Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

84results about How to "Reduce the amount of washing water" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

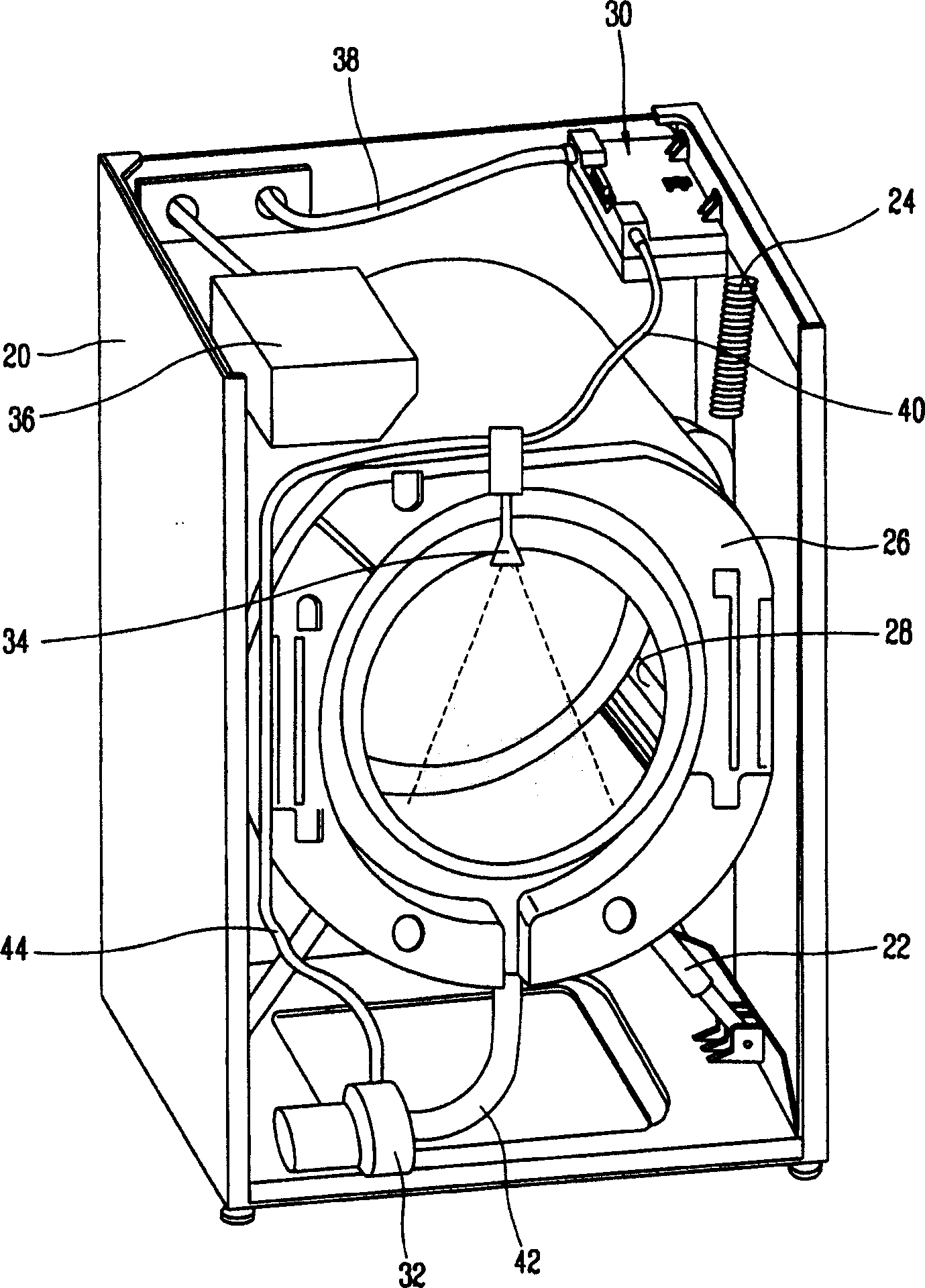

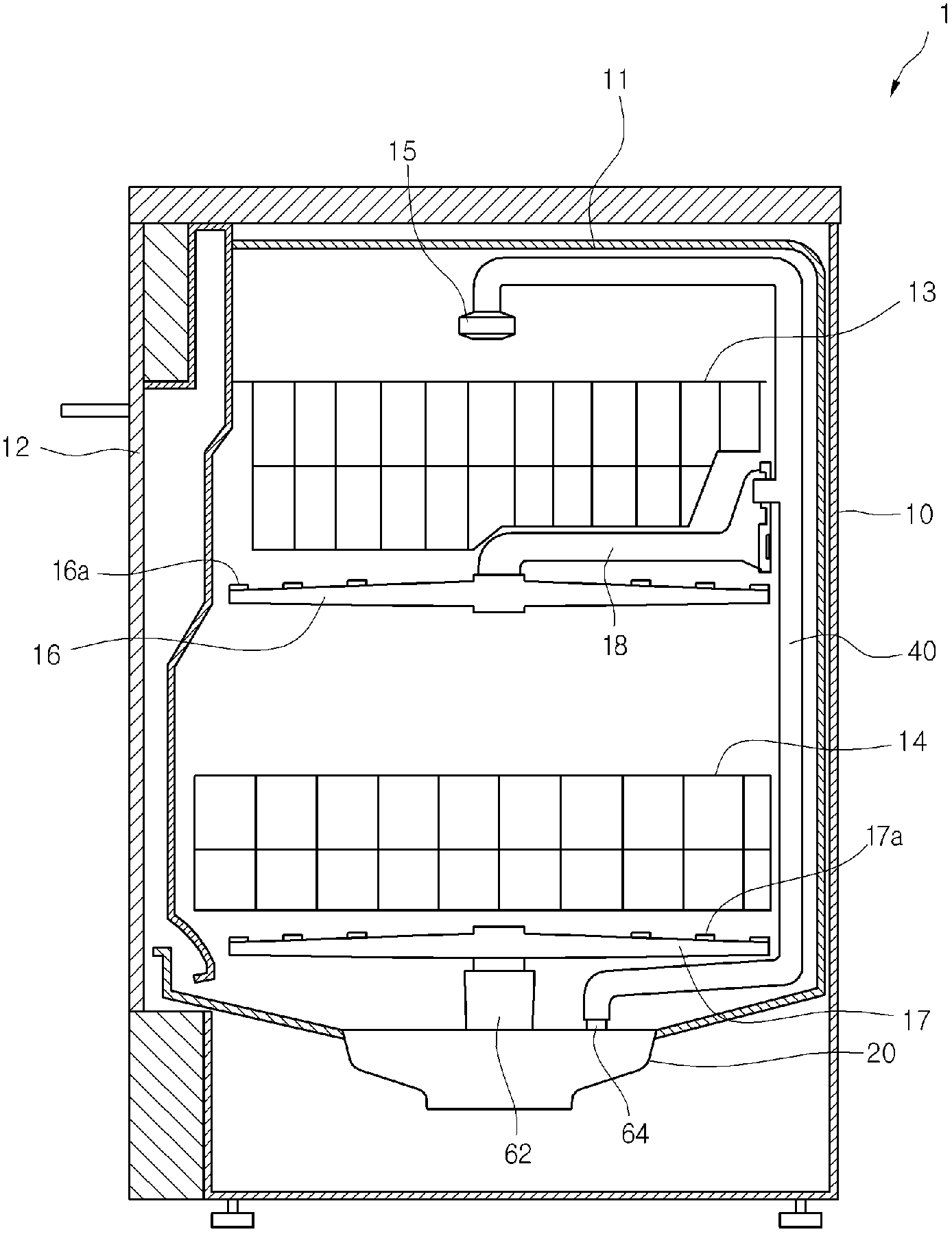

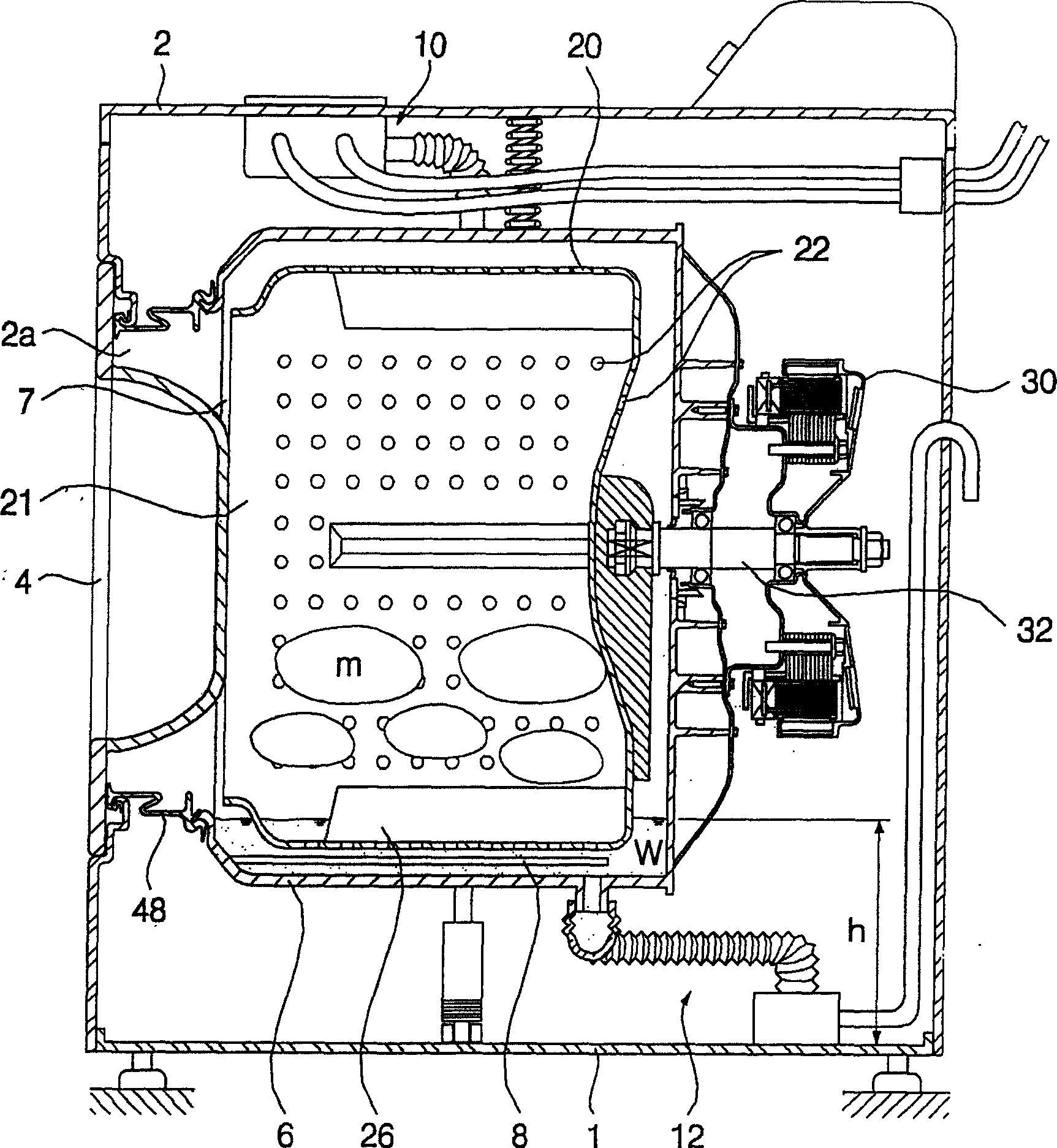

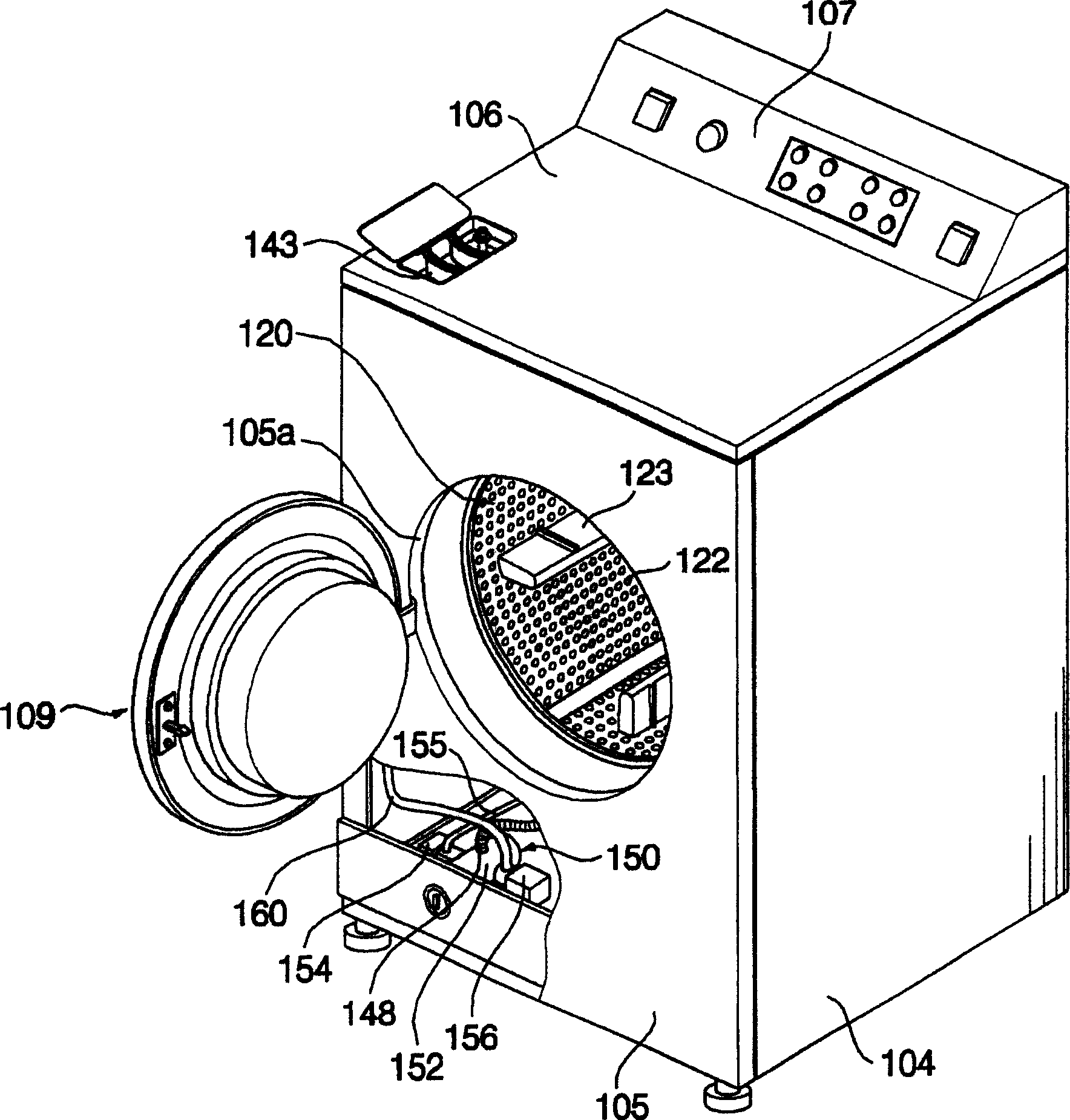

Steam generation apparatus for washing machine

ActiveCN1721616ASmall sizeReduce the amount of washing waterOther washing machinesTextiles and paperEngineeringWater level

A steam generation apparatus for a washing machine includes: a case having an accommodating space for storing water; a heater disposed inside the case to heat the water stored in the case; and a heater overheating prevention unit for cutting off power of the heater when the heater is overheated above the set temperature, so that a fire and deflection of a case can be prevented by preventing overheating of the heater by cutting off power being supplied to the heater when the heater is overheated due to malfunctions of a water level sensor or a clogged spray nozzle or a clogged flow passage.

