Solar cell and method for manufacturing solar cell

一种太阳能电池、电极的技术,应用在半导体/固态器件制造、电路、光伏发电等方向,能够解决填充因数降低、配线电阻大等问题

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~4

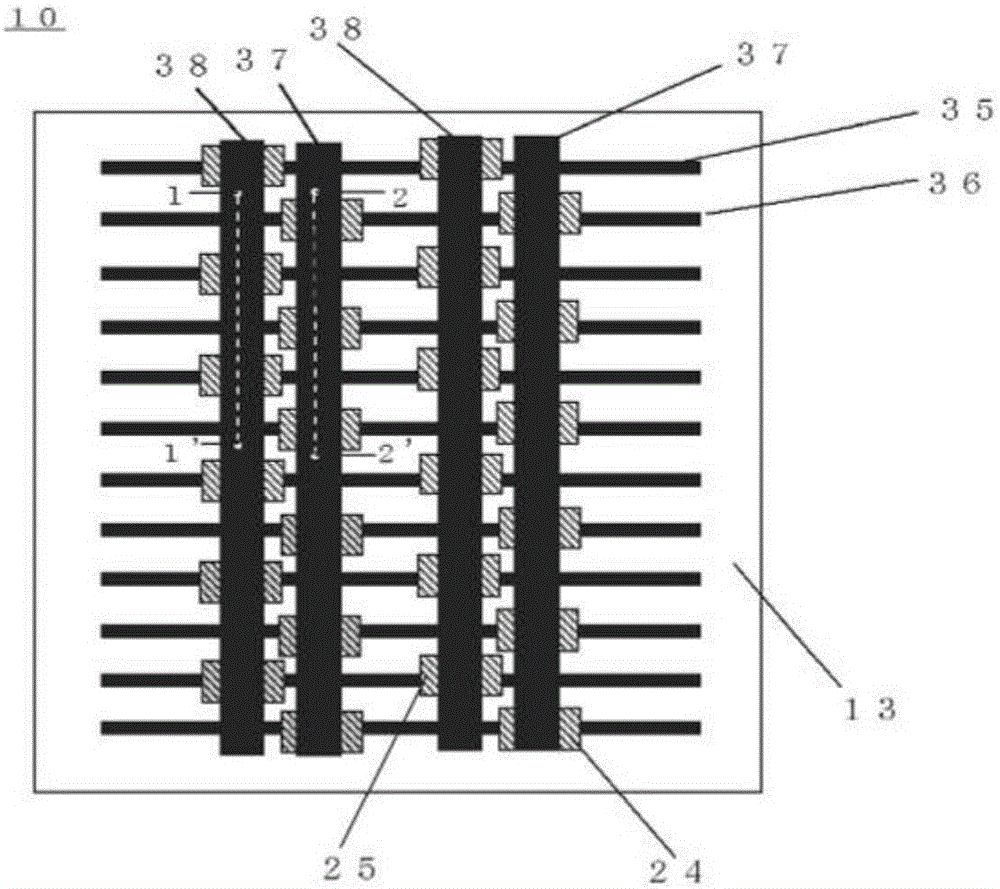

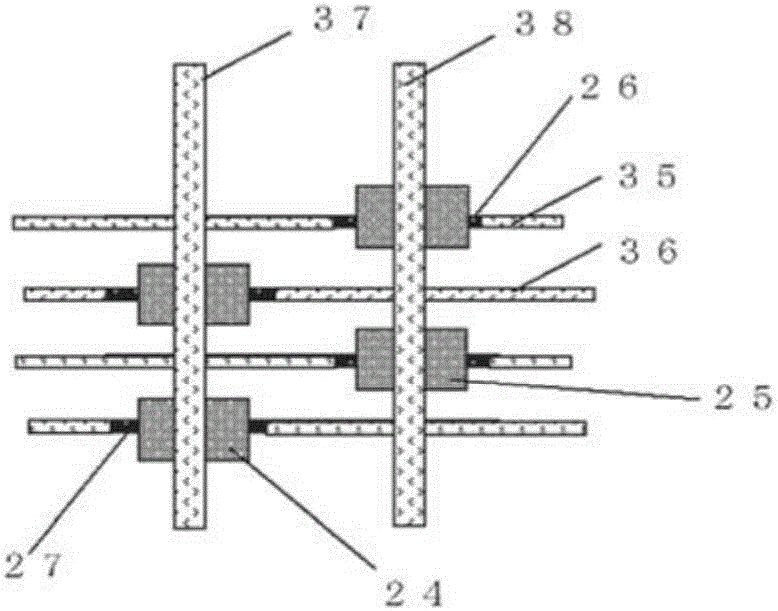

[0170] In Examples 1 to 4, the formation of Figure 7 The electrode part, insulating film, electrode line part and electrode bus bar part ( Figure 6 j~l).

[0171] First, the electrode portion was formed in a linear pattern with a width of 100 μm. Specifically, using screen printing, a conductive paste (sintering paste) composed of silver (Ag) particles, glass paste, binder, and solvent is coated on a specific position on the diffusion layer, dried, and dried at 700 ℃ for 5 minutes to form the first electrode part and the second electrode part. Next, an insulating film having a length of 3 mm and a width of 500 μm was formed in the insulating region. Polyimide paste was used as the material of the insulating film, and this paste was applied to a specific part by screen printing, and it was cured by heating at 150° C. for 20 minutes to form an insulating film.

