Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

154results about How to "Good thermal stability at high temperature" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

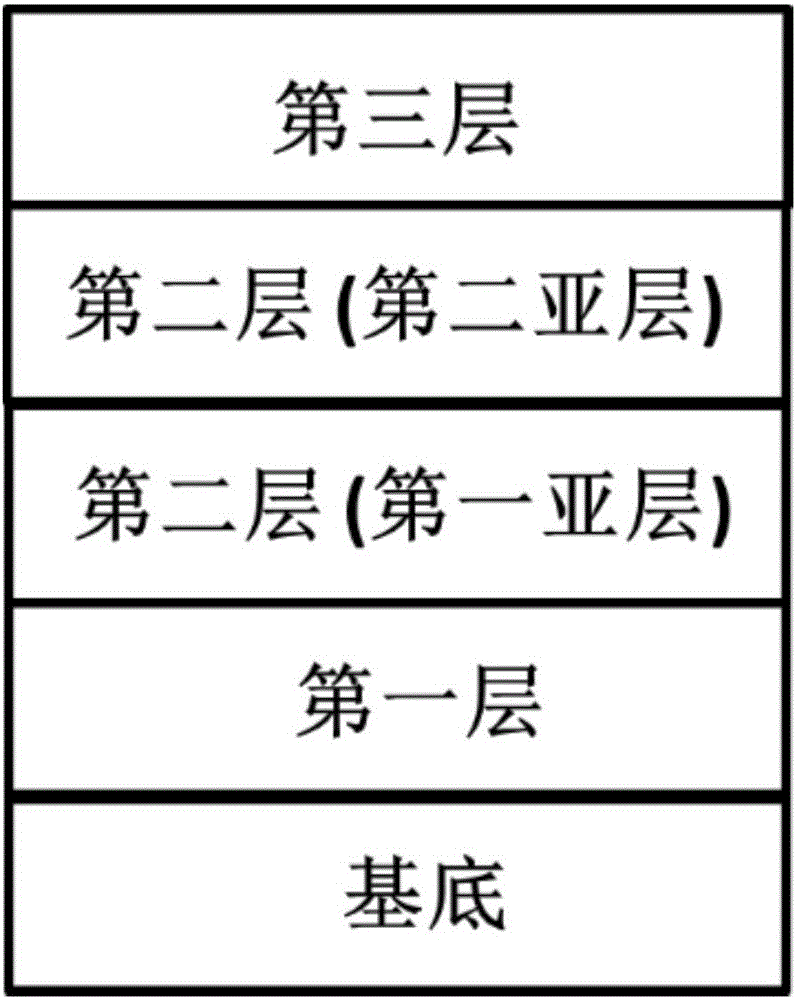

Solar selective absorbing coating and preparation method thereof

ActiveCN101922816ASimple preparation processEasy to operateSolar heat devicesVacuum evaporation coatingAbsorption layerCermet

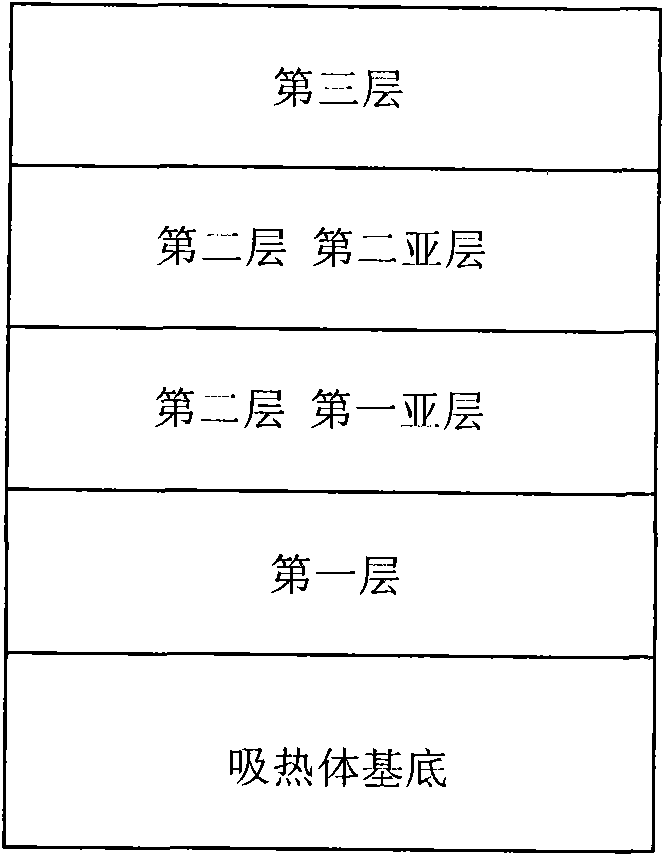

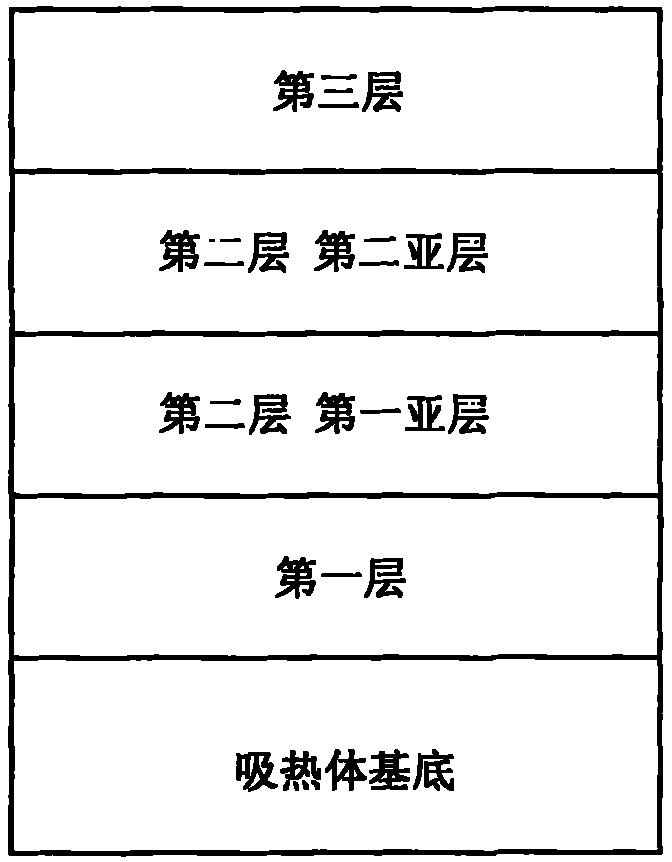

The invention discloses a solar selective absorbing coating and a preparation method thereof. The coating comprises three layers of films from bottom to top on the surface of a heat absorber substrate; the first layer is an infrared reflective layer and consists of a metal molybdenum film; the second layer is an absorption layer, consists of a composite metal ceramic layer made from Ni-Al alloy particles and an insulating medium and is formed by two sublayers with different thicknesses and different Ni-Al alloy volume percentages in structure, wherein the thickness of the first sublayer is 35-70nm, the Ni-Al alloy volume percentage of the first sublayer is 40-60 percent, the thickness of the second sublayer is 30-60nm, and the Ni-Al alloy volume percentage of the second sublayer is 20-40 percent; the third layer is an anti-reflection layer formed by an aluminum oxide ceramic film. The preparation method thereof comprises three steps. Under the condition that an air quality factor AM is 1.5, the absorptivity of the coating is no less than 0.93, and the emissivity of the coating is no more than 0.09. The coating has good heat stability and can be used in the vacuum environment at the temperature of 600 DEG C for a long term. The invention has the practical value and wide application prospect in the technical field of solar heat utilization and thermal generation.

Owner:安徽科鑫光热技术有限公司

Preparation method for zirconium-contained rare-earth composite oxide

ActiveCN102417352AExpand industrial applicationsHigh surface areaCatalyst carriersMetal/metal-oxides/metal-hydroxide catalystsChemical industryCalcium bicarbonate

The invention relates to a preparation method for a zirconium-contained rare-earth composite oxide. At a certain ratio, rare earth (cerium, yttrium, praseodymium or terbium) is mixed with zirconium to burden, or rare earth (cerium, yttrium, praseodymium or terbium) and zirconium are mixed with at least one of other metal ions (aluminum, barium, magnesium, strontium, titanium, manganese, ferrum, copper and hafnium) to burden. A magnesium bicarbonate or / and calcium bicarbonate aqueous solution prepared from raw materials of magnesium or / and calcium minerals or oxides and hydroxides by at least one working procedure of roasting, digesting, mixing size, carbonizing and the like can serve as a precipitator to carry out precipitation so as to obtain at least one of rare earth and zirconium composite carbonate and subcarbonate, and the at least one of rare earth and zirconium composite carbonate and subcarbonate is further roasted to obtain a zirconium-contained rare-earth composite oxide product. In the preparation method, cheap calcium or / and magnesium minerals or low-purity oxides and hydroxides can serve as initial raw materials to replace common chemical industry precipitators, such as ammonia water, ammonium bicarbonate, sodium carbonate, sodium hydroxide and the like, substances, such as magnesium, calcium, carbon dioxide and the like can be effectively circulated and utilized so as to greatly lower the production cost of the zirconium-contained rare-earth composite oxide, such as ceria-zirconia, yttrium zirconium, praseodymium zirconium, terbium zirconium and the like. In addition, in the production technology disclosed by the invention, no ammonia nitrogen wastewater, high-salinity wastewater and the like are generated, carbon dioxide greenhouse gas emission amount is reduced, the preparation technology is environmentally-friendly, and environment pollution is avoided.

Owner:GRIREM ADVANCED MATERIALS CO LTD

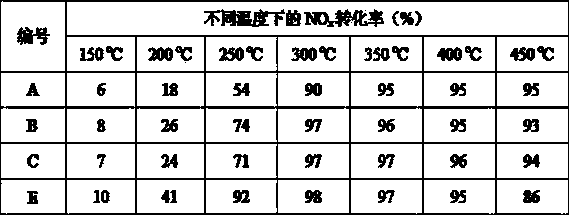

Preparation method of high temperature resistant vanadium tungsten titanium oxide catalyst

InactiveCN104162421AHigh selectivityGood water and sulfur resistanceDispersed particle separationMetal/metal-oxides/metal-hydroxide catalystsNitric oxideTemperature resistance

Owner:NANJING UNIV OF SCI & TECH

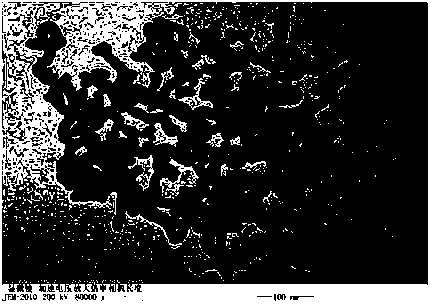

Ni-based catalyst adopting core-shell structure and used in DRM (dry reforming of methane) and preparation method

InactiveCN107552054AImprove anti-sinteringImprove anti-carbon performanceHydrogenMetal/metal-oxides/metal-hydroxide catalystsGas compositionReaction temperature

The invention discloses a Ni-based catalyst adopting a core-shell structure and used in DRM (dry reforming of methane) and a preparation method. A Ni-MOx@SiO2 (M is Zr, La and Ce) multi-core core-shell material is prepared with a reversed-phase microemulsion method with nickel nitrate, zirconium nitrate and the like as precursor salt. The additive amount of metal oxide in the catalyst is 1%-5% ofthe weight of the catalyst and the additive amount of nickel is 5%-10% of the weight of the catalyst. The sintering resistance and carbon deposit resistance of the catalyst are remarkably enhanced dueto addition of the metal oxide. The catalyst shows high activity, high stability and extremely high carbon deposit resistance and sintering resistance under the reaction conditions of normal pressure, reaction gas composition CH4:CO2 being 1.05:1, the air speed being 1,8000 ml.gcat<-1>.h<-1> and the reaction temperature being 800 DEG C. The catalyst has the advantages of being simple to prepare,free of secondary pollution to the environment, low in cost, high in catalytic efficiency and the like.