Owner:LG ELECTRONICS INC

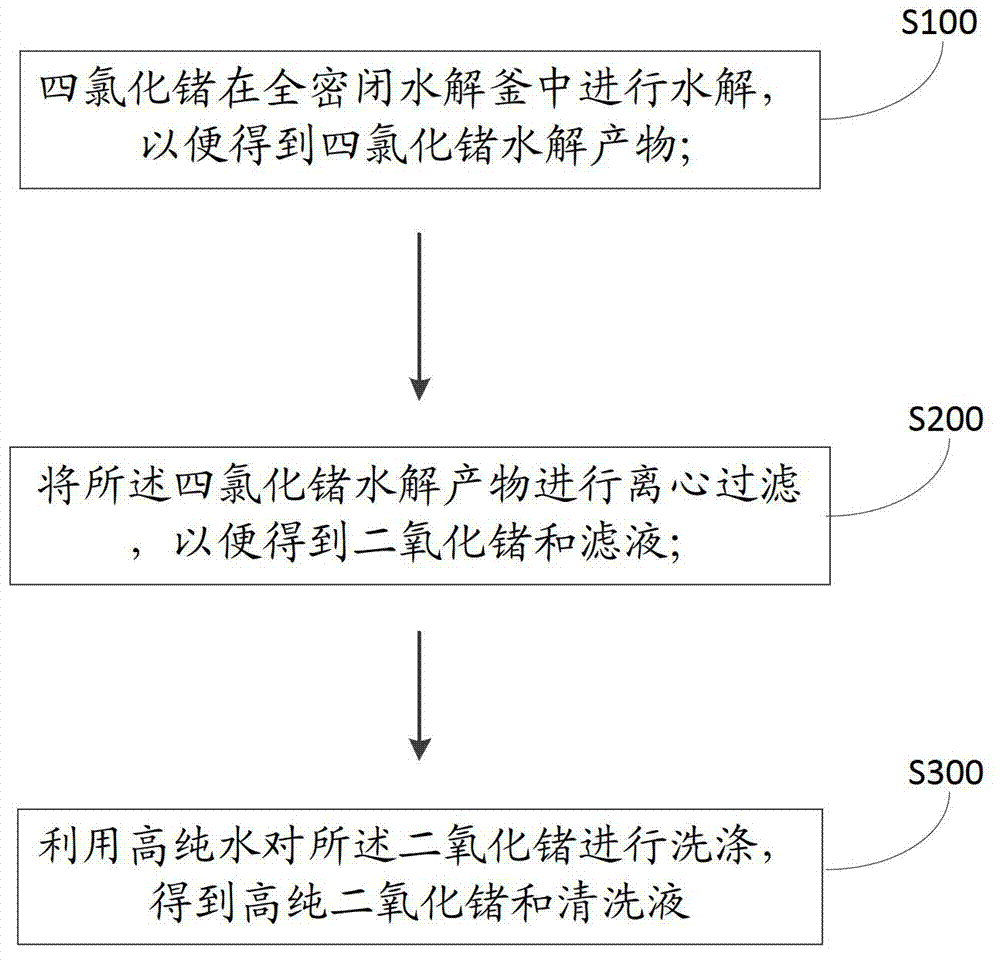

Novel process for preparing germanium dioxide (GeO2)

ActiveCN102774877AReduce lossesHigh degree of automationGermanium dioxideGermanium dioxideHydrolysis

The invention provides a method for preparing germanium dioxide (GeO2). According to the embodiment of the invention, the method comprises the following steps: hydrolyzing the germanium tetrachloride(GeCl4) in a fully-closed hydrolysis reactor to obtain the hydrolysis product of the GeCl4, centrifuging and filtering the hydrolysis product of the GeCl4 to obtain the GeO2 and the filtrate, and cleaning the GeO2 by high-purity water to obtain the high-purity GeO2 and the cleaning solution. According to the embodiment of the invention, the GeO2 hydrolyzing, filtrating and washing method and device have the advantages of high degree of automation, high GeO2 hydrolysis yield, good solid-liquid centrifugal separation effect, low production costs, less metal loss and environment friendliness.

Owner:云南驰宏国际锗业有限公司

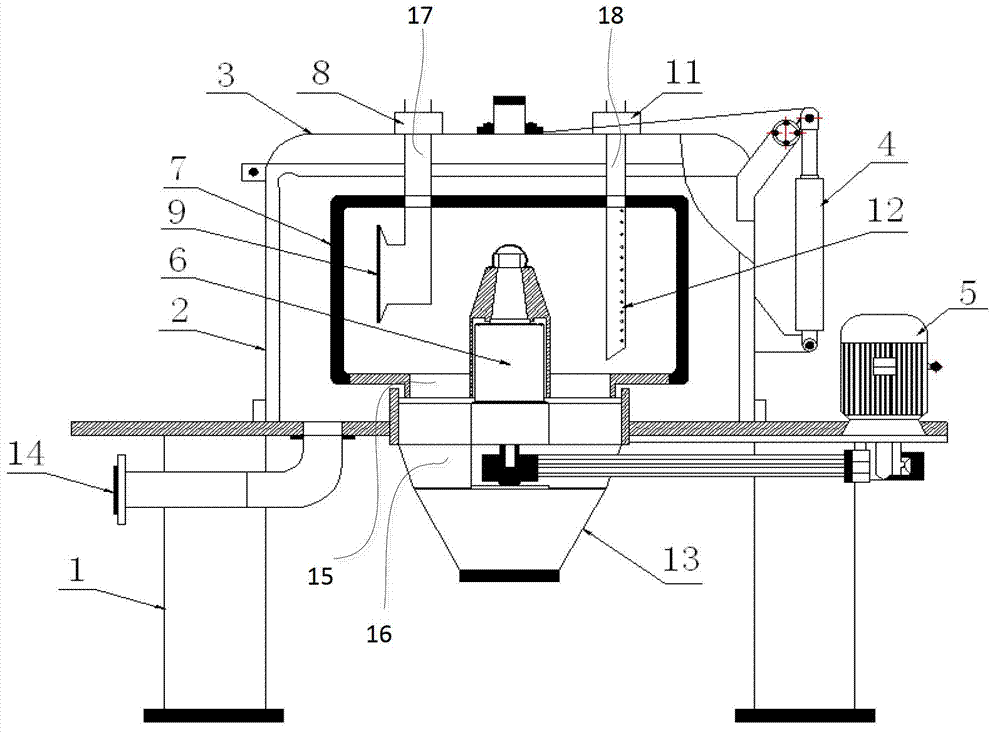

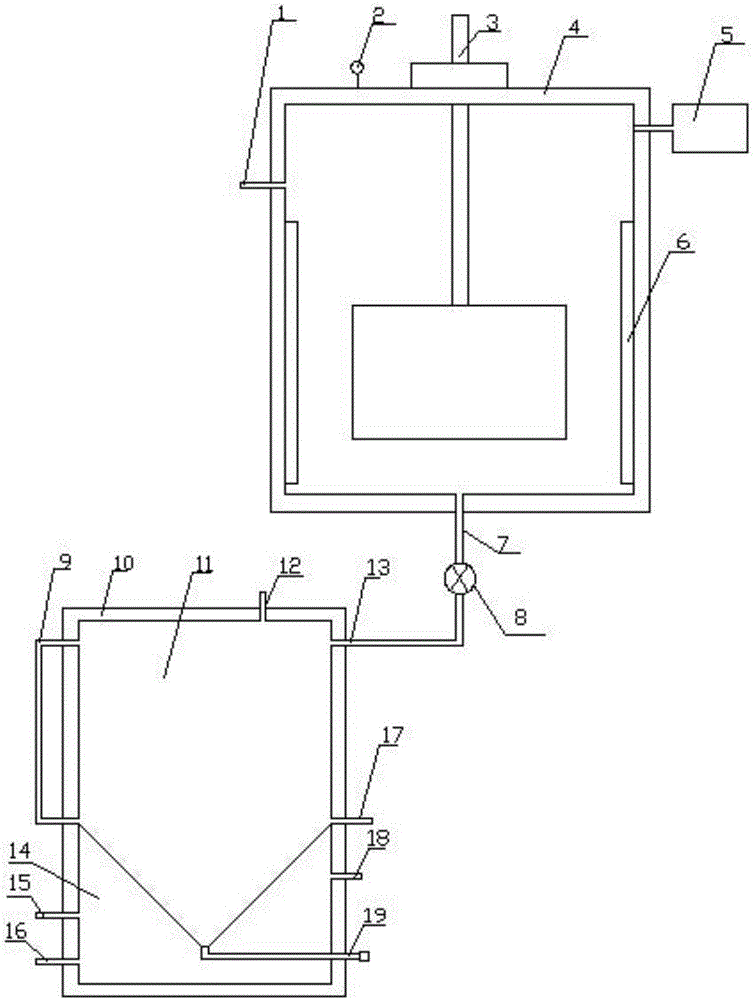

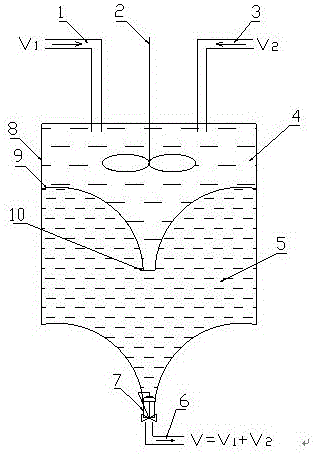

Production method and device of fine-grained low-chloride rare earth carbonate

ActiveCN104310456AAchieve spatial separationPromote formationRare earth metal compoundsChlorideReaction zone

The invention relates to a production method and device of fine-grained low-chloride rare earth carbonate. The production method is mainly characterized in that rare earth chloride and a carbonate solution are added in a concurrent flow feeding way on a designed special precipitation reaction device, the spatial separation of a reaction zone and a crystallization zone is realized by controlling the feeding speed and discharging speed and controlling the aging time of rare earth carbonate, and thus the double purposes of directly obtaining a fine-grained low-chloride rare earth carbonate product from a hydrochloric acid medium by precipitation and realizing continuous production are achieved. By adopting the production method and device provided by the invention, the fine-grained rare earth carbonate product with the chloride content of less than 50ppm can be directly obtained from the hydrochloric acid medium by using cheap ammonium bicarbonate, the precipitation reaction device has a simple structure, and the continuous production can be realized.

Owner:NAT ENG RES CENT OF RARE EARTH METALLURGY & FUNCTION MATERIALS

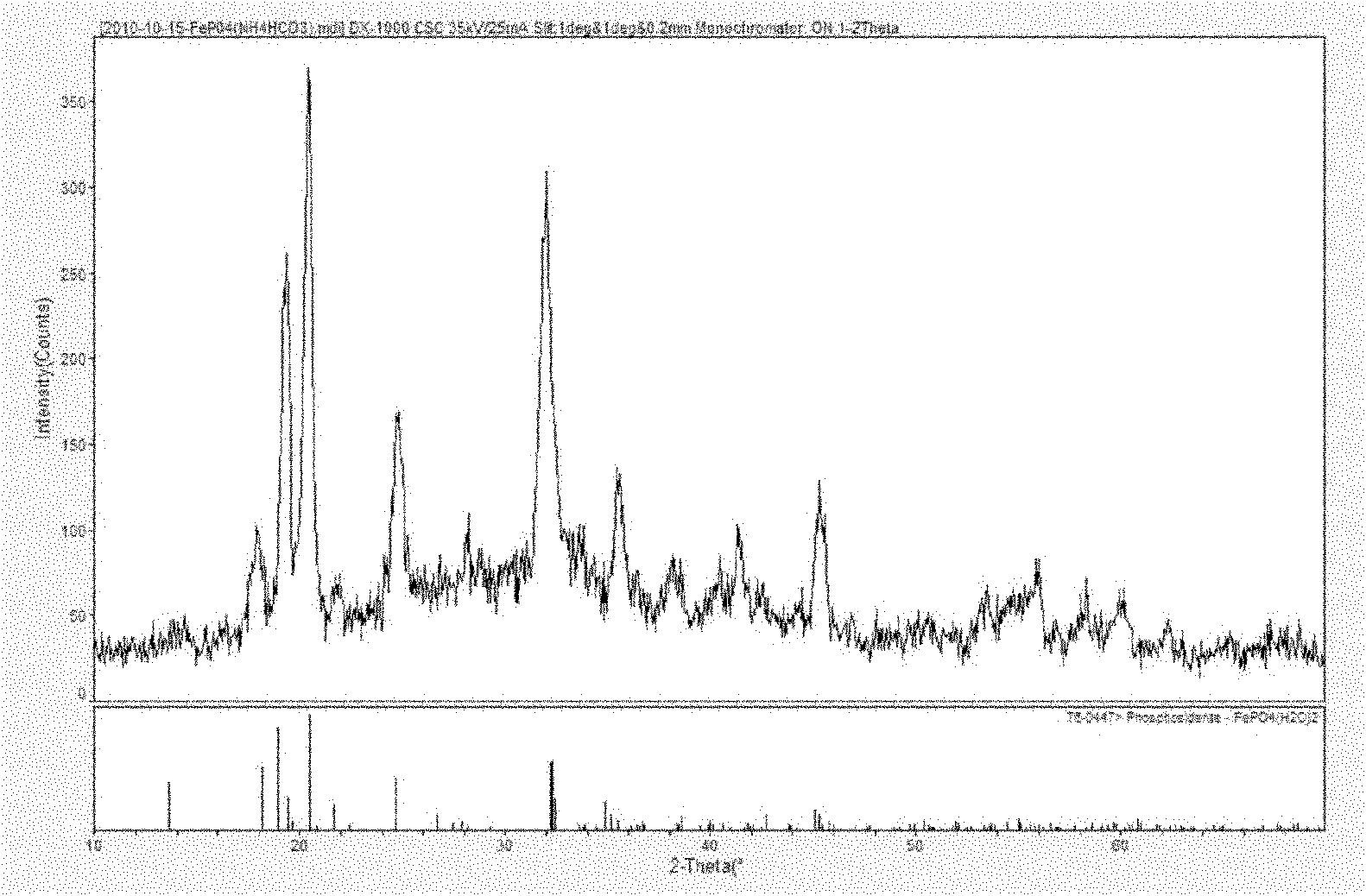

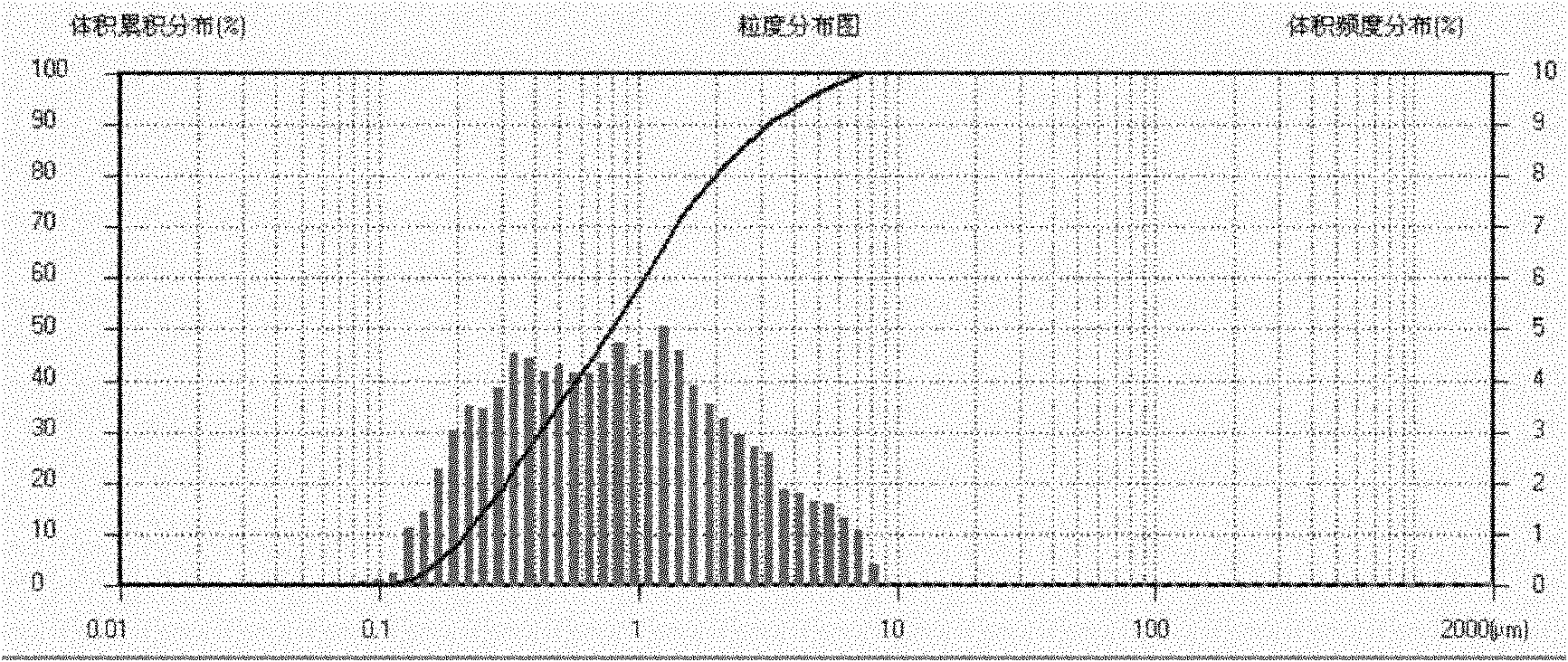

High-purity iron phosphate used for producing lithium ion battery positive-pole material and preparation method thereof

