Copper-base alloy and preparation method thereof

A technology for a copper-based alloy and a manufacturing method, which are applied in the field of copper-based alloys and their preparation, can solve the problems of alloy production and use day restrictions, human and ecological hazards, loss of beryllium copper alloys, and the like, and achieve good high-temperature thermal stability, The effect of excellent performance and high elastic thermal stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] 1. Material melting

[0030] 530 grams of commercially available electrolytic copper, 210 grams of nickel, 210 grams of manganese and 50 grams of iron were batched and smelted in a vacuum induction furnace. The melting temperature is 1250°C, the steel mold is poured, and the pouring temperature is 1100°C.

[0031] 2. Thermomechanical treatment

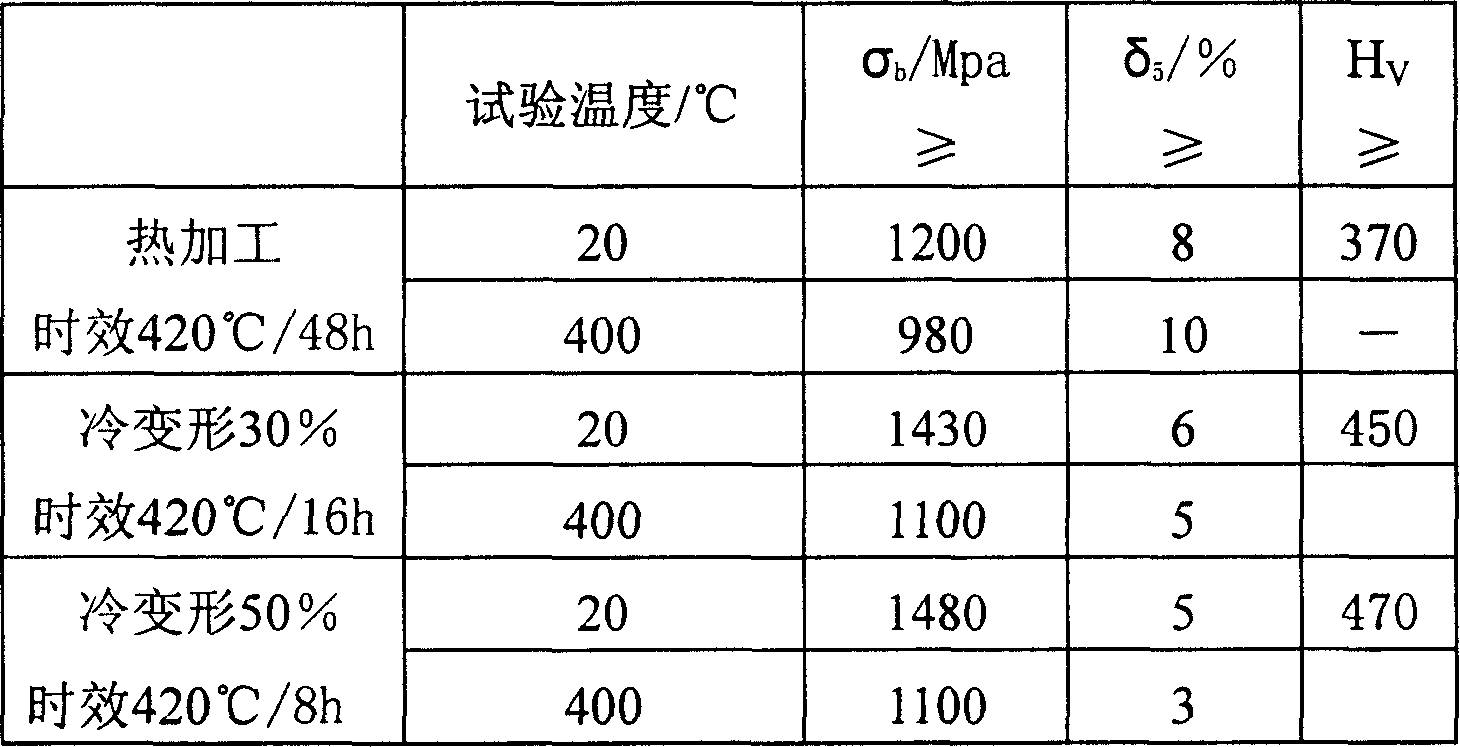

[0032] Process 1: First, the ingot is hot forged at 850°C, annealed at 750°C for 1.5h, and then rapidly cooled to room temperature; aging treatment is performed at 420°C for 48h.

[0033] Process 2: First, the ingot is hot forged at 850°C, annealed at 750°C for 1.5h, and then rapidly cooled to room temperature; cold rolled, and the cold rolling deformation is 30%. After cold rolling, carry out aging treatment, the aging temperature is 420 ℃, and the time is 16h.

[0034] Process 3: Firstly, the cast ingot is hot forged at 850°C, annealed at 750°C for 1.5h, and then rapidly cooled to room temperature; cold rolled, and the cold...

Embodiment 2

[0044] 1. Material melting

[0045] 550 grams of commercially available electrolytic copper, 300 grams of nickel, 140 grams of manganese and 10 grams of iron were batched and smelted in a vacuum induction furnace. The melting temperature is 1300°C, the steel mold is poured, and the pouring temperature is 1150°C.

[0046] 2. Thermomechanical treatment

[0047] The ingot is firstly hot-rolled at 750°C, annealed at 650°C for 2 hours, and then rapidly cooled to room temperature; cold-rolled, and the cold-rolled deformation is 60%. After cold rolling, carry out aging treatment, the aging temperature is 400°C, and the time is 8h.

[0048] Inductive plasma emission spectrometry (ICP) was used to analyze the content of alloy elements and impurities, as shown in Table 3.

[0049] Table 3. Impurity Chemical Composition of Alloys

[0050] the element

Al

Pb

Sb

Bi

P

no greater than

wt%

0.002

0.002

0.002 ...

Embodiment 3

[0057] 1. Material melting

[0058] 480 grams of commercially available electrolytic copper, 140 grams of nickel, 300 grams of manganese and 80 grams of iron were batched and smelted in a vacuum induction furnace. The melting temperature is 1250°C, the steel mold is poured, and the pouring temperature is 1100°C.

[0059] 2. Thermomechanical treatment

[0060] First, the ingot was hot forged at 900°C, annealed at 800°C for 40 minutes, and then rapidly cooled to room temperature; cold rolled, with a deformation of 20%. After cold rolling, carry out aging treatment, the aging temperature is 450 ℃, and the time is 24h.

[0061] Inductive plasma emission spectrometry (ICP) was used to analyze the content of alloy elements and impurities, as shown in Table 5.

[0062] Table 5. Impurity Chemical Composition of Alloys

[0063] the element

Al

Pb

Sb

Bi

P

no greater than

wt%

0.002

0.002

0.002

...

PUM

| Property | Measurement | Unit |

|---|---|---|

| elongation | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| breaking strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com