Owner:NANCHANG UNIV

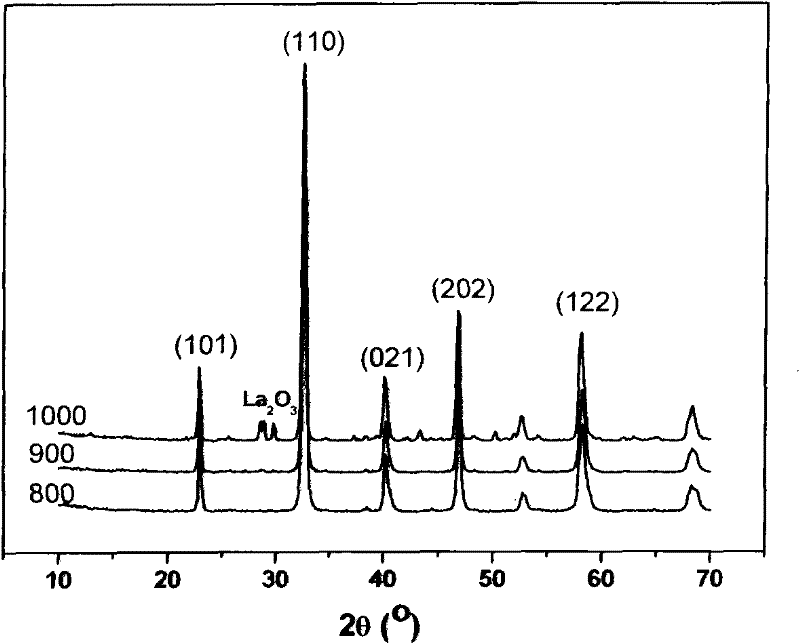

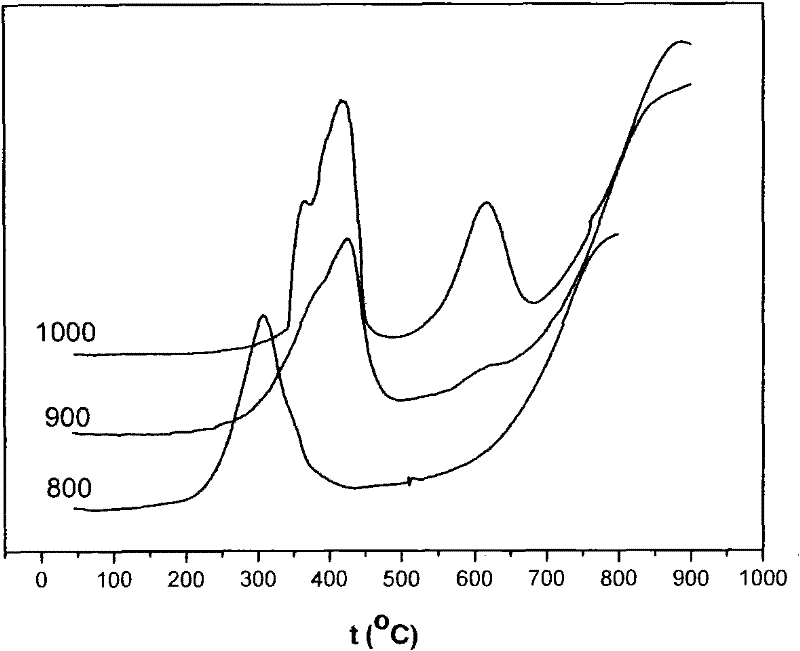

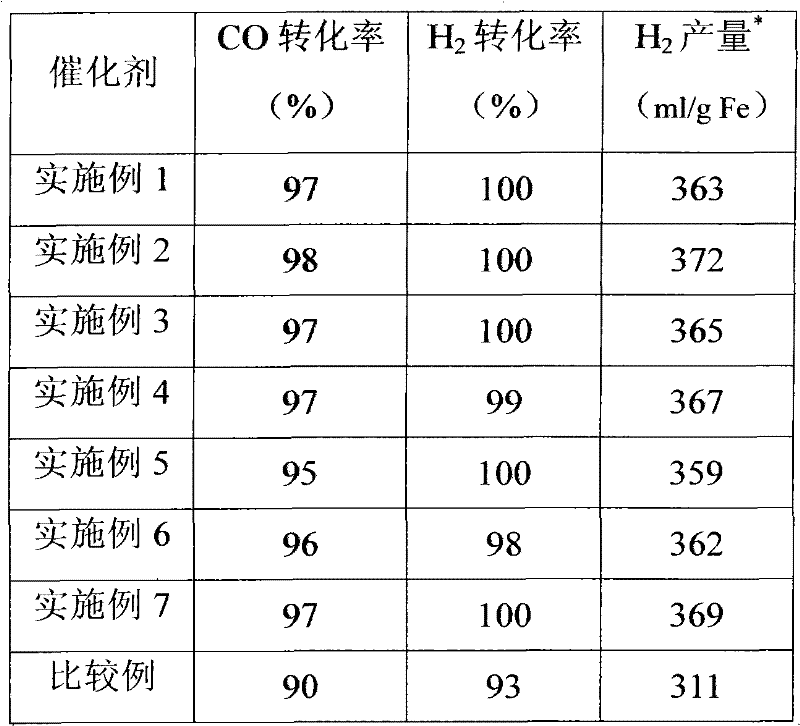

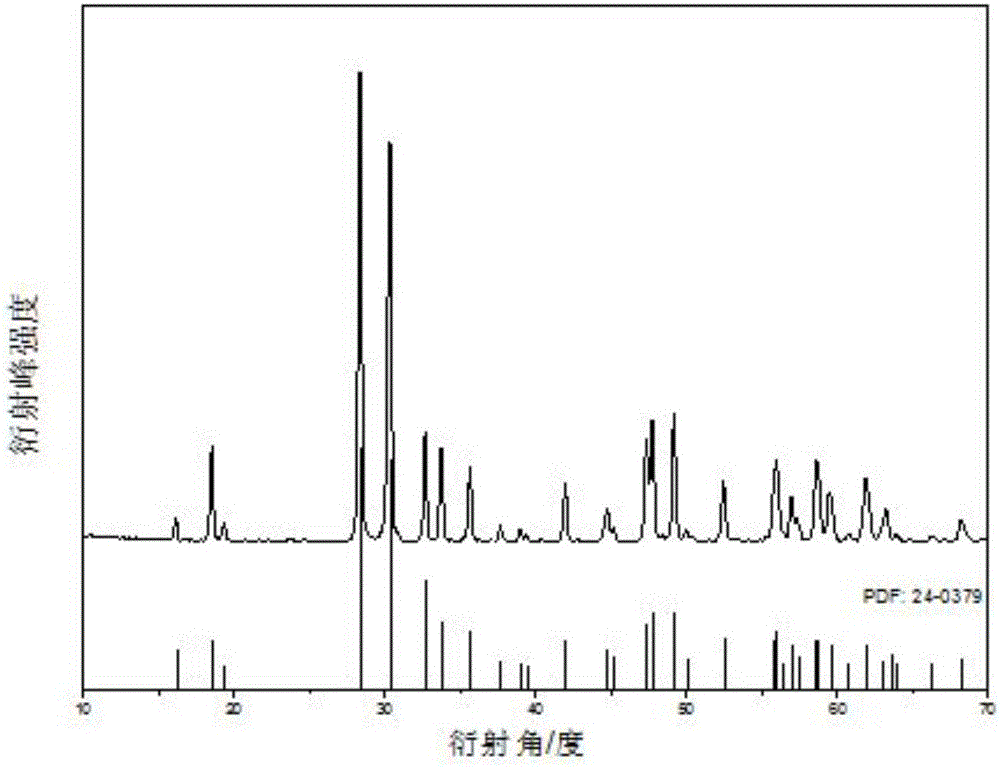

Application of double perovskite type oxide oxygen carrier in hydrogen production of chemical chain and preparation method

ActiveCN102441396AGood thermal stability at high temperatureHigh activityHydrogen productionMetal/metal-oxides/metal-hydroxide catalystsHigh oxygenLanthanum nitrate

The invention discloses application of a double perovskite type oxide oxygen carrier in the hydrogen production of a chemical chain and a preparation method. The oxygen carrier is a composite metal oxide with a double perovskite structure; the general formula of the composite metal oxide is A2B'B''O6, wherein A is rare earth metal lanthanum, B' is transition metal nickel, and B'' is transition metal iron; the combustion temperature of the oxygen carrier in water vapor is 500-1,000 DEG C; the reduction temperature of the oxygen carrier in fuel after the oxygen carrier is combusted is 500-1,000 DEG C; and the reaction pressure is the normal pressure. The preparation method comprises the following steps of: taking iron nitrate, nickel nitrate and lanthanum nitrate as precursors, taking citric acid as a complexing agent, preparing a solution from the precursors and the complexing agent, and evenly mixing and stirring; and then, carrying out water evaporation while the solution changes into viscous gel from transparent colloidal sol, then, drying, and roasting, wherein the roasted sample is the composite metal oxide with the double perovskite structure. The oxygen carrier prepared by the preparation method has high oxygen-carrying rate, high activity and good stability.

Owner:CHINA PETROLEUM & CHEM CORP +1

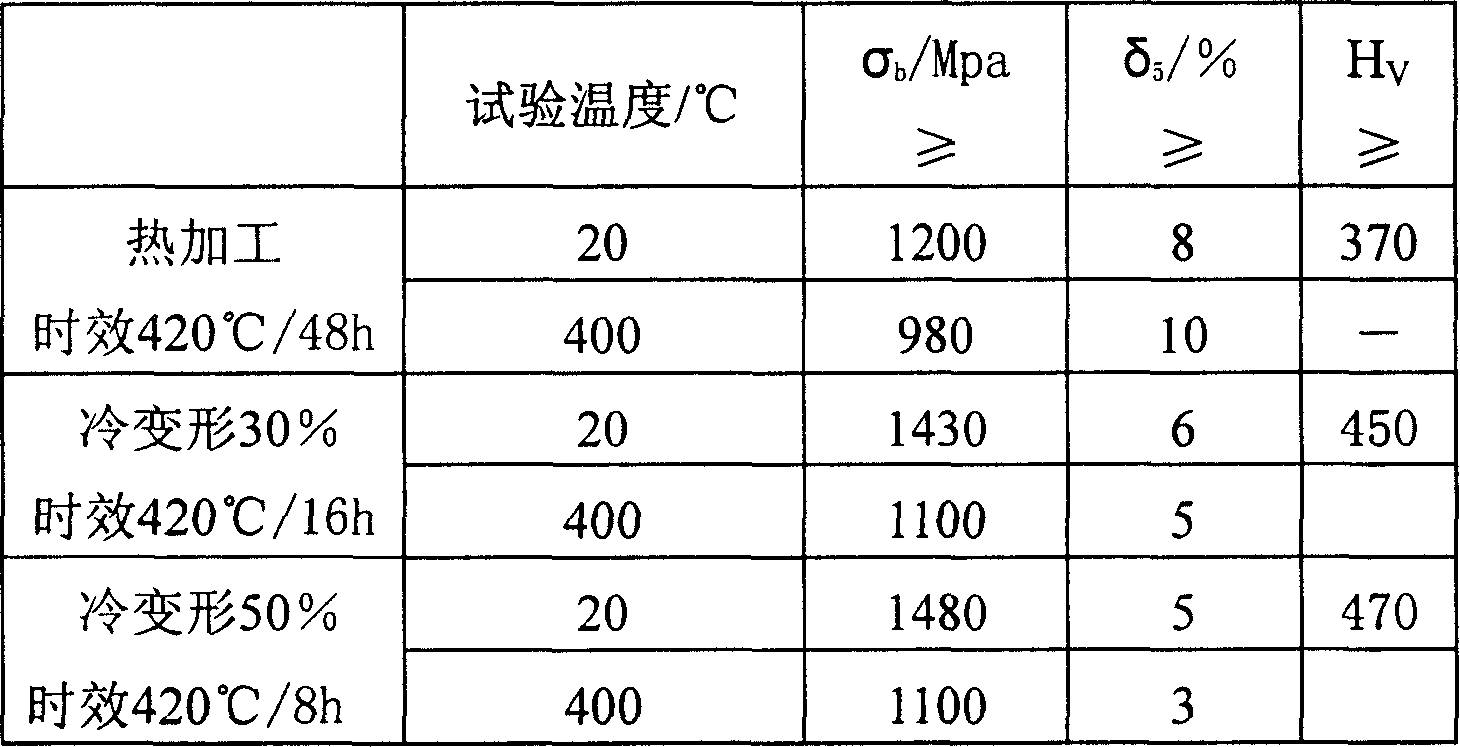

Copper-base alloy and preparation method thereof

The invention relates to a copper base alloy and a preparation method for the copper base alloy. Chemical compositions and weight percentage of the copper base alloy are that: nickel: 14.0 to 30.0 percent; manganese: 14.0 to 30.0 percent; ferrum: 1.0 to 8.0 percent; the residual is copper; moreover, aluminum: less than 0.002 percent; plumbum: less than 0.002 percent; antimony: less than 0.002 percent; bismuth: less than 0.002 percent; phosphorus: less than 0.01 percent; the residual composition is copper. The copper base alloy with high performance is prepared after smelting and thermo-mechanical treatment, microstructure of the alloy can be controlled to be nearly equiaxial crystal particles with the diameter of 50 micrometers. The alloy has ageing strengthening effect. When the alloy is stretched under room temperature by ageing after cold deformation, the breaking strength sigma b reaches 1480 MPa at maximum; the extensibility delta 5 reaches 6 percent at maximum; the Vickers hardness Hv reaches 470 at maximum. When the alloy is stretched under high temperature of 400 DEG C, the breaking strength sigma b reaches 1100MPa at maximum, and the extensibility delta 5 reaches 6 percent at maximum.