InactiveCN102126713ALow impurity contentImprove electrochemical performancePhosphorus compoundsFerrous saltsPhosphoric acid

The invention relates to high-purity iron phosphate used for producing a lithium ion battery positive-pole material and a preparation method thereof. The preparation method is characterized by comprising the following steps: taking ferrous salt and carbonate as raw materials; reacting to generate intermediate product ferrous carbonate precipitation, wherein, the ferrous carbonate is easy to filter, and the foreign ions are easy to wash; filtering and recovering ammonium sulfate; dissolving the ferrous carbonate precipitation; adding oxidant for oxidizing; regulating the pH value of the solution; heating and preserving the temperature for a certain time to obtain the iron phosphate precipitation; filtering, drying and precipitating to obtain the high-purity iron phosphate; and mixing and calcining the high-purity iron phosphate, the lithium source and the carbon source to obtain the lithium ion battery positive-pole material with excellent electrochemistrical performance. By using the method provided by the invention, the impurity content in the iron phosphate is effectively lowered, the process time is shortened, the energy consumption is reduced, and the cost and the consumption of the raw materials are lowered; and the filter liquor is easy to recover, and the production cost is very low, thus being beneficial for large-scale production in scaled industry.

Owner:SICHUAN UNIV

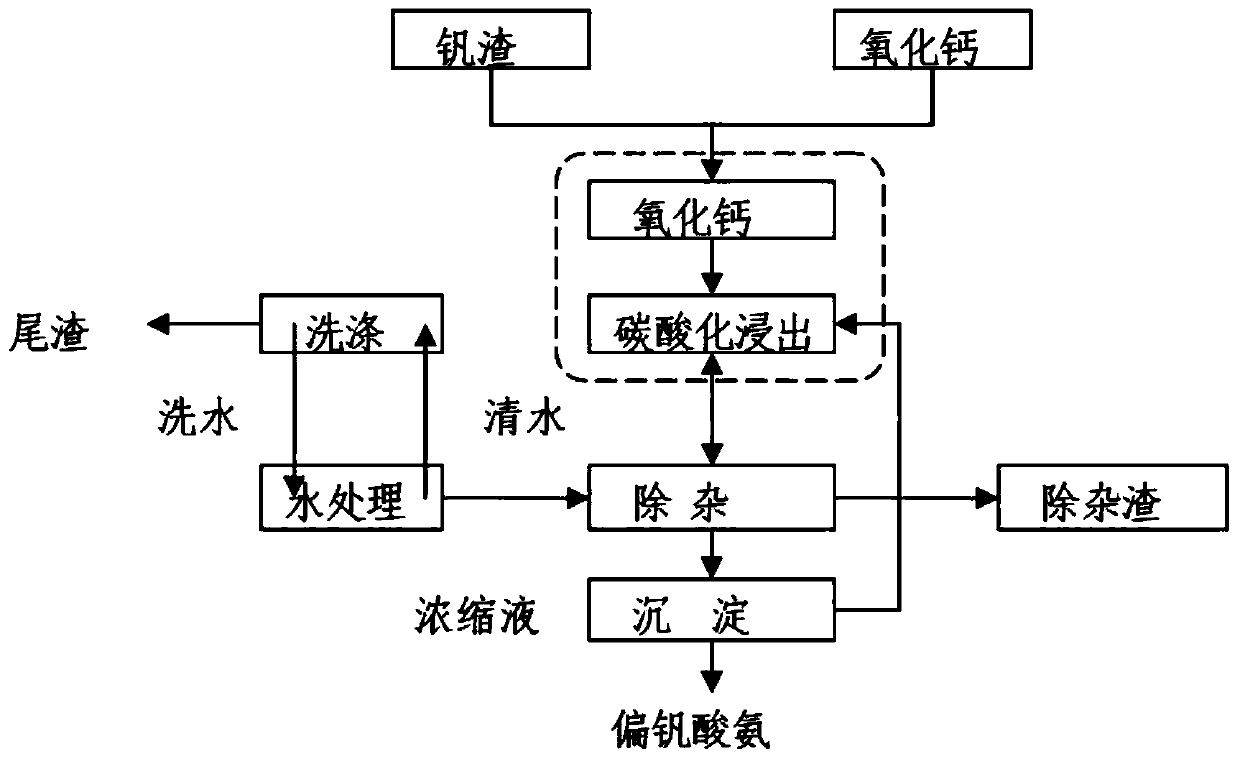

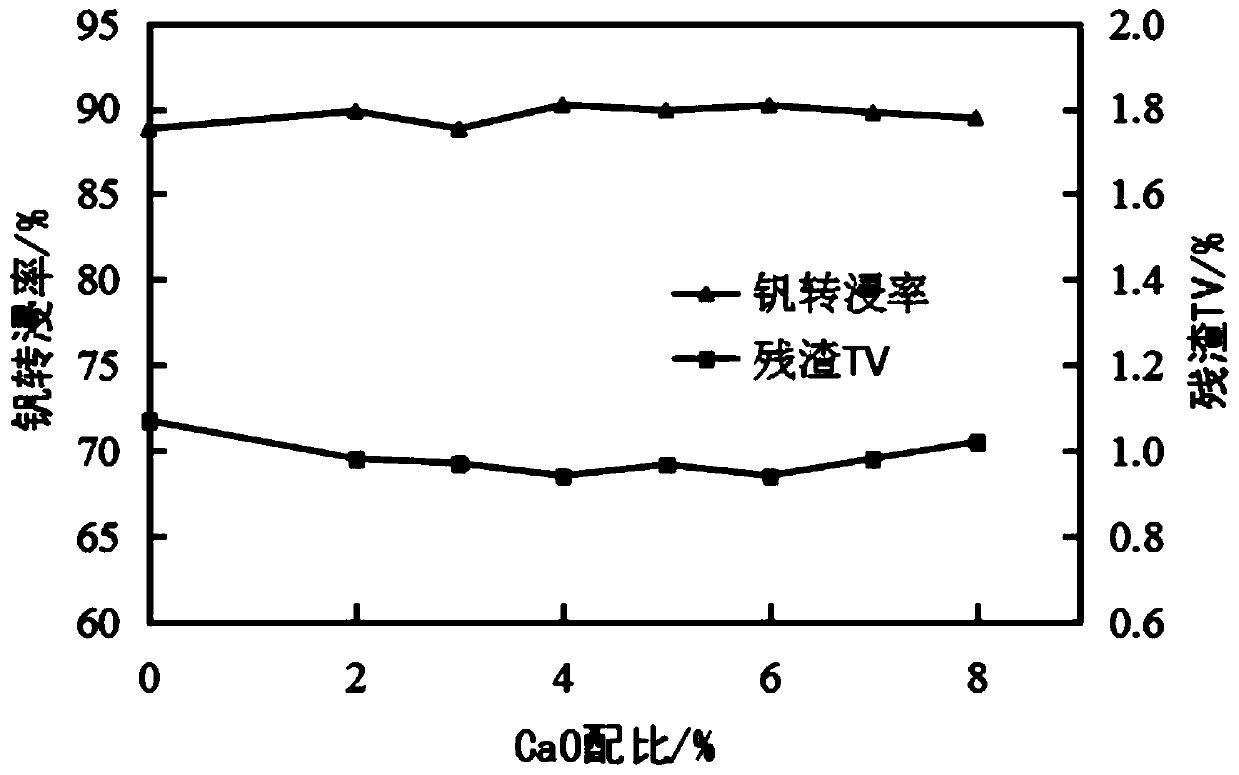

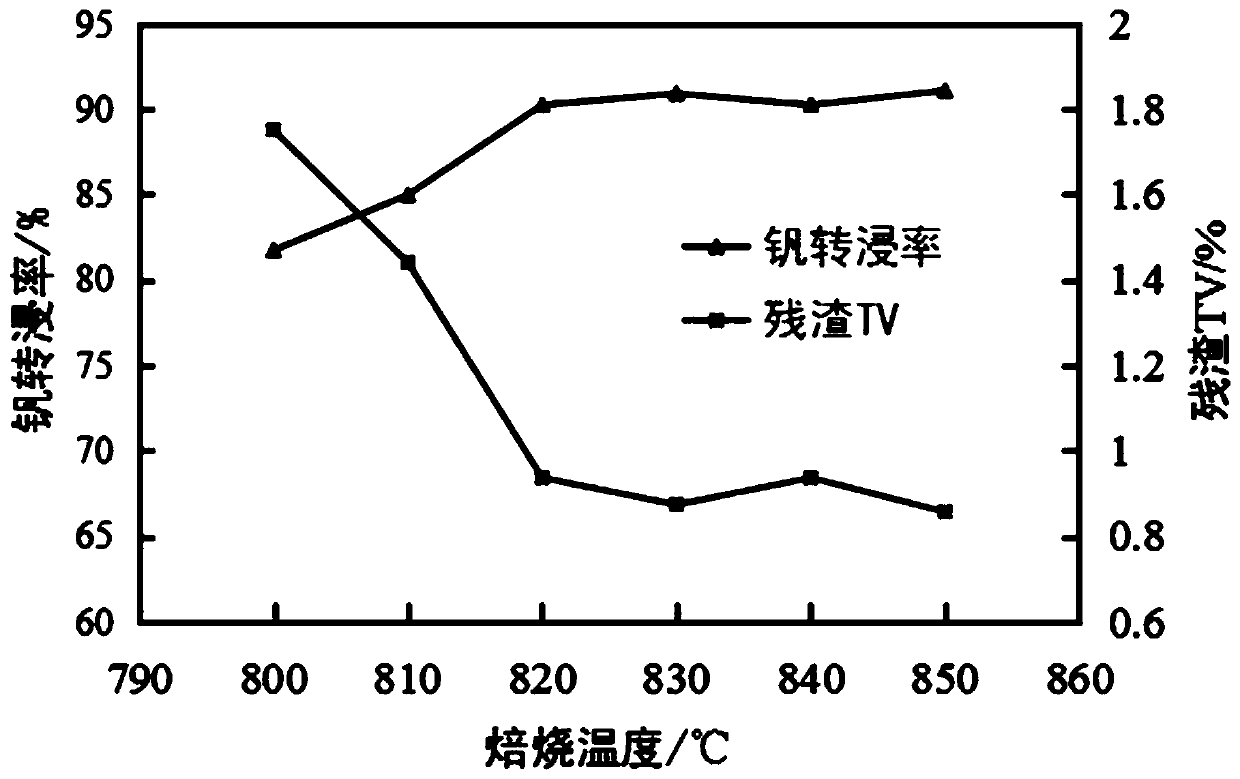

Low-cost method for cleanly extracting vanadium from vanadium slag

InactiveCN110760687ALow costLow Si concentrationProcess efficiency improvementAmmonium metavanadateMaterials science

The invention discloses a low-cost method for cleanly extracting vanadium from vanadium slag. The method comprises four steps of roasting the vanadium slag, carrying out alkaline leaching, purifying and precipitating the vanadium, wherein the vanadium slag and calcium oxide are mixed and then roasted to obtain roasted clinker; the roasted clinker is subjected to alkaline leaching to obtain residues and vanadium-containing leaching liquid; after the residues are cleaned, washing liquid is concentrated and is mixed with the vanadium-containing leaching liquid to obtain vanadium-containing mixedliquid; the vanadium-containing mixed liquid and calcium chloride are mixed to obtain a sodium vanadate solution; the sodium vanadate solution is added into an ammonium chloride solution and is subjected to solid-liquid separation to obtain ammonium metavanadate sediment and vanadium precipitation wastewater; the vanadium precipitation wastewater returns to the alkaline leaching step and is used for carrying out alkaline leaching on the roasted clinker. According to the low-cost method for cleanly extracting the vanadium from the vanadium slag, provided by the invention, the allowable CaO ratio and the roasting temperature fluctuation range are large and the solid ratio of the leaching liquid is small; industrialization is facilitated; the leached residues are easy to wash and the washingwater amount is small; the vanadium precipitation wastewater is directly and circularly leached out calcified clinker, so that the wastewater treatment amount can be greatly reduced; the Si concentration of the leaching liquid leached by alkaline liquid is low and the quantity of impurity-removed residues obtained in an impurity removing process is small.

