Pyrochlore structural rare-earth zirconate material and preparation method and application thereof

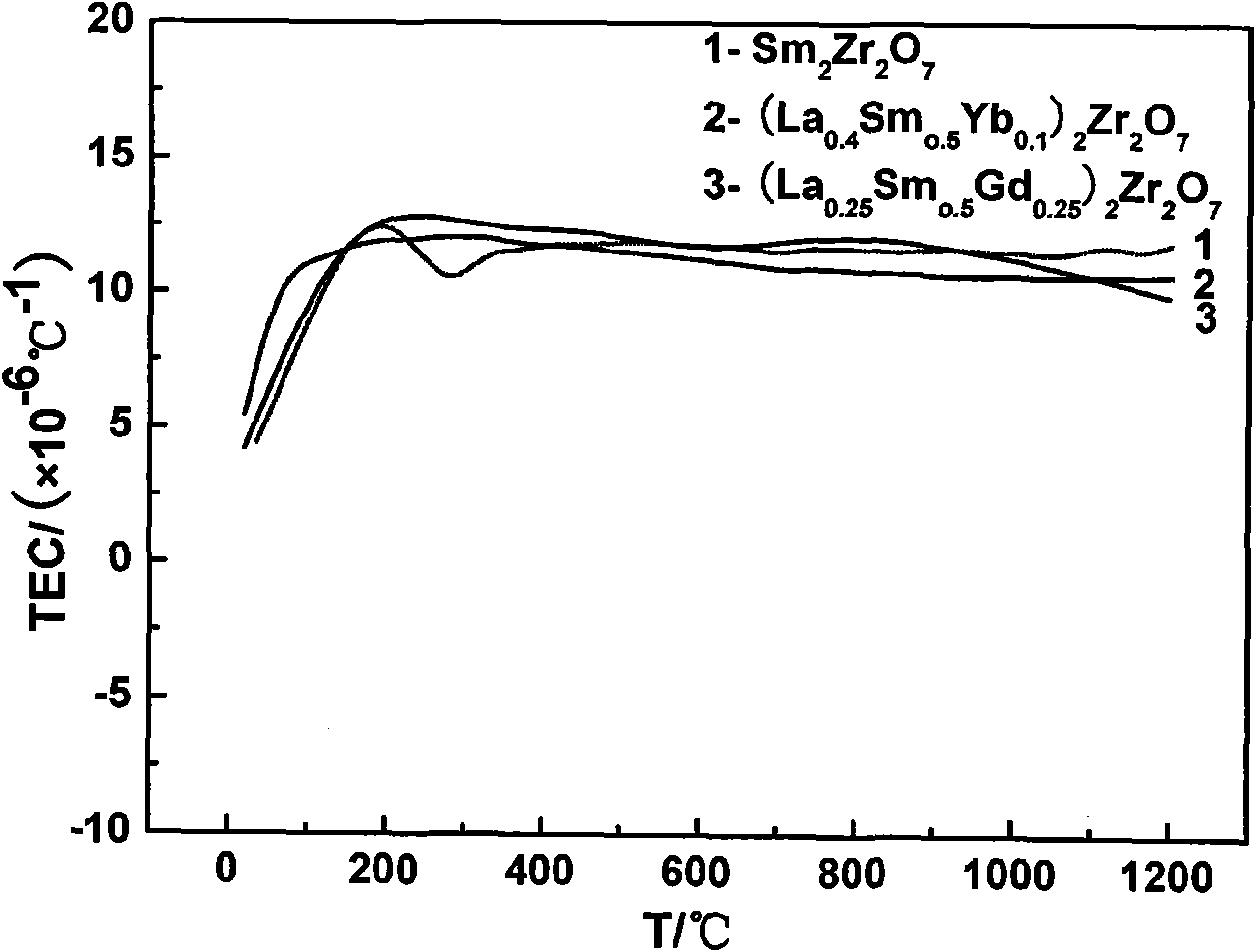

A pyrochlore structure, zirconate technology, applied in metal material coating process, coating, melt spraying and other directions, can solve the violent fluctuation of thermal expansion coefficient, the reduction of thermal cycle life of the coating, and the increase of thermal stress of the coating and other problems, to achieve the effect of improving low temperature fluctuation, reducing thermal stress and stabilizing thermal expansion coefficient