[0172] Next, finger electrodes (electrode line portions) having a width of 100 μm and bus bar electrodes (electr...

Embodiment 5~8

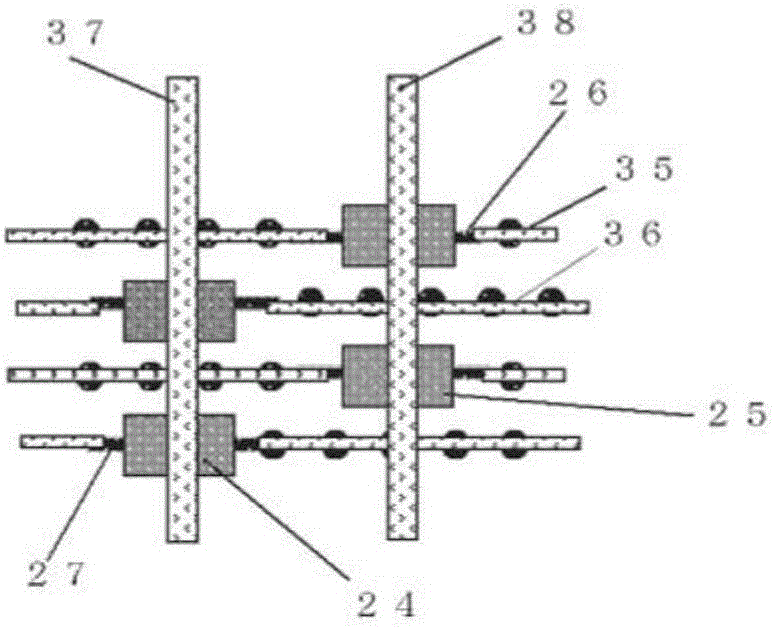

[0175] In embodiment 5~8, form such as Figure 8 The electrode part, insulating film, electrode line part and electrode bus bar part ( Figure 6 j~l).

[0176] formed as Figure 8 The electrode part of the pattern shown. Patterns having a diameter of 200 μm were provided at intervals of 0.5 mm along the extending direction of the diffusion layer, except for the portion where the insulating film was formed. In addition, only the insulating region is a linear pattern with a length of 4 mm and a width of 100 μm. The sintering paste was applied by screen printing, dried, and calcined at 700° C. for 5 minutes to form this pattern. Next, an insulating film having a length of 3 mm and a width of 500 μm was formed in the insulating region. Polyimide paste was used as the material of the insulating film, and the paste was applied to a specific position by screen printing, and was cured by heating at 150° C. for 20 minutes to form an insulating film.

[0177] Next, an electrode li...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com