Owner:SICHUAN DESHENG GRP VANADIUM & TITANIUM CO LTD

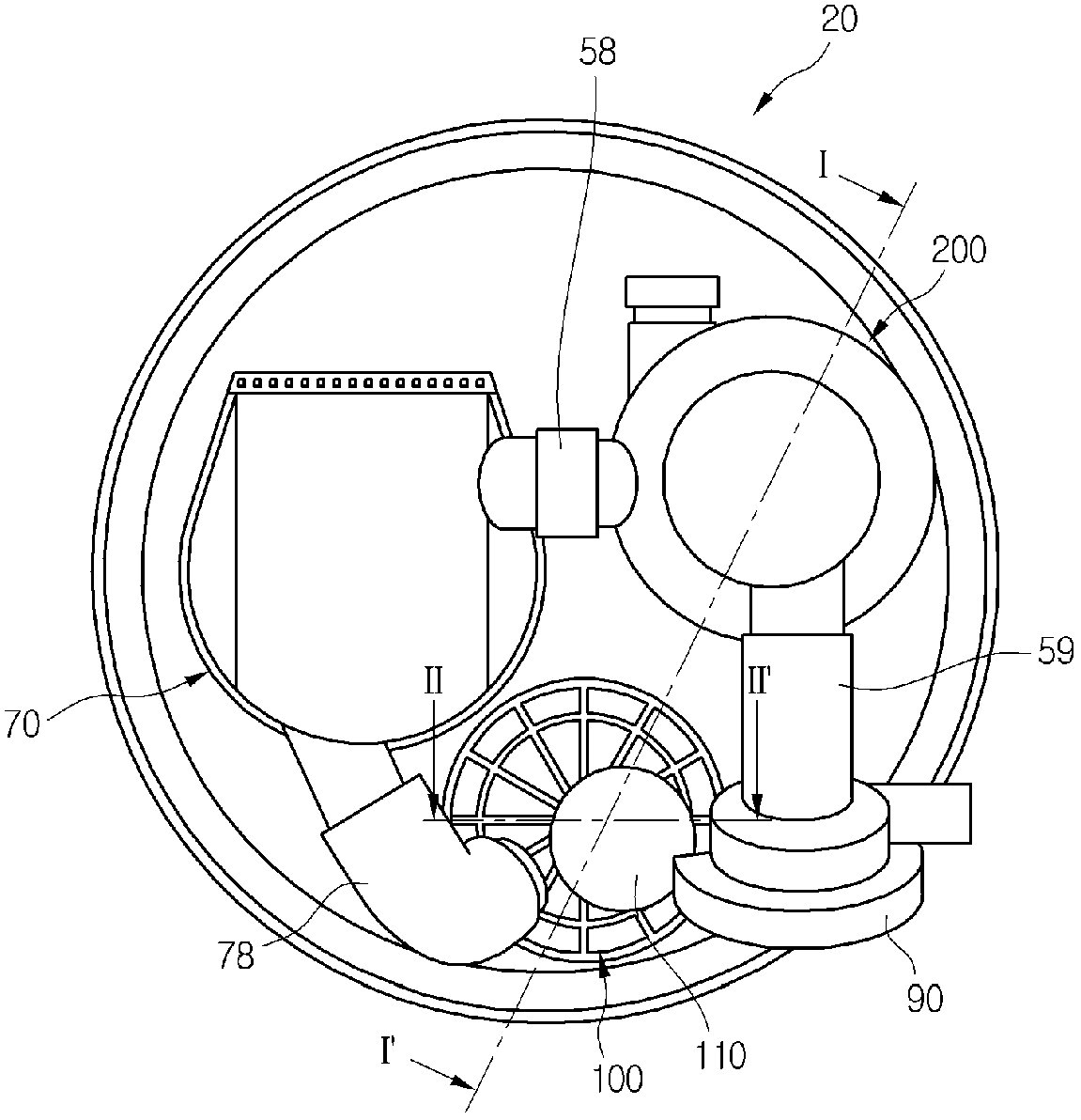

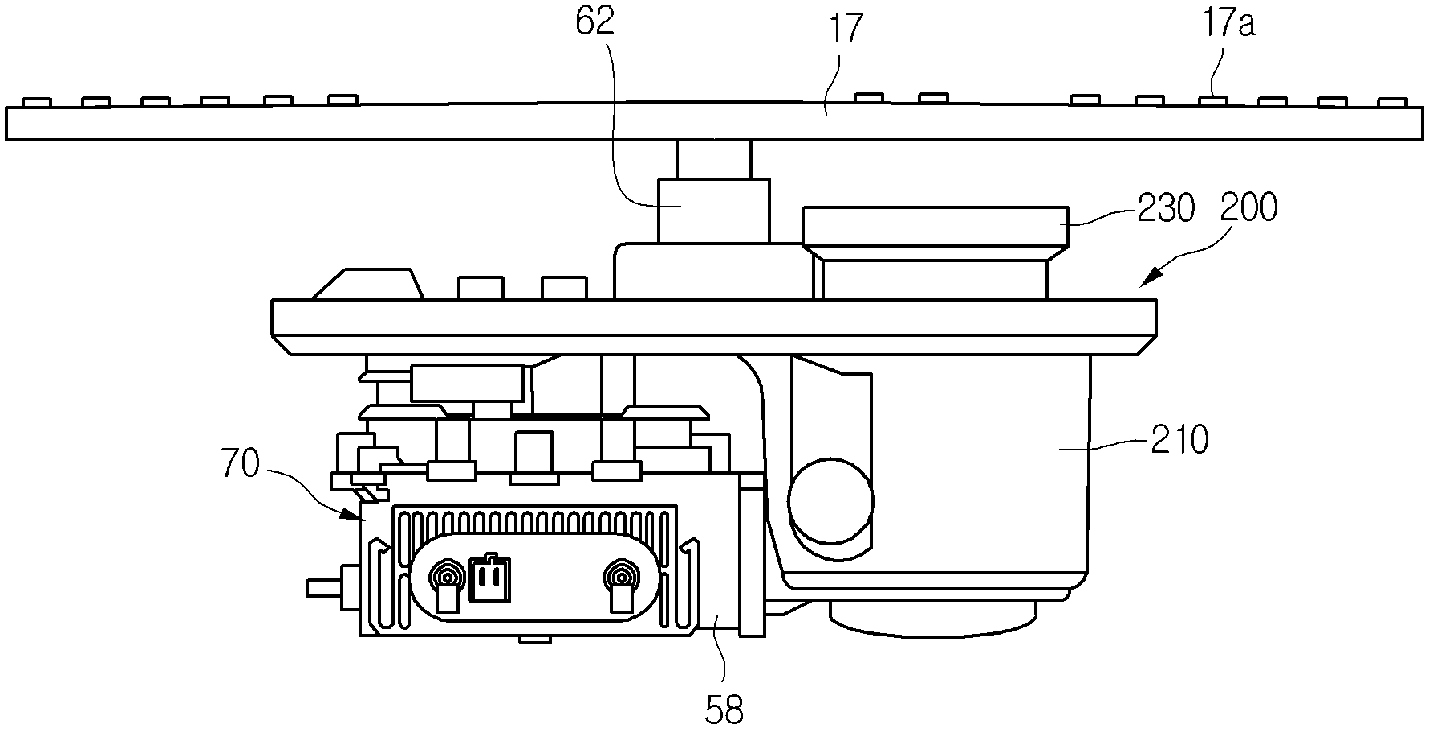

A dishwasher

InactiveCN103188985AReduce channel lengthReduce the amount of washing waterTableware washing/rinsing machine detailsImpellerSuction force

Provided is a dishwasher, which includes a washing chamber, a sump, and a washing water pump. The washing chamber accommodates a dish. The sump stores washing water supplied to the washing chamber. The washing water pump is provided to the sump and generates suction force for circulating washing water. The washing water pump includes a washing water motor for generating driving force, an impeller part disposed under the washing water motor and rotated by the driving force, and a heating space under the impeller part. Washing water is heated by a heater in the heating space.

Owner:LG ELECTRONICS INC

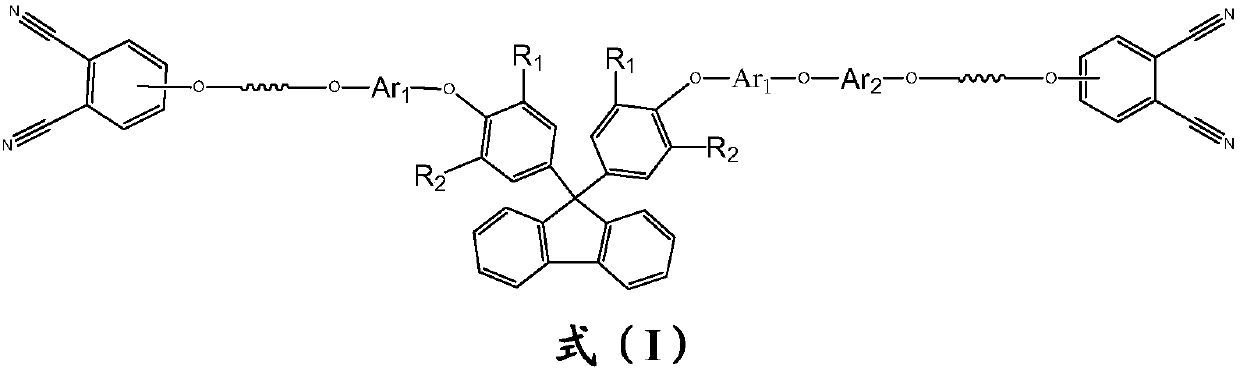

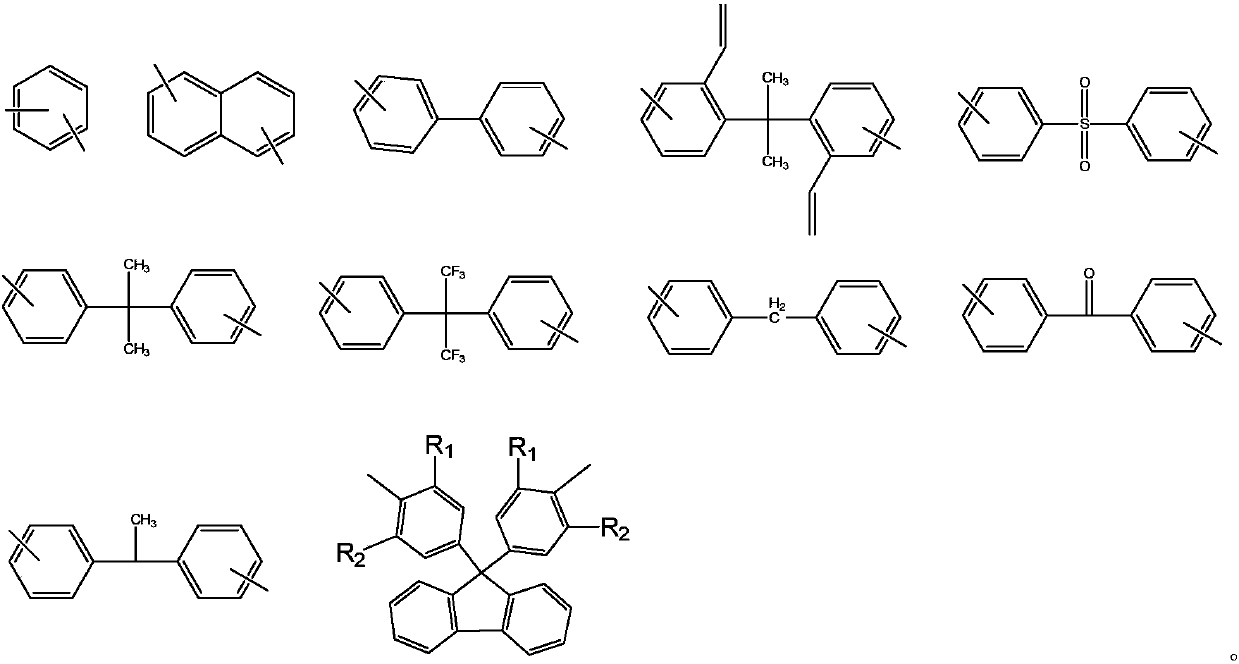

Phthalonitrile-terminated fluorine structure-containing poly(arylene ether nitrile) oligomer, phthalonitrile-terminated fluorine structure-containing poly(arylene ether nitrile)condensate, and preparation method of oligomer

ActiveCN107903189ALow melting pointImprove solubilityCarboxylic acid nitrile preparationOrganic compound preparationSolubilityDecomposition

The invention discloses a phthalonitrile-terminated fluorine structure-containing poly(arylene ether nitrile) oligomer, a phthalonitrile-terminated fluorine structure-containing poly(arylene ether nitrile) condensate, and a preparation method of the oligomer. The phthalonitrile-terminated fluorine structure-containing poly(arylene ether nitrile) oligomer has chain segments with different lengths and a large-volume side group structure, so the oligomer has a low melting point and a good dissolvability, can be dissolved in DMF, NMP and other strong polar solvents, and also can be dissolved in THF, dichloromethane and a toluene and acetonitrile mixed solvent. The phthalonitrile-terminated fluorine structure-containing poly(arylene ether nitrile) condensate has excellent heat stability and mechanical performances, the 5% decomposition temperature in a nitrogen atmosphere is 499-528 DEG C, the residue mass rate at 1000 DEG C is 69-73.2%, and the bending strength is higher than 500 MPa. Thepreparation method of the phthalonitrile-terminated fluorine structure-containing poly(arylene ether nitrile) oligomer is simple and controllable, and can be applied to industrial production.

Owner:INST OF CHEM CHINESE ACAD OF SCI +1

Process for producing food grade saleratus by double decomposition

The invention relates to a process for producing food grade saleratus by double decomposition. The food grade saleratus is produced through a double decomposition reaction of natural brine and ammonium bicarbonate by using the process comprising the following steps: brine refining, double decomposition reaction, thickening, filtering, centrifugal separation and drying. A three-stage reaction process is adopted for the double decomposition reaction, and a kettle type machine is used for stirring a reaction barrel; a vacuum belt type filter is used for filtration washing, and washing water can be utilized for multiple times. The food grade saleratus product has good quality, easy control of the double decomposition reaction, small washing water quantity and low production cost.

Owner:湖南裕华科技集团股份有限公司

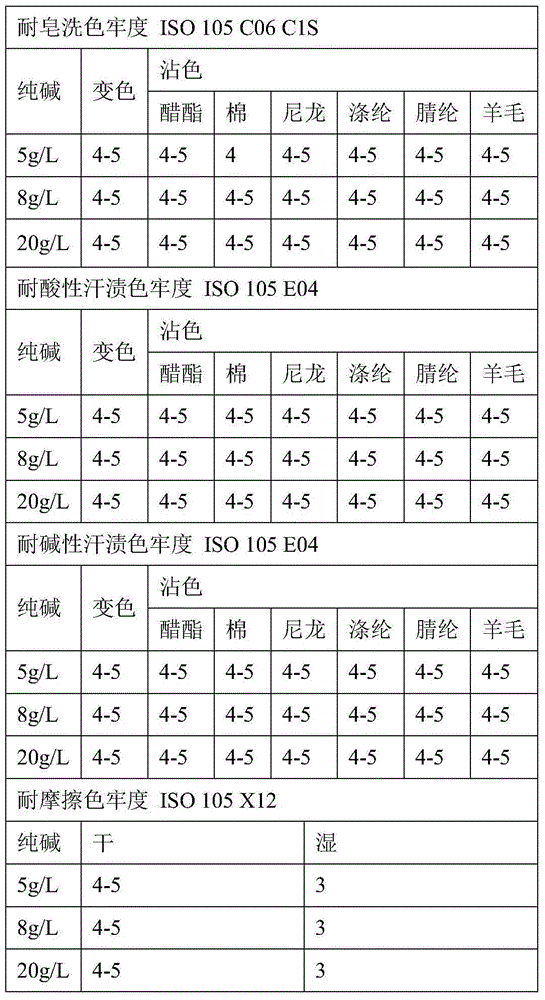

Activated dye low-alkaline dyeing method for black regenerated cellulose fiber cheese

ActiveCN104404797ALower dyeing temperatureReduce alkali consumptionDyeing processAcetic acidWater volume

The invention relates to the field of printing and dyeing, particularly to an activated dye low-alkaline dyeing method for a black regenerated cellulose fiber cheese. The method comprises the steps of pretreatment, dyeing, fixing and follow-up treatment; in addition, low alkaline is adopted in the dyeing and fixing processes and the working procedures are reduced. Therefore, the dyeing temperature of the regenerated cellulose fiber is reduced; the alkaline dosage for dyeing the regenerated cellulose fiber is lowered; the method is simple to operate, short in technical duration, and low in alkaline content in the dyeing waste water, can reduce the dosage of glacial acetic acid for neutralization in the follow-up procedure, lowers washing water volume, saves energy and reduces emission, improves the color fastness of the cheese, and lowers the dyeing cost.

Owner:浙江恒生印染有限公司

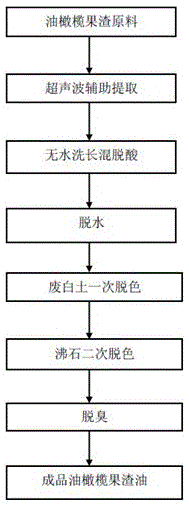

Method for ultrasonic-assisted extraction of olive pomace oil

InactiveCN105038943AEliminate the steps of deacidification and washingHigh yieldFatty-oils/fats refiningFatty-oils/fats productionUltrasonic assistedOil quality

The invention discloses a method for ultrasonic-assisted extraction of olive pomace oil. The method comprises the following steps: 1, preparing an olive pomace oil raw material; 2, adding n-hexane to the olive pomace oil raw material, and carrying out ultrasonic-assisted extraction to obtain crude olive pomace oil; 3, carrying out waterless washing long-mixing depickling treatment on the crude olive pomace oil to obtain depickled olive pomace oil; 4, dehydrating the depickled olive pomace oil to obtain dehydrated olive pomace oil; 5, respectively carrying out primary decoloring and secondary decoloring treatment on the dehydrated olive pomace oil to obtain double decolored olive pomace oil; and 6, deodorizing the double decolored olive pomace oil to obtain finished olive pomace oil. The method for ultrasonic-assisted extraction of olive pomace oil has the advantages of simple process, safety, environmental protection, high efficiency, fastness, good oil quality and high oil yield, and is suitable for small-lot production of the olive pomace oil.