Owner:GRIKIN ADVANCED MATERIALS

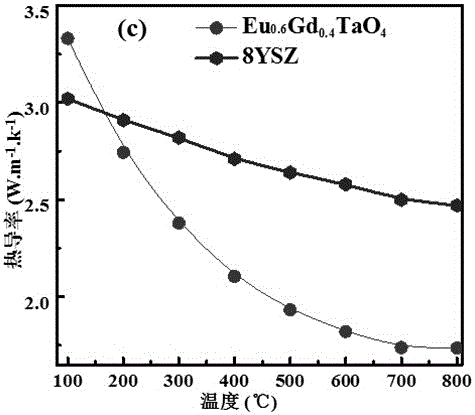

Preparation method of double-rare-earth-ion tantalite high-temperature ceramic

The invention relates to a preparation method of double-rare-earth-ion tantalite high-temperature ceramic and belongs to the technical field of high-temperature ceramic preparation. The molecular formula of the double-rare-earth-ion tantalite high-temperature ceramic is shown in the description (REa / REb = Y, La, Nd, Sm, Eu, Gd, Dy, Er and Yb, and REa and REb are not the same type of rare earth elements). The used raw materials are rare earth oxide and tantalum oxide andare weighed in proportion, the weighed raw materials and absolute ethyl alcohol are put in a ball milling tank for mixing and sealing, then the mixture is put on a planetary ball mill for ball milling, the mixture can be evenly mixed, and primary sintering is performed after the mixed powder is dried and screened; the cooled and taken-out sample is grinded, ball-milled, dried and screened and then is put in a mold for compaction, and then secondary sintering is performed. The preparation method is high in purity, low in impurity content, low in product device cost and suitable for batch production, and the product is expected to be a novel ceramic material resistant tohigh temperature, oxidation and abrasion.

Owner:KUNMING UNIV OF SCI & TECH

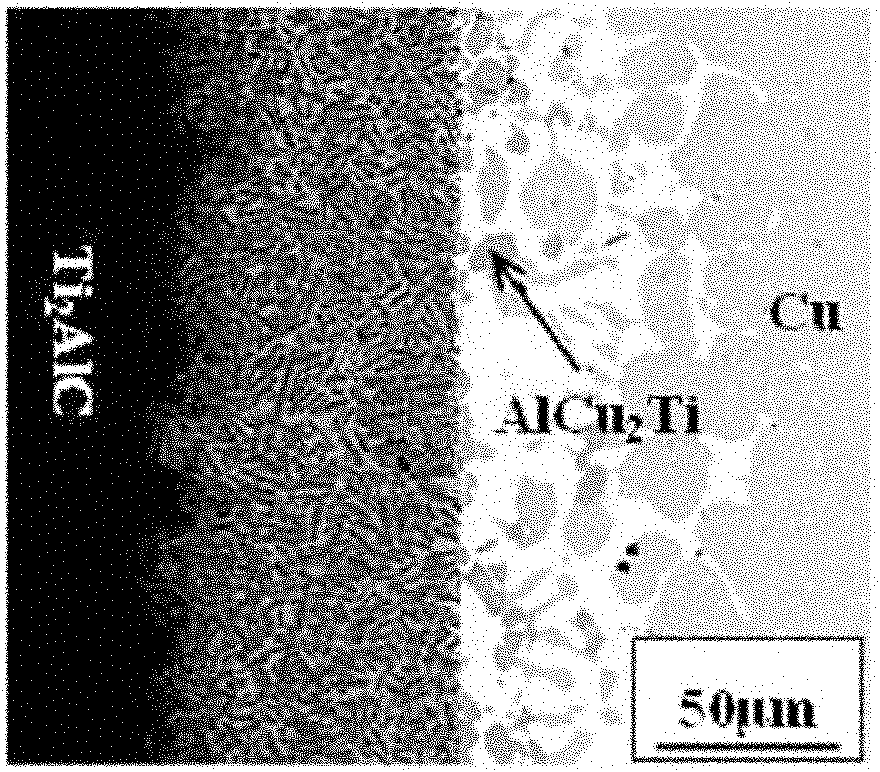

Method for soldering TiAlC ceramic and copper by using Ag-Cu eutectic solder

The invention discloses a method for soldering TiAlC ceramic and copper by using Ag-Cu eutectic solder, relating to a method for soldering TiAlC ceramic and copper and realizing high-strength and high-conductivity connection of the TiAlC ceramic and the copper. The method comprises the steps of: respectively grinding, polishing and cleaning the TiAlC ceramic and the copper, assembling the TiAlC ceramic, the Ag-Cu eutectic solder and the copper into a soldering assembling member, and then placing in a vacuum soldering furnace for soldering. The invention successfully realizes the connection of the TiAlC ceramic and the copper, and ensures joint compression shearing strength of 89.3-203.3MPa, conductivity of 5.034*10<6>-6.523*10<6>S / m, high joint strength and good conductivity. A joint of the TiAlC ceramic and the copper is used for current-carrying friction elements, and the general problems of high cost and shorter service life of the current-carrying friction elements applied to the traditional engineering can be solved.

Owner:HARBIN INST OF TECH

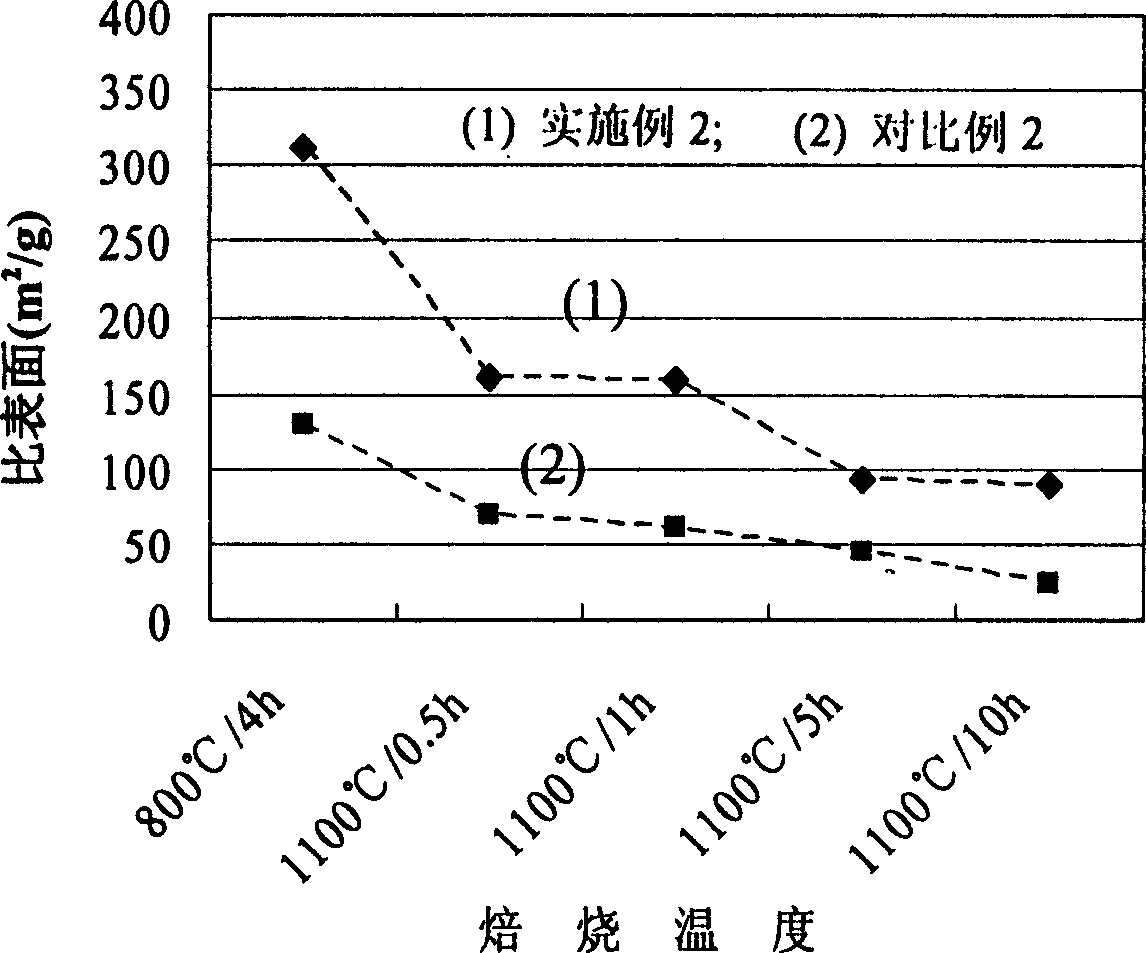

Method for preparing light temperature-resistance high surface area alumina and aluminiferous composite oxide

InactiveCN1528667AUniform particle size distributionParticle size controllableAluminium oxides/hydroxidesSurface-active agentsTemperature resistance

The invention discloses a method to prepare high-temperature high-surface area aluminum oxide and aluminous compound oxide. It uses surface-active agent, assistant surface-active agent, non-water soluble organic solvent, water, inorganic salt and basic material as raw materials to manufacture two reversed-phase microemulsions, then mixing the two microemulsions to react and produce sol, and then filtering, drying, baking, etc, to obtain high-thermal stability aluminum oxide and aluminous compound oxide. When they are baked at 1000 deg.C for 10h, their specific surface area are both kept at 50 sq m / g above, for an example, when the modified aluminum oxide is baked at 1100 deg.C for 10h, its specific surface area is 185.2 sq m / g. Their particle sizes are uniformly distributed and can be controlled. The raw materials are cheap and easy to obtain.

Owner:EAST CHINA UNIV OF SCI & TECH

High-temperature resistant strippable protection coating and preparation method thereof

The invention discloses a strippable resin which comprises the following components in parts by weight: 40-70 parts of polyvinyl chloride resin, 20-50 parts of plasticizer, 5-10 parts of epoxy compound, 2-5 parts of phosphite ester, 2-5 parts of polyhydric alcohol, 3-5 parts of stabilizing agent and 1-2 parts of thixotropic agent. The polyvinyl chloride resin is different polyvinyl chloride resins with polymerization degrees of 1000-1700 or a mixture thereof. The strippable protection coating disclosed by the invention is excellent in thermal aging resistance, shows excellent thermal stability in a high-temperature process of 150-160 DEG C, has no release of an HCl gas in the process, keeps a good strippability after being baked, has no residue after being stripped, thereby being free from generating corrosion and pollution to a protected ITO (Indium Titanium Oxide) line.

Owner:TONSAN ADHESIVES INC

Preparation method of fiber-reinforced titanium matrix composite precursors

ActiveCN102864397AGood interface performanceThe interface is tight and flatVacuum evaporation coatingSputtering coatingTitanium matrix compositesHeat stability

The invention provides a preparation method of fiber-reinforced titanium matrix composite precursors. The preparation method comprises the following steps of: (1) using zirconic acid lanthanum to serve as a sputtering target material, using silicon carbide fibers to serve as a substrate material, conducting magnetron sputtering on the zirconic acid lanthanum to deposit on surfaces of the silicon carbide fibers, and obtaining SiC-f / La2Zr2O7 silks; and (2) using a titanium alloy to serve as the sputtering target material, using the SiC-f / La2Zr2O7 silks to serve as the substrate material, conducting the magnetron sputtering on the titanium alloy to deposit on the surfaces of the SiC-f / La2Zr2O7 silks, and obtaining a fiber-reinforced titanium matrix composite precursor SiC-f / La2Zr2O7 / Ti alloy. The preparation method is simple in preparation process, high in production efficiency and strong in repeatability. The preparation method uses the zirconic acid lanthanum to serve as a separation layer to effectively protect silicon carbide fiber silks, the zirconic acid lanthanum has a good bonding performance with the silicon carbide fiber silks and the titanium alloy, and prepared fiber-reinforced titanium matrix composite precursors are good in high temperature heat stability and have good interface performances.

