Rotary pipe welding machine

A pipe welding machine, rotary technology, applied in the direction of welding equipment, tubular objects, welding accessories, etc., can solve the problems of insufficient welding precision and low welding efficiency, so as to improve welding efficiency, increase welding efficiency and welding precision, and increase fixing efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

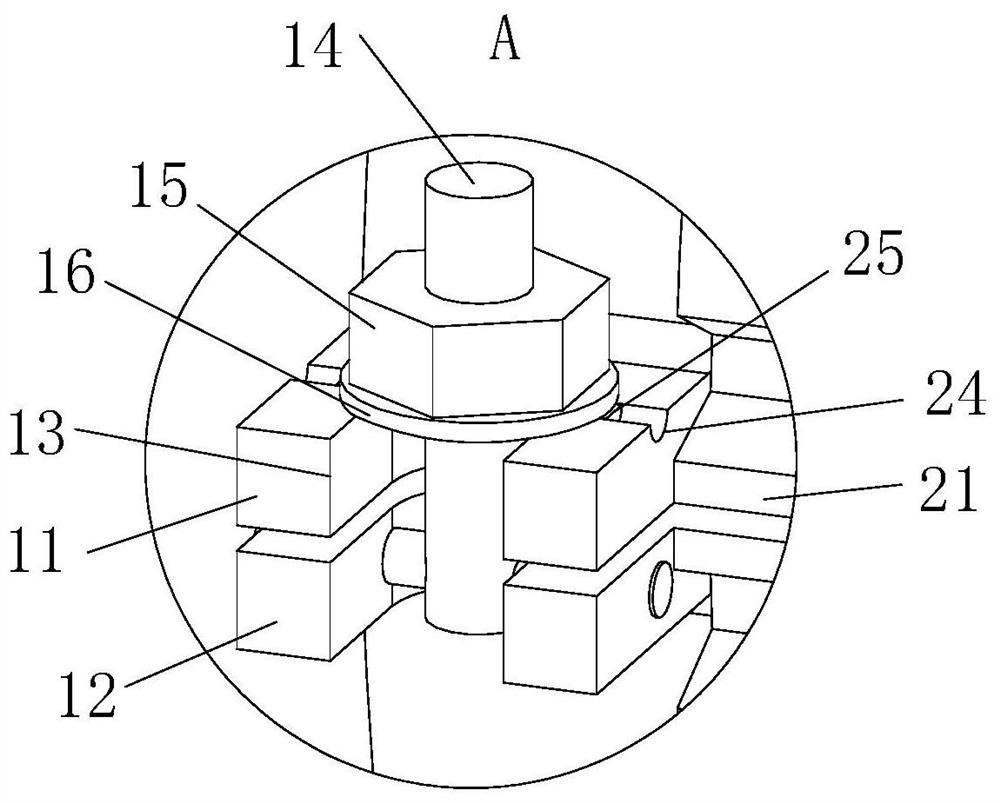

[0026]As an embodiment of the present invention, the top of the No. 1 splint 11 is provided with an arc-shaped groove 24, and the bottom of the gasket 16 is fixedly connected with an arc-shaped block 25 at the corresponding position of the arc-shaped groove 24, and the arc-shaped block 25 and the arc-shaped groove 24 cooperate with each other; the arc-shaped block 25 is snapped into the arc-shaped groove 24, and then the nut 15 is used to lock the gasket 16 and the snap ring 1, so that the arc-shaped block 25 presses the arc-shaped groove 24, thereby reducing the stud 14 The loosening of the vibration increases the firmness of the fixation between the snap ring 1 and the round pipe, and further reduces the adverse effect of the snap ring 1 loosening on the welding accuracy of the round pipe.