Owner:WUHAN POLYTECHNIC UNIVERSITY

Refining method of Idesia polycarpa edible oil

InactiveCN105861140AReduce contentMeet degumming requirementsFatty-oils/fats refiningFatty-oils/fats productionFiltrationEdible oil

The invention discloses a refining method of Idesia polycarpa edible oil, relating to the technical field of refining of Idesia polycarpa oil. The refining method comprises the steps of: 1) preparation of Idesia polycarparaw oil; 2) degumming treatment; 3) depickling treatment; 4) decoloring treatment; 5) debitterizing treatment; 6) deodorizing treatment; and 7) filtration to obtain the finished Idesia polycarpa oil. The refining method of the Idesia polycarpa edible oil has the advantages of safety, environment protection, high oil yield and impurity free, and improves the quality of the Idesia polycarpa oil.

Owner:四川森迪科技发展股份有限公司

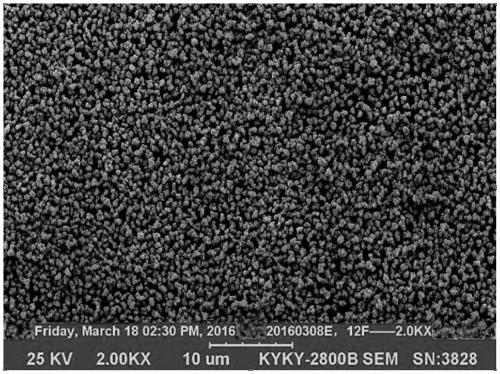

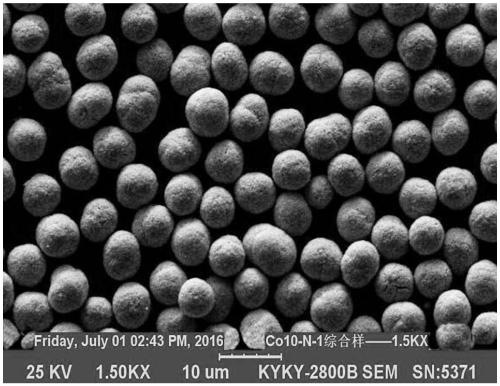

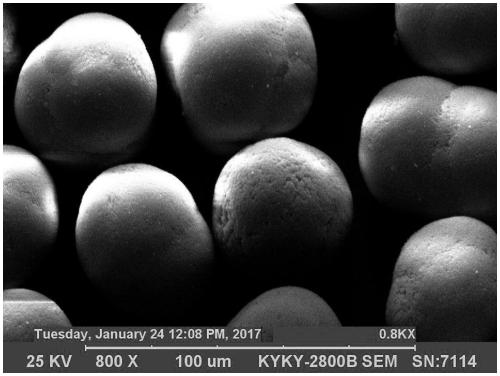

Production method of spherical basic cobalt carbonate with controllable particle size

ActiveCN110092421AGood removal effectShorten the induced nucleation periodCobalt carbonatesReaction temperatureCobalt

The invention discloses a production method of spherical basic cobalt carbonate with a controllable particle size, and the production method comprises the following general steps of: (1) preparing ofa solution; (2) magnetic inducing nucleation; (3) grain growth; (4) filter pressing and washing; and (5) drying. According to the method, nucleation supersaturation is reduced by applying of an external magnetic field during the synthesis of the basic cobalt carbonate, the induction nucleation period is shortened, and a large amount of basic cobalt carbonate crystal nuclei are instantly formed inthe solution; meanwhile, the quality of the product can be well adjusted by controlling the stirring speed, the reaction temperature and the adding speed of a cobalt liquid, so that the effects of uniform particles and spherical morphology are achieved, and the cobalt content can reach more than 52%. The basic cobalt carbonate product has standard normal distribution of particle size, uniform particle size and good fluidity, and the maximum D50 exceeds 40mu m, the uniformity and stability of the particle size of large-scale continuous produced spherical basic cobalt carbonate can be realized,and the production method simple process, easy operation and low cost, and provides a high-quality raw material for the production of high-end lithium batteries.

Owner:赣州逸豪优美科实业有限公司 +1

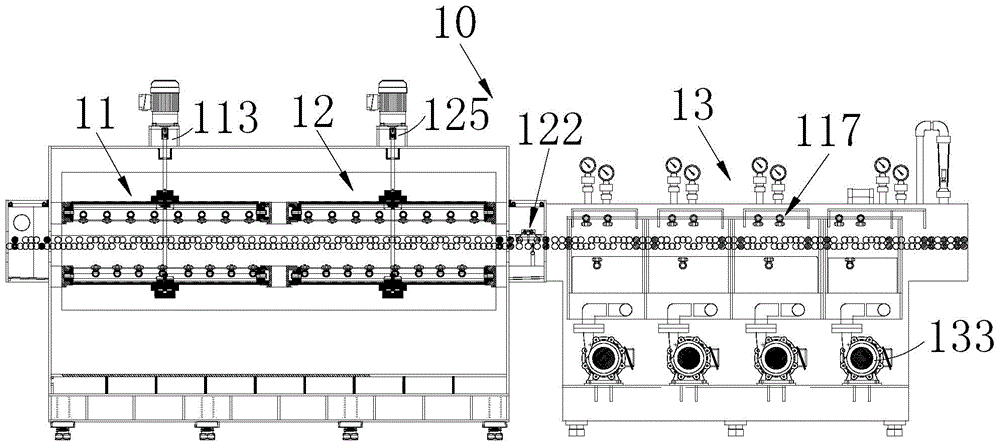

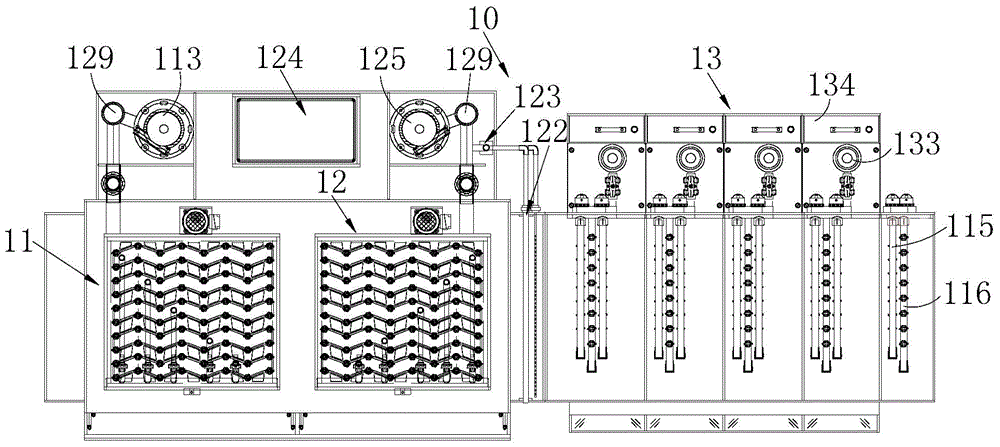

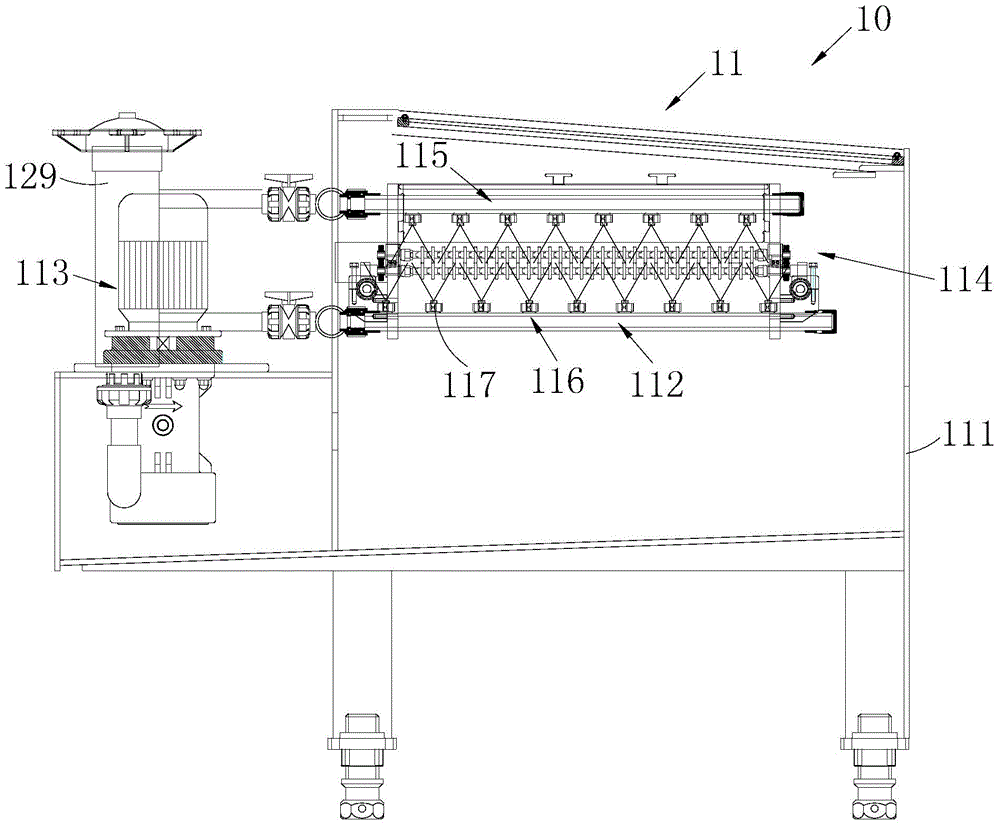

Wet process system

ActiveCN105297014AAvoid wastingReduce usageSemiconductor/solid-state device manufacturingPrinted circuit manufactureProcess systemsProcess equipment

The invention relates to the technical field of wet process technology equipment of PCBs, LCDs, LEDs, semiconductors, touch screens, solar energy, glass, hardware electroplating and the like and provides a wet process system. The wet process system comprises a liquid chemical section device, a liquid chemical reverse suction device and a washing device which are sequentially arranged in the workpiece machining direction and are optimized and integrated in structure. The liquid chemical section device comprises a liquid chemical spraying mechanism. The liquid chemical reverse suction device comprises a reverse suction section machine body, liquid suction cutters and jet devices. The washing device comprises a washing spraying mechanism, horizontal pumps and water storage tanks with the volume minimized. The washing spraying mechanism comprises upper spraying pipes, lower spraying pipes and nozzles. According to the wet process system, the liquid suction cutters and the jet devices are adopted, residual liquid chemical on a workpiece is sucked, and the purpose of saving the liquid chemical is achieved. The water exchange frequency is increased by reducing the volume of the water storage tanks, the horizontal pumps are arranged in vacant space, and the purposes of water and energy saving, high efficiency and effective space utilization are achieved. In a word, the effects of reducing sewage by 70%, saving energy by 50% and saving water by 50% through the change on the technology and the structure are achieved.

Owner:SHENZHEN JECH TECH

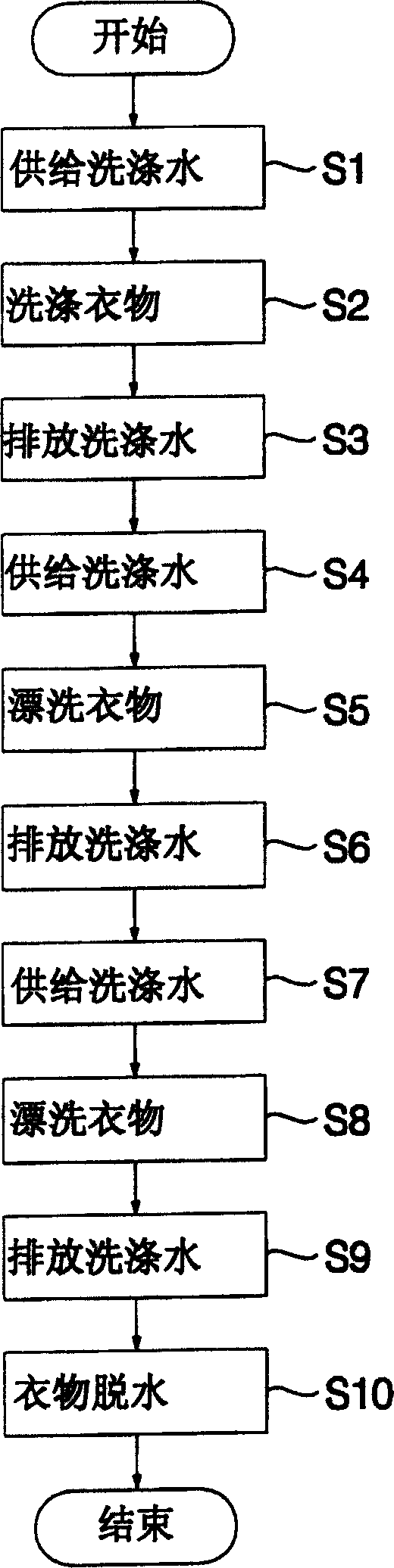

Method for controlling drum-type washing machine

InactiveCN1580357AReduce the amount of washing waterImprove energy efficiencyOther washing machinesControl devices for washing apparatusWash waterProcess engineering

Disclosed is a method for controlling a drum-type washing machine including the steps of (a) switching on a water supply valve and switching on a circulation pump and a heater, (b) switching off the water supply valve after the switching-on of the water supply valve, and (c) switching off the circulation pump and the heater after the switching-off of the water supply valve. The method allows laundry to be effectively cleaned using a small quantity of the wash water and minimizes a power consumption rate required to operate the heater through several repetitions of the steps (a) to (c).

