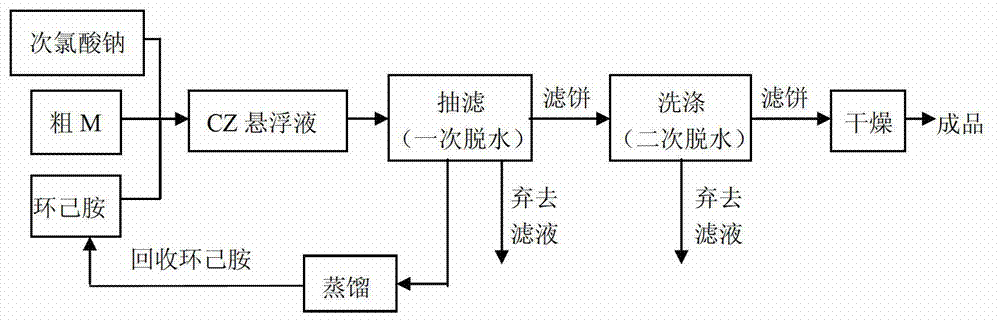

Dewatering method in production process of vulcanization promoter CZ

A rubber vulcanization and production process technology, applied in the field of rubber vulcanization accelerator CZ production, can solve the problems of affecting production efficiency, large energy consumption, and large amount of washing water, so as to reduce the amount of washing water, increase the filtration rate, and reduce the oil phase The effect of content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

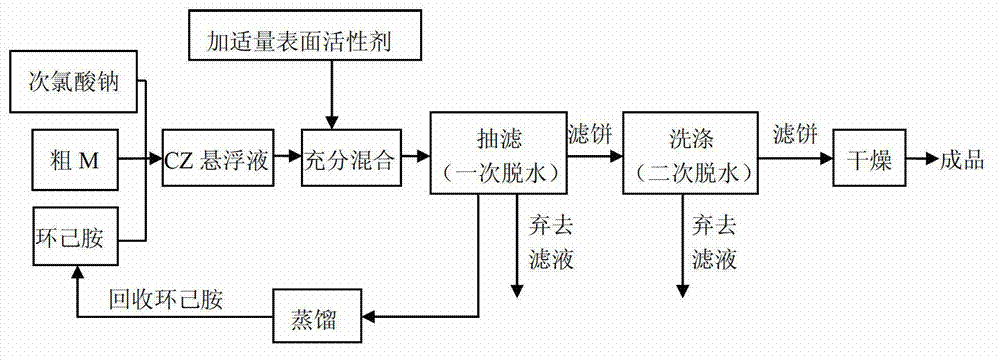

[0014] like figure 2 In the technical route shown, non-ionic surfactant sorbitan monooleate (span80) is added to the CZ suspension containing rubber vulcanization accelerator, and the addition amount is 0.75% of the solid phase mass in the CZ suspension. Stir evenly to fully mix the accelerator CZ suspension with the surfactant, and then use vacuum filtration to dehydrate once. The water content of the accelerator CZ filter cake is relatively lower than that of the CZ suspension without surfactant. 11.36% (wt).

Embodiment 2

[0016] like figure 2 In the technical route shown, the non-ionic surfactant span80 is added to the rubber vulcanization accelerator CZ suspension, and the addition amount is 0.5% of the solid phase mass in the CZ suspension. Stir evenly to fully mix the accelerator CZ suspension with the surfactant, and then use vacuum filtration to dehydrate once. The water content of the accelerator CZ filter cake is relatively lower than that of the CZ suspension without surfactant. 8.3% (wt).

Embodiment 3

[0018] like figure 2 In the technical route shown, the non-ionic surfactant span80 is added to the rubber vulcanization accelerator CZ suspension, and the addition amount is 0.25% of the solid phase mass in the CZ suspension. Stir evenly to fully mix the accelerator CZ suspension with the surfactant, and then dehydrate once by vacuum filtration. The water content of the accelerator CZ filter cake is relative to the water content of the filter cake when the CZ suspension without surfactant is filtered. decreased by 7.86% (wt).

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com