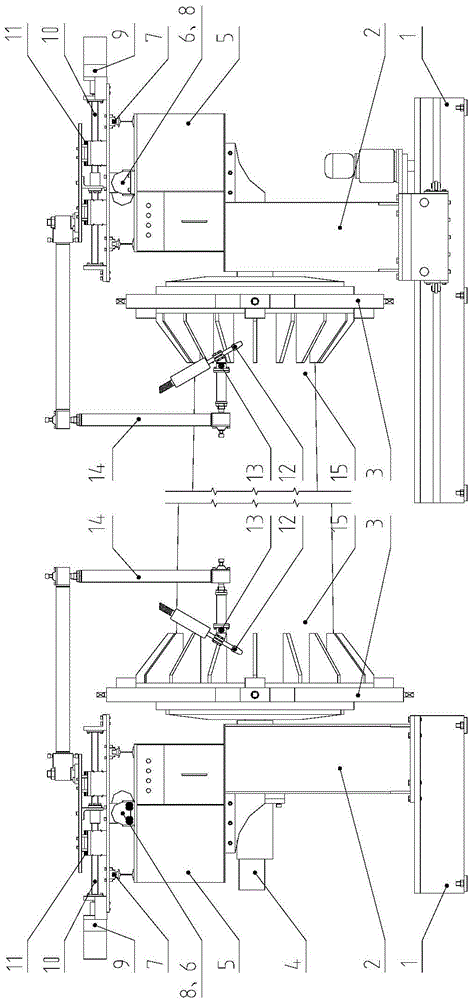

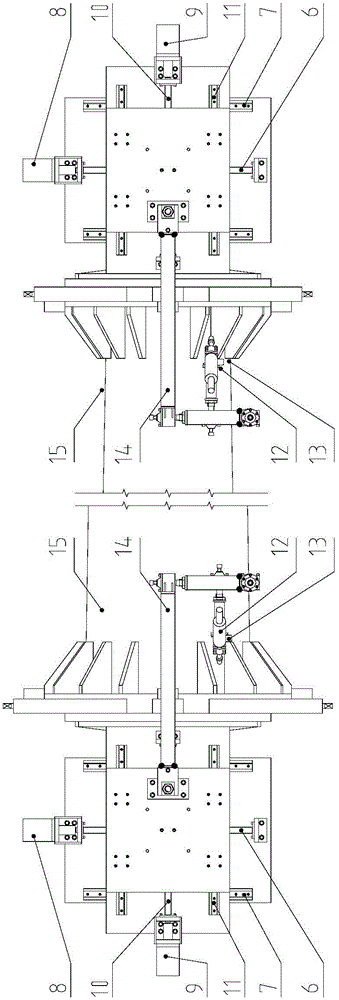

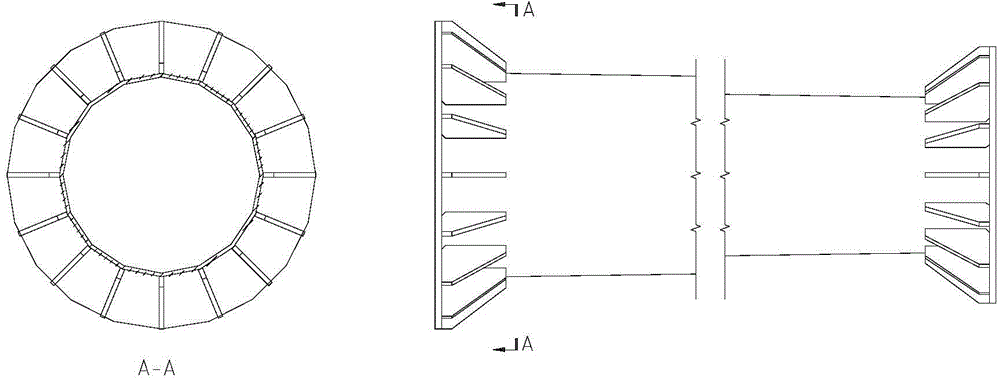

[0023] A special welding machine for NC flange assembly, including a base 1, a chassis 2, a self-aligning chuck 3, a Z-axis servo motor 4, a Z-axis reducer, a NC manipulator 5, an X-axis ball screw 6, and an X-axis linear Guide rail 7, X-axis servo motor 8, Y-axis servo motor 9, Y-axis ball screw 10, Y-axis linear guide 11, welding torch 12, welding machine, welding wire, shielding gas cylinder, oscillator 13 and universal bracket 14.

[0024] The base 1 is divided into two parts, the base A and the base B, and the base A and the base B are in a straight line but there is a gap in the middle. Chassis 2 is divided ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com