Owner:LG ELECTRONICS INC

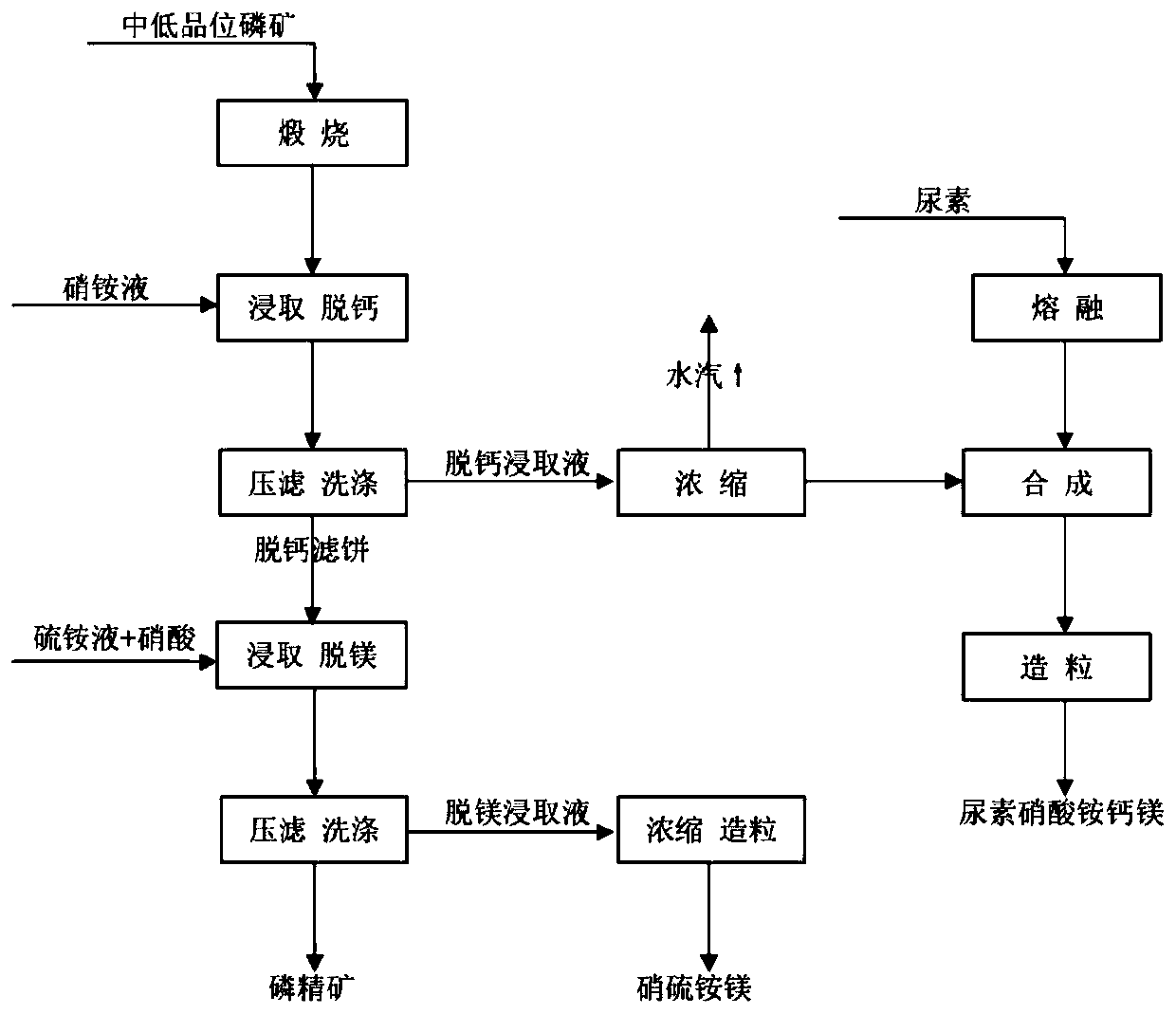

Mineral separation method for separating calcium and magnesium in medium-low-grade phosphorite, urea ammonium nitrate calcium-magnesium fertilizer and ammonium magnesium sulfate nitrate fertilizer

PendingCN111187100APromote growthConvenient supplementCalcareous fertilisersMagnesium fertilisersMagnesium phosphateSoil science

The invention provides a mineral separation method for separating calcium and magnesium in medium-low-grade phosphorite, a urea ammonium nitrate calcium-magnesium fertilizer and an ammonium magnesiumsulfate nitrate fertilizer, and relates to the technical field of mineral separation. The mineral separation method comprises the following steps: sequentially carrying out crushing, calcining, digesting, leaching decalcification and leaching magnesium removing on medium-low-grade phosphorite, wherein the decalcified filtrate obtained by leaching decalcification separation is subjected to concentration and synthesis to prepare a urea ammonium nitrate calcium-magnesium fertilizer, and / or the magnesium-removed filtrate obtained by leaching magnesium removing separation is subjected to concentration and granulation to obtain an ammonium magnesium sulfate nitrate fertilizer. The low-magnesium phosphate concentrate produced through the mineral separation method can meet the requirement for producing a nitrophosphate fertilizer with a low nitrogen-phosphorus ratio while a full-water-soluble urea calcium magnesium ammonium nitrate fertilizer and / or a magnesium ammonium sulfate fertilizer are / is produced as a byproduct, so that phosphorus, calcium and magnesium elements in medium-low-grade phosphorite are recycled.

Owner:GUIZHOU BATIAN ECOTYPIC ENG CO LTD

Method for filtering and separating red mud in sintering process

InactiveCN101732913AReduce the amount of washing waterEliminates settling capacity limitationsMoving filtering element filtersAluminium oxides/hydroxidesRed mudBelt filter

The invention discloses a method for filtering and separating red mud in a sintering process, and relates to a method for separating and washing red mud dissolved out from alumina production by the sintering process. A rubber belt filter is adopted to filter the red mud dissolved out in the sintering process; and the method is characterized in that: in the filtering and separating process, after the dissolved-out red mud enters the rubber belt filter, the red mud is subjected to solid-liquid separation first, and filter liquor which is crude solution is subjected to silicon removal; and the red mud separated from the crude solution continuously moves ahead on the filter along with belt filter cloth, and cleaning solution is injected to the red mud after the separation for washing separation. The method can effectively realize quick separation of the red mud dissolved out in the sintering process, reduce secondary reaction loss in a process of dissolving out and separating clinker, and improve the dissolution rate of alumina. Meanwhile, the water quantity for washing the red mud is reduced, the limitation to the sedimentation capacity of the red mud is eliminated, and the concentration of the crude solution after the red mud is separated can be greatly improved, so the production efficiency of the alumina by the sintering process is improved.

Owner:GUIZHOU BRANCH CHINA ALUMINUM IND

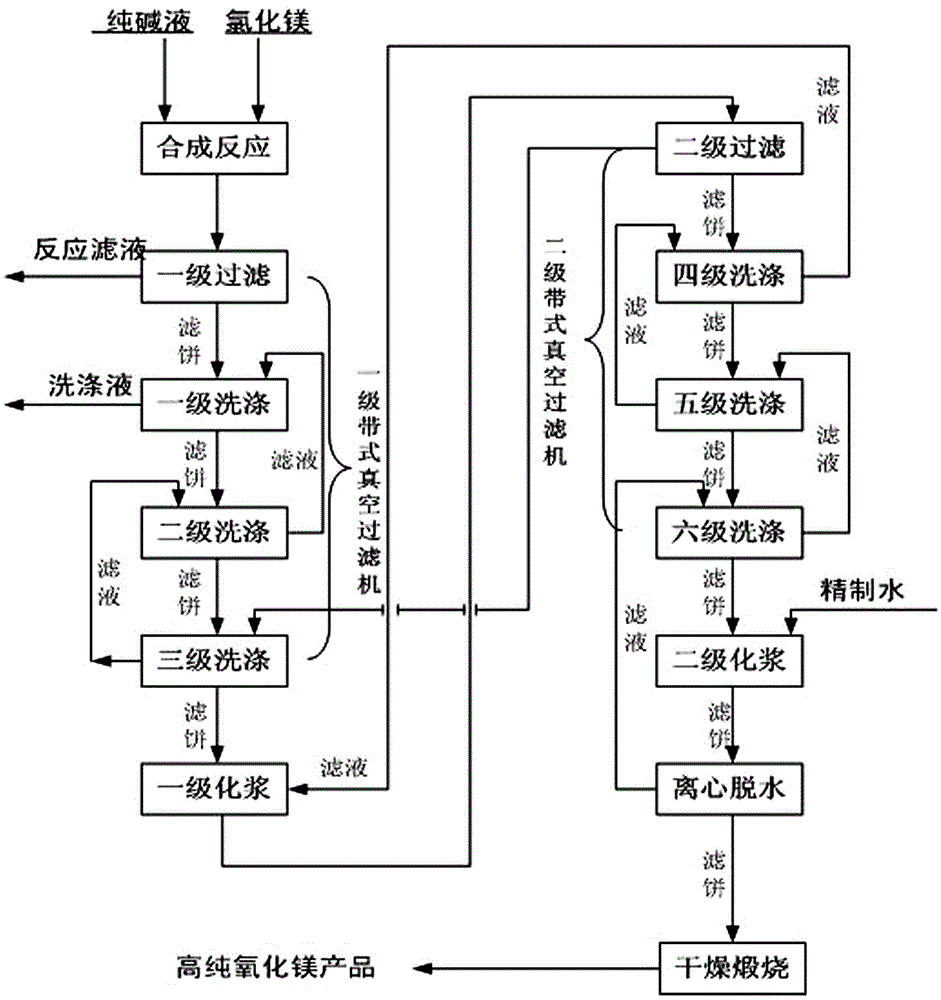

Method for producing low chlorine high purity magnesia by soda ash method

The present invention discloses a method for producing low chlorine high purity magnesia by taking hydrated magnesium chloride or a magnesium chloride solution and soda ash as raw materials. The method includes utilizing two filter devices (belt vacuum filter machine) having best washing effect as a washing device, at the same time performing slurrying washing twice, and using a filter device (a centrifugal machine) with best dehydrating effect for dehydration treatment. When the water content is reduced to less than 65%, basic magnesium carbonate is obtained, and then dried and calcined to get the high purity magnesia product with Cl less than 0.07% (by mass percentage). The method enables the magnesia product to reach the class of national superior products, and helps to reduce the amount of washing water and the energy consumption for drying.

Owner:桐柏兴源化工有限公司

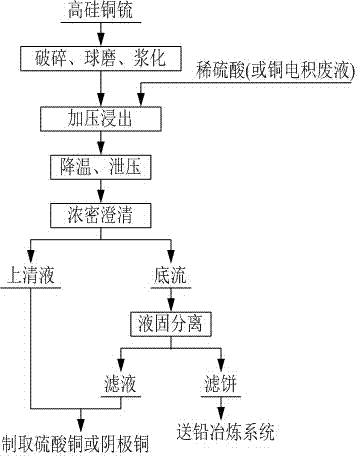

Method for controlling amount of hydrated silicatein crystal water in high-silicon-copper-matte oxygen-pressure acid leaching

InactiveCN104846210AControl volumeGood clarificationProcess efficiency improvementSlagHydrometallurgy

The invention relates to a method for controlling the amount of hydrated silicatein crystal water in high-silicon-copper-matte oxygen-pressure acid leaching, which belongs to the field of nonferrous metal hydrometallurgy. The method disclosed by the invention comprises the step that in the process of oxygen-pressure acid leaching, leached silicon dioxide is separated out and then subjected to slag intake by hydrated silicatein (SiO2.nH2O). By controlling the concentration of ore pulp and the technological parameters of oxygen-pressure acid leaching, the amount of formed hydrated silicatein crystal water is low, the supernatant rate is greater than 40% when the ore pulp stands for 30min, the moisture content of a filter cake after filter pressing is 30-40%, and the volume of filter cake is 1.5-2.0 times as large as the volume of raw materials. According to the technical scheme of the invention, the volume of leached slag can be effectively controlled, ore pulp which is easily clarified and filtrated is obtained, and the water content of the filter cake is low, so that the amount of water for washing the filter cake can be reduced, and the slag-intake loss of dissolved-out copper is reduced; the volume of a slag phase in leached ore pulp is reduced, and the ore pulp is clarified by using ore pulp thickening; and after the leached ore pulp is subjected to solid-liquid separation, the water content of the filter cake is reduced, thereby reducing the amount of water for washing the filter cake, saving the consumption of water, and facilitating the volumetric balance in the process.

Owner:YUNNAN CHIHONG ZINC & GERMANIUM

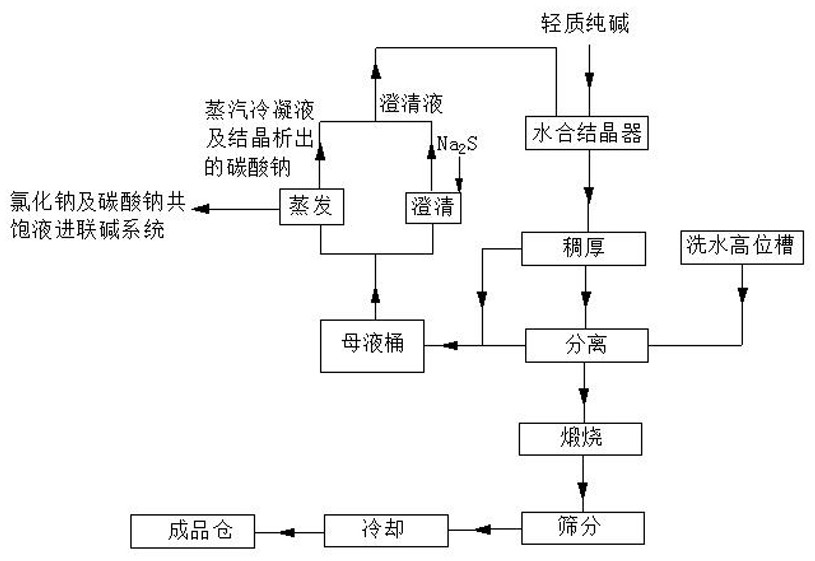

Production method of heavy soda ash

InactiveCN112551558AImprove product qualityReduce accumulationAlkali metal carbonatesSodium bicarbonateHydration reaction

The invention discloses a production method of heavy soda ash. The production method comprises the following steps: adding light soda ash and a sodium carbonate saturated solution into a hydration crystallizer; introducing crystal mush into a thickener to adjust the solid-to-liquid ratio after the reaction, separating the crystal mush in the thickener in a centrifugal machine, and introducing thesupernatant of the thickener into a mother liquor barrel; separating, washing with washing water, removing salt and impurities on the surface of crystal mush, and feeding centrifugate into the motherliquor barrel; treating the centrifuged solid to obtain a heavy soda ash product; evaporating the 20-50% mother liquor until the common saturation point of sodium carbonate and sodium chloride is reached to separate out sodium carbonate monohydrate crystals, mixing the sodium carbonate monohydrate crystals and steam condensate, recycling the mixture into a hydration crystallizer, and feeding the residual sodium chloride and sodium carbonate co-saturated solution into a combined-soda system vacuum salt making device; enabling 50-80% mother liquor to enter a clarification device, adding sodium sulfide, removing iron impurities, and enabling clarified liquor to enter a hydration crystallizer to continue to prepare heavy soda ash. According to the method, sodium chloride and iron impurities inthe sodium bicarbonate mother liquor in the current sodium bicarbonate production process can be removed, discharge of the sodium bicarbonate mother liquor is reduced, and the quality of the sodium bicarbonate product is improved.

Owner:TIANJIN BOHUA YONGLI CHEM IND

Method for quickly determining ash content in sulfenamide vulcanization accelerator

The invention relates to a method for quickly determining ash content in a sulfenamide vulcanization accelerator, the method comprises the following steps: using a conductivity meter to determine the conductivity of deionized water to obtain conductivity C1 of the deionized water at 25 DEG C, taking a sulfenamide accelerator sample, adding the sample into the deionized water, mixing evenly, then standing for 2min-10min to prepare a sample solution, and then using the conductivity meter to determine the conductivity of the sample solution to obtain conductivity C2 of the sample solution at 25 DEG C; and according to a formula W=K2(C2-K1*C1)*% to calculate the ash content in the sulfenamide vulcanization accelerator; the method for quickly determining the ash content in the sulfenamide vulcanization accelerator is simple and practicable and is convenient to operate, and the detection time is short; and through use of the method, the ash content determination of a single sample takes about 10 min, the ash content determination of batch sample takes about 5 min-8 min, compared with a method specified in national standard GB / T11409, the detection time is substantially shortened, the ash content being qualified or not can be quickly calculated only with the need of detection of the conductivity, a detection process is rigorous with a small error, and detection results are accurate and intuitive.