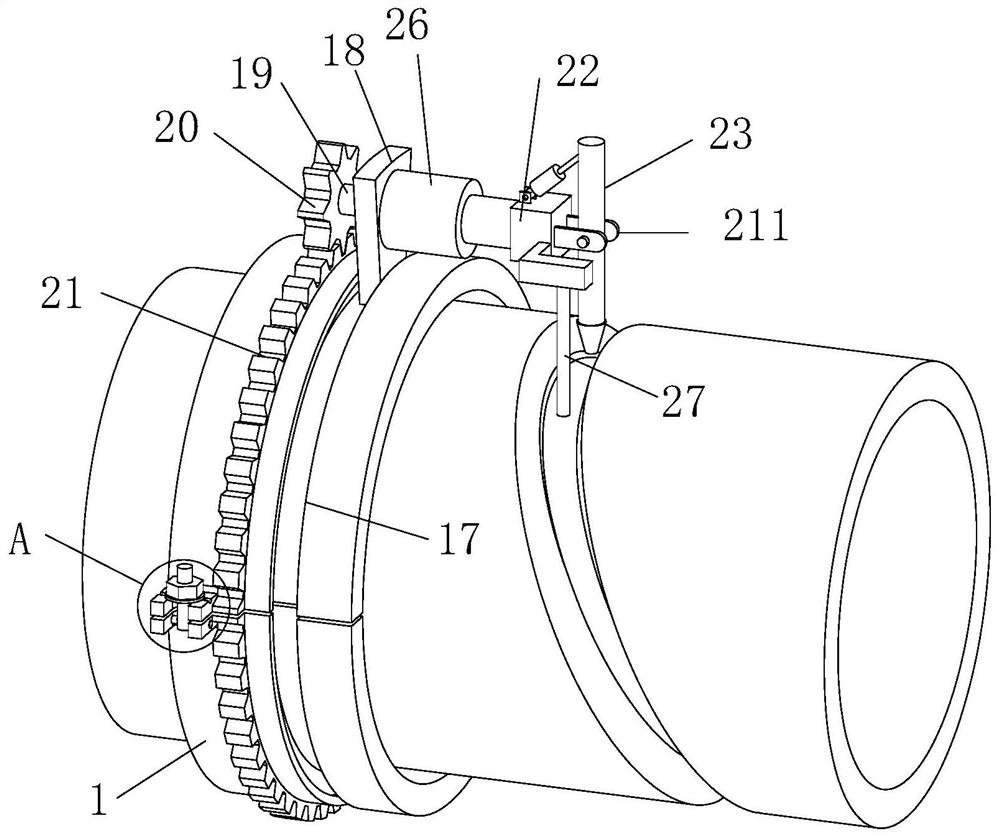

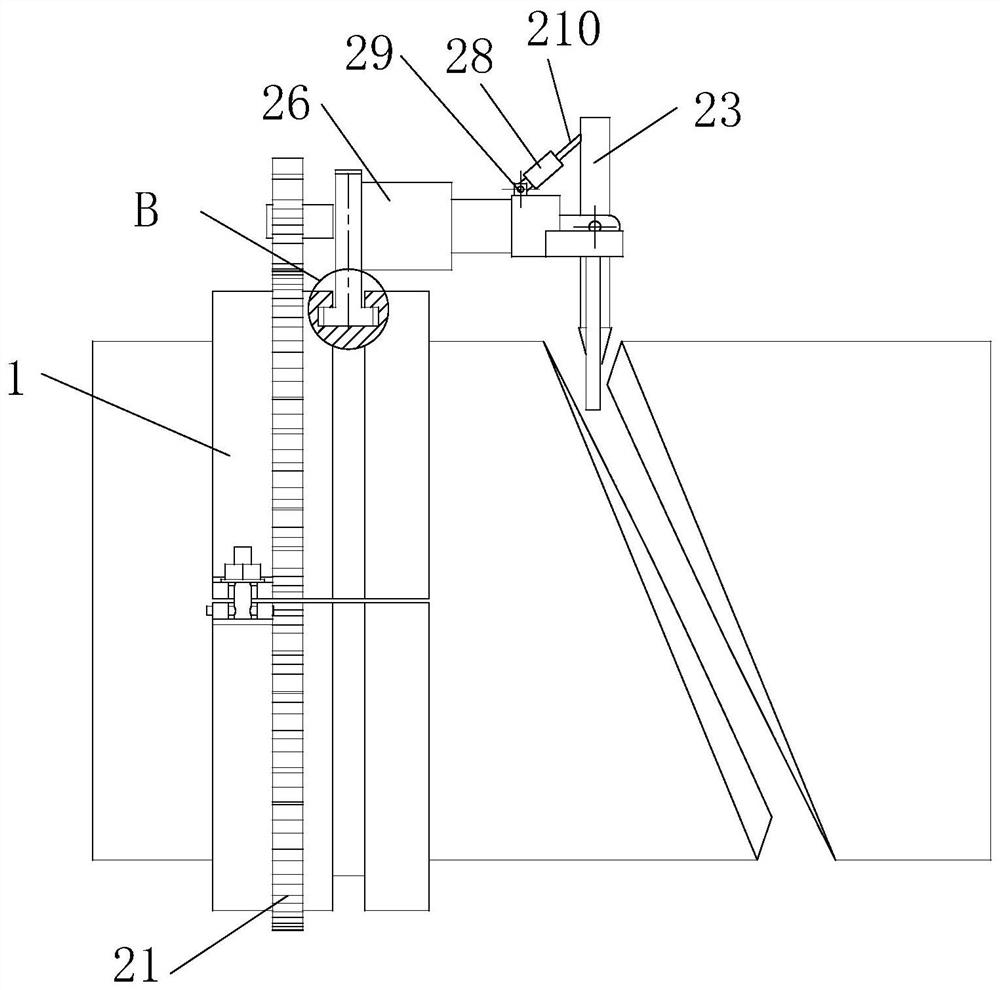

[0027] As an embodiment of the present invention, a telescopic rod 26 is fixedly connected between the soldering platform 22 and the T-shaped block 18; one side of the soldering platform ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com