Highly efficient distilling filled tower

A technology of rectification packing and packing tower, which is applied in the field of rectification tower structure, and can solve problems such as low separation efficiency and drop in tower efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

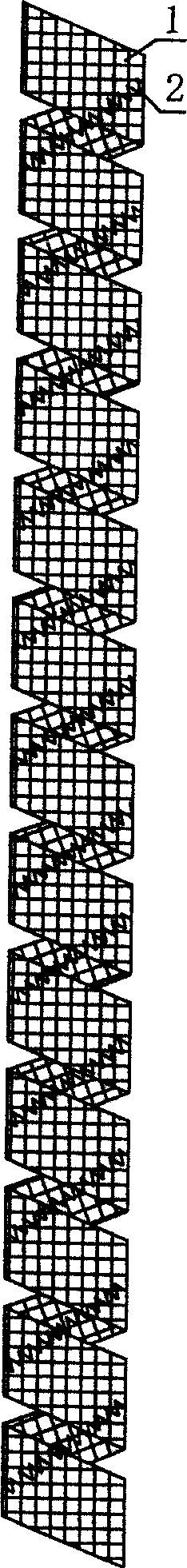

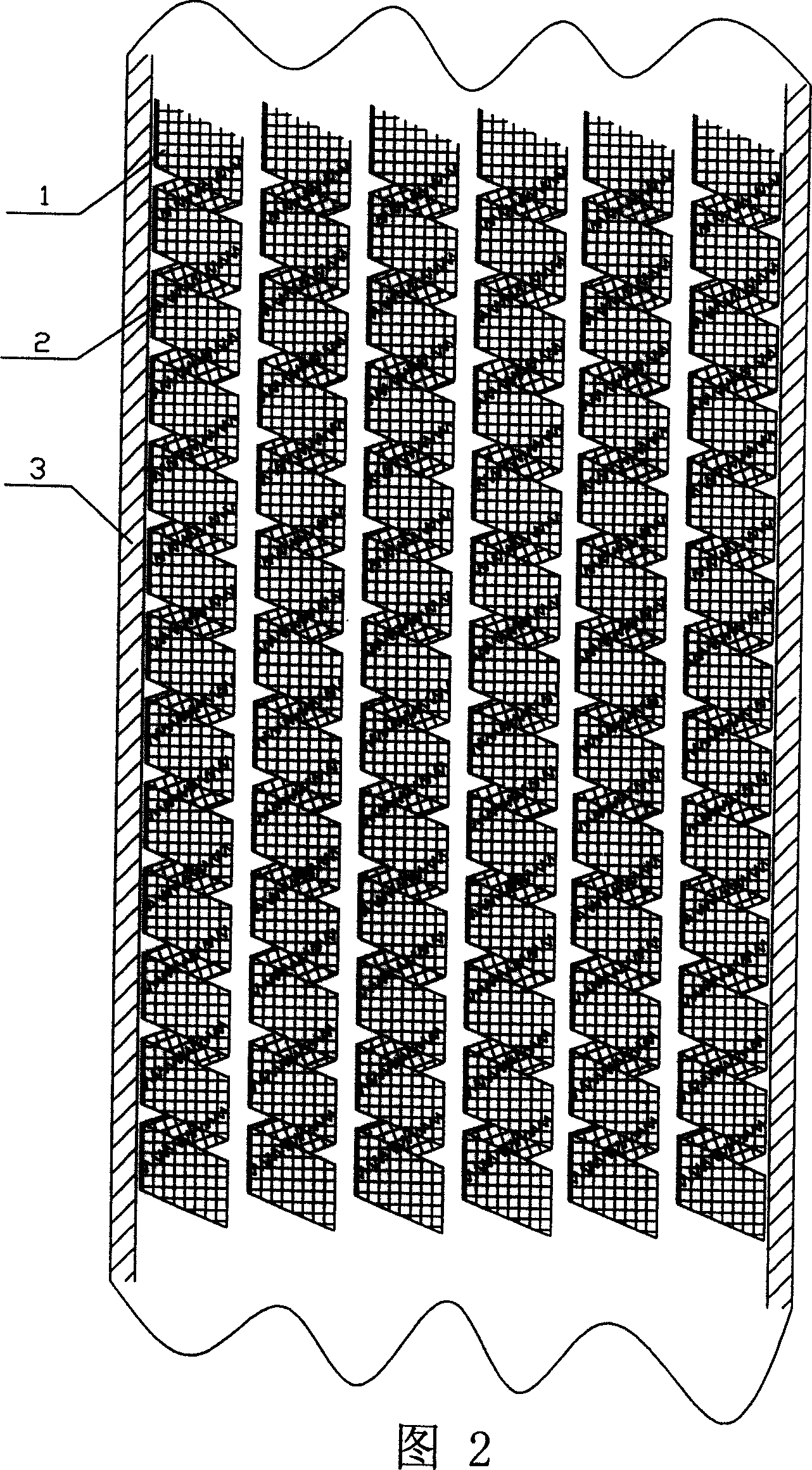

[0009] According to the accompanying drawings, the filler of the high-efficiency rectification packed tower of the present invention is composed of several meshed spiral tubes 1 connected in parallel, and the axis of the spiral tube is placed parallel to the axis of the packed tower. The invention adopts a parallel spiral structure, and a group of several mesh spiral pipes are connected in parallel and installed in the tower section to form a parallel spiral packed tower. The spiral tube is made of mesh belt material. There is a spiral gap between the upper and lower adjacent spiral coils of the rolled spiral tube. There is a spring sheath 2 outside a single spiral tube, and the spiral tubes are separated by the spring sheath. Open and form a parallel structure.

[0010] The present invention carries out rectification test with ethanol-water solution system, and the height of the parallel spiral packing used in test is 1000mm, and diameter is 500mm, and under the condition of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com