Owner:SHANDONG YANGGU HUATAI CHEM

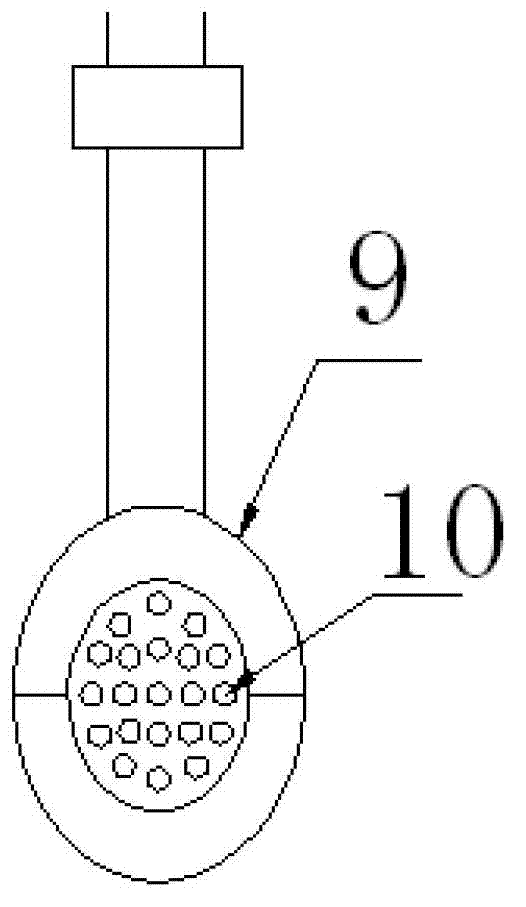

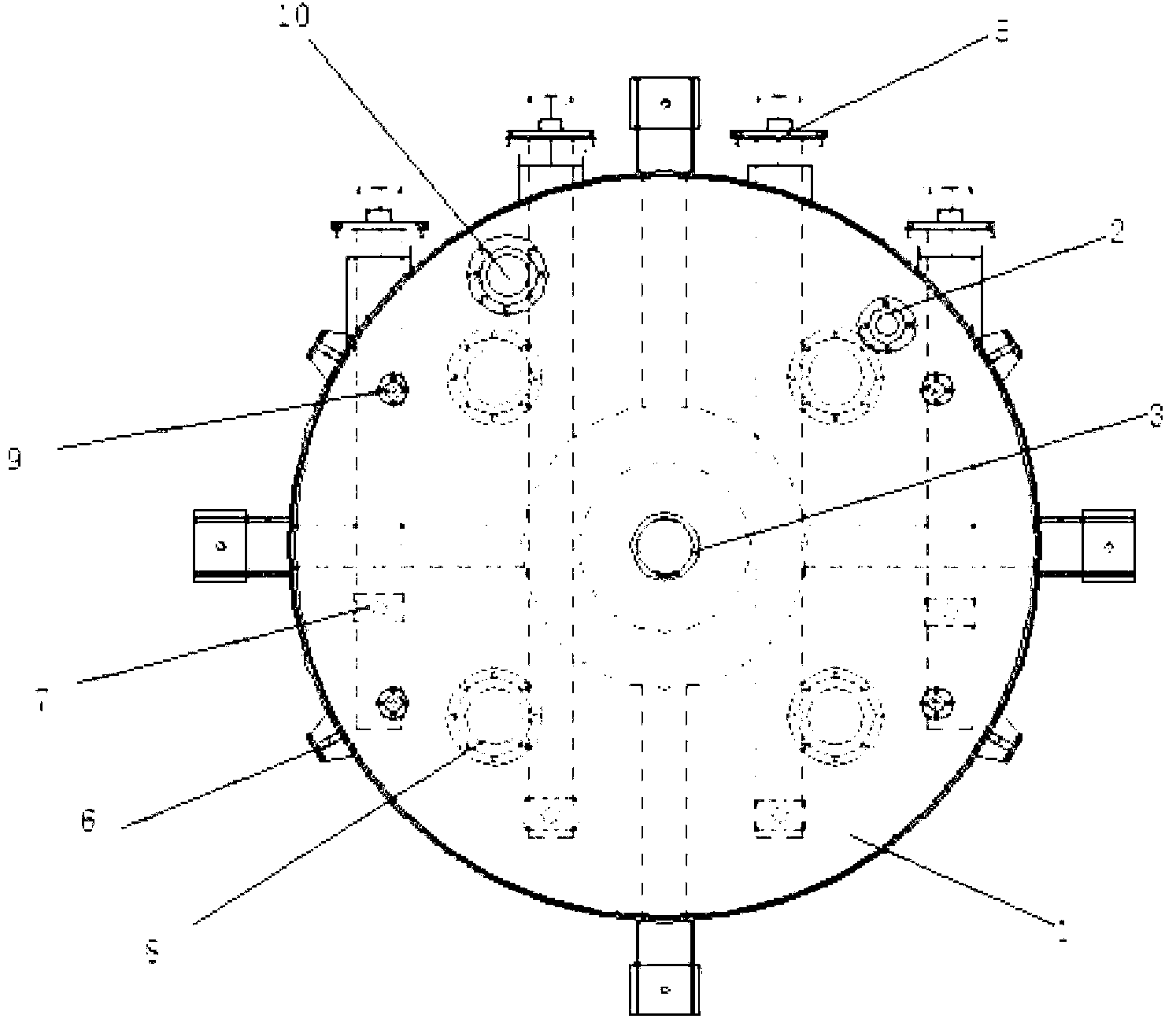

Filtering and washing device

InactiveCN103316519AImprove production environmentLow impurity contentStationary filtering element filtersExhaust pipeImpurity

The invention discloses a filtering and washing device which is composed of a hollow reactor, first filtering pipes, a stirring device, a material inlet, water inlets, a tail gas exhaust pipe, a filtering pipe opening, a material outlet, a liquid exhaust pipe and a liquid collecting pipe, wherein the first filtering pipes and the stirring device are arranged in the reactor; the material inlet, the water inlets, the tail gas exhaust pipe, the filtering pipe opening, the material outlet, the liquid exhaust pipe and the liquid collecting pipe are arranged outside the reactor; the filtering pipe opening is formed in the outer wall of the reactor; one ends of the first filtering pipes respectively extend into the reactor; the parts of the first filtering pipes, which extend into the reactor, are hollow pipes with through holes formed in the pipe walls; filtering cloth or filtering bags are tightly wrapped on the outer peripheries of the hollow pipes with the through holes formed in the pipe walls; the other ends of the first filtering pies are respectively fixed on the filtering pipe opening through flanges and are connected with the external liquid exhaust pipe. The filtering and washing device provided by the invention has a favorable filtering and washing effect, and is few in water washing quantity, and filtering cakes are loose, and pipeline delivery is convenient; enclosed operation is realized, and the production environment is improved; the impurity content is low; the product quality is good.

Owner:ZHEJIANG LONGSHENG GROUP +1

Dissolution method of diasporic bauxite

ActiveCN112158869AAdd lessHarm reductionAlkali-metal aluminates/aluminium-oxide/aluminium-hydroxide preparationEngineeringHydrometallurgy

The invention discloses a dissolution method of diasporic bauxite, and belongs to the technical field of hydrometallurgy. The method comprises the following steps: uniformly mixing diasporic bauxite and a circulating mother solution, carrying out pre-desilicication treatment, uniformly mixing the obtained pre-desilicication slurry with dealkalized red mud, carrying out dissolving out at a high temperature, carrying out dilution desilicication and red mud settlement separation washing treatment on the dissolved slurry to obtain red mud, and carrying out lime dealkalization on the red mud to obtain dealkalized red mud; and returning part of the dealkalized red mud to the high-temperature dissolution step, so that calcium is recycled. Compared with the prior art, the method has the advantagesthat the relative dissolution rate of aluminum oxide in the ore is obviously increased, the addition amount of lime can be greatly reduced by replacing lime with dealkalized red mud, waste emission is reduced, environmental protection is facilitated, the cost is low, and the method has industrial application value.

Owner:CENT SOUTH UNIV

Processing technology for rapeseed oil

InactiveCN109536277AMeets moderate refining requirementsReduce degumming water consumptionFatty-oils/fats refiningEdible oils/fatsWater useOil processing

The invention discloses a processing technology for rapeseed oil. As ultrasonic waves can be adopted to assist a phospholipase C degumming process to perform degumming processing on rapeseed crude oil, the water using amount of degumming can be greatly reduced, and the generated wastewater amount can be greatly reduced as well, so that the processing technology is green and environmentally friendly; and the degumming time can be shortened to 60 min, and the processing technology can accord with the moderate refining of oils and fats. The processing technology is safe, environmentally friendly,simple, convenient in operation, low in cost, high in refining rate and suitable for the industrial production of rapeseed oil processing.

Owner:余握中

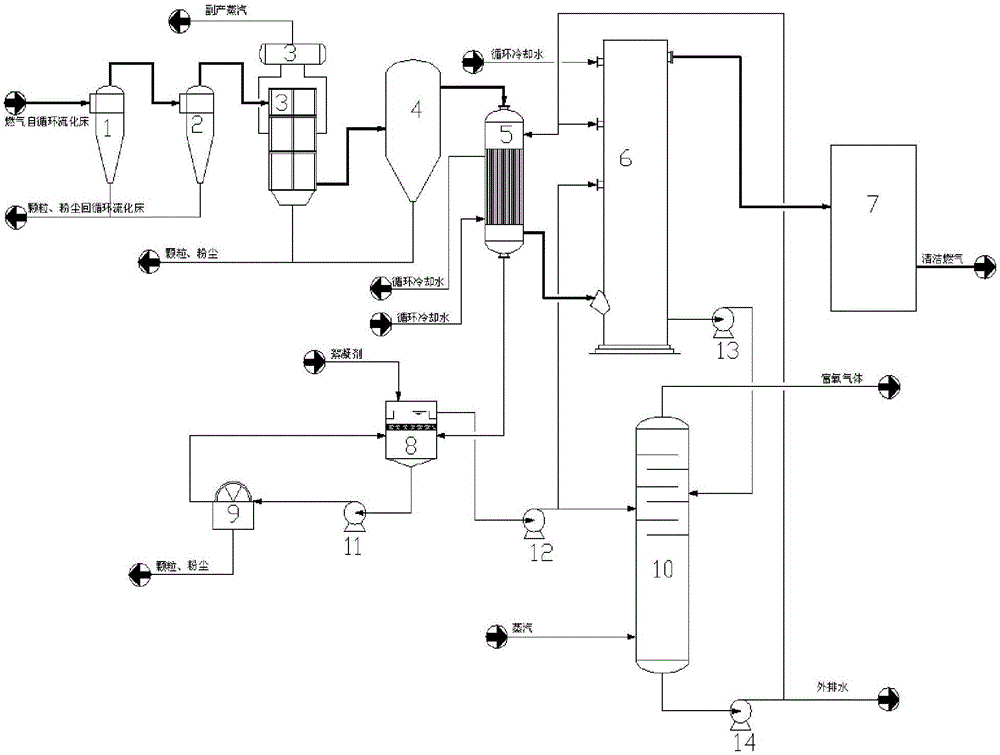

Circulating fluidized bed coal gas purification method

ActiveCN105001920AImprove cleanlinessReduce the amount of washing waterEnergy inputGas purification by non-gaseous materials condensationParticulatesPurification methods

The invention discloses a circulating fluidized bed coal gas purification method. A gas purification technology with the dry process and the wet process combined is adopted, and gas on which cyclone dust removal and waste heat recovery are carried out is fed to a dry dust collector and then enters a gas washing tower to be washed after being cooled by a gas cooler. By combining the two processes, the gas cleanliness is greatly improved, and washing water consumption is reduced. Gas condensation water and gas washing water are respectively processed according to different kinds of impurity content. Particulate matter in the gas condensation water is removed by means of filtering, and ammonia in the gas condensation water and the gas washing water is recycled by means of a stripping tower, so that closed cycle is achieved for the gas washing water.

Owner:HUALU ENG & TECH

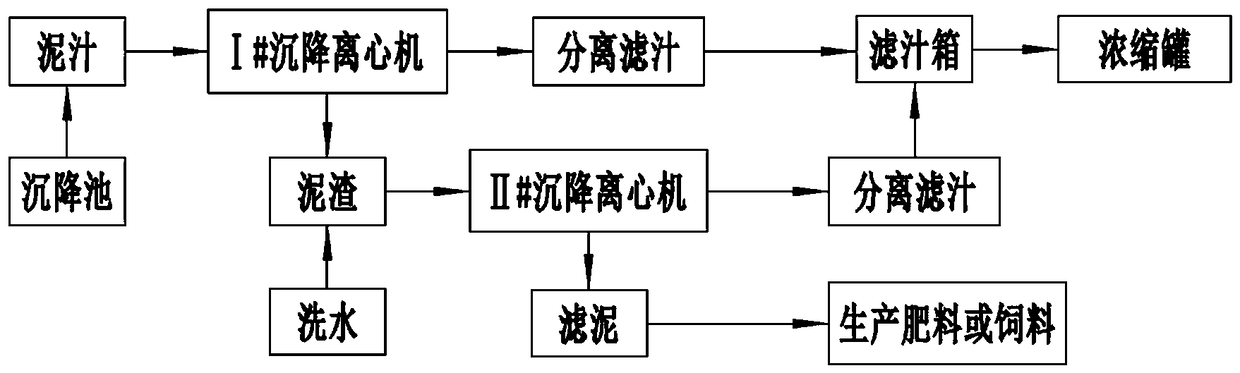

Centrifugal filtering method of paste juice in cane sugar factory

The invention relates to a centrifugal filtering method of paste juice in a cane sugar factory. The centrifugal filtering method comprises the following steps: (1) transporting paste juice obtained ina settling pond in a settling manner to a number-I centrifugal machine, separating the paste juice, transporting obtained filtered juice into a filtered juice box, and discharging obtained paste slaginto a paste slag and water stirring tank; (2) adding water into the mud slag and water stirring tank, and stirring; (3) transporting a material in the mud slag and water stirring tank to a number-IIcentrifugal machine, separating solids and liquid, transporting obtained filtered juice into a filter juice box, mixing the obtained filtered juice with the filtered juice in step (1), then transporting to a concentrating tank, and transporting obtained filtered paste to be used for producing organic fertilizer or feed, wherein the water content of the obtained filtered paste is less than 55 percent, and a sugar degree of the filtered paste is less than 4.5 percent. By adopting the method, the solids and the liquid of the paste juice in the cane sugar factory can be rapidly separated, the treatment time of the materials is shortened, the production efficiency is increased, the cane sugar loss of the filtered paste is reduced, the washing water amount is reduced, the energy is saved, the further comprehensive utilization of the filtered paste can be promoted, and the problems that the water content of the filtered paste is high, the filtered paste is difficult to transport and the clean production of the environment is influenced can be solved.

Owner:横县东糖糖业有限公司

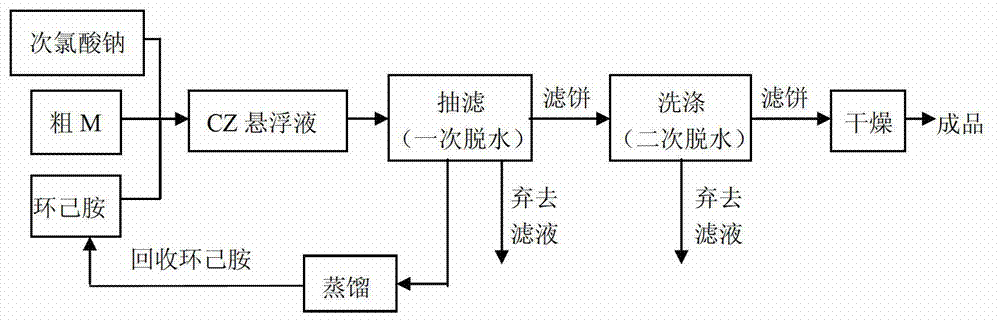

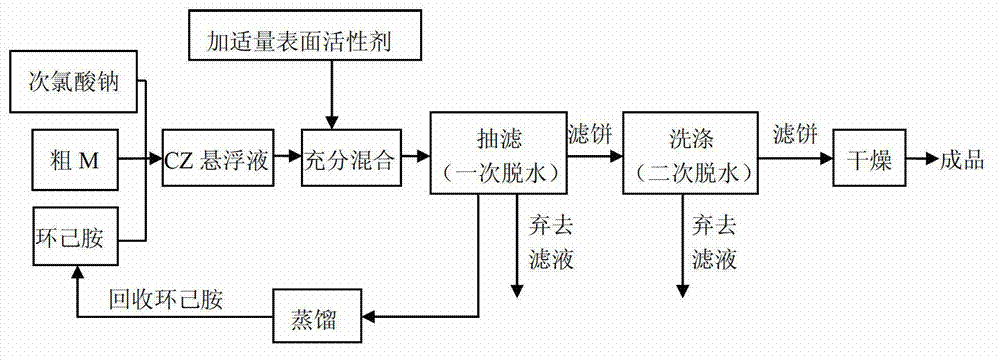

Dewatering method in production process of vulcanization promoter CZ

InactiveCN102924401AReduce moisture contentIncrease filtration rateOrganic chemistryVulcanizationOil phase

The invention relates to a dewatering method in the production process of vulcanization promoter CZ. Raw materials adopts rough mitochondria (M) which is rich in oil phase, and filtering rate is reduced, so in the first dewatering to vulcanization promoter CZ, nonionic surfactant or anionic surfactant is added in suspension liquid containing the vulcanization promoter CZ. After sufficient mixing, liquid phase in the suspension liquid is removed through vacuum filtering and dewatering. The dewatering method has the advantages that through adoption of new process, after the vulcanization promoter CZ being subjected to the first dewatering, water content of filter cakes is reduced by 10% or so compared with an original process so that the content of the oil phase in the filter cakes can be greatly reduced, and filtering rate is accelerated and subsequent washing water dosage is substantially reduced.

