CrAlSiN nano composite coating with gradient-change Al content and preparation method thereof

A nano-composite coating, gradient change technology, applied in coating, metal material coating process, ion implantation plating and other directions, can solve the large stress of coating, CrN phase lattice distortion, reduce the gap between coating and substrate Bonding force and other issues, to achieve the effect of low internal stress, dense structure and small grain size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] This example is a CrAlSiN nano-composite coating with a gradient change in Al content prepared on a polished cemented carbide sheet YG8 by using high-power pulse and DC pulse co-sputtering technology. The size of the high-speed steel sample is 19×19× 2mm 3 . The substrate was ultrasonically cleaned in acetone, alcohol and distilled water successively for 20 min, and then cleaned with high-purity N 2 Blow dry, and then place it on the sample rack facing the target in a high-power pulse and DC pulse co-sputtering coater. The revolution speed of the turntable is selected as 30r / min, and the distance between the target and the substrate is 70mm. The targets are made of pure metals Cr, Al and Si (all with a purity of 99.99wt.%), and the working gas and reaction gas are made of high-purity Ar and N respectively. 2 (both volumetric purity is 99.999%).

[0030] Use mechanical pump and molecular pump to evacuate, and firstly evacuate the background vacuum of the vacuum chambe...

Embodiment 2

[0037] In this example, a CrAlSiN nanocomposite coating with a gradient change in Al content is deposited on a polished cemented carbide substrate YG8, and the sample size is 19×19×2mm 3 . The substrate was ultrasonically cleaned in acetone, alcohol and distilled water successively for 20 min, and then cleaned with high-purity N 2 Blow dry, put the sample on the turntable, the rotating speed of the turntable is selected as 30r / min, and the target base distance is 70mm. The targets are made of pure metal Cr and Al (99.99wt.% pure), and the working gas and reaction gas are made of Ar and N respectively. 2 (both volumetric purity is 99.999%). In the process of depositing the CrAlSiN nanocomposite coating in this embodiment, the powers of the Cr target and the Si target are respectively 0.8 kW and 0.6 kW. The Al target power is linearly increased from 0.4kW to 0.8kW, and other process parameters are the same as in Example 1.

