Low-thermal-conductivity high-entropy ceramic thermal barrier coating material

A technology of thermal barrier coating and low thermal conductivity, which is applied in the field of high-entropy ceramic materials, can solve the problems of poor thermal stability, poor matching of thermal expansion coefficients, and high thermal conductivity of thermal barrier coating materials, so that it is not easy to agglomerate, Effect of reducing thermal conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

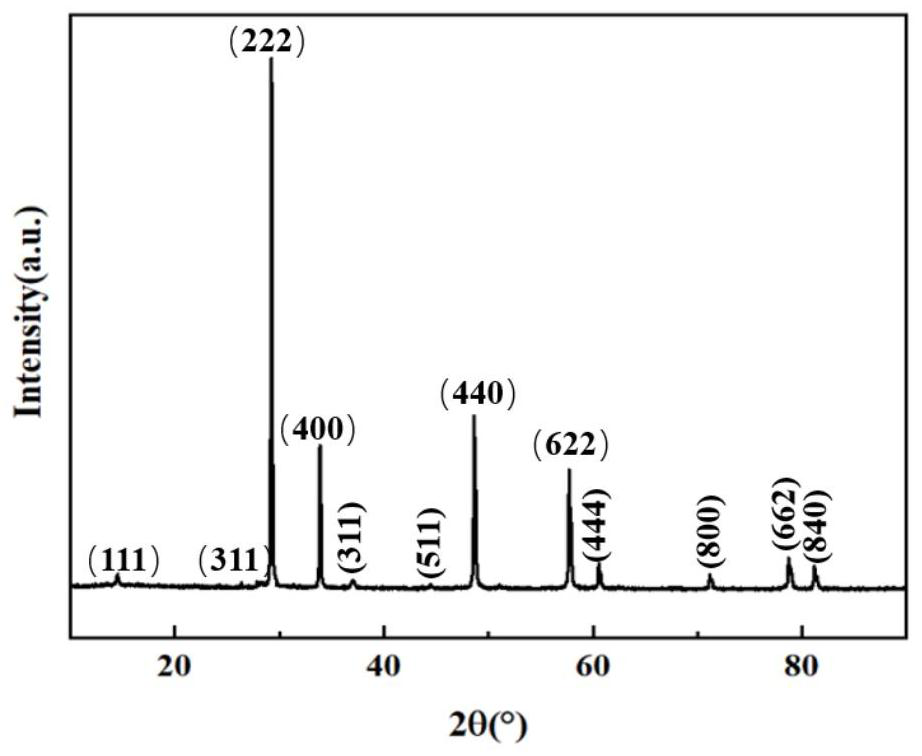

Image

Examples

Embodiment 1

[0039] In this example, the low thermal conductivity and high entropy ceramic thermal barrier coating material is prepared by the following steps:

[0040] Step A: Preparation of high-entropy ceramic powder: using nitrate of trivalent rare earth elements and acetate of tetravalent metal elements as raw materials, a high-entropy ceramic powder with a hollow spherical structure is prepared by a plasma spraying process; this embodiment The chemical formula of the high-entropy ceramic powder used is (La 1 / 5 SM 1 / 5 Gd 1 / 5 Nd 1 / 5 Yb 1 / 5 ) 2 Zr 2 o 7 , the preparation method of high-entropy ceramic powder comprises the steps:

[0041] Step (A-1): La(NO 3 ) 3 ·6H 2 O, Sm(NO 3 ) 3 ·6H 2 O, Gd(NO 3 ) 3 ·6H 2 O, Nd(NO 3 ) 3 ·6H 2 O and Yb(NO 3 ) 3 ·6H 2 O five kinds of nitrates are fully mixed according to the molar ratio of 1:1:1:1:1, then add an appropriate amount of deionized water to dissolve to obtain a mixed nitrate solution, and then mix the mixed nitrate sol...

Embodiment 2

[0051] In this example, the low thermal conductivity and high entropy ceramic thermal barrier coating material is prepared by the following steps:

[0052] Step A: Preparation of high-entropy ceramic powder: using nitrate of trivalent rare earth elements and acetate of tetravalent metal elements as raw materials, a high-entropy ceramic powder with a hollow spherical structure is prepared by a plasma spraying process; this embodiment The chemical formula of the high-entropy ceramic powder used is (La 1 / 5 SM 1 / 5 Gd 1 / 5 Nd 1 / 5 Er 1 / 5 ) 2 Zr 2 o 7 , the preparation method of high-entropy ceramic powder comprises the steps:

[0053] Step (A-1): La(NO 3 ) 3 ·6H 2 O, Sm(NO 3 ) 3 ·6H 2 O, Gd(NO 3 ) 3 ·6H 2 O, Nd(NO 3 ) 3 ·6H 2 O and Er(NO 3 ) 3 ·6H 2O five kinds of nitrates are fully mixed according to the molar ratio of 1:1:1:1:1, then add an appropriate amount of deionized water to dissolve to obtain a mixed nitrate solution, and then mix the mixed nitrate solu...

Embodiment 3

[0063] In this example, the low thermal conductivity and high entropy ceramic thermal barrier coating material is prepared by the following steps:

[0064] Step A: Preparation of high-entropy ceramic powder: using nitrate of trivalent rare earth elements and acetate of tetravalent metal elements as raw materials, a high-entropy ceramic powder with a hollow spherical structure is prepared by a plasma spraying process; this embodiment The chemical formula of medium and high entropy ceramic powder is (La 1 / 6 SM 1 / 6 Gd 1 / 6 Nd 1 / 6 Eu 1 / 6 Yb 1 / 6 ) 2 Zr 2 o 7 , the preparation method of high-entropy ceramic powder comprises the steps:

[0065] Step (A-1): La(NO 3 ) 3 ·6H 2 O, Sm(NO 3 ) 3 ·6H 2 O, Gd(NO 3 ) 3 ·6H 2 O, Nd(NO 3 ) 3 ·6H 2 O, Eu(NO 3 ) 3 ·6H 2 O and Yb(NO 3 ) 3 ·6H 2 O six kinds of nitrates are fully mixed according to the molar ratio of 1:1:1:1:1:1, then add an appropriate amount of deionized water to dissolve to obtain a mixed nitrate solution,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| surface tension | aaaaa | aaaaa |

| surface tension | aaaaa | aaaaa |

| surface tension | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com