Owner:TIANJIN UNIV +1

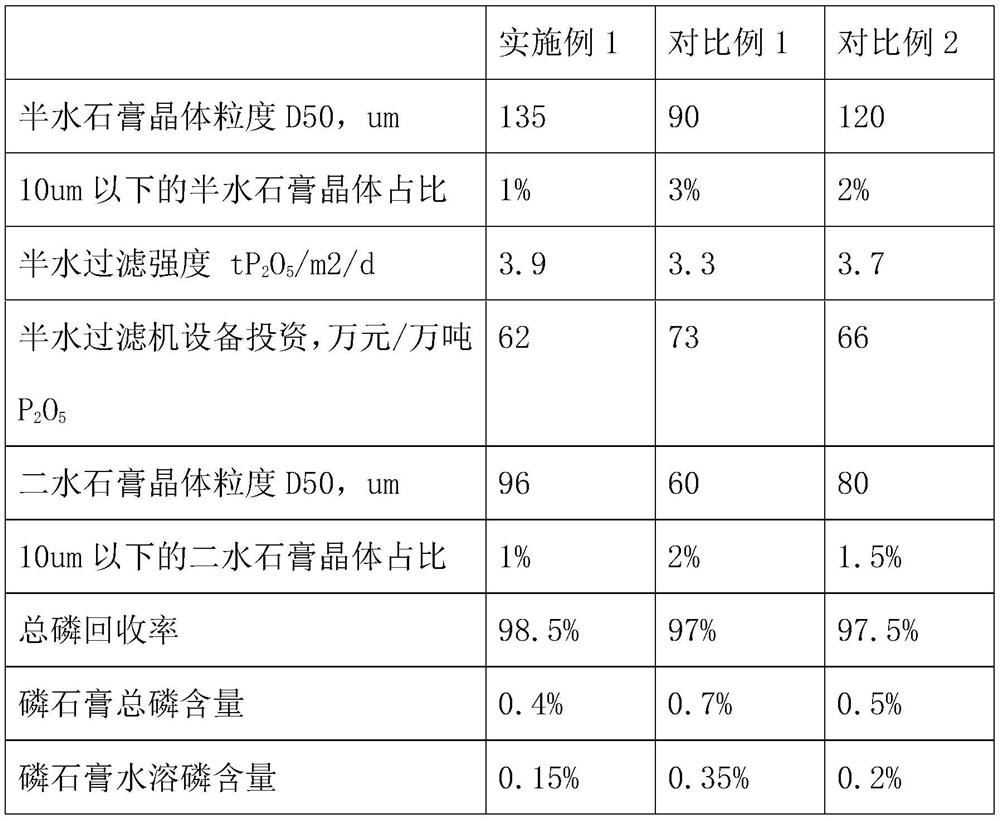

High-yield hydrated crystalline phase reconstruction wet-process phosphoric acid production technology

ActiveCN113173566AImprove overall recoveryAvoid acid accumulationPhosphorus compoundsHydration reactionO-Phosphoric Acid

The invention discloses a high-yield hydrated crystalline phase reconstruction wet-process phosphoric acid production technology. The technology comprises a semi-hydrated reaction filtration process and a dihydrate reaction filtration process, and the semi-hydrated reaction filtration process comprises the steps of premixing, dissolving, crystallizing, curing and semi-hydrated filtration; and the dihydrate reaction filtration process comprises a conversion step and a dihydrate filtering step. According to the invention, through gradient control of the relationship between the sulfate ion concentration and the CaO concentration in different stages of the semi-hydrated reaction, the crystal size is increased, the crystal is kept stable, and the semi-hydrated gypsum crystal with uniform particle size is obtained; by changing the circulation path of the slurry, the reaction retention time is prolonged, and the growth of semi-hydrated gypsum crystals in a relatively stable environment is ensured; coarse, uniform and stable dihydrate gypsum crystals are obtained by controlling the degree of supersaturation of a dihydrate reaction, the filtering performance is good, the content of water-soluble phosphorus in the dihydrate gypsum is reduced, and the filtering yield is improved; and by reasonably utilizing the filtrate and the flushing water, the wastewater discharge is reduced, and the total yield of P2O5 is increased.

Owner:WUHUAN ENG

A kind of production method of fine-grained low-chloride rare earth carbonate

ActiveCN104310456BAchieve spatial separationPromote formationRare earth metal compoundsGranularityRare earth

The invention relates to a production method and device of fine-grained low-chloride rare earth carbonate. The production method is mainly characterized in that rare earth chloride and a carbonate solution are added in a concurrent flow feeding way on a designed special precipitation reaction device, the spatial separation of a reaction zone and a crystallization zone is realized by controlling the feeding speed and discharging speed and controlling the aging time of rare earth carbonate, and thus the double purposes of directly obtaining a fine-grained low-chloride rare earth carbonate product from a hydrochloric acid medium by precipitation and realizing continuous production are achieved. By adopting the production method and device provided by the invention, the fine-grained rare earth carbonate product with the chloride content of less than 50ppm can be directly obtained from the hydrochloric acid medium by using cheap ammonium bicarbonate, the precipitation reaction device has a simple structure, and the continuous production can be realized.

Owner:NAT ENG RES CENT OF RARE EARTH METALLURGY & FUNCTION MATERIALS

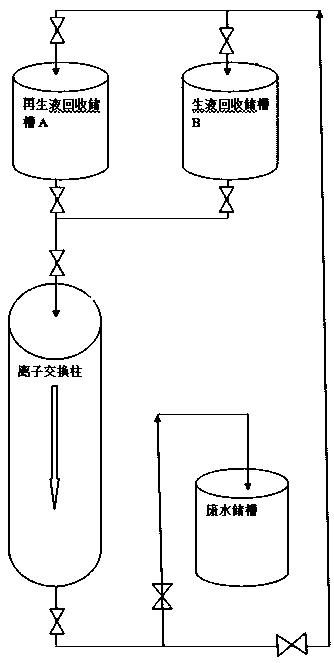

Method for recycling and reusing ionic exchange regenerated liquid

InactiveCN109201123AReduce effluxReduce the amount of washing waterIon-exchanger regenerationWater/sewage treatment by neutralisationWastewaterEconomic benefits

The invention provides a method for recycling and reusing the ionic exchange regenerated liquid. The regenerated liquid is recycled and stored after ionic exchange resin is regenerated, and serves aswashing water in the next separation, due to the acid-base neutralization reaction, the pH value of the in-column solution can reach the required value rapidly, a great amount of wastewater being drained out can be reduced while the washing water amount is saved, and the method can produce huge economic benefits in the situation that the environmental production trend is more and more important.

Owner:CHINA MOLYBDENUM

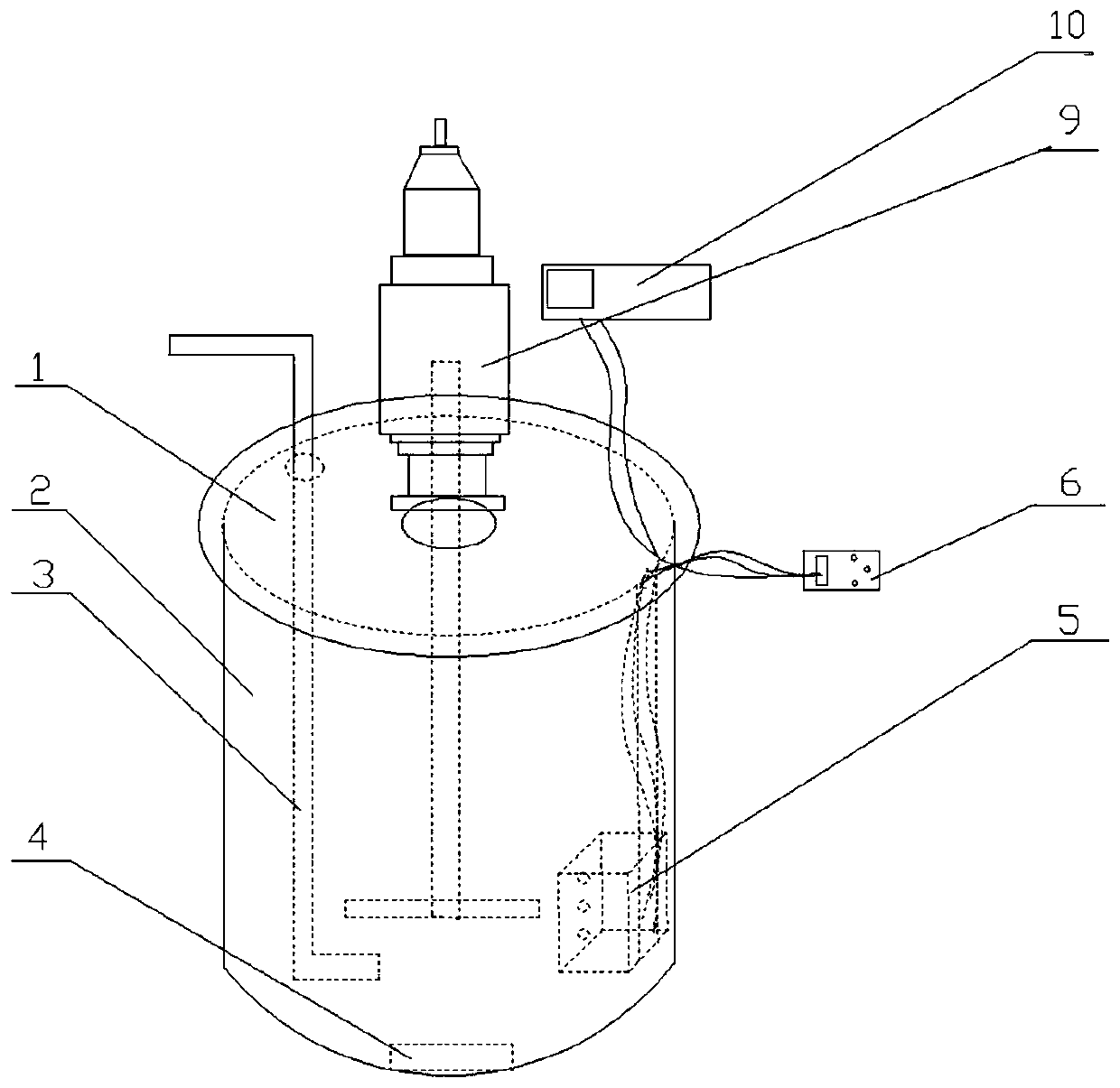

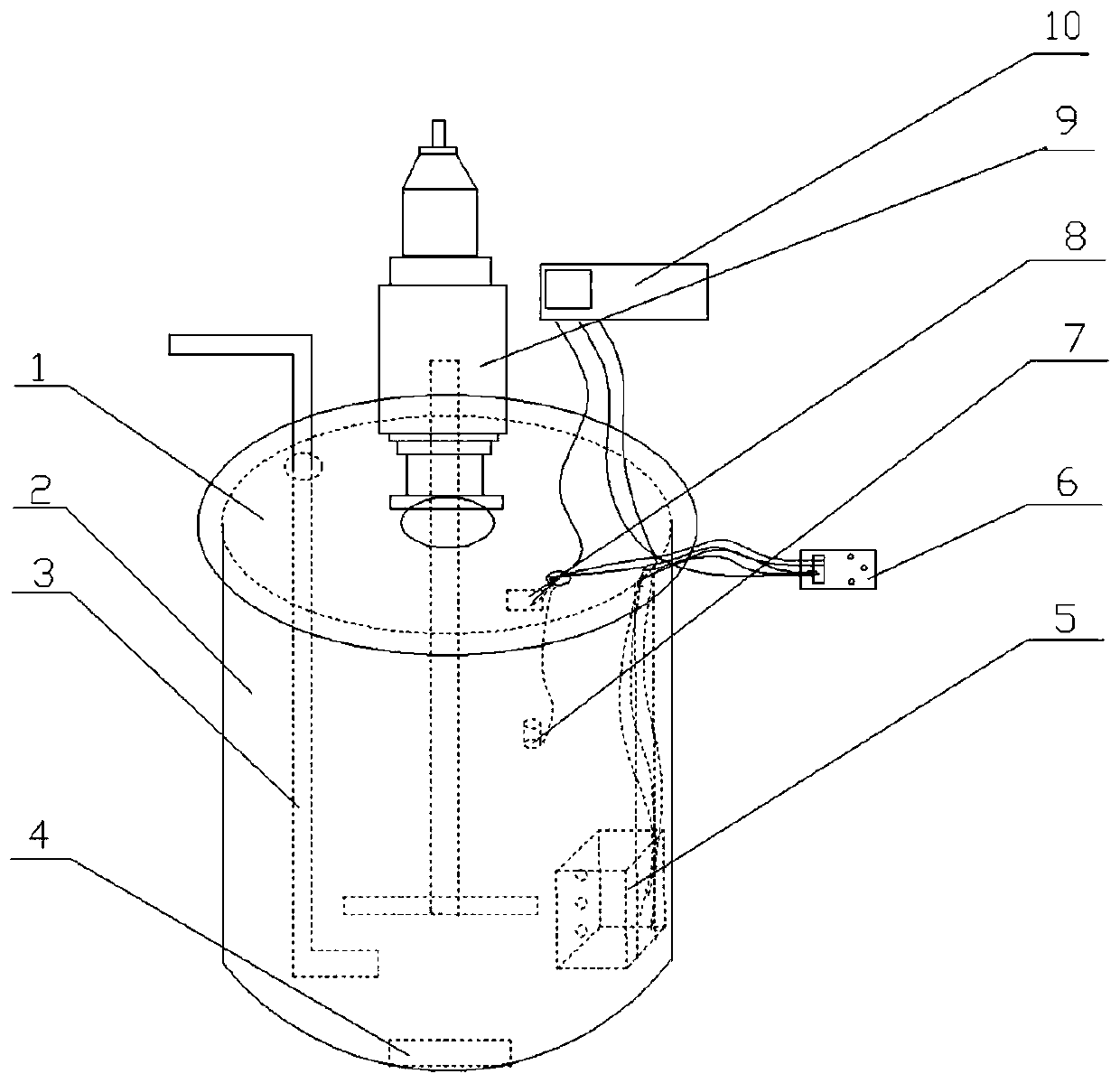

Preparation method for high-activity trimanganese tetraoxide

ActiveCN110422881AHigh specific surface areaEasy to operateManganese oxides/hydroxidesIonUltrasonic generator

The invention discloses a preparation method for high-activity trimanganese tetraoxide. The preparation method comprises the following steps: S1, mixing electrolytic manganese metal powder with a catalyst, carrying out wetting to form slurry, adding the slurry into warm deionized water to form a suspension, continuously introducing oxygen or pure air, and carrying out a stirring reaction; S2, starting an ultrasonic generator for treatment, adding a activator, and carrying out a reaction for 1.8-5 h to obtain the suspension slurry of high-activity trimanganese tetraoxide, wherein ultrasonic intensity is adjusted within the range of 20 kHz-40 kHz during the reaction; and S3, performing concentration, washing, dehydrating and drying to obtain the high-activity trimanganese tetraoxide. The method of the invention has the advantages of short production cycle, low cost, small environmental pollution and good safety, and can prepare high-activity trimanganese tetraoxide.

Owner:HUNAN SPECIAL METAL MATERIALS CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com