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039] Example 1: 0.4La 2 o 3 -0.5Sm 2 o 3 -0.1R″ 2 o 3 -2ZrO 2 Preparation of Ceramic Material Powder

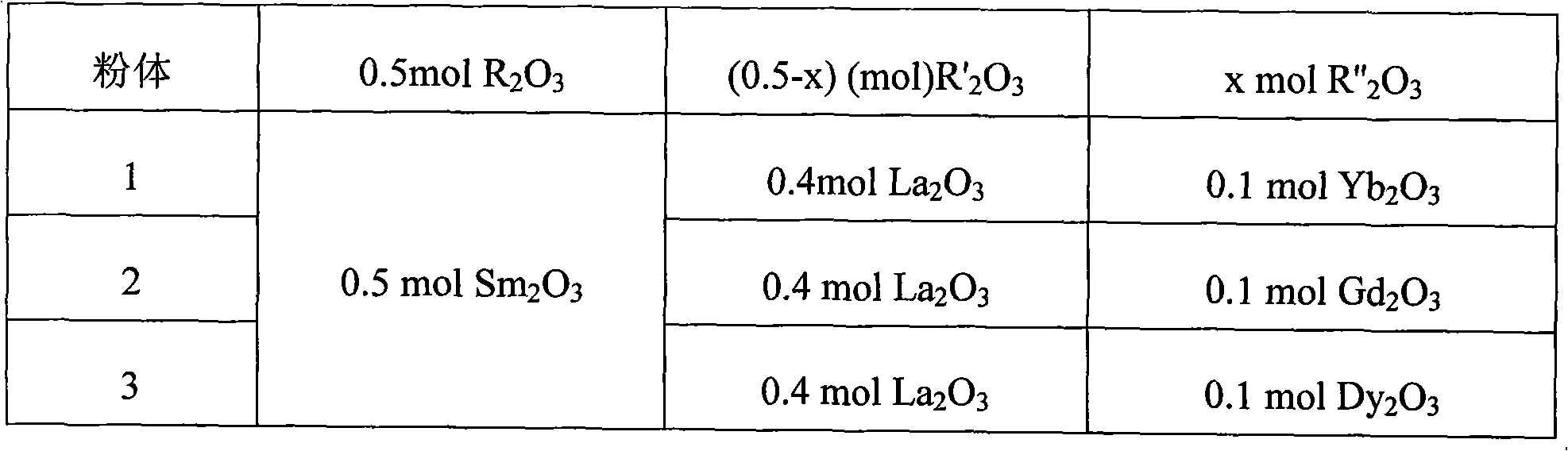

[0040] The rare earth element R" selected in this embodiment is Yb 2 o 3 、Gd 2 o 3 or Dy 2 o 3 , The selected raw material composition is shown in Table 1.

[0041] The first step: the La 2 o 3 、Sm 2 o 3 , R″ 2 o 3 , ZrO 2 Mix in a molar ratio of 0.4:0.5:0.1:2, and place the mixed powder in a ball mill jar;

[0042] Step 2: Add an appropriate amount of absolute ethanol and zirconia grinding media equal in mass to the mixed powder, mix and grind at a speed of 250r / min for 10 hours, and then dry the slurry at 80°C;

[0043] Step 3: Put the mixed powder in a zirconia crucible and compact it, heat at 1400°C for 6 hours and cool to room temperature, then crush the obtained material, sieve, and ball mill for 12 hours to obtain a powder with a particle size of less than 1 μm;

[0044] The fourth step: put the powder obtained in the third step into a zirconia c...

Embodiment 2

[0050] 0.3La 2 o 3 -0.5Sm 2 o 3 -0.2R″ 2 o 3 -2ZrO 2 Preparation of Ceramic Material Powder

[0051] The difference between this embodiment and Embodiment 1 is that La 2 o 3 、Sm 2 o 3 , R″ 2 o 3 , ZrO 2 The proportioning ratio is 0.3:0.5:0.2:2. Other steps are the same as Embodiment 1.

Embodiment 3

[0053] 0.25La 2 o 3 -0.5Sm 2 o 3 -0.25R″ 2 o 3 -2ZrO 2 Preparation of Ceramic Material Powder

[0054] The difference between this embodiment and Embodiment 1 is that La 2 o 3 、Sm 2 o 3 , R″ 2 o 3 , ZrO 2 The proportioning ratio is 0.25:0.5:0.2:25. Other steps are the same as Embodiment 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com