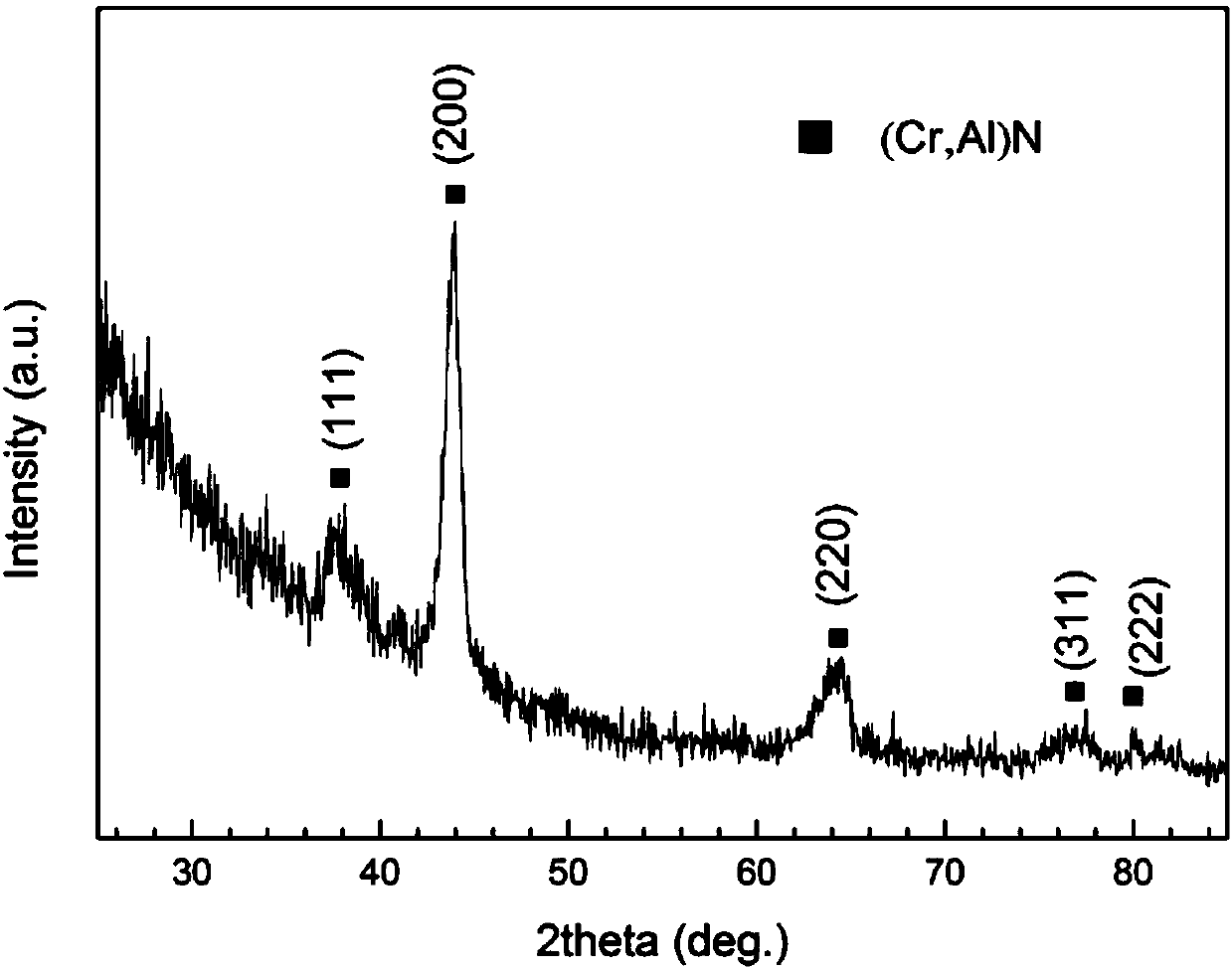

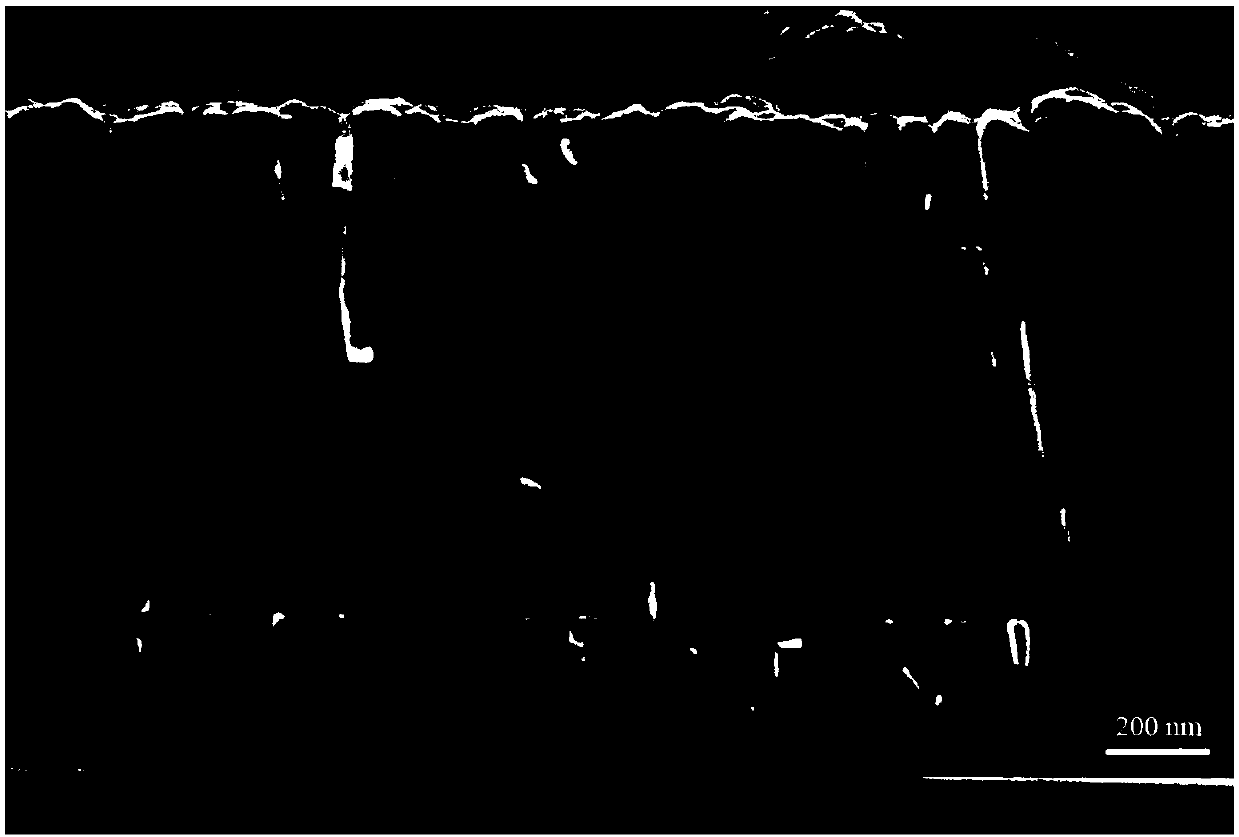

[0038] The CrAlSiN nanocomposite coating prepared ...

Embodiment 3

[0040] This example is to deposit a CrAlSiN nanocomposite coating with a gradient change in Al content on a polished 304 stainless steel substrate, and the sample size is 30×30×1mm 3 . The substrate was ultrasonically cleaned in acetone, alcohol and distilled water successively for 20 min, and then cleaned with high-purity N 2 Blow dry, put the sample on the turret, the rotating speed of the turret is selected as 20r / min, and the target base distance is still 70mm. The targets are made of pure metal Cr and Al (99.99wt.% pure), and the working gas and reaction gas are made of Ar and N respectively. 2 (volume purity is 99.999%), nitrogen and argon flow ratio N 2 / Ar is 1. In the process of depositing the CrAlSiN nanocomposite coating in this embodiment, the powers of the Cr target and the Si target are respectively 0.8 kW and 0.6 kW. The Al target power is linearly increased from 0.4kW to 1kW, and other process parameters are the same as in Example 1.

[0041] The CrAlSiN n...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

| elastic modulus | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com