Method and welding machine for welding pipe by using ultra-high molecular weight polyethylene membrane belt through hot melting

A technology of ultra-high molecular weight and polyethylene film, which is applied in the field of ultra-high molecular weight polyethylene film belt hot-melt welding pipes and welding machines, to achieve the effects of reducing production costs, continuous welding, and improving safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

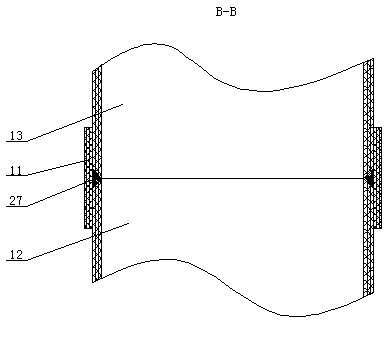

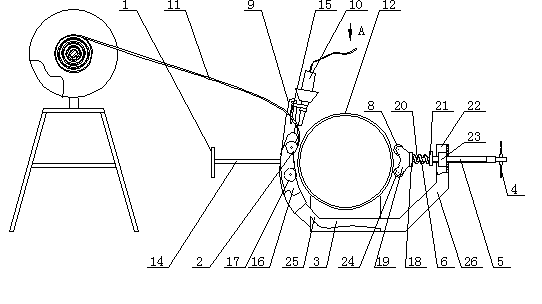

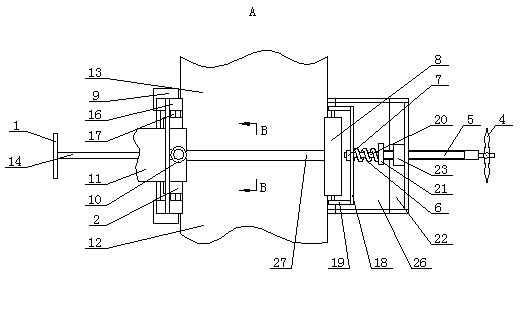

[0015] The method for the ultra-high molecular weight polyethylene diaphragm band heat-melt welding pipe material provided by the invention comprises the following steps:

[0016] ① Grind the joints of the ultra-high molecular weight polyethylene membrane pipes or ordinary polyethylene pipes to be connected into a 45° bevel;

[0017] ② Align the two pipe joints to form a V shape, weld the polyethylene welding wire along the V-shaped groove with a welding torch for one week, and fill the V-shaped groove with the hot-melted welding wire;

[0018] ③Use an angle grinder to grind the weld seam flat so that the surface of the weld seam and the outer surface of the pipe are in the same plane;

[0019] ④ Put the ultra-high molecular weight polyethylene film belt hot-melt welding machine on the outer circumference of the pipe, so that the pipe joint after welding and smoothing in step ③ is located in the middle of the welding machine;

[0020] ⑤Take one end of the membrane welding tap...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com