Owner:NORTHWEST INSTITUTE FOR NON-FERROUS METAL RESEARCH

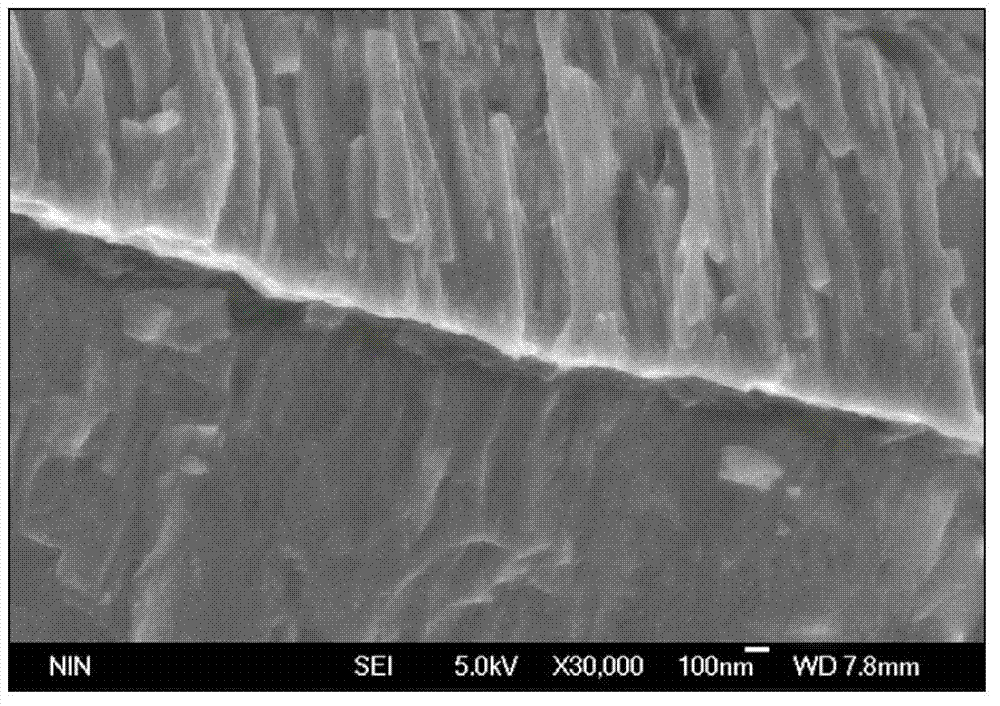

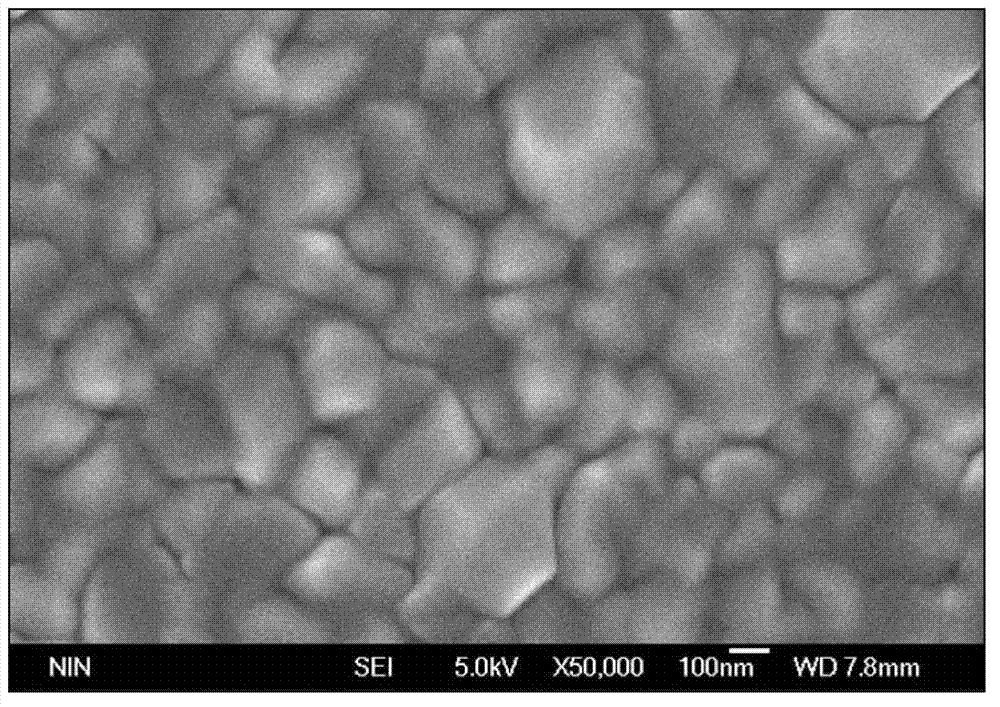

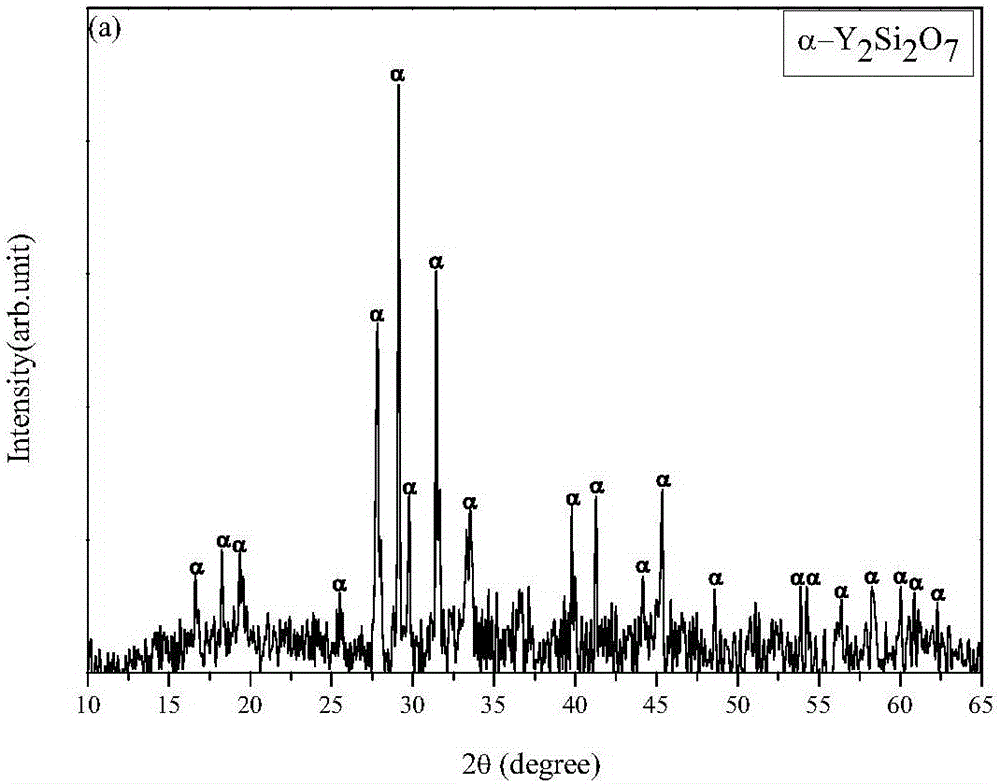

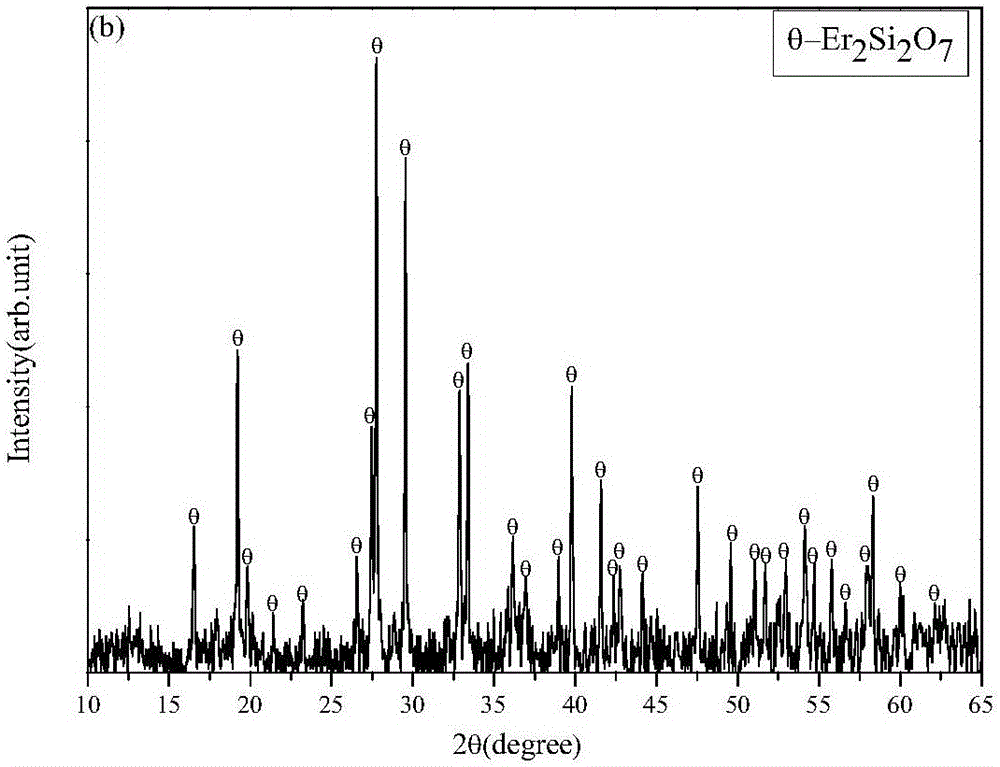

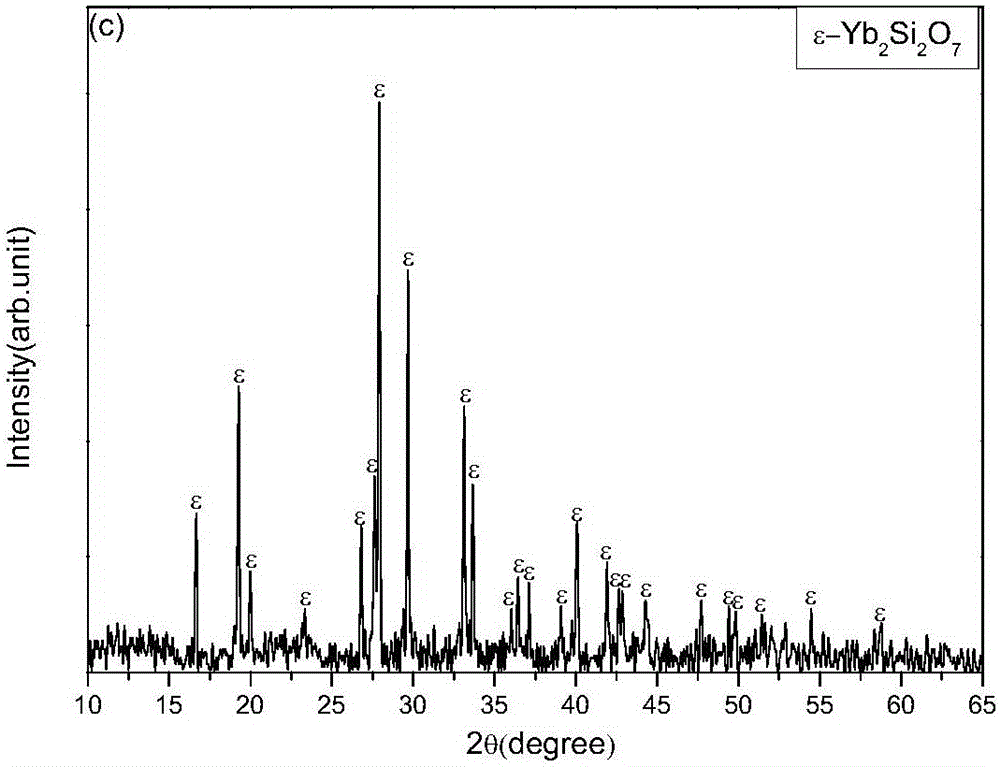

Preparation method of high-temperature oxidation resistant thermal barrier coating on Cf/SiC composite surface

The present invention provides a C f The invention discloses a method for preparing a high-temperature oxidation-resistant thermal barrier coating on the surface of a SiC composite material, belonging to the field of composite materials. resolve existing in C f The process for preparing coatings on the surface of / SiC composite materials is complicated, and the obtained coatings have poor performance in high temperature resistance and oxygen permeation and diffusion resistance. The method is to first synthesize Re by solid-state reaction method. 2 Si 2 o 7 and LaMgAl 11 o 19 Powder, synthetic powder prepared by APS technology after spray granulation in pretreated C f / Sequentially spray Re on the SiC substrate 2 Si 2 o 7 Ceramic layer and LaMgAl 11 o 19 ceramic layer, get C f / SiC composite surface high temperature oxidation resistance thermal barrier coating. The double-ceramic layer thermal barrier coating prepared by the invention has good high-temperature thermal stability, low thermal conductivity, and good sintering resistance, and is suitable for use as a high-temperature thermal protection thermal barrier coating for hot-end components.

Owner:CHANGCHUN INST OF APPLIED CHEMISTRY - CHINESE ACAD OF SCI

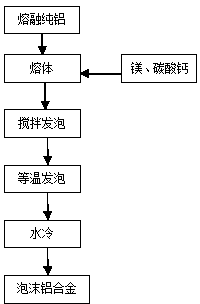

Technology for preparing small-aperture aluminum foam without viscous melt foaming method

The invention discloses a technology for preparing small-aperture aluminum foam without a viscous melt foaming method and belongs to the field of preparation of a porous metal material. The technology comprises the following steps: by taking calcium carbonate as a foaming agent, adding a pure magnesium block to melt, foaming the melt by a gas formed by reaction of Mg, Al and CaCO3. The viscosity of the melt can be improved by the oxide generated by reaction. The outgassing reaction is slow and stable, so that the problem of a thick aluminum foam structure is solved by the technology in comparison with titanium hydride as a foaming agent. The technology comprises the following concrete steps: adding the pure magnesium block to the aluminum melt; adding calcium carbonate after evenly agitating; agitating and foaming, carrying out water-cooling after keeping warm for a period of time, so as to obtain an aluminum foam sample of which the porosity is 50.0-85.0% and the mean pore size is about 1.0-2.0mm. The production technology is simplified, the production cost is reduced, and the technology is applicable to large-scale production under the condition of not needing tackifying.

Owner:HOHAI UNIV +1

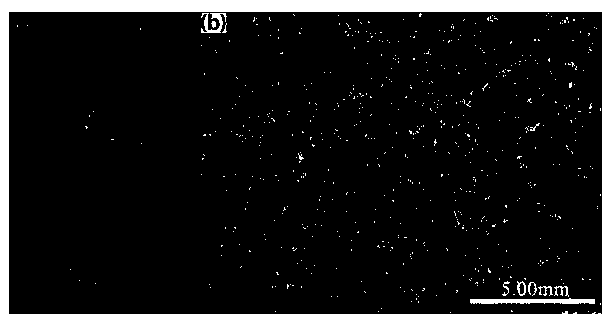

Preparation method for rare earth niobate high-temperature ceramics

The invention discloses a preparation method for rare earth niobate high-temperature ceramics RENbO4 (RE=Y, Nd, Sm, Eu, Gd, Dy, Er and Yb). The adopted raw materials include rare earth oxide and niobium oxide. The method comprises the following steps: weighting the raw materials in proportion; putting the weighted raw materials and absolute ethyl alcohol into a ball-milling tank, mixing, sealing and then putting on a planetary ball mill for milling, and uniformly mixing; adding binder, namely, polyvinyl alcohol hydrogel, into the milled mixture, and then milling for a period of time, and uniformly mixing; drying and screening the mixed powder and then putting into a mold for compacting; pre-sintering; cooling, taking out the sample after pre-sintering, grinding, milling, adding polyvinyl alcohol hydrogel, and then milling, drying and screening; putting the powder after screening in the mold and compacting, and then sintering for the second time. The preparation method has the advantages of high technical purity, low impurity content, low product preparation cost and suitability for bath production. The targeted product is expected to become a novel high temperature-resisting, antioxidant and abrasion-resisting ceramic material.

Owner:KUNMING UNIV OF SCI & TECH

Preparation method of stainless steel carrier catalysts and coating process

InactiveCN101444741AConducive to loadHigh catalytic activityCatalyst activation/preparationMetal/metal-oxides/metal-hydroxide catalystsPartial oxidationMetallurgy

The present invention relates to a preparation method of compound catalyst suitable for stainless steel carrier, and belongs to technical field of catalyst preparation process. The catalyst carrier in the invention consists of pseudo boehmite and gamma -Al2O3 with NiO, La2O3 and LiO mixed oxide as the active component, and is coated on the stainless steel carrier or basal body by dipping. Catalyst loading volume on stainless steel is from 20to 40; prepared compound catalyst is in firm combination with stainless steel, has good adhesion force, heat endurance and catalytic performance. The compound catalyst through the invention has broad application prospect in automobile tail gas discharge purifier, methane partial oxidation reforming syngas and fuel battery etc.

Owner:SHANGHAI UNIV

In-situ-synthesized fake binary complex-phase rare earth niobate ceramic and preparation method thereof

The invention discloses in-situ-synthesized fake binary complex-phase rare earth niobate ceramic and a preparation method thereof. The preparation method comprises the following steps: 1), calcinatingrare earth oxide RE2O3, then mixing with niobium oxide (Nb2O5) by a wet ball milling method, performing rotary evaporative drying, sintering and sieving to obtain presintered powder, grinding the pre-sintered powder by the wet ball milling method, performing rotary evaporation and sieving to obtain fine powder; 2), placing the fine powder in a mould, hydraulically compacting, performing cold isostatic compacting and then secondarily sintering to obtain the fake binary complex-phase rare earth niobate ceramic. By the preparation method, a technology is simple, a product is low in preparation cost and high in purity and is suitable for batch production, and the prepared fake binary complex-phase rare earth niobate ceramic has relatively good thermal properties.

Owner:TSINGHUA UNIV

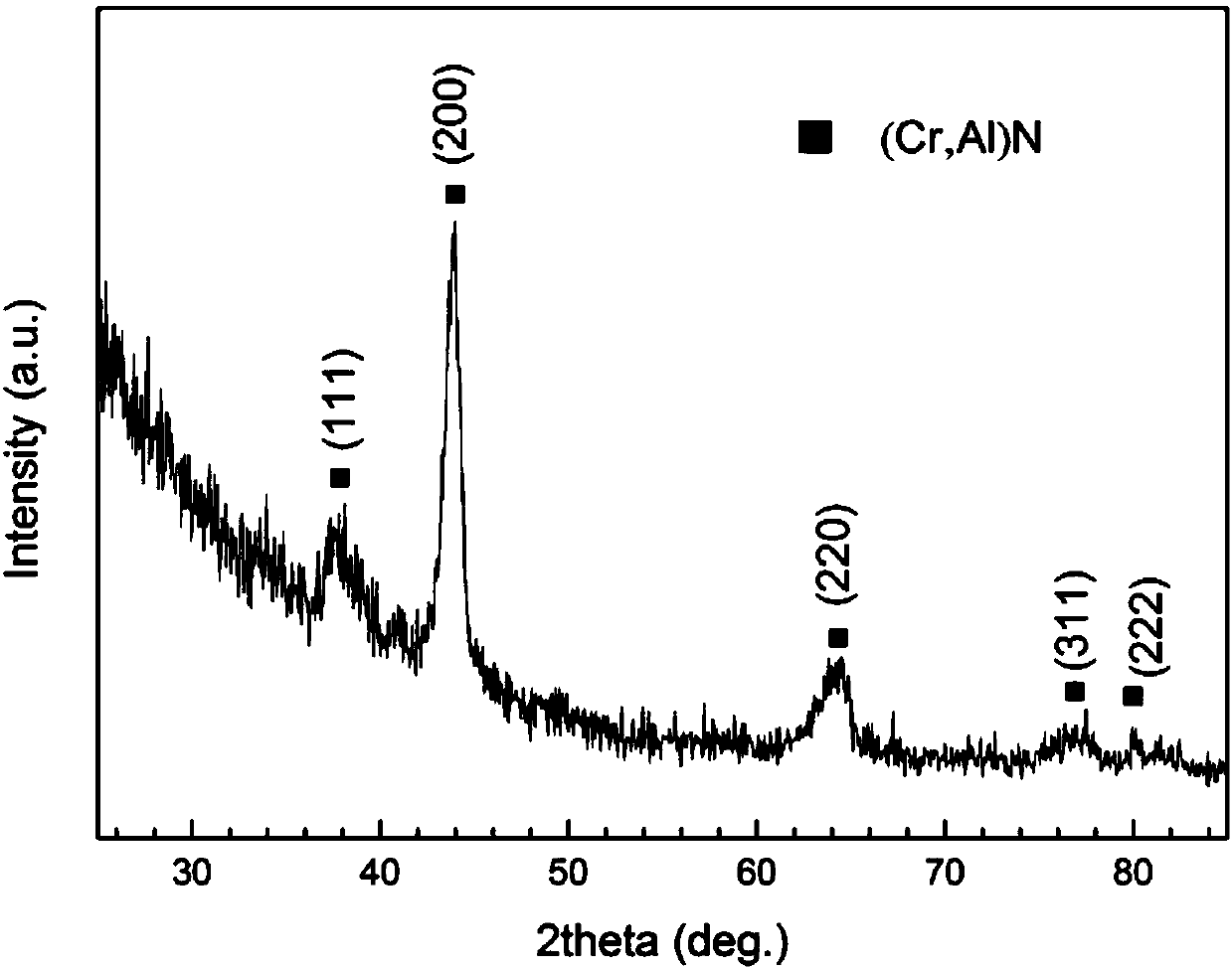

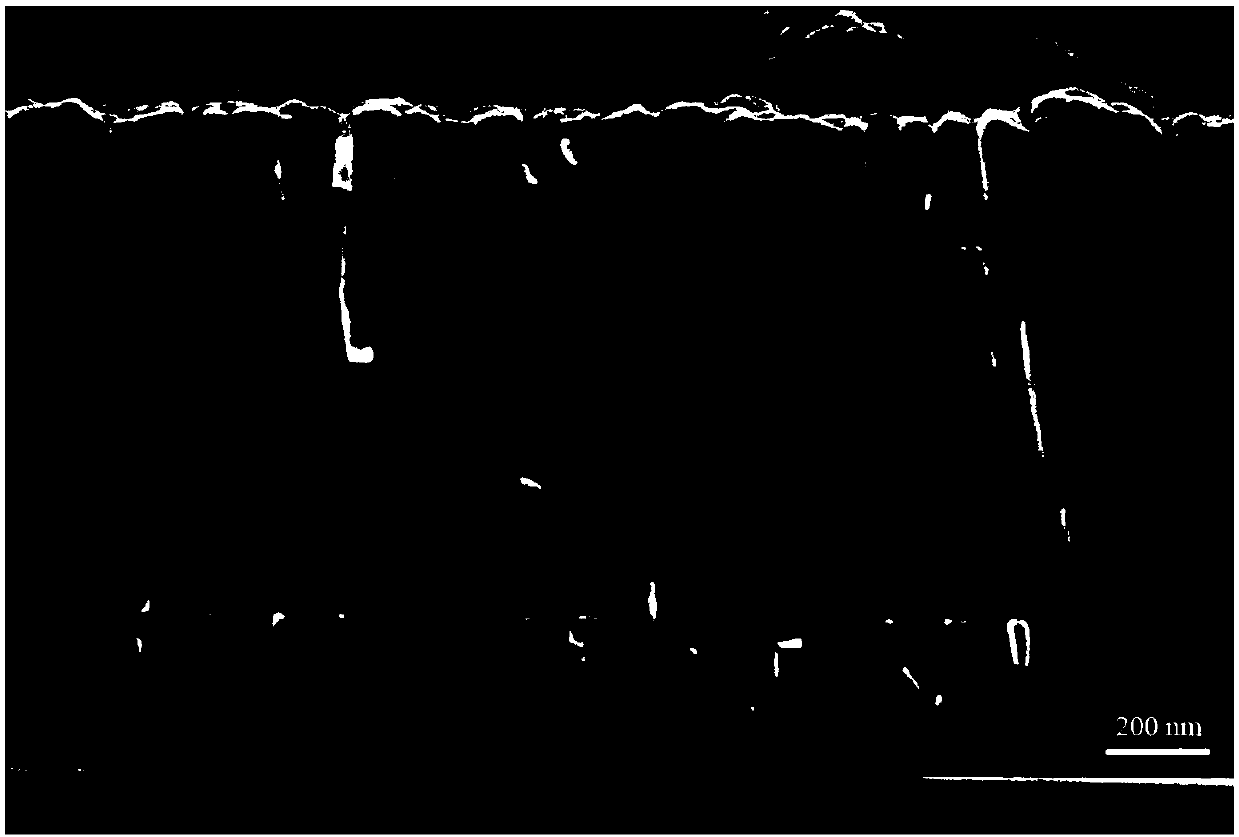

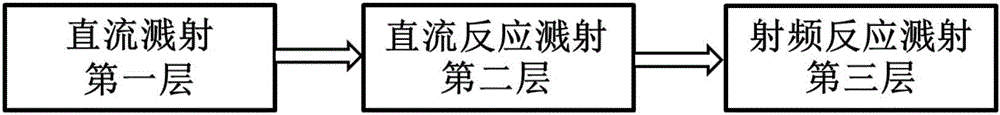

CrAlSiN nano composite coating with gradient-change Al content and preparation method thereof

ActiveCN107858647AFine grainCompact structureVacuum evaporation coatingSputtering coatingSputteringAlloy substrate

The invention relates to the field of coating preparation, in particular to a CrAlSiN nano composite coating with a gradient-change Al content and a preparation method thereof. The CrAlSiN nano gradient coating is prepared on a metal or hard alloy substrate through high-power pulse and direct current pulse co-sputtering technology. Pure metals Cr, Al and Si are selected as target materials, the Crtarget is selected for high-power pulse, and the Al and Si targets are selected for direct current pulse sputtering. Al gas is introduced in first before coating, -800 V bias voltage is adopted, andglow cleaning is conducted on the substrate for 10-30 min. The three target materials are started afterwards, and bombardment cleaning is conducted on the surfaces of the substrate and target materials. The Al and Si targets are closed, and a pure Cr transition layer is deposited for 10-40 min. The Al target and the Si target are started, the CrAlSiN nano composite coating is deposited for 120-480min. In the depositing process, power of the Cr target and the Si target is kept unchanged, and the power of the Al target is increased linearly to 0.8-2 kW from 0.4 kW. The CrAlSiN nano gradient coating is good in comprehensive performance and has high hardness and small residual internal stress.

Owner:TIANJIN UNIV OF TECH & EDUCATION TEACHER DEV CENT OF CHINA VOCATIONAL TRAINING & GUIDANCE

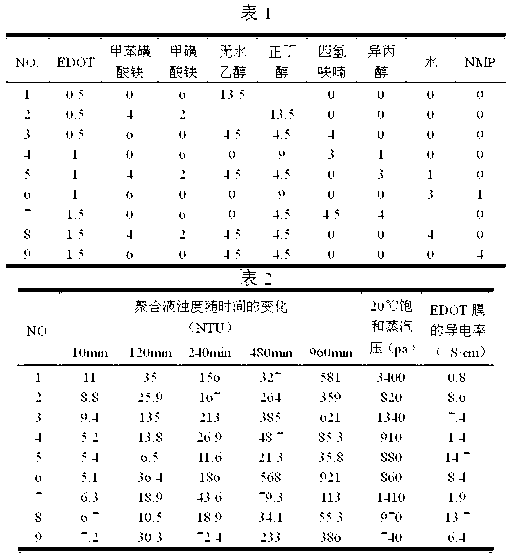

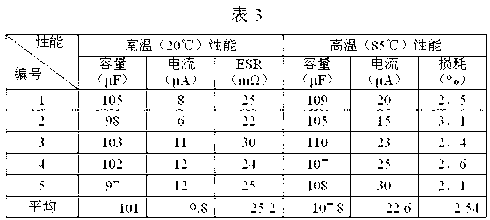

Conductive high polymer catholyte solution as well as preparation method and application thereof

ActiveCN102709055AGood impedance frequency characteristicsStable ESR valueSolid electrolytic capacitorsPolymer scienceElectrolysis

The invention provides a conductive high polymer catholyte solution as well as a preparation method and application thereof, and belongs to an important part of a manufacturing method of a solid electrolytic capacitor, namely a conductive high polymer catholyte solution with high permeability and long storage period, a preparation method thereof, as well as an application of the solution in manufacturing a solid polymer electrolytic capacitor. The invention discloses a method for dispensing, proportioning and preparing a conductive high polymer catholyte solution and processing steps of applying the prepared conductive high polymer catholyte solution in an anode porous sintering surface with a medium oxidation film so as to form a conductive high polymer. The conductive high polymer solid electrolytic capacitor manufactured by utilizing the conductive high polymer catholyte solution provided by the invention has the advantages that the impedance frequency characteristic is good; and the ESR (Equivalent Series Resistance) value can be kept stable within a range of 10KHz-1000KHz, and the change rate of the ESR value is less than 10%.

Owner:CHINA ZHENHUA GRP XINYUN ELECTRONICS COMP ANDDEV CO LTD

Preparation of high temperature-resistant active aluminum oxide

InactiveCN101302023ALarge specific surface areaImprove high temperature resistanceAlkali-metal aluminates/aluminium-oxide/aluminium-hydroxide preparationAir atmosphereSodium aluminate

The invention relates to a method for preparing fireresistant activated alumina. A liquid phase counter-titration precipitation method is adopted; a sodium aluminate solution and a nitric acid solution are used as raw material; organisms are used as a pore expanding agent; a rare earth oxide is used as a stabilizing agent; the alumina with large specific surface area and good fireresistant performance is prepared by adopting the liquid phase counter-titration precipitation method. The rare earth oxide content in the alumina is between 0.1 and 10 wt percent; an alumina solid is treated for 5 hours in the atmosphere of 700 DEG C; the specific surface area of the alumina solid is more than 350m <2> / g; the average pore volume is 0.3122 mL / g; the average aperture is 5.23 nm; and the aperture distribution range is between 3 and 12 nm. The alumina solid is treated for 5 hours in the atmosphere of 1100 DEG C; and the specific surface area of the alumina solid is more than 150 m <2> / g. The method has the characteristics of low production cost, simple process, large specific surface area, even aperture distribution and good high-temperature thermal stability.

Owner:SHENYANG POLYTECHNIC UNIV +1

Preparation method of porous activated aluminum oxide adsorbing material

InactiveCN104445323AEliminate the effects ofSolve processing problemsOther chemical processesAlkali metal chloridesDiasporeTetrachloroaluminate

The invention relates to a preparation method of a porous activated aluminum oxide adsorbing material. The preparation method comprises the following steps: (1) dissolving and hydrolyzing solid sodium tetrachloroaluminate by using an ethanol water solution; (2) adding water into an obtained solution to generate aluminum trichloride hexahydrate; (3) adding ammonia water for reaction to generate hydrated alumina suspension liquid, and ageing to obtain alpha-diaspore; (4) peptizing by using acid to obtain sol, dropwise adding the sol into an oil-ammonia column by adopting a dripping method, allowing the sol to retract to form balls under the effect of a surface tensile force in oil, putting the balls into ammonia water, neutralizing and ageing to form hard gel ball-like substances, washing away oil ammonia by using water and drying; and (5) baking to obtain the porous activated aluminum oxide adsorbing material. The preparation method disclosed by the invention can be used for solving the problems of wastewater treatment, improving cyclic utilization of resources, realizing value maximization and increasing the additional value of byproducts; the porous activated aluminum oxide adsorbing material is good in thermal stability at high temperature, large in specific surface area, good in adsorption performance, simple in production process, convenient to operate, low in cost and basically free of environmental pollution from aspect of production technology.

Owner:武汉铂莱材料科技有限公司

Yttrium tantalate high-temperature ceramic and preparation method thereof

The invention discloses a method for preparing an yttrium tantalate high-temperature ceramic through a solid phase method, wherein the molecular formula of the compound yttrium tantalate is YTaO4. According to the preparation method, the used raw materials are yttrium oxide and tantalum oxide; and the method comprises: weighing the raw materials according to a certain ratio, mixing the raw materials in anhydrous ethanol, placing into a planetary ball mill, carrying out ball milling to achieve a uniformly-mixing state, drying the mixed powder, screening, placing into a mold, compacting, pre-sintering, cooling, taking out the pre-sintered sample, grinding, carrying out ball milling, drying, screening, placing the screened powder into the mold, compacting, and carrying out secondary sintering. According to the present invention, the product purity of the process is high, the impurity content is low, the product preparation cost is low, the method is suitable for mass production, and the target product is expected to be used as the novel high-temperature resistant, anti-oxidation and anti-wear ceramic material.

Owner:KUNMING UNIV OF SCI & TECH

Method for improving interlayer bonding strength of polyphenylene sulfide non-woven fabrics compound filter material

InactiveCN106362484AExtended service lifeOvercome the defect of delamination and detachmentMembrane filtersFiltration separationFiberFilter material

The invention discloses a method for improving interlayer bonding strength of a polyphenylene sulfide non-woven fabrics compound filter material, and belongs to the field of filter materials. The method aims to improve interlayer bonding strength of the compound filter material and comprises the steps of A, mingling polyphenylene sulfide short fiber in polyphenylene sulfide superfine fibermesh; B, conducting composite strengthening between polyphenylene sulfide superfine fibermesh mingled with polyphenylene sulfide short fiber and polyphenylene sulfide short fibermesh.

Owner:SICHUAN TEXTILE SCI RES INST +1

Preparation method of high temperature-resistant aluminium alloy material

InactiveCN105154699AHigh hardnessGood thermal stability at high temperaturePotassium feldsparCopper sulfide

The invention discloses a preparation method of a high temperature-resistant aluminium alloy material. The material is prepared from the following powder materials in parts by weight: 60-64 parts of aluminum powder, 6-10 parts of tin powder, 4-8 parts of copper sulphide, 3-6 parts of molybdenum dioxide powder, 4-7 parts of fused alumina zirconia powder, 4-8 parts of bismuth powder, 10-14 parts of quartz sand powder, 5-10 parts of electric smelted ceramsite sand, 10-14 parts of carbon powder, 1-4 parts of zirconium dioxide, 2-5 parts of cobalt powder, 2-5 parts of barium oxide and 2-5 parts of potassium feldspar powder. The preparation method comprises the steps of mixing, compacting, sintering, shaping and oil-impregnated treatment. By adjusting and optimizing the components of the material, the aluminium alloy material provided by the invention has the advantages of high strength and rigidity and high-temperature thermal stability; the raw materials are easily available; the processing cost is low; the preparation process is simple; parameters are easy to control; the production process is safe and environment-friendly; and the preparation method is suitable for large-scale industrial production.

Owner:SUZHOU NETABHAPE COMPOSITE MATERIALS

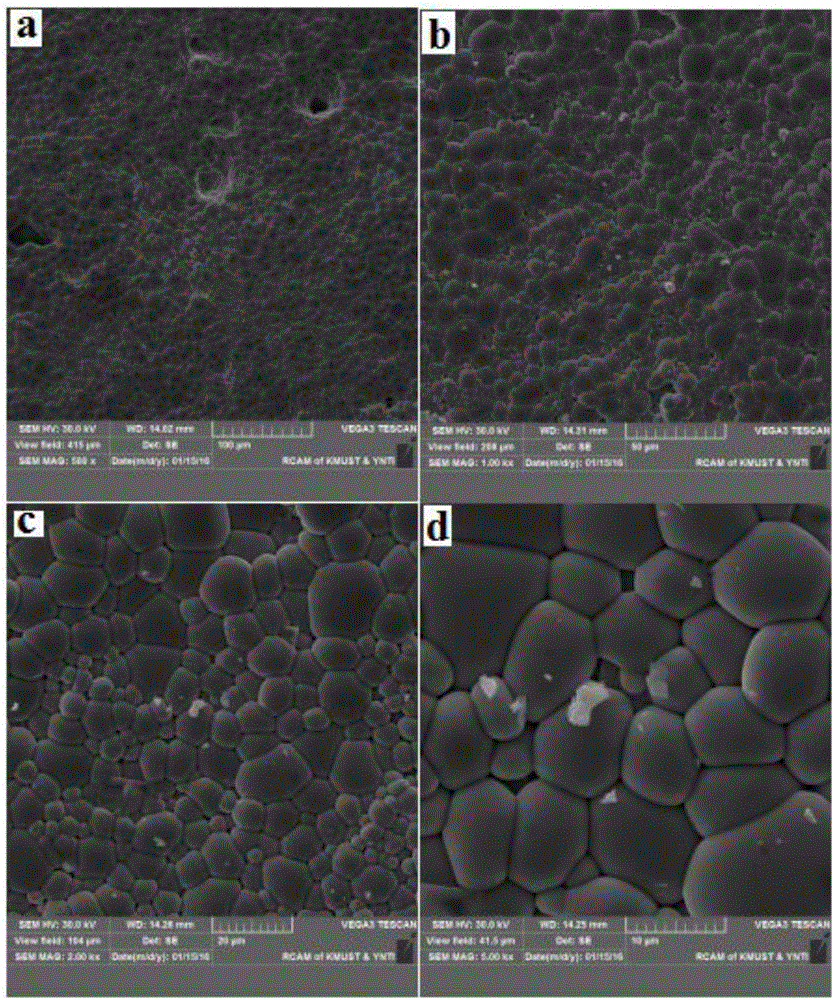

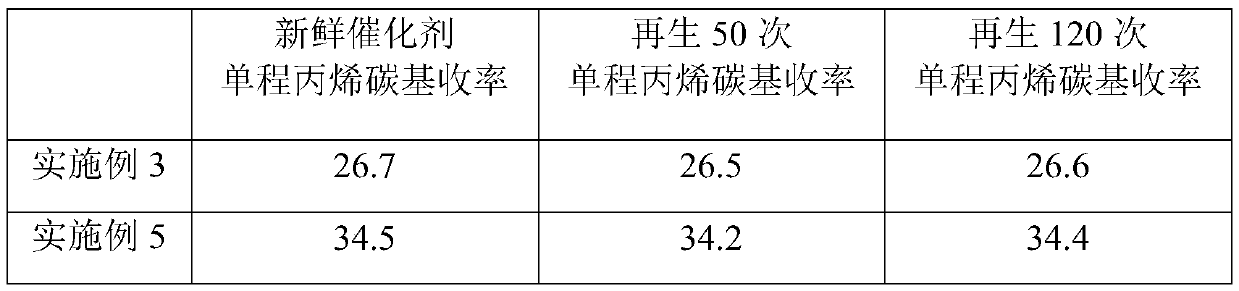

Environment-friendly catalyst for preparing propylene by directly dehydrogenating propane and preparation method thereof

ActiveCN110801861AGood stability and activityGood thermal stability at high temperatureMolecular sieve catalystsMolecular sieve catalystMolecular sievePtru catalyst

The invention belongs to the field of catalysts, and particularly relates to an environment-friendly catalyst for preparing propylene by directly dehydrogenating propane and a preparation method of the catalyst, wherein the particle size of the catalyst is 40-150 [mu] m; the catalyst comprises 30%-70% of a Zn-doped Hbeta molecular sieve, 15%-50% of Al2O3 and 3%-30% of a multi-element active modifier, wherein the modifier comprises at least one element of W, Mo, Mn, Zr, Ni, Fe and Co as a first modifier, at least one element of Ga, In, P, La and Ce as a second modifier, and any one element of Sr, Ba, Ca, Mg, Na and Li as a third modifier, and the sum of the mass percentages of oxides of all the element components is 100%. The prepared fluidized bed dehydrogenation catalyst is low in cost and good in wear resistance, and has good dehydrogenation activity and stability when used for propane dehydrogenation.

Owner:SOUTHWEST RES & DESIGN INST OF CHEM IND

Solar spectrum selective absorption coating and preparation method thereof

ActiveCN106884145ASimple preparation processEasy to operateSolar heat devicesVacuum evaporation coatingLow emissivityHeat stability

The invention provides a solar spectrum selective absorption coating. A heat-absorbing body base material is a polished stainless steel sheet. The first layer is an infrared reflection layer, the second layer is an absorption layer, and the third layer is an antireflection layer. The preparation method of the solar spectrum selective absorption coating comprises the following steps that firstly, the first infrared reflection layer is prepared; secondly, a first metalloid sub-layer of the second layer is prepared, and a second quasi-medium sub-layer of the second layer is prepared; and thirdly, the third SiO2 antireflection layer is prepared, and thus the coating is prepared. The solar spectrum selective absorption coating provided by the invention has the characteristics of high absorptivity in the visible-near infrared band and low emissivity in the infrared band and has good high-temperature heat stability and cold-hot circulating stability. The preparation technique of the coating is simple, operation is convenient, control is easy, and the production cost is obviously reduced. The solar spectrum selective absorption coating is suitable for high-temperature solar heat collection pipes.

Owner:BEIHANG UNIV

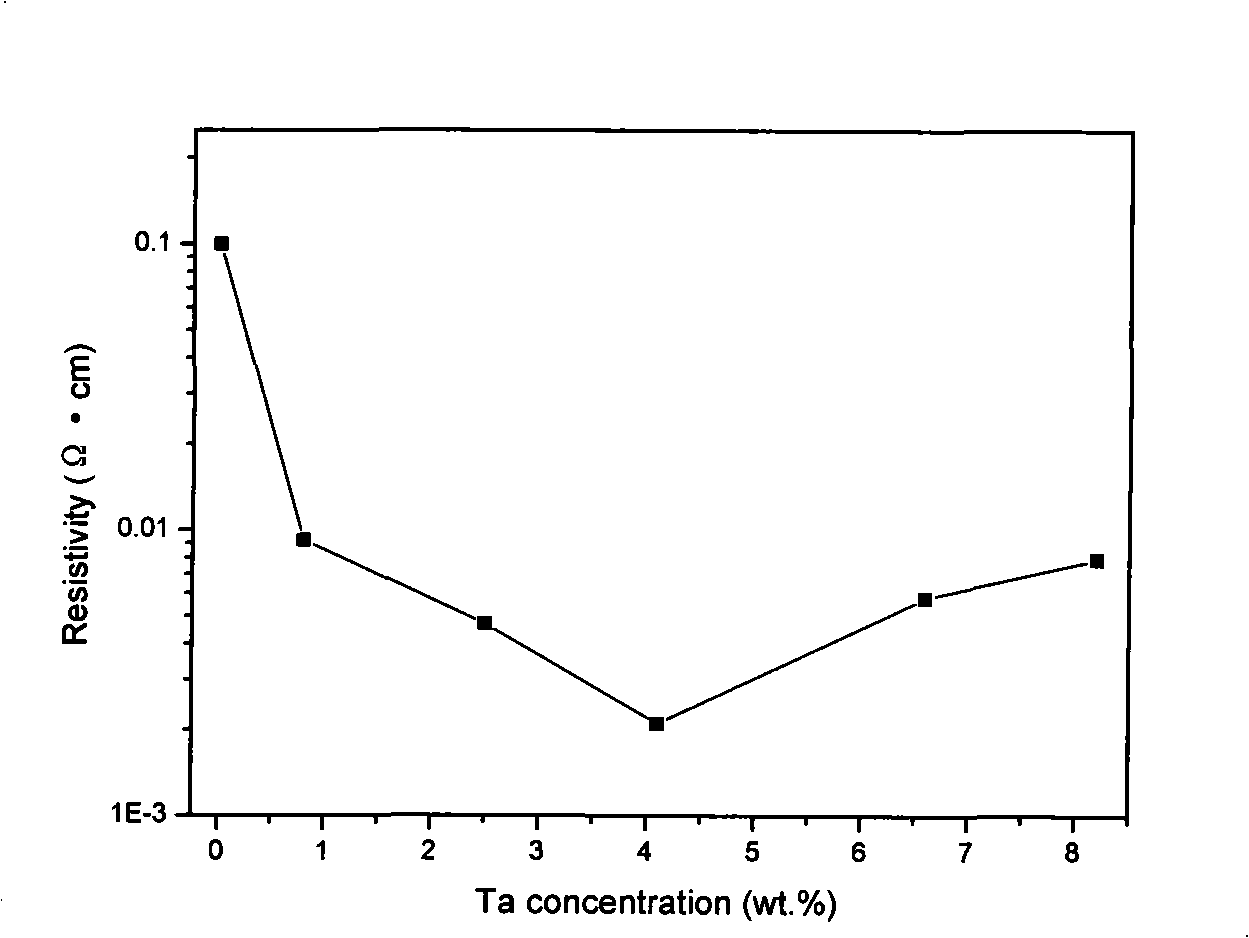

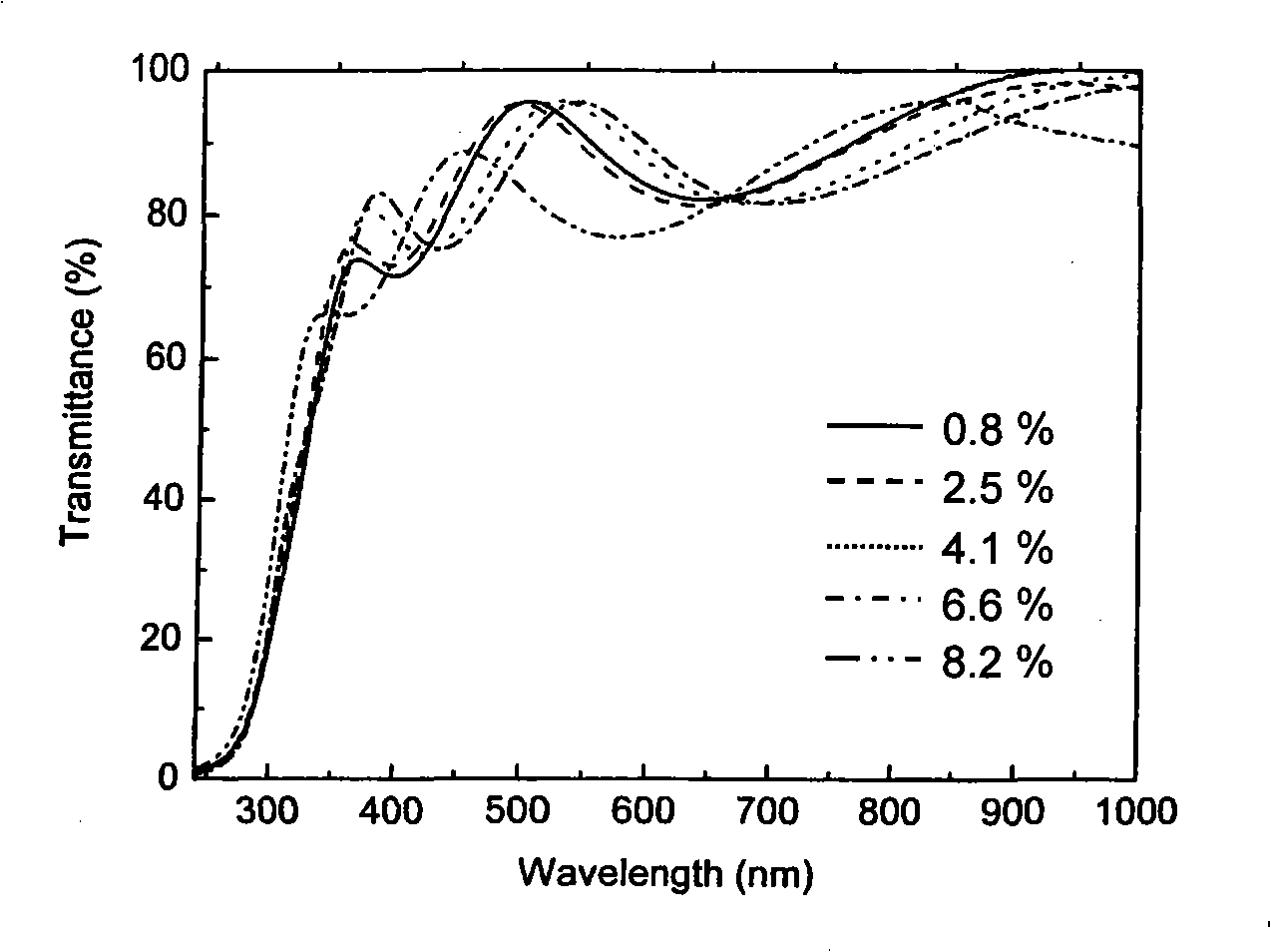

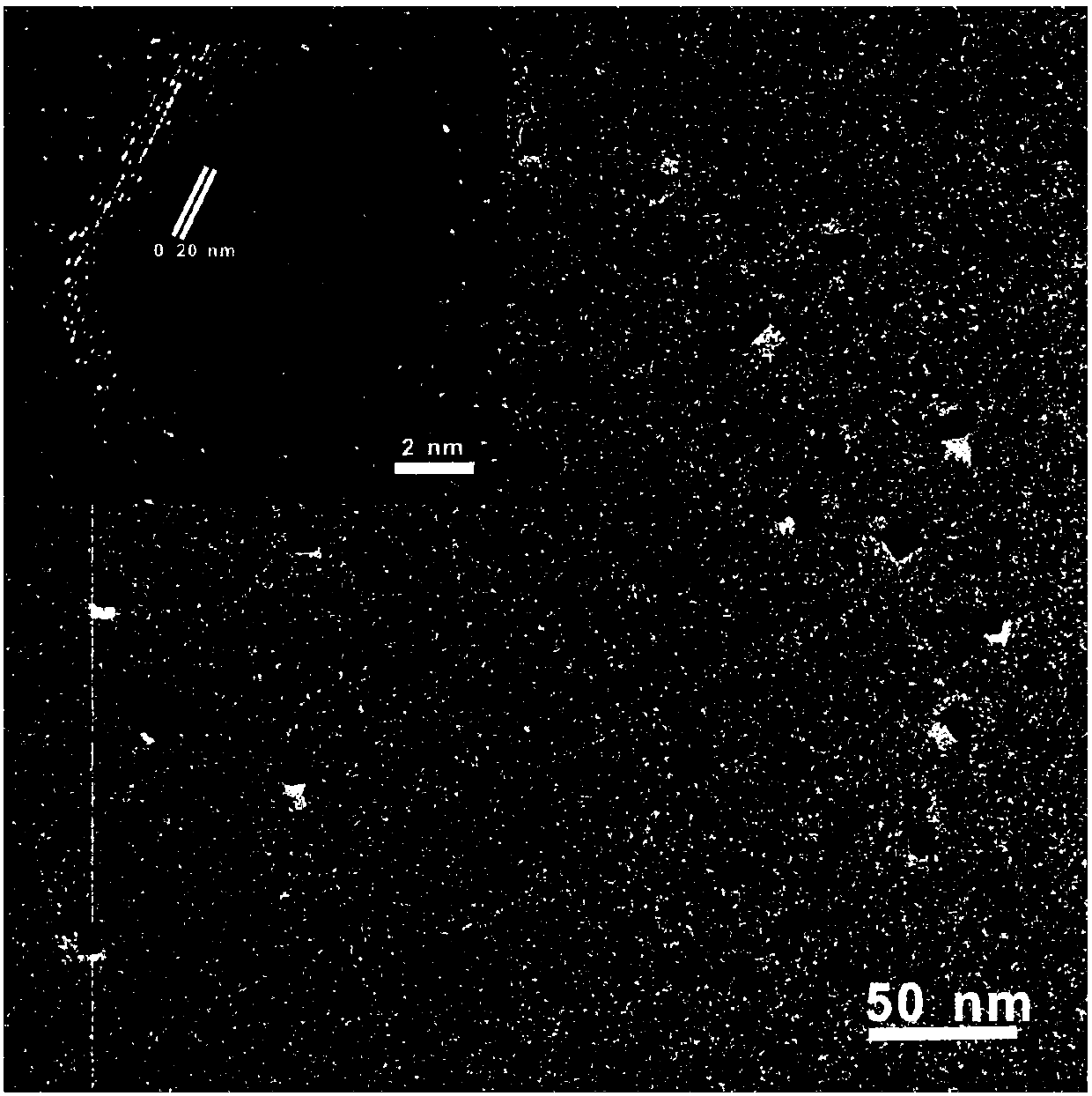

Method for preparing tantalum doping tin oxide transparent conductive film

InactiveCN101260512AImprove photoelectric performanceExcellent chemical durabilityVacuum evaporation coatingSputtering coatingBiocompatibility TestingElectromagnetic shielding

The invention relates to a method for preparing tantalum jewellers putty-doped transparent conductive film. The method is characterized in that Ta2O5 powder and SnO2 powder with 99.99 percent purity quotient are fully mixed according to weight ratio between 1:99 to 10:90, pressed, molded and sintered into a tantalum jewellers putty-doped sputtering target material under the temperature between 1500 DEG C and 1650 DEG C, then a jewellers putty-doped transparent conductive film with different tantalum contents is prepared by a magnetron sputtering method. The prepared film has the characteristics of smooth and compact surface, uniform film thickness, excellent photoelectric performance, simple preparation technology, low cost and easy realization of industrialized production, etc. and also has good mechanical performance, chemical durability, high-temperature thermal stability and biocompatibility. The film can not only be used for a flat-panel dispaly, a solar battery, a transparent electromagnetic shielding and antistatic device but also used for a resistance type touch screen, a biosensor, etc. which have special needs on the toxicity and biocompatibility of the film.

Owner:KUNMING UNIV OF SCI & TECH

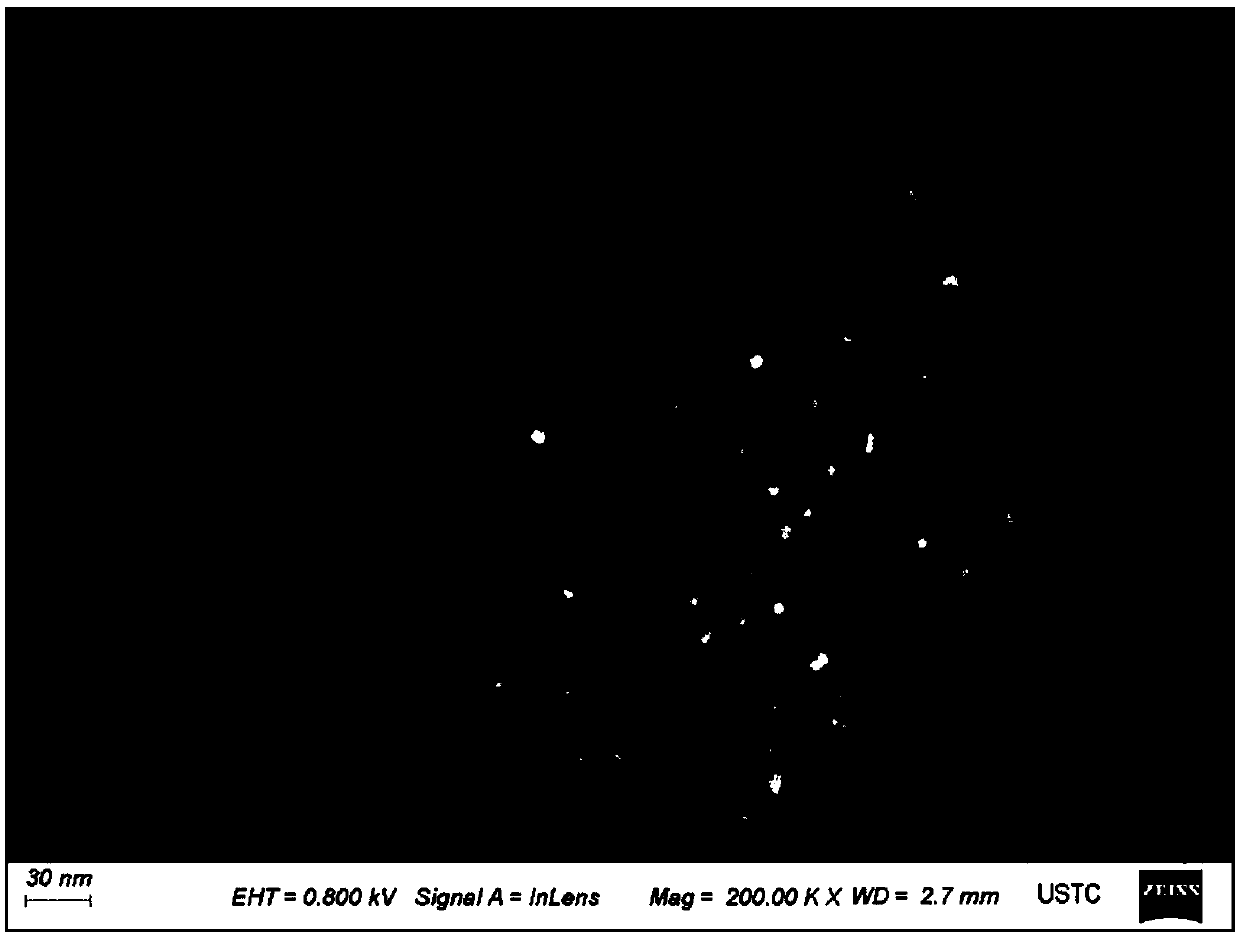

Pd/SiO2@Al2O3 (palladium/silicon dioxide@aluminum oxide) nanocrystalline material and preparation method and application thereof

ActiveCN107855123AImprove stabilityHigh activityGaseous fuelsLiquid carbonaceous fuelsAlkaneCombustion

The invention provides a Pd / SiO2@Al2O3 (palladium / silicon dioxide@aluminum oxide) nanocrystalline material. The Pd / SiO2@Al2O3 nanocrystalline material comprises Pd / SiO2 nanocrystalline and an Al2O3 layer, wherein the surface of the Pd / SiO2 nanocrystalline is coated with the Al2O3 layer; the Pd / SiO2 nanocrystalline consists of Pd nanocrystalline and SiO2; the Pd nanocrystalline is compounded to thesurface of the SiO2. The Pd / SiO2@Al2O3 nanocrystalline material has the advantages that a core-shell type material with Al2O3 coated Pd / SiO2 nanocrystalline is provided; the Pd / SiO2 nanocrystalline is internally coated by the Al2O3 layer with certain thickness; the Pd / SiO2@Al2O3 nanocrystalline material is applied to high-temperature combustion reaction of alkane, the low-temperature catalyzing property in terms of alkane combustion is higher, and the high-temperature thermal stability is better; by adjusting the shape of Pd, and changing the property of the Pd / SiO2@Al2O3 nanocrystalline material, the important guidance meaning is provided in the design aspects of the catalyst in the field of high temperature combustion of alkane.

Owner:UNIV OF SCI & TECH OF CHINA

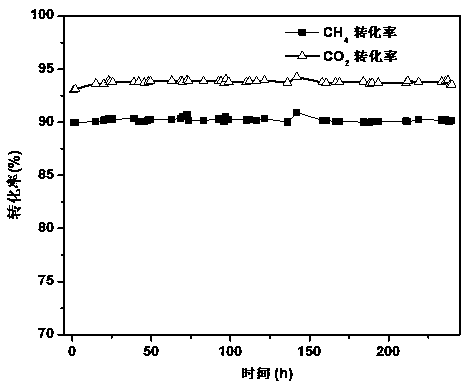

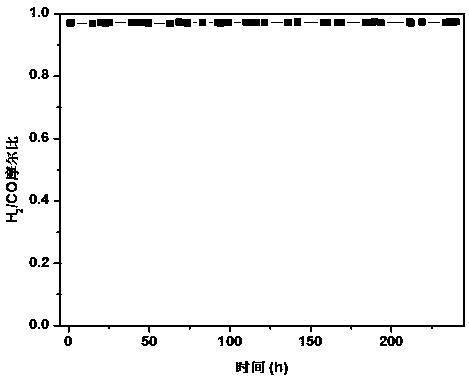

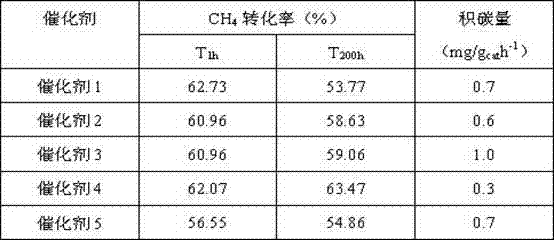

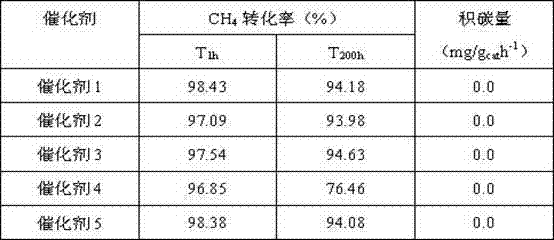

Mixed rare-earth modified methane steam reformed nickel-based catalyst and preparation method thereof

ActiveCN103752320AEasy to prepareHigh reactivityHydrogenMetal/metal-oxides/metal-hydroxide catalystsSteam reformingWater vapor

The invention provides a mixed rare-earth modified methane steam reformed nickel-based catalyst and a preparation method thereof. According to the mixed rare-earth modified methane steam reformed nickel-based catalyst, nickel nitrate and the like are used as precursors and are directly immersed and loaded on spherical aluminum oxide modified by mixed rare earth. The mixed rare earth is obtained by mixing two selected from lanthanum-cerium, lanthanum-yttrium, lanthanum-praseodymium, lanthanum-samarium and the like, wherein the loading weight of nickel in the catalyst is 5-30% of the weight of the catalyst and the loading weight of the mixed rare earth is 0.5-10% of the weight of the catalyst; the ratio of the mixed rare earth is 7 / 3-3 / 7. With the adoption of the mixed rare earth, the separation cost of the rare earth can be greatly reduced; the preparation method of the catalyst is simple; the catalyst has the good catalytic activity and stability on reforming methane steam in a fixed bed.

Owner:NANCHANG UNIV +1

Magnesium-containing rare earth oxygen storage material and preparation method thereof

InactiveCN102416315AHigh surface areaImprove stabilityDispersed particle separationCatalyst activation/preparationCalcium bicarbonateCerium

The invention relates to a magnesium-containing rare earth oxygen storage material and a preparation method thereof. The expression of the magnesium-containing rare earth oxygen storage material is RExZryMzO2, wherein M represents Mg or other metal which comprises cerium zirconium composite oxide, praseodymium zirconium composite oxide, terbium zirconium composite oxide, and the like. The content of magnesium oxide is 0.001 wt% -5 wt%. The magnesium-containing rare earth oxygen storage material is prepared by using magnesium bicarbonate as a precipitant. The preparation method comprises the following steps: mixing rare earth (cerium, praseodymium or terbium) and zirconium, or mixing rare earth (cerium, praseodymium or terbium), zirconium and at least one of other rare earth ions (lanthanum, praseodymium, neodymium, samarium, gadolinium, yttrium) and / or other metal ions (aluminium, barium, strontium, titanium, manganese, iron, copper, hafnium); performing precipitation by using a magnesium bicarbonate or / and calcium bicarbonate aqueous solution as a precipitant, wherein the magnesium bicarbonate or / and calcium bicarbonate aqueous solution is prepared by at least one procedure of roasting, digestion, slurry mixing, and carbonization of raw materials of minerals or oxides or hydroxides of magnesium or / and calcium, then performing at least one procedure of filtration, washing, drying, and the like, and finally roasting at a certain temperature to obtain the product. The preparation method of the invention adopts a cheap routine chemical precipitant, realizes the effective recycling of magnesium, calcium, carbon dioxide and the like, and greatly reduces the production cost of the rare earth oxygen storage material. On the other hand, the production process in the invention does not generate ammonia nitrogen waste water, or waste water with high salinity, and reduces the discharge of carbon dioxide greenhouse gas; the preparation process is green and environment-friendly, and eliminates environment pollution.

Owner:GRIREM ADVANCED MATERIALS CO LTD

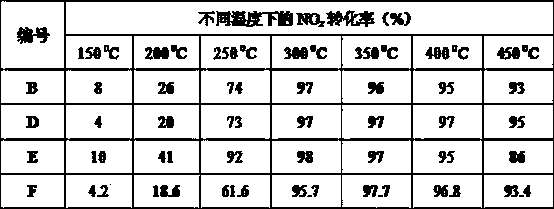

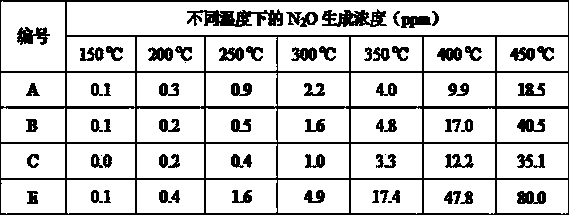

Catalyst for low-temperature V2O5-WO3/TiO2NH3 selective reduction catalysis of NO and preparation method thereof

PendingCN111036229AGood thermal stability at high temperatureLarge specific surface areaHeterogenous catalyst chemical elementsDispersed particle separationPtru catalystPhysical chemistry

The invention discloses a catalyst for low-temperature V2O5-WO3 / TiO2NH3 selective reduction catalysis of NO and a preparation method of the catalyst, and relates to the technical field of preparationof oxide low-temperature SCR catalysts. According to the catalyst for NH3 selective reduction catalysis of NO, cordierite (2MgO.2Al2O<3>.5SiO2) is used as an inert carrier, cerium-modified titanium dioxide with a high specific surface area is used as a second carrier, and an active component is oxide of vanadium; the catalyst for NH3 selective reduction catalysis of NO comprises, by weight, 100 parts of TiO2, 1 to 5 parts of V2O5, 10 to 60 parts of CeO2, 5 to 20 parts of WO3 and 1 to 5 parts of auxiliary agent oxide.

Owner:SHIYAN HUIBO ENVIRONMENTAL SCI & TECHCO

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com